15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2023 10 27

2023 10 27 Aluminum CNC machining is a highly precise process that demands careful attention to every detail. While the final product should ideally be flawless, challenges can arise during the machining process, such as material damage and cracking.

66

66

Read more

Read more

VMT

VMT  2023 10 26

2023 10 26 Burrs are raised edges or rough areas on the machined surface. They can be quite small but are still visible and can compromise the aesthetics and functionality of the part. Burrs are typically the result of cutting tools that are not properly maintained or when the cutting parameters are not optimized.

66

66

Read more

Read more

VMT

VMT  2023 10 25

2023 10 25 In the world of CNC machining, precision and consistency are paramount, especially when working with aluminum, a material known for its versatility and wide range of applications. However, dealing with process variations and deviations can be a challenge.

66

66

Read more

Read more

VMT

VMT  2023 10 24

2023 10 24 In the world of CNC machining, precision and durability are critical, especially when it comes to aluminum parts. Aluminum's lightweight properties and excellent machinability make it a popular material in various industries including aerospace, automotive, electronics, and more.

66

66

Read more

Read more

VMT

VMT  2023 10 23

2023 10 23 In the world of precision manufacturing, aluminum CNC machined parts play a pivotal role. These components are essential in various industries, from aerospace to automotive, and their quality and performance are of utmost importance. However, achieving the desired results in aluminum CNC machining can be challenging, with cutting force and power consumption being two significant concerns.

66

66

Read more

Read more

VMT

VMT  2023 10 22

2023 10 22 In the world of precision manufacturing, ensuring the structural integrity of CNC-machined aluminum parts is paramount. Whether you're a seasoned engineer or new to the field, understanding how to evaluate and analyze the structure of these components is key to producing high-quality results.

66

66

Read more

Read more

VMT

VMT  2023 10 21

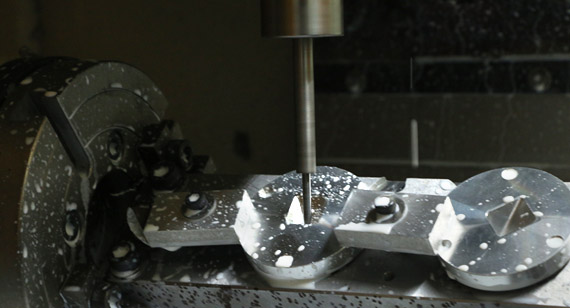

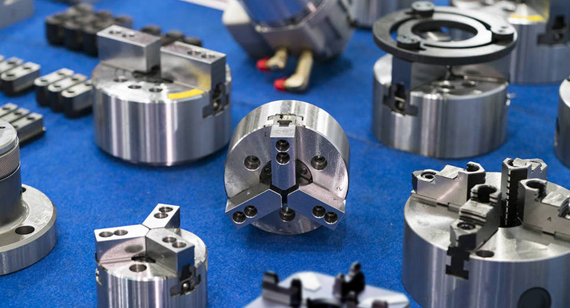

2023 10 21 When it comes to CNC machining, the devil is in the details. Achieving precision and efficiency in aluminum CNC machining requires a deep understanding of the methods you use to secure your workpiece. Selecting the right fixturing and clamping techniques can make all the difference in producing high-quality aluminum parts.

66

66

Read more

Read more

VMT

VMT  2023 10 20

2023 10 20 By implementing these strategies, you can effectively address surface oxidation and corrosion concerns when CNC machining aluminum components, ensuring the longevity and reliability of your parts.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!