15 years one-stop China custom CNC machining parts factory

99 |

Published by VMT at Sep 11 2025 | Reading Time:About 8 minutes

99 |

Published by VMT at Sep 11 2025 | Reading Time:About 8 minutes

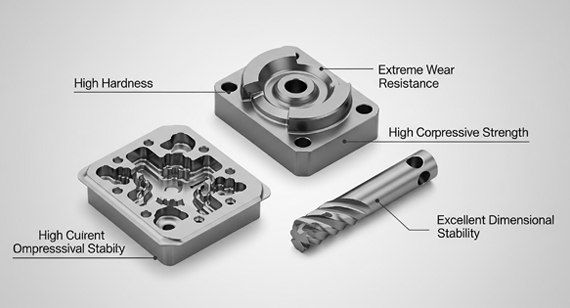

Many buyers face confusion when choosing the right steel for CNC machining projects. Using the wrong material can lead to higher costs, poor durability, and wasted time. MC66 steel provides a balanced solution, offering strength, hardness, and corrosion resistance—making it a trusted choice for precision CNC machined parts.

MC66 steel is a high-performance stainless steel known for its excellent hardness, wear resistance, and corrosion protection. It is widely used in CNC machining parts, knives, and industrial components due to its strength and durability. MC66 stainless steel combines toughness with machinability, making it ideal for demanding applications.

Now that you know the basics of MC66 steel, let’s explore its definition, characteristics, benefits, and applications in CNC machining to see if it fits your project needs.

MC66 steel is a high-performance stainless steel known for its unique blend of strength, hardness, and corrosion resistance. It is part of the alloy family designed specifically for use in demanding industries, including CNC machining. This steel is created with a specific chemical composition to ensure excellent durability and resistance to wear, making it ideal for precision machining parts.

MC66 steel is often used in components that must withstand harsh environments without losing their integrity. Whether in mechanical parts, automotive, or industrial applications, MC66 steel is highly valued for its ability to maintain strength and resist corrosion even in high-temperature or abrasive conditions.

Yes, MC66 steel is highly suitable for CNC machining due to its balanced composition and mechanical properties. This steel offers a combination of strength, hardness, and ductility that allows it to be easily machined into complex parts with precise dimensions. CNC machining services often choose MC66 steel for applications requiring durable, high-performance components, as it retains its integrity during the machining process and provides long-term wear resistance.

MC66 steel is also known for its excellent surface finish after machining. This makes it a go-to material for industries like automotive, aerospace, and medical device manufacturing, where precise and smooth finishes are critical. Additionally, its ability to resist oxidation and corrosion ensures that parts made from MC66 steel maintain their quality even in harsh operating conditions.

MC66 steel is a high-performance material known for its outstanding mechanical properties that make it suitable for precision CNC machining applications. One of the key characteristics of MC66 steel is its excellent hardness, which allows it to withstand significant wear and tear in harsh environments. Its combination of toughness, strength, and corrosion resistance makes it a reliable choice for industries requiring high durability and longevity.

The steel’s properties are a result of its carefully crafted chemical composition. MC66 steel is designed to balance both machinability and performance, ensuring it can be processed into complex components without compromising strength or integrity. These characteristics make MC66 steel an ideal material for applications such as automotive parts, industrial machinery, and even medical devices.

MC66 Steel: Chemical Composition

The chemical composition of MC66 steel plays a crucial role in its performance, influencing properties like strength, corrosion resistance, and machinability. Understanding these elements can help you determine whether this material fits your project’s requirements.

Carbon (C), %

Carbon is the primary element that enhances the hardness and strength of MC66 steel. The higher the carbon content, the harder and stronger the steel becomes. However, it can also make the steel more brittle if not balanced properly.

Chromium (Cr), %

Chromium increases corrosion resistance, making MC66 steel highly resistant to rust and oxidation. This is particularly important for parts exposed to moisture or high temperatures.

Iron (Fe), %

Iron is the base element in MC66 steel, contributing to its overall structure and stability. Iron’s presence supports the combination of other elements to enhance strength and machinability.

Manganese (Mn), %

Manganese strengthens the steel and improves its hardness, making it ideal for parts subjected to wear and mechanical stress. It also helps in deoxidizing the steel during production.

Molybdenum (Mo), %

Molybdenum enhances the steel’s resistance to high temperatures and helps maintain its strength at elevated temperatures. This property is vital for components that operate under extreme conditions.

Vanadium (V), %

Vanadium increases the hardness and wear resistance of the steel. It also improves the steel's ability to retain strength at higher temperatures, making it valuable in demanding applications.

Nickel (Ni), %

Nickel adds toughness and improves the corrosion resistance of MC66 steel. It also enhances the steel’s ability to withstand extreme environments, making it suitable for critical components.

Nitrogen (N), %

Nitrogen helps improve the strength and hardness of the steel, enhancing its ability to resist corrosion. It also contributes to the steel’s overall structural integrity.

Phosphorus (P), %

Phosphorus can improve the machinability of the steel but should be kept at low levels, as too much can reduce its toughness.

Silicon (Si), %

Silicon increases the steel’s strength and resistance to oxidation. It also helps to maintain the steel’s overall stability.

Sulfur (S), %

Sulfur can make the steel more machinable, but high levels of sulfur may negatively impact its toughness.

