15 years one-stop China custom CNC machining parts factory

327 |

Published by VMT at Sep 10 2025 | Reading Time:About 4 minutes

327 |

Published by VMT at Sep 10 2025 | Reading Time:About 4 minutes

Choosing the right aluminum alloy for die casting can be overwhelming. Many engineers and buyers struggle between ADC12 aluminum and A380 aluminum, as both are widely used but have subtle differences. If you pick the wrong one, it could mean higher costs or poor performance. The good news? Understanding their differences makes selection much easier.

ADC12 aluminum and A380 aluminum are both popular die casting alloys with similar properties. The main difference lies in composition: ADC12 is preferred in Asian markets, while A380 dominates North America. Each offers unique casting performance, cost advantages, and machining suitability.

Now that we’ve introduced the comparison, let’s dive deeper into what ADC12 aluminum is and how it compares with A380.

ADC12 aluminum is a die-casting alloy widely used in Asia, especially Japan and China. It is valued for its excellent castability, corrosion resistance, and good mechanical properties. Manufacturers choose ADC12 when they need reliable performance for automotive parts, electronics housings, and industrial equipment.

Because it flows easily into complex molds, ADC12 is ideal for thin-walled die casting. It also offers good wear resistance, making it suitable for CNC machining into durable parts.

ADC12 aluminum is considered the Japanese standard alloy for die casting and is roughly equivalent to A383 aluminum in the North American market. Both share similar levels of silicon and copper, which give them high fluidity and make them suitable for producing thin, intricate die-cast parts.

This equivalence helps global manufacturers standardize production across regions. If your project specifies ADC12 aluminum, you can often substitute A383 aluminum when sourcing from North America, as the properties remain nearly the same.

A380 aluminum is the most widely used die-casting alloy in North America. Known for its excellent balance of strength, corrosion resistance, and thermal conductivity, A380 is a go-to material for automotive parts, electrical housings, and aerospace components.

Its popularity comes from its versatility—it offers good mechanical properties while still being easy to cast, even for complex shapes. A380 is also highly compatible with CNC machining services, making it ideal for projects that require both die casting and precision finishing.

A380 aluminum is a U.S. die-casting alloy and is often considered equivalent to ADC10 or ADC12 aluminum in Asian standards, though ADC12 is closer in composition. These alloys share comparable silicon and copper content, which provide strong castability and balanced mechanical properties.

This equivalence allows manufacturers to source parts internationally without compromising performance. If a design specifies A380 but you’re working with an Asian CNC machining factory, ADC12 is usually the recommended alternative.

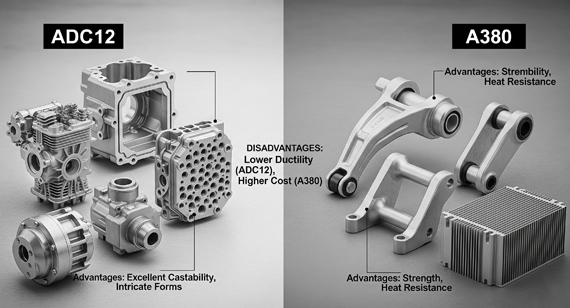

Both ADC12 aluminum and A380 aluminum are widely used in die casting, but each alloy comes with unique strengths and trade-offs. Understanding their advantages and disadvantages helps engineers, buyers, and designers choose the right alloy for performance, cost, and long-term durability.

ADC12 Aluminum: Advantages and Disadvantages

Advantages

Disadvantages

Tip: If your design needs thin-walled, complex parts at a low cost, ADC12 is an excellent option, but avoid it for parts exposed to high heat or heavy loads.

A380 Aluminum: Advantages and Disadvantages

Advantages

Disadvantages

Tip: Choose A380 if your project requires strong, versatile parts with international recognition, but be mindful of higher raw material costs compared to ADC12 in some regions.

While ADC12 aluminum and A380 aluminum share many similarities, their key differences lie in chemical composition. The varying amounts of silicon, copper, magnesium, and other elements directly affect castability, corrosion resistance, and machinability. Understanding these distinctions helps engineers select the alloy that best meets performance and cost requirements.

