15 years one-stop China custom CNC machining parts factory

337 |

Published by VMT at Sep 16 2025 | Reading Time:About 5 minutes

337 |

Published by VMT at Sep 16 2025 | Reading Time:About 5 minutes

Do you often feel confused when choosing the right aluminum alloy? ADC12 aluminum, A380 aluminum, and 6063 aluminum are among the most common materials in manufacturing, but the wrong choice can lead to higher machining costs, reduced durability, and shorter part life. The good news is that once you understand their differences, you can select the best alloy for your project with confidence.

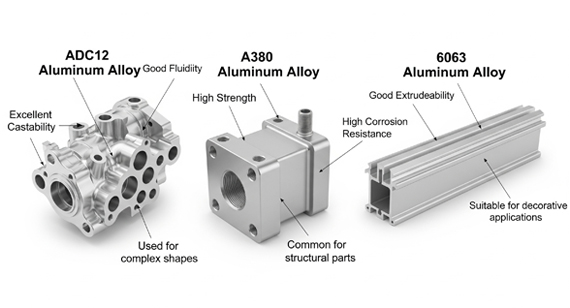

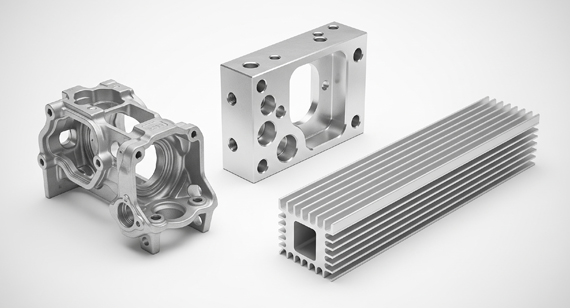

ADC12 aluminum, A380 aluminum, and 6063 aluminum differ mainly in composition, strength, and applications. ADC12 alloy is widely used for die casting, A380 aluminum offers excellent strength-to-weight balance for automotive and aerospace parts, and 6063 aluminum is preferred for extrusion, especially in architectural and decorative applications. Choosing depends on casting, extrusion, or machining needs.

Now that you know the general differences between ADC12 aluminum, A380 aluminum, and 6063 aluminum, let’s take a closer look at each alloy. By understanding their properties, standards, and machining performance, you’ll be able to make the right choice for your specific project requirements.

ADC12 aluminum alloy is one of the most widely used die-casting alloys. It offers a good balance of strength, corrosion resistance, and castability, making it suitable for complex shapes and thin-walled components. ADC12 die-casting alloy is popular in automotive engine parts, housings, and electronic components due to its excellent dimensional stability and cost efficiency.

A380 aluminum alloy is one of the most commonly used materials for aluminum die casting. It combines excellent strength-to-weight ratio, good corrosion resistance, and high thermal conductivity. A380 aluminum is widely applied in automotive, aerospace, and industrial equipment because it offers reliable performance at a relatively low cost. It is especially valued for parts requiring both durability and lightweight properties.

6063 aluminum alloy, often called the “architectural alloy,” is mainly used for extrusion. It offers excellent corrosion resistance, smooth surface finish, and good weldability. 6063 aluminum extrusion is widely applied in window frames, doors, piping, and decorative trims. Compared with die-casting alloys like ADC12 and A380, 6063 is softer but easier to form and anodize.

Different countries have their own standards for aluminum alloys, but many overlap. ADC12 aluminum is widely used in Asia and corresponds closely to A383 in the U.S. standard. A380 aluminum is the U.S. standard die-casting alloy and is similar to ADC10 in some markets. 6063 aluminum is standardized globally and often labeled as 6063-T5 or 6063-T6, depending on heat treatment.

| Alloy |

U.S. Standard (ASTM/AA) |

Japan (JIS) |

Europe (EN) |

China (GB) |

International (ISO) |

Notes |

| ADC12 Aluminum |

A383.0 (ASTM B179) | ADC12 (JIS H5302) | EN AC-46000 (EN 1706) | YL113 (GB/T 15115) | ISO Al-Si9Cu3(Fe) | Widely used in Asia for die casting |

| A380 Aluminum |

A380.0 (ASTM B179) | ADC10 (close equivalent) | EN AC-46500 (EN 1706) | YL102 (GB/T 15115) | ISO Al-Si8Cu3 | Most common U.S. die-casting alloy |

| 6063 Aluminum |

6063 (ASTM B221) | 6063 (JIS H4100) | EN AW-6063 (EN 573) | 6063 (GB/T 3190) | ISO Al-Mg0.7Si | Global extrusion alloy, often heat treated (T5/T6) |

When it comes to die casting, not all aluminum alloys perform the same. Both ADC12 aluminum and A380 aluminum were developed specifically for die-casting processes, which means they offer excellent fluidity during casting, good strength after solidification, and consistent dimensional stability. These properties make them ideal for producing complex shapes and thin-walled components, where precision and repeatability are essential.

