15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2023 11 28

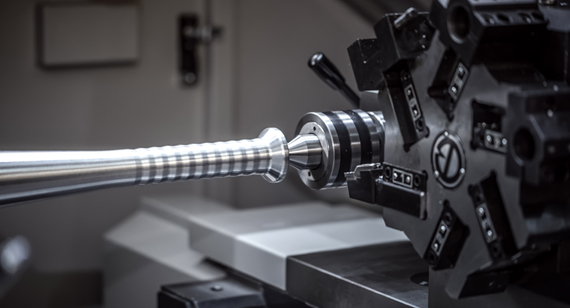

2023 11 28 CNC machining of stainless steel faces challenges such as work hardening and thermal deformation. Taking a strategic approach can help mitigate these issues and ensure a successful machining process.

66

66

Read more

Read more

VMT

VMT  2023 11 27

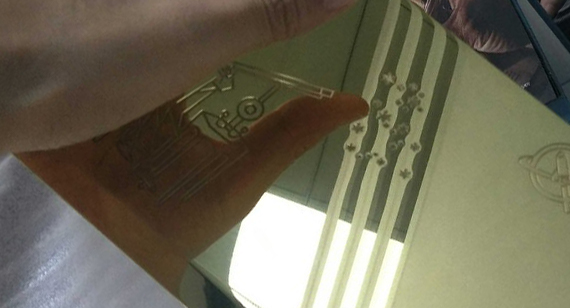

2023 11 27 This article mainly introduces all aspects of the stainless steel CNC parts mirror polishing process, including material selection, surface pretreatment, mechanical polishing, chemical polishing, electrochemical polishing, grinding and polishing, and surface cleaning.

66

66

Read more

Read more

VMT

VMT  2023 11 26

2023 11 26 Aerospace CNC machined parts play a pivotal role in the aviation and aerospace industries, contributing to the production of components crucial for aircraft and spacecraft. Let's explore the applications, materials, and common challenges encountered in the CNC machining of aerospace parts.

66

66

Read more

Read more

VMT

VMT  2023 11 25

2023 11 25 By incorporating these techniques into the CNC machining process for drilling stainless steel, you enhance efficiency, precision, and the overall success of your machining operations.

66

66

Read more

Read more

VMT

VMT  2023 11 24

2023 11 24 Selecting the right CNC machining manufacturer for stainless steel components is a critical decision that impacts the quality, precision, and overall success of your project. Here are key considerations to guide you in making an informed choice.

66

66

Read more

Read more

VMT

VMT  2023 11 23

2023 11 23 When it comes to CNC machining, the cost-effectiveness of manufacturing is influenced by various factors, including material prices, machinability, and specific project requirements. Here are some metals known for their generally lower machining costs.

66

66

Read more

Read more

VMT

VMT  2023 11 22

2023 11 22 Yes, CNC machining manufacturers commonly offer both sample production and small batch manufacturing services to cater to a wide range of customer needs. Here's an overview of these services.

66

66

Read more

Read more

VMT

VMT  2023 11 21

2023 11 21 Precision in aluminum alloy CNC machining is often specified in terms of tolerances, which are the allowable deviations from the nominal dimensions. The required precision can vary based on the specific application and the function of the machined part. Commonly, precision is expressed in terms of linear dimensions (e.g., ±0.1 mm) or geometric tolerances (e.g., perpendicularity, parallelism).

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!