MC66 Steel: Chemical Composition Table

Understanding the chemical composition of MC66 steel is essential for assessing its performance in CNC machining applications. The following table breaks down the key elements that make up MC66 steel, highlighting their roles in enhancing the material's strength, hardness, and resistance to wear and corrosion.

| Element |

Symbol |

Percentage (%) |

Function |

| Carbon |

C | ~0.90-1.10 | Increases hardness and strength; higher carbon content enhances toughness. |

| Chromium |

Cr | ~13.00-14.00 | Improves corrosion resistance, making the steel ideal for harsh environments. |

| Iron |

Fe | Balance | Acts as the primary element, providing the structural base for the alloy. |

| Manganese |

Mn | ~0.30-0.50 | Enhances strength and hardness; contributes to deoxidizing the steel. |

| Molybdenum |

Mo | ~0.50-0.60 | Increases high-temperature strength and resistance to corrosion. |

| Vanadium |

V | ~0.10-0.20 | Enhances hardness, wear resistance, and high-temperature strength. |

| Nickel |

Ni | ~1.50-2.00 | Improves toughness and corrosion resistance, especially in harsh conditions. |

| Nitrogen |

N | ~0.10-0.15 | Increases strength and hardness; contributes to corrosion resistance. |

| Phosphorus |

P | ~0.02-0.04 | Can improve machinability but should be kept low to avoid brittleness. |

| Silicon |

Si | ~0.30-0.50 | Increases strength and resistance to oxidation, especially at high temperatures. |

| Sulfur |

S | ~0.02-0.03 | Enhances machinability but too much can reduce toughness. |

MC66 steel boasts a range of mechanical properties that make it an excellent choice for high-performance CNC machining applications. These properties determine how the material will behave under stress, temperature, and other operational conditions, ensuring it delivers the desired performance in critical components.

The following breakdown highlights key mechanical properties of MC66 steel:

| Property |

Value |

Description |

| Hardness (HRC) |

~58-62 HRC | Indicates the material's resistance to indentation and wear. Higher values mean better wear resistance. |

| Hardness (HV) |

~550-600 HV | Hardness measurement in Vickers scale, ensuring durability under heavy use. |

| Hardness (HRC/HRB) |

Varies based on heat treatment | A combination of Rockwell C and B scales used to assess hardness for different applications. |

| Tensile Strength (MPa) |

~1000-1200 MPa | Measures the maximum stress MC66 can withstand without breaking. |

| Elongation (Rp0.2/MPa) |

~15-18% | Indicates the material’s ability to stretch before breaking under stress. |

| Ductility (%) |

~10-12% | Shows the material’s ability to deform without breaking, making it suitable for machining. |

| Yield Strength (MPa) |

~800-1000 MPa | The stress at which the material starts to permanently deform. |

| Reduction of Area (Z/%) |

~50-60% | The percentage reduction in cross-sectional area after fracture, indicating toughness. |

| Heating Temperature |

~800-850°C | The temperature range in which MC66 can be heat-treated to achieve optimal properties. |

| Elastic (Young’s) Modulus, GPa |

~200 GPa | Indicates the stiffness of the material; higher values mean less deformation under load. |

| Elongation at Break (%) |

~10-15% | Measures how much the material can elongate before breaking, contributing to toughness. |

| Fatigue Strength (MPa) |

~600-800 MPa | The maximum stress MC66 can endure without failure under cyclic loading conditions. |

| Poisson's Ratio |

~0.30 | Describes the ratio of lateral strain to axial strain when under stress, influencing material behavior. |

| Shear Modulus (GPa) |

~80 GPa | Measures the material's response to shear stress, relevant for machining operations. |

| Shear Strength (MPa) |

~600-700 MPa | Indicates the material’s resistance to shear forces, essential for machining durability. |

In addition to its mechanical properties, the physical characteristics of MC66 steel are essential to understand its performance in real-world applications. These properties influence how the material reacts to environmental factors like temperature, corrosion, and electrical conductivity. Whether you're working with high-temperature components or parts exposed to corrosive environments, understanding the physical properties of MC66 steel ensures that it meets your project needs.

Here’s a detailed overview of the key physical properties of MC66 steel:

| Property |

Value |

Description |

| Density (g/cm³) |

~7.8 g/cm³ | The material's mass per unit volume, important for weight-sensitive applications. |

| Melting Point |

~1450°C | The temperature at which MC66 steel transitions from solid to liquid, critical for high-temperature applications. |

| Specific Heat (J/kg·K) |

~500 J/kg·K | The amount of heat energy required to raise the temperature of the material by 1°C. |

| Thermal Conductivity (W/m·K) |

~30 W/m·K | The ability of the material to conduct heat; lower values indicate better heat resistance. |

| Thermal Expansion Coefficient (10⁻⁶/K) |

~12 µm/m·K | Describes how much the material expands or contracts with temperature changes, important for parts subjected to temperature fluctuations. |

| Resistivity (μΩ·m) |

~0.7 μΩ·m | The material's resistance to the flow of electrical current; higher resistivity indicates better insulation. |

| Modulus of Elasticity (kN/mm²) |

~210 kN/mm² | Measures the material’s stiffness, helping to predict how it will deform under stress. |

| Magnetic Properties |

Non-magnetic | MC66 steel is non-magnetic, making it suitable for applications requiring non-ferrous properties. |

| Electrical Conductivity |

Low | MC66 steel is not a good conductor of electricity, which is beneficial in applications where electrical insulation is needed. |

| Rust Resistance |

High | Due to its chromium content, MC66 steel exhibits excellent rust resistance, making it ideal for use in wet or humid environments. |

| Toughness |

High | MC66 steel maintains toughness even at lower temperatures, which is essential for impact-resistant components. |

| Corrosion Resistance |

Excellent | The high chromium content ensures that MC66 steel performs well in corrosive environments, including exposure to chemicals, saltwater, and moisture. |

When selecting materials for CNC machining parts, it's essential to choose a steel that balances performance, durability, and cost-effectiveness. MC66 steel stands out as an ideal choice for a variety of applications. With its excellent mechanical properties, versatility, and cost-efficient nature, MC66 steel is increasingly preferred in industries like automotive, aerospace, and industrial machinery.