ADC12 Aluminum vs. A380 Aluminum: Chemical Composition

Both alloys are primarily made of aluminum, but slight differences in silicon, copper, iron, and zinc content create distinct mechanical and casting properties. Below is a comparison of their standard composition ranges:

| Element |

ADC12 Aluminum (%) |

A380 Aluminum (%) |

Effect on Properties |

| Aluminum (Al) |

Balance | Balance | Base metal, provides light weight and corrosion resistance. |

|

Silicon (Si) |

9.6 – 12.0 | 7.5 – 9.5 | Improves castability and wear resistance. |

| Copper (Cu) |

1.5 – 3.5 | 3.0 – 4.0 | Increases strength and hardness but reduces corrosion resistance. |

| Magnesium (Mg) |

≤ 0.3 | ≤ 0.1 | Adds strength and improves heat resistance. |

| Iron (Fe) |

≤ 1.3 | ≤ 1.3 | Controls shrinkage, but too much reduces corrosion resistance. |

| Manganese (Mn) |

≤ 0.5 | ≤ 0.5 | Enhances strength and reduces brittleness. |

| Nickel (Ni) |

≤ 0.5 | ≤ 0.5 | Improves strength at high temperatures. |

| Zinc (Zn) |

≤ 1.0 | ≤ 3.0 | Adds strength but can reduce corrosion resistance if excessive. |

| Titanium (Ti) |

≤ 0.3 | ≤ 0.2 | Refines grain structure, improving strength. |

| Other |

Trace | Trace | Small impurities, generally negligible. |

Element-by-Element Breakdown

Tip: If your project requires thin-wall casting, ADC12 is usually superior due to its higher silicon content. For higher strength requirements, A380 is generally a better choice thanks to its higher copper and zinc content.

Mechanical properties are crucial in determining whether an alloy can withstand stress, wear, and temperature demands in real-world applications. While ADC12 aluminum and A380 aluminum are similar, subtle differences make them better suited for different use cases.

| Property |

ADC12 Aluminum |

A380 Aluminum |

Notes |

| Tensile Strength (MPa) |

310 – 330 | 310 – 340 | Both provide good overall strength; A380 can reach slightly higher values. |

| Yield Strength (MPa) |

~150 – 170 | ~160 – 180 | A380 offers better resistance to permanent deformation. |

| Elongation (%) |

1.0 – 3.5 | 1.0 – 3.5 | Both have limited ductility due to die-cast structure. |

| Hardness (Brinell HB) |

80 – 100 | 80 – 100 | Nearly identical hardness values. |

| Density (g/cm³) |

~2.74 | ~2.73 | Very similar; weight differences are negligible. |

| Thermal Conductivity (W/m·K) |

~96 – 105 | ~96 – 105 | Both allow good heat dissipation, useful for electronics. |

| Coefficient of Expansion (µm/m·°C) |

~21 – 23 | ~22 – 23 | Similar expansion rates; must be considered in high-heat designs. |

Key Insights

Tip: For CNC machining services, both alloys perform well, but if your design involves high load-bearing parts, A380 may provide slightly better reliability.

Casting properties determine how well an alloy fills molds, avoids defects, and maintains dimensional accuracy. Both ADC12 aluminum and A380 aluminum are popular in die casting, but their flowability and castability differ slightly, which can influence manufacturing efficiency and final part quality.

Flowability

Tip: If your part design involves complex, thin-walled features, ADC12 aluminum is often the safer choice to reduce casting defects and minimize CNC machining rework.

Castability

Tip: For large, structural die-cast parts, A380 aluminum offers better reliability. For precision, thin-wall parts, ADC12 aluminum is usually the better option.

ADC12 Aluminum vs. A380 Aluminum: Casting Properties Table

Casting properties like flowability and castability determine how efficiently an alloy fills molds, reduces defects, and delivers consistent quality. Here’s how ADC12 aluminum and A380 aluminum compare:

| Property |

ADC12 Aluminum |

A380 Aluminum |

Notes |

| Flowability |

Excellent – high silicon improves fluidity, ideal for thin walls and complex geometries. | Good – flows well, but may struggle in ultra-thin sections. | ADC12 preferred for intricate designs. |

| Castability |

Very good – low shrinkage, dimensional stability, but can show porosity in thick sections. | Excellent – versatile for medium to large castings with fewer defects. | A380 is better for structural parts. |

| Defect Risk |

Slightly higher porosity risk if wall thickness is uneven. | Lower porosity tendency in thicker sections. | Design adjustments can minimize issues. |

| Dimensional Accuracy |

High – maintains precision after casting and machining. | High – strong consistency, especially in larger parts. | Both suitable for CNC machining. |

