15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2023 11 04

2023 11 04 This article is about frequently asked questions from customers of polished aluminum CNC machined parts. Will you ask these questions?

66

66

Read more

Read more

VMT

VMT  2023 11 03

2023 11 03 It's essential to apply the right polishing techniques, use appropriate polishing compounds, and ensure a clean and controlled environment to minimize these common problems encountered during the polishing of aluminum CNC machined parts. Regular inspection and adjustment of the polishing process can help in achieving a high-quality, consistent, and defect-free polished surface.

66

66

Read more

Read more

VMT

VMT  2023 11 02

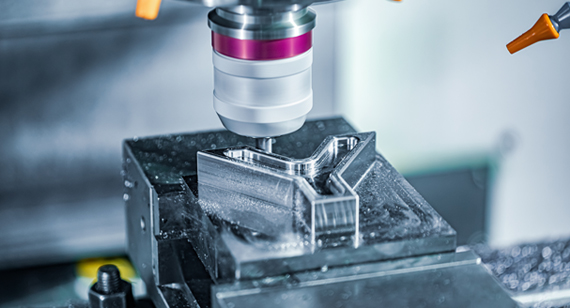

2023 11 02 Interpolation in CNC (Computer Numerical Control) machining refers to the process of calculating intermediate points between two known data points on a trajectory. It involves determining and generating the tool's path or motion between these points to create a smooth and accurate toolpath for manufacturing.

66

66

Read more

Read more

VMT

VMT  2023 11 01

2023 11 01 To achieve a mirror-like finish on aluminum, the process involves several steps of polishing and buffing. Here's a general guide on how to polish and achieve a mirror finish on aluminum

66

66

Read more

Read more

VMT

VMT  2023 10 31

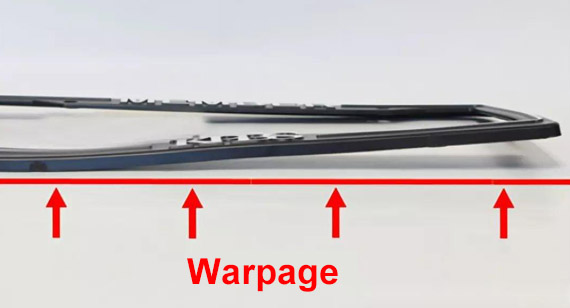

2023 10 31 After understanding the basics of the mechanism, we can start from four aspects: plastic materials, plastic parts design, mold structure and molding process, so as to solve it systematically, structured and logically.

66

66

Read more

Read more

VMT

VMT  2023 10 30

2023 10 30 how can plastics have a metallic texture, be a better substitute for metal materials, and combine the advantages of the two? The following are several surface metallization processes for plastic CNC machined parts. Let us take a look at what is the surface metallization process for plastic CNC machined parts.

66

66

Read more

Read more

VMT

VMT  2023 10 29

2023 10 29 When it comes to manufacturing precision components from aluminum through CNC machining, one crucial aspect that demands attention is the surface finish. The surface roughness of aluminum CNC machined parts plays a pivotal role in determining the component's quality, functionality, and aesthetics.

66

66

Read more

Read more

VMT

VMT  2023 10 28

2023 10 28 Producing high-quality aluminum CNC parts is essential, but cost considerations are equally important. To estimate and optimize the manufacturing costs of aluminum CNC parts, you need a systematic approach. In this article, we'll explore the key steps to help you manage costs effectively.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!