Excellent Durability and Strength

One of the primary reasons to choose MC66 steel for CNC machining parts is its outstanding durability and strength. This high-performance material offers superior resistance to wear, making it ideal for parts that need to withstand high stress, friction, or exposure to harsh conditions. Whether it’s mechanical components, gears, or industrial tools, MC66 steel ensures long-lasting performance.

MC66 steel’s impressive tensile strength (up to 1200 MPa) and hardness (58-62 HRC) help it resist deformation under load, ensuring your CNC machined parts retain their shape and functionality over time. This durability minimizes maintenance needs, reducing long-term operational costs.

Versatility in CNC Machining

MC66 steel is incredibly versatile when it comes to CNC machining. Despite its high hardness, it’s still machinable, which makes it suitable for a wide range of applications requiring precise, high-quality components. Whether you're producing complex geometries or intricate designs, MC66 steel can be shaped, drilled, and milled with ease.

Moreover, its high surface finish characteristics ensure that parts come out with a smooth, polished appearance, making it a preferred material for industries that demand aesthetic quality and precision, such as medical devices or high-end automotive parts.

Cost-Effectiveness

While MC66 steel offers premium performance, it remains cost-effective, making it an attractive choice for manufacturers. The steel’s durability means fewer repairs and replacements, ultimately saving you money over the long term. Additionally, its machinability reduces the wear on CNC tools, helping to extend tool life and reduce maintenance costs.

In terms of material cost, MC66 steel provides excellent value when compared to other high-performance steels like stainless steel or tool steel, which can be more expensive to machine.

MC66 steel is a high-performance material, offering various benefits for CNC machining projects. However, like any material, it has both advantages and potential drawbacks that should be considered based on your project requirements.

Advantages

High Durability

Corrosion Resistance

Good Machinability

Temperature Resistance

Cost-Effective

Disadvantages

Higher Initial Cost

Machining Challenges

Limited Formability

Tip: Carefully evaluate your project's budget, machining capabilities, and performance requirements before choosing MC66 steel. While it offers excellent advantages, its higher initial cost and tool wear may impact projects with tight budgets or specific machining constraints.

MC66 steel is a high-performance material, and its cost reflects the exceptional durability and machining capabilities it offers. While its initial price may be higher than some other steels, its long-term cost-effectiveness often makes it a more economical choice in the long run.

Initial Cost Comparison

The upfront cost of MC66 steel is generally higher than other common alloys like 304 stainless steel or carbon steel due to its high-strength properties and alloying elements. This may make it seem less attractive for projects with tight budgets. However, when evaluating material costs, it’s important to consider the specific requirements of your project—particularly if you need parts that will endure high wear or exposure to extreme conditions.

Long-Term Cost-Effectiveness

While the initial cost of MC66 steel may be higher, its long-term benefits significantly reduce overall project costs. The steel’s durability and resistance to wear and corrosion mean fewer repairs, replacements, and maintenance requirements over time. Additionally, its machinability helps reduce tooling costs by preventing excessive wear on CNC tools.

MC66 Steel: Cost and Pricing Table

| Cost Category |

Estimated Price Range |

Description |

| Initial Material Cost (per kg) |

~$3.50 - $5.00 | MC66 steel’s base cost is higher due to alloying elements like chromium and molybdenum. Price varies based on quantity and supplier. |

| Machining Cost (per part) |

~$10 - $30 | Machining costs depend on complexity, tooling requirements, and labor. MC66 steel’s hardness can lead to slightly higher machining costs. |

| Tool Wear (per part) |

~$1 - $3 | Due to MC66 steel’s hardness, CNC tools may wear faster, leading to increased tool replacement and maintenance costs. |

| Maintenance Cost (per year) |

~$50 - $100 | MC66 steel’s corrosion resistance and durability minimize the need for maintenance, reducing overall operational costs. |

| Replacement Cost (over 5 years) |

~$150 - $250 | Due to MC66’s excellent wear resistance and longevity, parts will likely require fewer replacements, saving money in the long term. |

MC66 steel is a high-performance material renowned for its excellent machinability and strength, making it a top choice in a wide range of demanding industries. Known for its ability to withstand high stress and harsh environments, MC66 steel is often used in CNC machining for precision components that require durability and resistance to wear. Its superior strength-to-weight ratio makes it especially useful in applications where performance is critical and where traditional materials may fail.

Here, we explore the various applications and industries that benefit from the unique properties of MC66 steel.

MC66 steel is commonly used in the automotive industry for manufacturing engine components, brackets, and suspension parts. Its high strength ensures these critical parts can withstand the intense pressures and stresses found in automotive systems. Additionally, its excellent machinability ensures that precision components can be easily fabricated.