ADC12 aluminum is especially popular in Asia and is widely used for automotive engine parts, electronic housings, and general industrial components. It offers a good balance between strength and corrosion resistance while keeping costs reasonable. On the other hand, A380 aluminum dominates the North American and European markets. It is valued for its excellent strength-to-weight ratio, high thermal conductivity, and ability to produce durable parts that still remain lightweight.

In contrast, 6063 aluminum is not suitable for die casting. Instead, it belongs to the extrusion category, which makes it ideal for products such as window frames, architectural trims, and tubes. Its softer nature and excellent anodizing response make it perfect for decorative finishes, but it lacks the casting properties needed for high-precision die-cast components.

When choosing between ADC12 aluminum, A380 aluminum, and 6063 aluminum, understanding their properties is crucial. Each alloy has a unique combination of chemical composition, mechanical strength, and physical properties, which affects die casting, extrusion, CNC machining, and overall part performance. Comparing these properties side by side helps you select the right alloy for your project, whether you prioritize strength, corrosion resistance, or machinability.

ADC12 Aluminum, A380 Aluminum, and 6063 Aluminum: Chemical Composition and Alloying Elements

ADC12 Aluminum Alloy Composition

ADC12 aluminum is a silicon-copper based die-casting alloy, designed for high castability and moderate mechanical strength. Its main alloying elements include silicon (Si), copper (Cu), iron (Fe), and small amounts of manganese (Mn), nickel (Ni), and zinc (Zn). Silicon improves fluidity and reduces shrinkage, while copper increases strength.

Chemical Composition Table – ADC12 Aluminum

| Element |

Si (%) |

Cu (%) |

Fe (%) |

Mn (%) |

Ni (%) |

Zn (%) |

Others (%) |

| ADC12 | 9–12 | 2–3 | ≤1 | ≤0.5 | ≤0.5 | ≤0.5 | Balance Al |

A380 Aluminum Alloy Composition

A380 aluminum is another Al-Si-Cu die-casting alloy but with slightly higher mechanical strength compared to ADC12. It contains silicon, copper, iron, and small amounts of nickel and zinc. A380 is widely used in the U.S. and Europe for structural components where strength and corrosion resistance are critical.

Chemical Composition Table – A380 Aluminum

| Element |

Si (%) |

Cu (%) |

Fe (%) |

Mn (%) |

Ni (%) |

Zn (%) |

Others (%) |

| A380 | 7–9 | 3–4 | ≤1 | ≤0.5 | ≤0.5 | ≤0.5 | Balance Al |

6063 Aluminum Alloy Composition

6063 aluminum is an Al-Mg-Si wrought alloy primarily used for extrusion. It differs significantly from die-casting alloys because it is softer, highly corrosion-resistant, and easy to anodize. Its main alloying elements are magnesium (Mg) and silicon (Si), which provide moderate strength and excellent corrosion resistance.

Chemical Composition Table – 6063 Aluminum

| Element |

Si (%) |

Mg (%) |

Fe (%) |

Cu (%) |

Mn (%) |

Cr (%) |

Zn (%) |

Others (%) |

| 6063 | 0.2–0.6 | 0.45–0.9 | ≤0.35 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | Balance Al |

ADC12 Aluminum, A380 Aluminum, and 6063 Aluminum: Mechanical Properties

Mechanical properties are crucial for choosing the right aluminum alloy for die casting, extrusion, or CNC machining parts. Properties such as tensile strength, yield strength, elongation, and hardness directly affect durability, machinability, and long-term performance. Comparing ADC12, A380, and 6063 side by side helps you make an informed choice for your project.

ADC12 Aluminum Mechanical Properties

Strength and Hardness

Ductility and Elongation

A380 Aluminum Mechanical Properties

Higher Strength

Moderate Ductility

6063 Aluminum Mechanical Properties

Moderate Strength

High Ductility and Formability

Mechanical Properties Comparison Table

| Property |

ADC12 Aluminum |

A380 Aluminum |

6063 Aluminum |

| Tensile Strength (MPa) |

220–260 | 240–280 | 130–185 |

| Yield Strength (MPa) |

180–210 | 200–240 | 70–145 |

| Elongation (%) |

2–4 | 2–5 | 8–12 |

| Brinell Hardness (HB) |

70–90 | 85–105 | 50–70 |

| Ductility |

Moderate | Moderate | High |

| Castability/Formability |

Excellent (Die Casting) | Excellent (Die Casting) | Excellent (Extrusion) |

| Application Focus |

Engine housings, electronic casings | Structural die-cast components | Extruded profiles, decorative frames |

ADC12 Aluminum, A380 Aluminum, and 6063 Aluminum: Physical Properties

Physical properties such as density, thermal conductivity, melting point, and coefficient of thermal expansion affect casting, machining, and end-use performance. Comparing ADC12, A380, and 6063 aluminum side by side helps you understand which alloy performs best under specific thermal, mechanical, and structural conditions.

