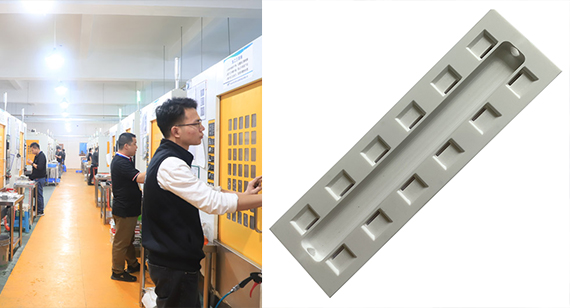

15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2023 01 05

2023 01 05 PEEK (polyetherimide) is a high-performance engineering plastic material with excellent heat resistance, chemical resistance, mechanical strength and wear resistance. PEEK material is usually used in applications under high temperature, high pressure, high load and harsh environment, such as aerospace, medical equipment, automotive industry, electronic equipment, oil and gas exploration and other fields. It is also widely used in manufacturing processes such as 3D printing, CNC machining, and injection molding.

66

66

Read more

Read more

VMT

VMT  2023 01 04

2023 01 04 Tolerance is the acceptable range for the designer to determine the size based on the form, fit and function of the CNC part. Understanding how CNC machining tolerances affect cost, choice of manufacturing process, inspection options and materials can help you better determine CNC machining product designs.

66

66

Read more

Read more

VMT

VMT  2023 01 03

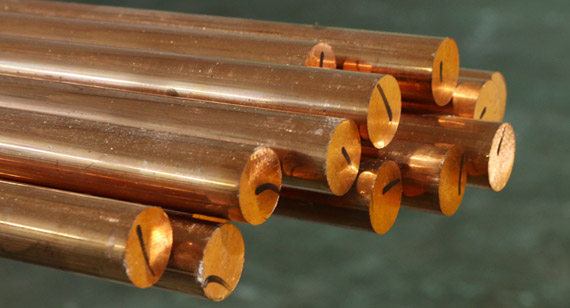

2023 01 03 CNC machining is the main process for producing brass parts in many industries. brass has good ductility, electrical conductivity and thermal conductivity, and various CNC machined brass parts are widely used in various industries such as automobiles, aerospace, and medical treatment. brass is one of the materials that are easy to CNC process.

66

66

Read more

Read more

VMT

VMT  2022 12 30

2022 12 30 A comparison of copper and brass reveals the different properties of the two materials. It is therefore also easier to select the correct material. For CNC machining projects that don't know how to choose materials, come and contact us!

66

66

Read more

Read more

VMT

VMT  2022 12 29

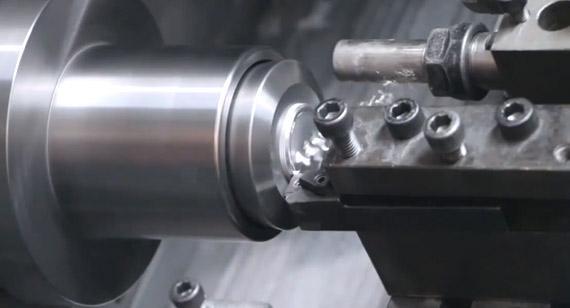

2022 12 29 CNC lathe is one of the most widely used CNC machine tools. It is mainly used for machining symmetrical rotary parts, such as shaft parts, inner and outer cylindrical surfaces of disk parts, inner and outer conical surfaces with arbitrary cone angles, complex inner and outer curved surfaces of rotation, and cylindrical and conical threads.

66

66

Read more

Read more

VMT

VMT  2022 12 28

2022 12 28 Austenitic 304 stainless steel is a very common stainless steel with corrosion resistance, heat resistance, low temperature strength and overall mechanical properties. Widely used in food equipment, chemical equipment and nuclear industry equipment.

66

66

Read more

Read more

VMT

VMT  2022 12 27

2022 12 27 In the process of thread CNC turning, it is often necessary to reinstall the tool and set the tool due to the wear and tear of the thread tool. The quality of the tool setting directly affects the accuracy of the turning thread, especially the repair turning of the thread, which requires secondary clamping The second tool setting restricts the machining efficiency of CNC lathe machining threads.

66

66

Read more

Read more

VMT

VMT  2022 12 24

2022 12 24 Aluminum alloy die casting refers to the method in which liquid aluminum alloy flows from the pressure chamber into the mold cavity at an extremely fast speed under high temperature and high pressure, and forms a casting after cooling.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!