Aerospace and Defense

MC66 steel’s ability to maintain high strength and performance under extreme temperatures makes it ideal for aerospace components such as turbine blades, landing gear components, and airframe structures. In the defense sector, MC66 is used to manufacture military-grade fasteners, structural components, and heavy-duty equipment parts that need to endure extreme conditions.

Industrial Machinery

In industrial machinery, MC66 steel is commonly used for parts that require high wear resistance, such as cutting tools, bearings, and industrial valves. Its toughness and resistance to corrosion ensure that parts maintain their function over time, even in demanding factory environments.

Heavy Machinery

Due to its high wear resistance and toughness, MC66 steel is often used in the manufacturing of parts for mining equipment, construction machinery, and industrial tools. Parts like gears, shafts, and bearings are commonly produced from MC66 to provide durability and long-lasting performance.

Oil & Gas Industry

MC66 steel is particularly suited for drilling equipment, pumps, and valve components used in the oil and gas industry, where extreme pressure, corrosion, and wear are common. The steel's resistance to fatigue and cracking makes it reliable for these high-stress applications.

Energy Sector

MC66 steel is used in the production of parts for energy generation systems, including turbine shafts, generator components, and pressure vessels. Its ability to endure high temperatures and corrosive environments makes it invaluable for nuclear, solar, and wind energy applications.

Tooling and Dies

The exceptional machinability of MC66 steel makes it a preferred material for tooling, molds, and dies. It is often used in the production of cutting tools, forming dies, and injection molds, where precision and durability are paramount.

Medical Equipment

MC66 steel’s strength and resistance to corrosion make it suitable for medical tools and surgical instruments, where high precision and cleanliness are essential. Parts such as scalpels, surgical scissors, and implants benefit from MC66’s durability and resistance to wear over time.

Military and Defense

MC66 steel is used in military and defense applications for its strength and corrosion resistance. Components such as firearm parts, military vehicles, and protective gear benefit from its durability and ability to perform in extreme conditions.

Consumer Goods

MC66 steel is also used in high-end consumer goods, such as knives, watches, and sporting equipment. Its strength and ability to maintain a sharp edge make it a preferred material for high-performance tools and accessories.

Tip: To maximize the benefits of MC66 steel, assess the specific needs of your application, such as resistance to heat, wear, or corrosion. Tailoring the material to your project will optimize performance and longevity.

Why MC66 Steel Is Ideal for These Applications

MC66 steel is a versatile and highly reliable material that meets the demanding needs of industries ranging from automotive and aerospace to heavy machinery and energy. With its combination of strength, durability, and machinability, MC66 continues to be an essential choice for manufacturers who need precision parts that perform reliably over time.

MC66 Steel: Applications and Uses Table

MC66 steel’s exceptional mechanical properties make it highly versatile across a wide range of industries. Below is a table outlining key applications and uses of MC66 steel.

| Industry |

Applications |

Benefits of MC66 Steel |

| Automotive |

Gears, shafts, engine parts | High wear resistance, ability to withstand high temperatures and mechanical stress. |

| Aerospace |

Aircraft components, landing gear, engine parts | High tensile strength, corrosion resistance, and performance at high altitudes. |

| Industrial Machinery |

Cutting tools, bearings, valves | Toughness, wear resistance, and corrosion protection for long-lasting performance. |

| Military & Defense |

Firearm parts, military vehicles, protective gear | Durability under extreme conditions, resistance to corrosion, and high strength. |

| Consumer Goods |

High-performance knives, watches, sporting equipment | Strength, sharpness retention, and aesthetic appeal for high-end products. |

Processing MC66 steel in CNC machining requires careful attention due to its hardness and toughness. While MC66 steel is machinable, its high hardness means that specialized techniques and tools are often needed to achieve high precision and quality results. In this section, we will cover essential tips for cutting and drilling MC66 steel, followed by heat treatment and surface coatings that can enhance its performance.

Cutting and Drilling Tips

Use Carbide Tools

Use Slow Cutting Speeds

Proper Cooling and Lubrication

Sharp Tools Are Essential

Avoid Deep Cuts

Check for Workpiece Stability

Tip: Consider working with an experienced CNC machinist when processing MC66 steel, as proper techniques and tools will reduce costs and ensure better results.

MC66 Steel: Heat Treatment

Heat treatment is crucial to enhance the mechanical properties of MC66 steel. Depending on the desired characteristics, the steel can undergo various heat treatments, such as annealing, quenching, and tempering. Proper heat treatment improves hardness, wear resistance, and toughness, which are essential for high-performance parts.

Tip: Always follow the recommended heat treatment guidelines for MC66 steel to ensure that its properties are optimized for your specific CNC machining project.

Surface Treatment and Coatings

To further enhance the performance of MC66 steel, various surface treatments and coatings can be applied, depending on the intended use. These treatments improve wear resistance, corrosion resistance, and surface hardness.

Tip: Surface treatments like nitriding or carburizing can significantly improve the durability and lifespan of MC66 steel components, especially in industries like automotive or aerospace.

When selecting the best material for CNC machining, it’s important to understand how different alloys compare to each other. MC66 steel is a versatile and durable choice, but there are several other materials, such as 304 stainless steel, SG2 steel, and D2 tool steel, which may also be suitable for specific applications. In this section, we’ll compare MC66 steel with these alloys based on key properties like strength, corrosion resistance, and machinability.