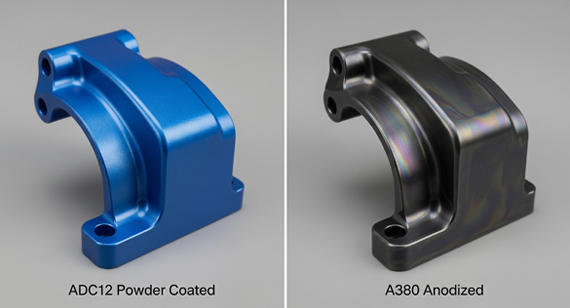

Surface treatments improve corrosion resistance, wear resistance, and appearance of die-cast parts. Both ADC12 aluminum and A380 aluminum can undergo common finishing processes, but slight compositional differences affect the results.

| Surface Treatment |

ADC12 Aluminum |

A380 Aluminum |

Notes |

| Anodizing |

Limited – high silicon content causes uneven or dark finishes. | Limited – similar challenges; often not recommended for decorative anodizing. | Powder coating or plating is better for aesthetics. |

| Powder Coating |

Excellent adhesion, smooth finish, strong corrosion protection. | Excellent adhesion, durable coating, widely used in automotive and electronics. | Preferred for outdoor and consumer products. |

| Electroplating |

Good compatibility (nickel, chrome, zinc plating). | Good compatibility, widely used in automotive parts. | Adds wear and corrosion resistance. |

| Painting |

Works well with proper surface prep. | Works well with proper surface prep. | Cost-effective finishing option. |

| CNC Surface Finishing |

Good – machining provides smooth base for coatings. | Good – easy to finish with CNC machining. | Both alloys are compatible. |

Key Insights

Tip: If your project requires decorative anodizing, neither ADC12 nor A380 is ideal. Instead, consider alloys like 6061 aluminum, which respond much better to anodizing.

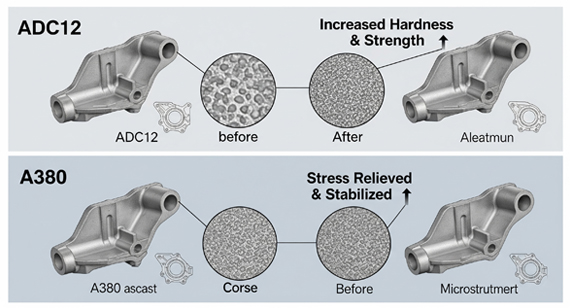

Heat treatment can enhance the strength and performance of many aluminum alloys, but die-cast alloys like ADC12 and A380 behave differently because of their high silicon content and porosity levels.

| Heat Treatment Method |

ADC12 Aluminum |

A380 Aluminum |

Notes |

| Solution Heat Treatment (T4, T6) |

Not recommended – high silicon and porosity make it prone to cracking and distortion. | Not recommended – suffers from the same limitations as ADC12. | Rarely applied to die-cast alloys. |

| Stress Relief Annealing |

Possible – low-temperature annealing can relieve internal stresses. | Possible – helps reduce warping in large castings. | Improves dimensional stability before CNC machining. |

| Artificial Aging (T5) |

Limited effect – does not significantly increase strength. | Limited effect – minor improvements, but not widely used. | More effective on wrought alloys. |

| As-Cast Condition |

Best option – maintains natural balance of strength and castability. | Best option – retains strength and machinability without heat treatment. | Industry standard. |

Key Insights

Tip: If your project requires heat-treated aluminum with high strength, consider wrought alloys such as 6061-T6 or 7075-T6 instead of ADC12 or A380.

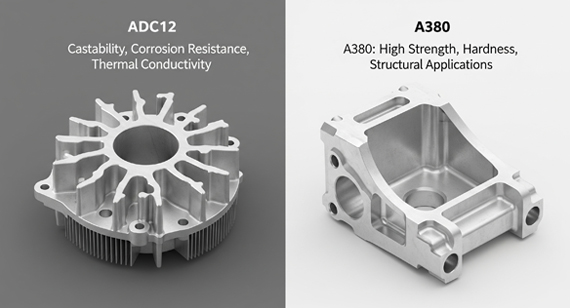

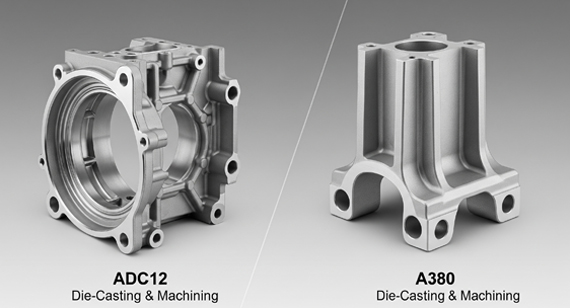

Both ADC12 aluminum and A380 aluminum are widely used in die casting for automotive, electronics, and industrial components. Their applications overlap, but subtle differences in composition and performance make each alloy more suitable for certain industries.

