15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2023 08 11

2023 08 11 As we delve into the world of metals, we often encounter the captivating transformation of their surfaces over time. One curious question that arises is, "Does brass or bronze turn green?" This article aims to unravel the mystery behind the verdigris patina that sometimes graces these metals, exploring the science, reasons, and ways to manage this fascinating phenomenon.

66

66

Read more

Read more

VMT

VMT  2023 08 10

2023 08 10 Bronze alloys have been an integral part of human civilization for centuries, known for their versatility, durability, and aesthetic appeal. However, a question that often arises is whether bronze alloys, including bronze, brass, and red brass, possess any magnetic properties. In this comprehensive exploration, we will delve into the intriguing world of these metal alloys and uncover the truth behind their magnetic behavior.

66

66

Read more

Read more

VMT

VMT  2023 08 09

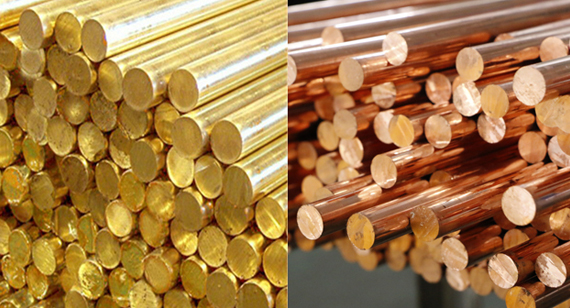

2023 08 09 Brass, bronze, and red copper are three distinct copper-based alloys, each with unique characteristics and applications. These alloys play crucial roles in various industries and artistic endeavors due to their specific properties and versatility. Let's delve into the differences between Brass, bronze, and red copper, shedding light on their compositions, appearances, and uses.

66

66

Read more

Read more

VMT

VMT  2023 08 08

2023 08 08 Polyethylene (PE) is a widely used multifunctional polymer that has revolutionized various industries and everyday products. It is a synthetic material belonging to the thermoplastic family that is malleable and adaptable. The excellent properties and applications of PE make it an indispensable part of modern life.

66

66

Read more

Read more

VMT

VMT  2023 08 07

2023 08 07 As a discerning customer looking for the best value in manufacturing, it's essential to delve into the global landscape and explore countries offering the most cost-effective solutions. By understanding the CNC machining manufacturing costs, prices, advantages, primary industries, and applications in different countries, you can make informed decisions that combine top-notch quality with affordability.

66

66

Read more

Read more

VMT

VMT  2023 08 01

2023 08 01 In today's CNC machining manufacturing world, CNC machining plays a vital role in the efficient production of precise and complex parts. However, for a CNC machining facility to thrive, it is important to have a thorough understanding of the costing involved. In this article, we will look at all the factors and techniques that help in calculating the cost of CNC machining.

66

66

Read more

Read more

VMT

VMT  2023 07 31

2023 07 31 When it comes to custom CNC machining manufacturing, companies are often faced with a critical decision: choosing between Chinese and American CNC machining factories. This article aims to provide a comprehensive cost comparison from a

66

66

Read more

Read more

VMT

VMT  2023 05 31

2023 05 31 Micro hole machining plays a pivotal role in various industries, meeting the demand for highly precise and miniaturized components. With the growing need for smaller, complex parts, it becomes crucial to understand the requirements and challenges associated with micro hole machining.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!