MC66 Steel vs. 304 Stainless Steel

| Property |

MC66 Steel |

304 Stainless Steel |

| Corrosion Resistance |

Excellent due to high chromium content | Excellent, but may corrode in highly acidic environments |

| Strength |

Higher tensile strength (up to 1200 MPa) | Moderate strength (around 520 MPa) |

| Machinability |

Good, though requires carbide tools | Excellent machinability with minimal tool wear |

| Applications |

Automotive, aerospace, industrial machinery | Food processing, kitchen equipment, general fabrication |

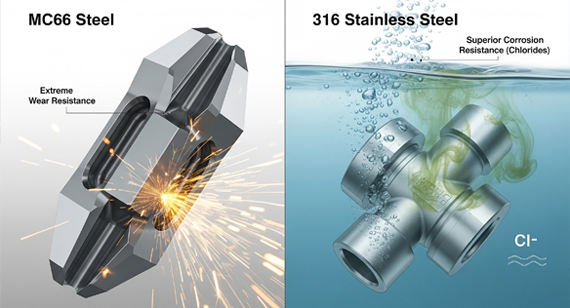

MC66 Steel vs. 316 Stainless Steel

| Property |

MC66 Steel |

316 Stainless Steel |

| Corrosion Resistance |

Excellent, especially in harsh conditions | Exceptional, particularly in marine environments |

| Strength |

Higher tensile strength (up to 1200 MPa) | Moderate strength (around 580 MPa) |

| Machinability |

Good, requires carbide tools | Good, but more challenging than 304 stainless |

| Applications |

Automotive, aerospace, high-wear parts | Marine, medical, chemical industries |

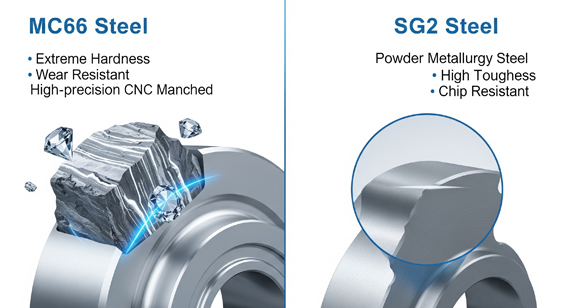

MC66 Steel vs. SG2 Steel

| Property |

MC66 Steel |

SG2 Steel |

| Corrosion Resistance |

Excellent | Excellent, particularly for knife blades |

| Strength |

Higher tensile strength (up to 1200 MPa) | Moderate to high tensile strength |

| Machinability |

Good, with carbide tools | Excellent for producing sharp edges (ideal for knives) |

| Applications |

Aerospace, industrial machinery, automotive | Kitchen knives, cutting tools |

MC66 Steel vs. D2 Tool Steel

| Property |

MC66 Steel |

D2 Tool Steel |

| Corrosion Resistance |

Excellent due to chromium content | Moderate, requires coatings for corrosion resistance |

| Strength |

Higher tensile strength (up to 1200 MPa) | Very high hardness (58-62 HRC), good for tooling |

| Machinability |

Good, requires carbide tools | Challenging to machine, requires special tools |

| Applications |

Aerospace, automotive, high-wear parts | Tooling, dies, knives |

MC66 Steel vs. Carbon Steel

| Property |

MC66 Steel |

Carbon Steel |

| Corrosion Resistance |

Excellent due to chromium content | Poor, susceptible to rust and corrosion |

| Strength |

High tensile strength (up to 1200 MPa) | Moderate to high, depending on grade |

| Machinability |

Good, requires carbide tools | Good, easy to machine but may require more frequent tool changes |

| Applications |

Aerospace, automotive, industrial machinery | Structural components, general-purpose tools |

MC66 Steel vs. Stainless Steel

| Property |

MC66 Steel |

Stainless Steel |

| Corrosion Resistance |

Excellent | Excellent, but may vary by grade |

| Strength |

Higher tensile strength (up to 1200 MPa) | Moderate strength (typically 520-600 MPa) |

| Machinability |

Good, requires carbide tools | Generally easier to machine than MC66 steel |

| Applications |

High-performance parts, automotive, aerospace | General fabrication, medical devices, food processing |

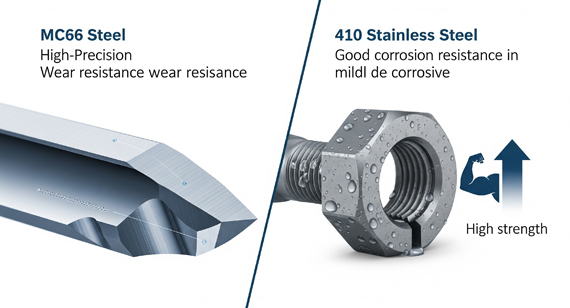

MC66 Steel vs. 410 Stainless Steel

| Property |

MC66 Steel |

410 Stainless Steel |

| Corrosion Resistance |

Excellent | Moderate, better than carbon steel but worse than higher grades of stainless |

| Strength |

High tensile strength (up to 1200 MPa) | High, but lower than MC66 steel |

| Machinability |

Good, requires carbide tools | Moderate, easier to machine than MC66 steel |

| Applications |

High-performance automotive, aerospace | Valves, pumps, medical tools |

Tip: When comparing MC66 steel with other alloys, consider factors like corrosion resistance, strength, and machinability based on your specific application needs. MC66 steel is ideal for high-

stress and wear-resistant parts, while alloys like stainless steel and carbon steel may be more suitable for general applications with less stringent performance requirements.