| Industry / Use Case |

ADC12 Aluminum |

A380 Aluminum |

Notes |

| Automotive |

Engine housings, transmission cases, brackets, thin-walled structural parts. | Gearboxes, engine blocks, motor housings, load-bearing brackets. | ADC12 for precision, A380 for strength. |

| Electronics |

Laptop housings, mobile device casings, heat sinks, connectors. | Electrical enclosures, motor housings, industrial electronics cases. | ADC12 preferred for intricate, thin designs. |

| Consumer Goods |

Kitchen appliances, camera bodies, power tool housings. | Appliance housings, sporting goods, industrial equipment casings. | Both alloys are common here. |

| Aerospace / Transport |

Limited – used for small non-critical components. | Non-structural aerospace parts, housings, brackets. | A380 more recognized internationally. |

| Industrial Machinery |

Pump housings, valve bodies, small mechanical components. | Larger housings, machine bases, connectors. | A380 used when parts face more stress. |

Key Insights

Tip: If your project involves exporting products, A380 aluminum may be safer since it is more globally recognized, while ADC12 is mainly standardized in Asian markets.

Cost is one of the most important factors when choosing between ADC12 aluminum and A380 aluminum. While their performance is similar, differences in regional availability, raw materials, and processing requirements can significantly affect total project costs.

Raw Material Costs

Tip: Always source locally when possible—importing the “wrong” alloy for your region can raise costs unnecessarily.

Casting Costs

Casting Process Costs

Post-Processing Costs

Initial Cost Comparison

Long-Term Cost Benefits

CNC Machining Costs

Tip: For CNC machining services, both alloys are cost-efficient, but ADC12 die casting CNC machined parts may offer slightly lower machining costs.

Market Price

Summary:

ADC12 Aluminum vs. A380 Aluminum: Casting Costs

| Cost Component |

ADC12 Aluminum |

A380 Aluminum |

Notes |

| Raw Material Costs |

Lower in Asian markets; widely available locally. | Lower in North America; locally produced in bulk. | Source locally to reduce cost. |

| Casting Costs |

Reduced scrap and defects due to excellent flowability; ideal for thin walls. | Efficient for medium-to-large parts; slightly higher scrap risk in thin sections. | Match alloy to part size/complexity. |

| Casting Process Costs |

Shorter cycle times; less tooling wear due to high fluidity. | Slightly longer cycles for thin-walled designs; better for larger molds. | Optimizing mold design reduces cost. |

| Post-Processing Costs |

May need more surface finishing due to porosity. | Lower finishing costs in thicker sections. | Consider surface treatment early. |

| CNC Machining Costs |

Good machinability; lower tool wear. | Slightly harder; marginally higher tool wear. | Both alloys work well for die-cast CNC machined parts. |

| Initial Cost Comparison |

Generally cheaper in Asia. | Generally cheaper in North America. | Depends on regional availability. |

| Long-Term Cost Benefits |

Lower upfront cost, may require more corrosion protection. | Slightly higher upfront cost, better durability and lower maintenance. | Factor lifecycle costs into selection. |

| Market Price |

Lower in Asian markets. | More stable global pricing. | Consider supply chain and export markets. |

Choosing the right alloy depends on your project’s design complexity, load requirements, cost constraints, and geographic production location. Both ADC12 aluminum and A380 aluminum are reliable die-cast materials, but knowing their strengths and limitations ensures optimal performance and cost-efficiency.

When Should I Use ADC12 Aluminum?

Tip: Avoid ADC12 for heavy structural parts or high-temperature applications, as its mechanical strength is lower than A380.

When Should I Use A380 Aluminum?

Tip: Choose A380 aluminum when strength, global recognition, and durability outweigh initial cost considerations.