Physical Properties Comparison Table

| Property |

ADC12 Aluminum |

A380 Aluminum |

6063 Aluminum |

| Density (g/cm³) |

2.78–2.82 | 2.77–2.80 | 2.70 |

| Melting Point (°C) |

550–640 | 540–640 | 595–650 |

| Thermal Conductivity (W/m·K) |

100–130 | 120–150 | 200–220 |

| Coefficient of Thermal Expansion (10⁻⁶/°C) |

21–23 | 21–24 | 23–24 |

| Electrical Conductivity (% IACS) |

28–33 | 30–35 | 40–45 |

| Machinability |

Moderate | Moderate | High |

| Corrosion Resistance |

Moderate | Moderate | High |

Every aluminum alloy has its strengths and limitations. Understanding the advantages and disadvantages of ADC12, A380, and 6063 helps you select the right material for your CNC machining, die casting, or extrusion project. Choosing the wrong alloy can increase production costs, cause machining issues, or reduce part durability.

ADC12 Aluminum

Advantages

Disadvantages

Tip: Use ADC12 when die-cast complexity and cost control are more important than maximum strength or corrosion resistance.

A380 Aluminum

Advantages

Disadvantages

Tip: Choose A380 when strength, thermal performance, and dimensional precision are critical.

6063 Aluminum

Advantages

Disadvantages

Tip: Use 6063 aluminum primarily for extrusion and CNC machining of decorative or structural profiles, not for die-cast parts.

ADC12 Aluminum, A380 Aluminum, and 6063 Aluminum: Advantages and Disadvantages Table

| Alloy |

Advantages |

Disadvantages |

| ADC12 Aluminum |

Excellent die-castability for complex, thin-walled parts - Moderate strength suitable for engine housings and electronic casings - Cost-effective and widely available in Asia - Good dimensional stability |

- Limited ductility, less flexible than extrusion alloys - Moderate corrosion resistance; may require coating - Not suitable for extrusion or high surface finish parts |

| A380 Aluminum |

- High strength-to-weight ratio for structural die-cast parts - Excellent thermal conductivity for heat-exposed components - Good castability for intricate shapes - Maintains tight dimensional tolerances |

- Moderate ductility, still less flexible than 6063 - Corrosion resistance requires surface treatment - More common in U.S./Europe; availability may be limited elsewhere |

| 6063 Aluminum |

- Excellent corrosion resistance for outdoor applications - High ductility and formability; easy to extrude, bend, and weld - Smooth surface finish and excellent for anodizing - Lightweight, ideal for structural frames and decorative profiles |

- Low tensile strength; not suitable for high-strength die-cast parts - Poor die-cast performance; cannot fill complex molds - Lower thermal conductivity than die-cast alloys |

Machinability and weldability are critical for CNC machining parts, post-processing, and assembly. Understanding how ADC12, A380, and 6063 aluminum perform under cutting, drilling, and welding operations can save time, reduce tool wear, and improve part quality.

Comparison Table: Machinability and Weldability

| Alloy |

Machinability |

Weldability |

| ADC12 Aluminum |

- Moderate machinability - Can be milled and drilled but requires sharp tools and careful feed rates - Slightly abrasive due to high silicon content |

- Limited weldability - Not ideal for structural welding - Commonly joined using mechanical fasteners or adhesives |

| A380 Aluminum |

- Moderate machinability, slightly better than ADC12 - Handles complex CNC machining with proper tooling |

- Limited weldability - Similar to ADC12; mechanical joining is preferred for structural components |

| 6063 Aluminum |

- Excellent machinability - Easy to cut, drill, and shape using CNC machines - Produces smooth surface finishes |

- Excellent weldability - Can be TIG, MIG, or resistance welded - Ideal for extrusion joints and structural assembly |

Tip: For die-cast components, avoid welding ADC12 or A380; use 6063 aluminum for extrusion-based welded assemblies. Always consult your CNC machining factory for recommended cutting speeds, feeds, and tooling.

