15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

347 |

Published by VMT at Oct 21 2023

347 |

Published by VMT at Oct 21 2023

Mastering Fixturing and Clamping Methods for Aluminum CNC Machining

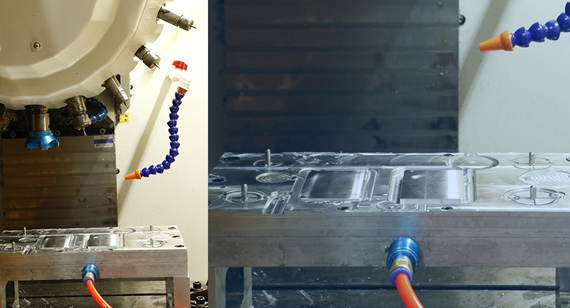

When it comes to CNC machining, the devil is in the details. Achieving precision and efficiency in aluminum CNC machining requires a deep understanding of the methods you use to secure your workpiece. Selecting the right fixturing and clamping techniques can make all the difference in producing high-quality aluminum parts. In this guide, we'll unveil the secrets to choosing the most suitable fixturing and clamping methods, hope VMT can help you.

The Importance of Proper Fixturing

Fixturing is the foundation of successful CNC machining. Without secure and stable fixturing, you risk compromising the quality and accuracy of your aluminum parts. To avoid such pitfalls, consider these key factors when choosing your fixturing methods:

1. Material Compatibility

Aluminum has unique properties that affect how it should be fixtured. Its lightweight nature and susceptibility to vibration make it crucial to select fixturing materials and methods that dampen vibrations effectively. Soft jaws or custom-designed fixtures can be ideal for accommodating aluminum's characteristics.

2. Part Geometry

The shape and size of your aluminum part play a significant role in determining the best fixturing approach. For complex geometries, custom fixturing may be necessary to ensure all critical features are accessible during machining.

3. Accessibility

Consider how easily you can access various surfaces of the workpiece for machining. Ensure that your fixturing method doesn't obstruct tool access or create interference issues.

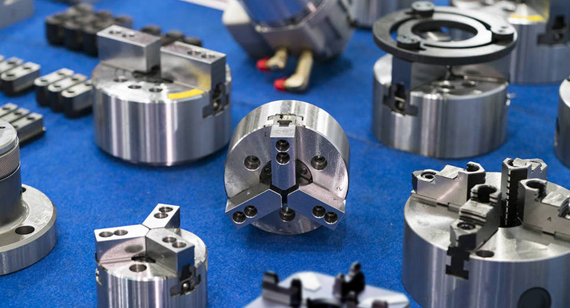

Clamping Methods for Aluminum CNC Machining

The way you clamp your aluminum workpiece can impact machining quality and efficiency. Here are some effective clamping methods to consider:

1. Vise Clamping

Using a vise is a common and versatile clamping method. Ensure that the vise jaws are soft or fitted with aluminum-specific jaw liners to prevent damage to the workpiece. Proper pressure distribution is essential to avoid distortion.

2. Custom Fixtures

For intricate parts or those with unique shapes, custom fixtures are often the best choice. These fixtures can be tailored to your specific part and designed to provide secure and vibration-free clamping.

3. Vacuum Chucks

Vacuum chucks are excellent for thin aluminum sheets. They provide uniform support without applying physical pressure, minimizing distortion risks. However, they may not be suitable for thicker or heavier workpieces.

4. Adhesive Workholding

Double-sided tape and adhesive fixtures can be effective for securing thin aluminum parts. They are easy to set up and reduce the risk of distortion. However, they are typically limited to smaller parts.

5. Mechanical Clamps

Mechanical clamps, such as toggle clamps, are quick and efficient for batch production. They can provide a strong grip without damaging the workpiece if used correctly.

Achieving Stability and Precision

In aluminum CNC machining, the pursuit of stability and precision is a continuous endeavor. Consider the following tips to enhance the quality of your work:

1. Use Proper Workholding Accessories

Accessories like soft jaws, custom inserts, and specialized clamping elements can enhance stability and protect the workpiece from damage.

2. Rigorous Testing

Always verify the stability and accuracy of your chosen fixturing and clamping methods through thorough testing before full-scale production.

3. Adaptive Clamping

For more complex parts, consider clamping strategies that allow for adjustments during machining. This adaptability can help you tackle intricate geometries with ease.

4. Consult with Experts

If you're unsure about the best fixturing and clamping methods for your specific aluminum part, seek advice from experienced CNC machinists or consult with professional CNC machining services.

Conclusion

Selecting the right fixturing and clamping methods for aluminum CNC machining is a critical step in ensuring high-quality, accurate, and efficient production. By understanding the unique properties of aluminum, the geometry of your part, and the accessibility requirements, you can make informed choices that will set the stage for CNC machining success. Elevate your CNC machining today by mastering the art of fixturing and clamping!

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!