MC66 steel is a high-performance material with unique properties that make it ideal for demanding applications, but whether it’s the right choice for your project depends on several factors. Let’s break down the key considerations to help you decide if MC66 steel is the best material for your needs.

Strength and Durability Requirements

If your project involves parts that must withstand high stress, wear, or extreme environments, MC66 steel is an excellent choice. Its high tensile strength (up to 1200 MPa) and hardness (58-62 HRC) make it highly resistant to deformation and wear, ensuring long-lasting performance. This makes it perfect for industries like aerospace, automotive, and industrial machinery where high strength and durability are critical.

Corrosion Resistance

MC66 steel is highly resistant to corrosion, thanks to its chromium content. If your project involves parts that will be exposed to harsh environments, moisture, or chemicals, MC66 steel provides excellent protection against rust and degradation. Its corrosion resistance is ideal for applications in industries like automotive, aerospace, and marine environments.

Machinability

Although MC66 steel is harder than many other alloys, it is still machinable with the right tools. Carbide tools are recommended for machining MC66 steel, and it is essential to use slow cutting speeds and proper cooling methods to avoid excessive tool wear. If your project involves high-precision components or complex geometries, MC66 steel can be processed to meet those needs, though it may require more careful machining techniques compared to softer steels.

Cost Considerations

MC66 steel is more expensive than some other steel grades, particularly due to its high strength and corrosion-resistant properties. While its initial cost may be higher, the material’s durability and low maintenance requirements can offset these costs in the long run. If your project involves components that need to perform under harsh conditions or have a long service life, MC66 steel’s long-term cost-effectiveness may make it a smart investment.

Conclusion: Is MC66 Steel Right for You?

If your project demands high strength, wear resistance, and corrosion protection, MC66 steel is likely the right choice. It excels in high-performance applications, particularly in industries that require durability and precision. However, its higher initial cost and more demanding machinability may not make it the best option for every project.

Is MC66 Steel Right for Your Project? Table

| Consideration |

Why MC66 Steel is Suitable |

When to Consider Alternatives |

| Strength & Durability |

MC66 steel offers high tensile strength (up to 1200 MPa) and hardness (58-62 HRC), making it ideal for high-stress, wear-resistant components. | If your project does not require high strength or will be subjected to low mechanical stress, other materials may be more cost-effective. |

| Corrosion Resistance |

MC66 steel is highly resistant to corrosion, ideal for environments exposed to moisture or chemicals. | For applications with minimal exposure to corrosive environments, other steels like 304 or 410 stainless steel may suffice. |

| Machinability |

It is machinable with carbide tools, offering good precision for high-performance components. | If your project requires fast and easy machining with minimal tool wear, softer steels might be easier and cheaper to work with. |

| Cost |

While MC66 steel has a higher initial cost, its durability leads to long-term cost savings by reducing maintenance and replacements. | If your project has a tight budget and does not require the specific advantages of MC66 steel, a less expensive steel may be a better option. |

| Applications | Best for high-performance applications in automotive, aerospace, industrial machinery, and medical devices. | For less demanding applications that don’t require the performance characteristics of MC66 steel, consider using standard carbon steel or stainless steel. |

Real-world applications of MC66 steel highlight its strengths and performance across various industries. Below are a few customer success stories that showcase how MC66 steel’s durability, machinability, and cost-effectiveness have contributed to successful projects.

Aerospace Component Manufacturer: High-Performance Gears

A leading aerospace company needed high-performance gears for an aircraft engine. The components were required to withstand extreme temperatures, mechanical stress, and wear over long operational periods. After testing several materials, the company chose MC66 steel due to its high tensile strength (up to 1200 MPa) and excellent corrosion resistance.

The results were impressive. The gears performed reliably under high-stress conditions and showed no signs of wear after extensive testing. The company reported a significant reduction in maintenance costs, as the parts did not need to be replaced frequently, unlike previous steel options.

Customer Feedback:

"MC66 steel has proven to be the ideal material for our aerospace components. The parts lasted longer than expected and withstood the high temperatures of engine operation without any issues. We saw a noticeable reduction in maintenance costs."

Automotive Manufacturer: Durable Engine Parts

An automotive manufacturer needed durable, high-strength parts for engines that would perform in high-stress environments, such as racing engines. MC66 steel was selected for critical engine components like shafts and pistons, which required high wear resistance and the ability to handle constant mechanical stress.

MC66 steel's excellent hardness and wear resistance allowed the automotive manufacturer to produce parts that not only performed well under the harsh conditions of racing but also showed minimal signs of wear after prolonged use. The decision to use MC66 steel led to improved engine performance and fewer component failures.

Customer Feedback:

"MC66 steel has been a game changer for our high-performance engine components. The strength and wear resistance have helped us deliver better results, while reducing downtime during races."

Medical Device Manufacturer: Precision Surgical Instruments

A medical device manufacturer was looking for a material to produce precision surgical instruments. The company needed a steel that was both biocompatible and resistant to corrosion, as the instruments would be used in sterile environments. After testing various materials, the manufacturer selected MC66 steel for its corrosion resistance, machinability, and strength.