How to Choose Between ADC12 Aluminum and A380 Aluminum?

| Criteria |

ADC12 Aluminum |

A380 Aluminum |

Notes |

| Design Complexity |

Excellent – ideal for thin-walled, intricate parts. | Good – best for medium-to-large structural designs. | ADC12 preferred for fine details. |

| Mechanical Strength |

Moderate – sufficient for light to medium loads. | Higher – better for load-bearing and structural parts. | A380 stronger in thicker sections. |

| Geographic Advantage |

Cheaper and more available in Asian markets. | Standard and cost-effective in North America & Europe. | Local sourcing reduces costs. |

| Dimensional Accuracy |

High – excellent for precise die-cast CNC machined parts. | High – stable in medium-to-large castings. | Both suitable for precision machining. |

| Durability & Corrosion Resistance |

Good, may need additional surface protection. | Slightly better in thick sections; long-term durability is higher. | Consider environment exposure. |

| CNC Machining Compatibility |

Excellent – lower tool wear due to higher silicon. | Excellent – slightly harder, minor increase in tool wear. | Both alloys are machinable. |

| Best Use Cases |

Small automotive parts, electronics, precision components. | Larger automotive parts, industrial machinery, structural components. | Match alloy to application needs. |

Both ADC12 aluminum and A380 aluminum are reliable choices for die-cast CNC machined parts, but the right selection depends on part design, mechanical requirements, and production location.

Tip: For projects requiring international compliance, A380 is often safer. For cost-sensitive, precision, thin-walled parts produced in Asia, ADC12 usually offers better value.

Conclusion: Assess your project’s part size, complexity, strength requirements, and location of production. Choosing the right alloy ensures lower costs, fewer defects, and longer-lasting parts.

At VMT, we specialize in ADC12 aluminum die casting CNC machined parts and A380 aluminum die casting CNC machined parts, delivering high-quality, precision components for various industries. Our team ensures every part meets strict dimensional tolerances, surface finish requirements, and mechanical specifications.

We offer:

Tip: Partnering with a professional CNC machining factory like VMT reduces casting defects, post-processing costs, and project delays. Our expertise ensures your parts are ready for assembly and end-use applications.

Choosing between ADC12 aluminum and A380 aluminum depends on your project’s design complexity, mechanical requirements, part size, and regional production considerations.

Both alloys are highly compatible with die casting and CNC machining services, offering reliable performance, good corrosion resistance, and machinability. Understanding their differences ensures optimized part performance, reduced production costs, and fewer post-processing issues.

At VMT, we provide comprehensive services for ADC12 and A380 aluminum die casting CNC machined parts, helping you turn your design into high-quality, ready-to-use components.

1. What is the difference between ADC10 and ADC12?

ADC10 has lower silicon content (around 7–10%) compared to ADC12 (9–12%). This makes ADC12 better for thin-walled and intricate die-cast parts, while ADC10 is slightly easier to machine and less brittle.

2. What is the material cost of A380?

The cost of A380 aluminum varies by region and market demand. In North America, it is widely available and moderately priced, but importing it into Asia may increase costs. Contact your CNC machining factory for accurate pricing.

3. How is A380 aluminum manufactured?

A380 is produced using high-pressure die casting. Molten aluminum alloy is injected into steel molds under pressure, cooled, and ejected. Post-processing may include CNC machining, surface treatment, and inspection.

4. What is the difference between A380 and A356?

5. What is the difference between A380 aluminum and 383 aluminum?

A383 is similar to ADC12, with slightly higher silicon and lower copper than A380. It offers excellent flowability for thin-walled die-cast parts, while A380 provides higher strength for thicker, structural components.

6. What is the difference between A380 aluminum and A360 aluminum?

A360 is a high-silicon die-cast alloy, designed for thin, detailed parts with excellent corrosion resistance. A380 offers higher strength but slightly less flowability for thin sections.

7. What materials should not be used for casting?

Materials with very low fluidity, high melting points, or high brittleness, such as some high-carbon steels or titanium alloys, are generally unsuitable for high-pressure die casting.

8. What are the best materials for casting?

Commonly used casting materials include ADC12 aluminum, A380 aluminum, A356 aluminum, magnesium alloys, and zinc alloys. Selection depends on mechanical requirements, part size, and surface finish needs.

9. What is the best aluminum for casting?

10. Which is stronger, 6061 or 6063?

11. What’s the difference between ADC12 and AL6063?

12. Which is better, 6061 aluminum or 7075 aluminum?

13. What’s the difference between Al 6063 and Al 6082?

Tip: When selecting aluminum for die casting or CNC machining, consider alloy type, strength, flowability, and intended application. ADC12 and A380 remain the most common die-cast alloys for precision CNC machined parts.