Cost is a crucial factor when choosing between ADC12, A380, and 6063 aluminum for CNC machining or die casting. While raw material prices vary by region and availability, other factors such as initial cost, long-term benefits, machining costs, and post-processing expenses can impact your total project budget. Understanding the cost structure helps you select the most economical alloy without compromising performance.

Raw Material Market Cost and Price

The base price of aluminum alloys depends on regional supply, alloy composition, and market demand:

| Alloy |

Approx. Raw Material Cost (USD/kg) |

Notes |

| ADC12 Aluminum |

3.0–4.0 | Widely available in Asia; cost-effective for high-volume die-casting. |

| A380 Aluminum |

4.0–5.0 | Common in U.S./Europe; slightly higher cost due to higher strength and market demand. |

| 6063 Aluminum |

4.5–6.0 | Typically sold as extrusions; premium price for corrosion resistance and surface finish. |

Tip: Check local suppliers for up-to-date pricing. Bulk orders reduce costs significantly.

Initial Cost Comparison

Tip: Consider regional availability—ADC12 is cheaper in Asia, while A380 may be more economical in the U.S. market.

Long-Term Cost Benefits

Tip: Don’t only consider raw material price—long-term durability and performance matter.

CNC Machining Costs

Tip: Choose 6063 for CNC machining of extruded parts when high-speed production and low tool wear are priorities.

Post-Processing Costs

Tip: Factor in finishing processes when calculating the total cost per part.

ADC12 Aluminum, A380 Aluminum, and 6063 Aluminum: Cost and Pricing

| Cost Factor |

ADC12 Aluminum |

A380 Aluminum |

6063 Aluminum |

| Raw Material Cost (USD/kg) |

3.0–4.0 | 4.0–5.0 | 4.5–6.0 |

| Initial Cost |

Low; widely available in Asia | Medium to high; standard in U.S./Europe | High; premium for extrusion and surface finish |

| Long-Term Cost Benefits |

Low scrap rate, reliable for mass production | High strength reduces operational costs; durable | Durable, corrosion-resistant, low maintenance cost |

| CNC Machining Costs |

Moderate; tool wear possible due to high Si | Moderate; careful feed and speed needed | Low; excellent machinability and faster production |

| Post-Processing Costs |

Moderate; may require coating or plating | Moderate; may require coating or plating | Low; easy anodizing, smooth surface finish |

The applications of ADC12, A380, and 6063 aluminum differ significantly because of their alloying, mechanical, and physical properties. Understanding which alloy fits each application helps you select the right material for die-casting, extrusion, or CNC machining projects. Choosing the wrong alloy can lead to premature wear, poor surface finish, or structural failure.

ADC12 Aluminum Applications

Die-Cast Automotive Parts

Electronic Housings

Industrial Components

Tip: ADC12 is ideal when high-volume die-cast production is required with moderate strength and cost control.

A380 Aluminum Applications

Structural Die-Cast Parts

Heat-Exposed Components

Precision Die-Cast Components

Tip: A380 is preferred for high-strength die-cast applications, particularly in the U.S. and Europe.

6063 Aluminum Applications

Extruded Profiles

Architectural and Decorative Parts

CNC Machined Components

Tip: Use 6063 aluminum for extrusion-based projects, architectural components, or CNC machined decorative parts rather than die-cast applications.

| Alloy |

Typical Applications |

Key Advantages for These Applications |

| ADC12 Aluminum |

- Automotive engine housings and transmission cases - Electronic enclosures and connectors - Industrial fittings and small machinery parts |

- Excellent die-castability for complex shapes - Moderate strength - Cost-effective for high-volume production |

| A380 Aluminum |

- Structural die-cast automotive and aerospace components - Engine blocks and heat sinks - Precision die-cast housings |

- Higher strength-to-weight ratio - Good thermal conductivity - Maintains tight dimensional tolerances |

| 6063 Aluminum |

- Extruded profiles: windows, doors, frames, tubing - Architectural and decorative parts - CNC machined custom components |

- Excellent corrosion resistance and ductility - Smooth surface finish, ideal for anodizing - Lightweight and easy to machine |

Choosing the right aluminum alloy depends on your project requirements, including mechanical strength, corrosion resistance, machinability, cost, and production method. Selecting incorrectly can increase machining costs, reduce part lifespan, or compromise performance. ADC12, A380, and 6063 each excel in specific applications, so understanding their strengths and limitations ensures the best fit for your project.

When to Choose ADC12 Aluminum

Best for High-Volume Die Casting

Cost-Sensitive Projects

Tip: Use ADC12 when die-castability and cost-efficiency outweigh the need for maximum strength or corrosion resistance.