The results were outstanding. The surgical instruments made from MC66 steel maintained their sharpness and durability even after numerous sterilization cycles. The material’s non-reactive properties also ensured that it met the strict biocompatibility standards required in the medical industry.

Customer Feedback:

"Using MC66 steel for our surgical instruments has allowed us to achieve superior performance and durability. It’s been a great choice for both precision and corrosion resistance in medical environments."

Heavy Machinery Manufacturer: Industrial Valves

A heavy machinery manufacturer was producing industrial valves that needed to withstand high-pressure environments. The company required a material that could handle both the high mechanical stress and exposure to corrosive fluids. After evaluating several options, MC66 steel was chosen for its excellent strength and corrosion resistance.

The valves manufactured from MC66 steel demonstrated exceptional longevity, even in environments where other materials would degrade quickly. The manufacturer saw a significant decrease in downtime and maintenance costs due to the valves' superior performance.

Customer Feedback:

"MC66 steel has been a reliable material for our industrial valves. The combination of strength and corrosion resistance has reduced maintenance costs and extended the service life of our products."

MC66 steel, known for its strength and durability, has several qualities that might make it appealing for knife manufacturing. However, whether it is the best choice depends on the specific requirements of the knife, such as sharpness, edge retention, and corrosion resistance. Let's dive into the factors that determine if MC66 steel is suitable for knives.

Strength and Hardness

MC66 steel offers impressive strength and hardness, with a tensile strength of up to 1200 MPa and hardness levels between 58-62 HRC. These qualities ensure that the steel can handle the mechanical stresses involved in cutting tasks. This makes MC66 steel ideal for heavy-duty knives that require both strength and the ability to hold an edge over time.

Edge Retention

One of the critical aspects of knife performance is edge retention, and MC66 steel excels in this area. The hardness of the material helps it maintain a sharp edge for longer periods, even when used for tough tasks. The material's ability to resist wear and tear means fewer sharpenings are needed, which adds to the knife's long-term value.

Corrosion Resistance

While MC66 steel does offer good corrosion resistance thanks to its chromium content, it may not be as resistant to corrosion as higher-end stainless steels like 316 stainless steel or specialized knife steels like M390. For knives that are regularly exposed to moisture, such as in marine environments or wet conditions, corrosion resistance is a significant consideration.

Machinability and Sharpening

MC66 steel, while machinable, can be challenging to sharpen due to its high hardness. The steel's toughness means that specialized tools and techniques are required for precise sharpening. This may not be an issue for professional knife makers, but for general consumers, it could make maintenance more difficult.

Conclusion: Is MC66 Steel Suitable for Knives?

MC66 steel can be a good choice for heavy-duty knives that require strength, edge retention, and resistance to wear. It’s particularly suitable for knives used in demanding environments, such as utility knives, hunting knives, or industrial cutting tools. However, if you're looking for a knife that requires regular sharpening or will be used in highly corrosive conditions, you may want to explore other steel options like VG10, 440C, or M390.

At VMT, we specialize in providing high-quality CNC machining services for MC66 steel, offering precision and reliability for industries that require the utmost performance from their components. Whether you need parts for aerospace, automotive, industrial machinery, or any other high-demand application, we have the expertise and technology to deliver superior MC66 steel CNC machined parts.

Our Expertise in MC66 Steel CNC Machining

MC66 steel is known for its toughness and high-performance properties, making it ideal for critical components in a wide range of applications. At VMT, our CNC machining factory is equipped with state-of-the-art machinery and staffed by skilled professionals who understand the complexities of working with high-performance materials like MC66 steel.

We offer a range of services tailored to meet the specific needs of your project, including:

Tip: When working with MC66 steel, it’s essential to partner with a machining provider who understands the material’s characteristics and can ensure high-quality results. VMT’s expertise in handling MC66 steel guarantees precise, durable components for your project.

Why Choose VMT for Your MC66 Steel CNC Machining Needs?

Tip: For projects requiring custom MC66 steel parts, choosing a reliable CNC machining service like VMT ensures that your components will meet your design and performance expectations on time.

Industries Served

VMT provides MC66 steel CNC machining services for a wide range of industries, including:

Tip: If you are in need of MC66 steel parts for any industry, contact VMT to discuss how we can assist you with tailored CNC machining solutions that fit your exact requirements.

Get in Touch with VMT Today

Ready to get started with your MC66 steel CNC machining project? Contact VMT today to learn more about how our services can help you achieve the precision and quality your project demands. Whether you need a small batch or large-scale production, our team is here to support you every step of the way.

In conclusion, MC66 steel stands out as a high-performance material with exceptional strength, durability, and corrosion resistance, making it an ideal choice for a wide range of applications. From aerospace and automotive components to medical devices and industrial machinery, MC66 steel provides the reliability and toughness needed for critical parts that must endure harsh conditions.

While its machinability requires careful attention, particularly with carbide tools, the benefits of using MC66 steel in CNC machining far outweigh the challenges. Its ability to maintain edge retention, withstand high stress, and resist wear makes it suitable for demanding industries that require top-tier performance.

For projects where strength, longevity, and resistance to corrosion are paramount, MC66 steel is an excellent option. Whether you are designing complex aerospace parts, industrial tools, or even high-performance knives, MC66 steel offers unmatched value, ensuring long-lasting and cost-effective results.

At VMT, we specialize in providing high-quality MC66 steel CNC machined parts, delivering precision, customization, and timely solutions for a variety of industries. By choosing VMT, you ensure that your MC66 steel components are produced with the highest standards of quality and reliability.

