15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2023 12 22

2023 12 22 The verification process for stable mass production of a set of CNC precision parts is a complex and rigorous process. It involves drawing review, material preparation, CNC programming, processing process monitoring, quality inspection and other links. Only through rigorous verification and testing can the stability and reliability of CNC precision parts be ensured.

66

66

Read more

Read more

VMT

VMT  2023 12 21

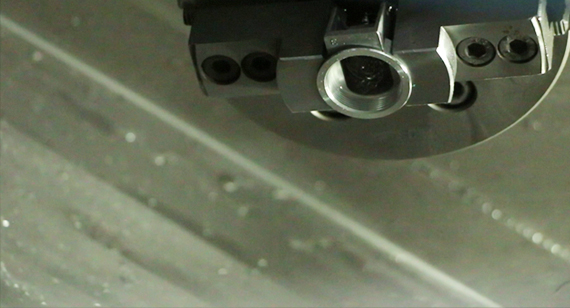

2023 12 21 This article explores the key factors that affect the smoothness of threads in CNC precision parts, including the sharpness of the tool, the selection of cutting parameters, the use of coolant, and equipment accuracy and adjustment. At the same time, this article also proposes optimization methods to improve the smoothness of threads in CNC precision parts, including selecting high-quality tools, adjusting appropriate cutting parameters, rational use of coolant, regular inspection and adjustment of equipment, and improving the skill level of operators.

66

66

Read more

Read more

VMT

VMT  2023 12 20

2023 12 20 it is crucial to conduct air tightness testing of automobile oil-cooled AN fitting adapters, which is related to the performance, safety, stability and service life of the automobile. Therefore, during the automotive CNC processing and manufacturing process, strict air tightness testing must be performed on oil-cooled AN fittings to ensure that their quality meets standards.

66

66

Read more

Read more

VMT

VMT  2023 12 19

2023 12 19 During the automotive CNC machining and manufacturing process, many components need to be tested for air tightness, such as brake systems, fuel systems, cooling systems and exhaust systems. These components require good air tightness to ensure their normal operation and the safety performance of the car.

66

66

Read more

Read more

VMT

VMT  2023 12 18

2023 12 18 The occurrence of poor oil contamination during the delivery of CNC machined parts will have a negative impact on the appearance and quality of the product. This article will introduce the causes of poor oil staining and provide solutions to ensure that CNC machined parts are delivered in good condition.

66

66

Read more

Read more

VMT

VMT  2023 12 17

2023 12 17 In today's era of high mechanical automation, CNC turning, as an important processing method, is widely used in various industries and fields. CNC turning service, that is, computer numerical control turning service, achieves high-precision and high-efficiency turning processing through precise digital control. This service has a wide range of applications in manufacturing, aerospace, medical equipment and other fields.

66

66

Read more

Read more

VMT

VMT  2023 12 16

2023 12 16 In the process of CNC machining, aluminum is a common processing material, and its surface finish has a significant impact on product quality and performance. Selecting the appropriate surface finish is important for improving product quality, reducing production costs, and enhancing product competitiveness. This article will explore how to select the appropriate surface finish for CNC machining aluminum.

66

66

Read more

Read more

VMT

VMT  2023 12 15

2023 12 15 Aluminum alloy anodizing is a commonly used surface treatment technology. By adjusting process parameters and using different dyes, aluminum alloy products can be given various colorful colors. This article will introduce the common colors that can be achieved by anodizing aluminum alloys, as well as its applications in different fields.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!