When to Choose A380 Aluminum

High-Strength Die-Cast Components

Regional Preference

Tip: Choose A380 when strength, thermal performance, and dimensional precision are critical.

When to Choose 6063 Aluminum

Extrusions and CNC Machining

Ease of Processing

Tip: Use 6063 aluminum for extrusion-based designs, decorative CNC machining, or projects requiring corrosion resistance. Avoid using it for die-cast parts.

Summary Table: Alloy Selection Guide

| Alloy |

Best Use Cases |

Key Considerations |

| ADC12 Aluminum |

High-volume die-cast automotive/electronics/industrial parts | Excellent castability, moderate strength, cost-effective in Asia |

| A380 Aluminum |

High-strength structural die-cast automotive/aerospace parts | Higher strength, good thermal conductivity, standard in U.S./Europe |

| 6063 Aluminum |

Extruded frames, architectural/decorative parts, CNC machining | Excellent corrosion resistance, surface finish, high ductility, easy machining |

At VMT, we specialize in high-precision die-cast and extruded aluminum CNC machining parts, providing complete solutions from material selection to finished components. Whether you are working with ADC12, A380, or 6063 aluminum, our team ensures optimal machining, tight tolerances, and superior surface finishes tailored to your project needs.

Die-Cast Aluminum CNC Machining Services

Expertise with ADC12 and A380

Post-Processing Options

Tip: Use our die-cast CNC services for parts that require strength, precision, and high-volume production.

Extruded Aluminum CNC Machining Services

Specializing in 6063 Aluminum

Advanced CNC Capabilities

Tip: Choose our extruded aluminum CNC services for corrosion-resistant, aesthetically appealing, or lightweight structural parts.

Why Choose VMT?

Tip: Contact VMT to discuss your project requirements and receive expert recommendations for alloy selection, machining strategy, and finishing options.

Choosing the right aluminum alloy is critical for ensuring the performance, durability, and cost-effectiveness of your CNC machined parts. ADC12 aluminum excels in high-volume die-cast applications where moderate strength, excellent castability, and cost efficiency are required. A380 aluminum offers higher strength and thermal performance, making it ideal for structural die-cast components, particularly in the automotive and aerospace sectors. 6063 aluminum is the go-to choice for extrusions, architectural profiles, and CNC-machined decorative or structural parts due to its excellent corrosion resistance, high ductility, and superior surface finish.

By understanding the mechanical properties, physical properties, advantages, disadvantages, machinability, weldability, and cost of each alloy, you can make an informed decision tailored to your project’s needs. Working with a professional CNC machining factory like VMT ensures precise machining, high-quality surface finishes, and optimal post-processing, whether you choose ADC12, A380, or 6063 aluminum.

1. Is A380 better than ADC12 for automotive parts?

Yes, A380 aluminum generally provides higher tensile and yield strength compared to ADC12, making it better for structural automotive components that require durability and load-bearing performance. However, ADC12 is more cost-effective and excellent for high-volume die-cast components where moderate strength is sufficient.

2. What is the difference between A380 aluminum and ADC12 aluminum?

3. What is the difference between 6063 and A380 aluminum alloys?

4. What makes 6063 aluminum extrusion a top choice for architectural and decorative parts?

6063 aluminum offers high corrosion resistance, smooth surface finish, and excellent anodizing compatibility, making it ideal for window frames, doors, structural profiles, and decorative elements. Its ductility and machinability allow for easy bending, welding, and cutting without compromising integrity.

5. What is the difference between A380 aluminum and A360 aluminum?

6. What is the difference between 5052 and 6063 aluminum?

7. What is the difference between 7075 and 6063 aluminum?

8. Can 6063 aluminum be welded with 4043 welding wire?

Yes, 6063 aluminum can be welded with 4043 welding wire, especially using TIG or MIG welding. This combination provides good corrosion resistance and minimal cracking during welding.

9. What is the easiest aluminum to weld?

Alloys in the 6xxx series, such as 6063 and 6061, are generally the easiest to weld due to their ductility and moderate strength. These alloys respond well to TIG, MIG, or resistance welding with minimal cracking risk.

10. Is 6063 aluminum suitable for bending?

Yes, 6063 aluminum is highly ductile, making it ideal for bending and forming processes without cracking. It is widely used in extrusions for architectural profiles, tubing, and decorative applications.

11. Can you anodize 6063 aluminum?

Yes, 6063 aluminum is highly suitable for anodizing. Its excellent surface finish and chemical composition allow for vibrant colors and corrosion-resistant coatings, making it perfect for decorative and architectural parts.