Is MC66 Steel Stronger Than 304 Stainless Steel?

Yes, MC66 steel is stronger than 304 stainless steel. MC66 has a higher tensile strength (up to 1200 MPa) compared to 304 stainless steel, which typically has a tensile strength around 520 MPa. MC66 steel's superior strength makes it more suitable for high-stress applications like aerospace, automotive, and industrial machinery.

Can MC66 Steel Be Used in High-Temperature Applications?

Yes, MC66 steel is well-suited for high-temperature applications. Its strength and hardness are maintained even under elevated temperatures, making it ideal for components exposed to extreme heat. However, if the temperature exceeds certain limits, additional heat treatment or coatings may be necessary for optimal performance.

What Makes MC66 Steel Ideal for CNC Machining?

MC66 steel’s ideal CNC machinability comes from its hardness and strength, which can be effectively managed with carbide tools. While it requires careful machining with slower speeds and proper cooling, its durability and wear resistance make it an excellent choice for producing high-performance parts with precision.

What is the Best Heat Treatment for MC66 Steel?

The best heat treatment for MC66 steel involves a combination of quenching and tempering. Quenching enhances hardness, while tempering adjusts the material's toughness and reduces brittleness. Depending on the specific application, nitriding or carburizing treatments may also be applied to improve wear resistance.

What is the Highest-Quality Steel for Knives?

The highest-quality steel for knives depends on the desired properties such as sharpness, corrosion resistance, and durability. High-carbon stainless steels like M390, VG10, and CPM S90V are often regarded as some of the best for knives due to their excellent edge retention, strength, and corrosion resistance.

Is M390 a Super Steel?

Yes, M390 is often considered a "super steel" because of its excellent edge retention, high corrosion resistance, and overall toughness. It's a popular choice for high-end knives, especially those used in demanding tasks or in harsh environments.

What Steel is Best for Chef's Knives?

For chef's knives, high-carbon stainless steels like VG10, 440C, and AUS10 are some of the best options. These steels offer a good balance of sharpness, edge retention, and corrosion resistance, which are crucial for kitchen knives that are exposed to moisture and require frequent use.

What's the Difference Between AUS10 and VG10 Steel Knives?

Both AUS10 and VG10 are excellent knife steels, but VG10 is typically considered superior in terms of edge retention and corrosion resistance. VG10 is a high-carbon stainless steel, while AUS10, which is similar to Japanese 440C, is a bit easier to sharpen and less prone to chipping.

Is VG10 Better Than 440C?

Yes, VG10 is generally better than 440C when it comes to edge retention and corrosion resistance. VG10 has higher carbon content and is known for its excellent sharpness, which makes it a top choice for premium knives. 440C, on the other hand, is more affordable but has slightly lower performance in terms of wear resistance.

Is D2 Steel Better Than VG10?

D2 steel offers exceptional wear resistance and toughness, but VG10 excels in sharpness and corrosion resistance. For a high-performance knife that needs a tough, durable edge, D2 is a great option. However, for a knife that requires superior edge retention and rust resistance, VG10 would be a better choice.

What is the Highest Quality Steel?

The highest quality steel depends on the application. M390 and CPM S90V are considered among the highest-quality steels for knives due to their outstanding edge retention, corrosion resistance, and overall durability. For industrial and engineering purposes, MC66 steel is regarded as one of the highest-quality steels for high-stress applications.

What is 1066 Steel?

1066 steel is a medium-carbon steel commonly used for forging blades and tools. It offers good toughness and can hold a sharp edge, but it is not as high-performance as more advanced steels like 440C or D2.

What is the Difference Between 14C28N and X30Cr13?

14C28N is a Swedish stainless steel that offers excellent edge retention and corrosion resistance, making it suitable for knives. X30Cr13 is a more basic stainless steel used in entry-level knives. 14C28N has superior performance, particularly in sharpness and durability, compared to X30Cr13.

What is the Difference Between 4Cr13 and 8Cr13MoV?

4Cr13 is a budget-friendly stainless steel commonly used in entry-level knives. 8Cr13MoV is a slightly upgraded version, with better edge retention and corrosion resistance due to the addition of molybdenum. 8Cr13MoV is more commonly used in mid-range knives, offering a better balance of performance and price.

What is the Difference Between 420J2 and 420HC?

420J2 is a low-carbon stainless steel known for its ease of sharpening, but it has lower corrosion resistance and edge retention than 420HC. 420HC has a higher carbon content, making it stronger, more durable, and better for edge retention.

Is 14C28N a Super Steel?

While 14C28N is an excellent steel for knives, it is not typically categorized as a "super steel" like M390 or CPM S110V. However, it offers an excellent combination of edge retention, corrosion resistance, and ease of sharpening, making it a premium choice for many mid-range and high-end knives.

Is D2 Steel Better Than 8Cr13MoV?

Yes, D2 steel is significantly better than 8Cr13MoV in terms of wear resistance, toughness, and edge retention. D2 is a high-carbon steel, which allows it to maintain a sharp edge longer and perform better in heavy-duty applications.

What is the Toughest Knife Steel?

The toughest knife steel depends on the required application. D2 steel, CPM S30V, and M390 are known for their toughness, but CPM S110V and S90V are considered some of the toughest steels, especially for knives exposed to extreme wear.