15 years one-stop China custom CNC machining parts factory

118 |

Published by VMT at Aug 22 2025 | Reading Time:About 5 minutes

118 |

Published by VMT at Aug 22 2025 | Reading Time:About 5 minutes

Steel is one of the most widely used metals in modern industry, from automotive manufacturing to CNC machining parts. Yet, a common question often arises: Is steel magnetic? Many engineers, product designers, and manufacturers face confusion when selecting steel grades for specific applications. Choosing the wrong type of steel without understanding its magnetism can lead to design failures, unexpected costs, or compatibility issues in sensitive environments such as electronics and medical devices. This guide explores the science behind steel magnetism, its influencing factors, and how it impacts CNC machining services. By the end, you will clearly know which steels are magnetic, which are not, and how to make the right choice for your project.

Steel can be magnetic depending on its composition and structure. Carbon steel and ferritic or martensitic stainless steels are magnetic, while austenitic stainless steels are generally non-magnetic. Heat treatment, alloying, and crystal structure affect steel magnetism. Understanding these properties ensures proper selection for CNC machining parts and industrial applications.

Now that we’ve answered the core question briefly, let’s dive deeper. To fully understand steel magnetism, we need to examine what steel is, what makes metals magnetic, and how composition, structure, and processing determine whether steel behaves as a magnetic or non-magnetic material. This knowledge is essential for engineers, manufacturers, and anyone sourcing CNC machining services.

Steel is an alloy primarily composed of iron and carbon, often combined with other elements such as chromium, nickel, and manganese to improve strength, durability, or corrosion resistance. Its versatility makes it a preferred material for industries ranging from automotive and aerospace to construction and CNC machining factories. However, its magnetism depends largely on the specific type of steel and how it is processed.

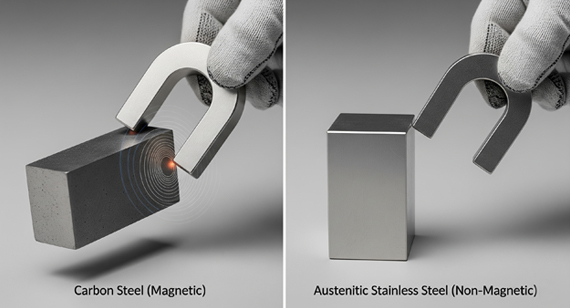

For example, carbon steel typically shows strong magnetic properties because it contains mostly iron with minimal alloying elements. In contrast, certain stainless steels, such as austenitic grades (304 or 316), are generally non-magnetic due to their crystal structure. This means that although “steel” is often thought of as magnetic, the reality is more nuanced.

The short answer is: sometimes. Steel can be magnetic or non-magnetic depending on its composition and internal structure. Magnetism in steel primarily comes from iron, which is a ferromagnetic metal. If the steel maintains a crystal structure that allows magnetic alignment, it will attract magnets.

Carbon steels, ferritic stainless steels, and martensitic stainless steels are typically magnetic. On the other hand, austenitic stainless steels are not, unless they undergo certain manufacturing processes like cold working, which can induce partial magnetism. This distinction is crucial in industries like CNC machining services, where material properties directly impact performance.

Magnetism in metals arises from the arrangement of electrons around atoms. Metals that allow unpaired electrons to align in the same direction create magnetic fields, making the material magnetic. Iron, cobalt, and nickel are the primary ferromagnetic metals. Since steel is mostly iron, it often inherits magnetic properties—unless alloying or structural changes disrupt electron alignment.

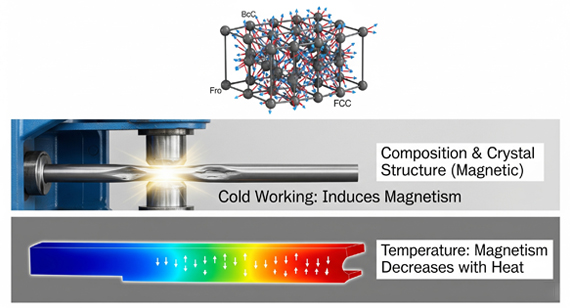

In steel, magnetism depends not just on the presence of iron but also on the crystal structure. The body-centered cubic (BCC) arrangement of atoms in ferritic and martensitic steels supports magnetism. Meanwhile, the face-centered cubic (FCC) arrangement in austenitic steels prevents magnetic alignment, making them mostly non-magnetic.

Steel magnetism is not a fixed property—it changes based on multiple internal and external factors. While iron in steel provides the foundation for magnetism, the alloy’s exact chemical composition, crystal structure, heat treatment, and microstructural characteristics ultimately determine whether the steel will be magnetic or non-magnetic. For engineers, manufacturers, and CNC machining factories, understanding these factors is vital to avoid material mismatches in sensitive projects. For example, steel used in motors and transformers requires strong magnetic properties, while surgical instruments often need non-magnetic steel to prevent interference with electronic devices. Recognizing what controls steel magnetism allows manufacturers to select the right steel grade for CNC machining parts and ensures high performance across industries.

Chemical Composition

The chemical composition of steel is the first and most influential factor affecting its magnetism. Steel is primarily made of iron, which is strongly magnetic, but the addition of other elements can either strengthen or reduce its magnetic response. For example, carbon steel, with minimal alloying elements, retains iron’s natural ferromagnetism. However, stainless steels with high levels of chromium and nickel can disrupt magnetic alignment.

Nickel, in particular, plays a significant role—adding 8–10% nickel (as in austenitic stainless steel 304) stabilizes the non-magnetic face-centered cubic (FCC) structure, making the steel mostly non-magnetic. In contrast, ferritic stainless steel (containing chromium but little to no nickel) remains magnetic. This means that simply calling a material “stainless steel” does not guarantee whether it will respond to a magnet.

Crystal Structure

The crystal structure of steel has a direct impact on its magnetic properties. Steel can exist in different lattice arrangements depending on its composition and processing. The two most important are:

Interestingly, external influences like cold working can partially transform FCC structures, introducing magnetic behavior in otherwise non-magnetic steels. This explains why some grades of stainless steel that are supposed to be non-magnetic can still attract weak magnets after machining or forming.

Effects of Heat Treatment

Heat treatment is another crucial factor influencing steel magnetism. Processes such as annealing, quenching, and tempering can alter steel’s crystal structure, which in turn affects its magnetic properties. For instance, heating steel above its critical temperature can transform its structure to austenite (FCC), temporarily eliminating magnetism. Upon cooling, the steel may revert to a ferritic or martensitic structure (BCC), restoring magnetism.

In hardened steels, the transformation to martensite often increases magnetism due to its BCC-like structure. Conversely, annealing can reduce magnetism by relieving internal stresses and stabilizing phases that resist magnetic alignment. This is why steel used in magnetic applications such as transformers undergoes precise thermal treatments to optimize magnetic performance.

Microstructural Characteristics

Finally, the microstructure of steel, which refers to the arrangement of grains, dislocations, and inclusions, plays a subtle but important role in magnetism. Even if two steels share the same composition and crystal structure, differences in grain size and orientation can lead to variations in magnetic behavior. Smaller, well-aligned grains typically enhance magnetism by allowing domains to align more easily.

Additionally, impurities or inclusions such as sulfur, phosphorus, or non-metallic particles can interrupt domain alignment, reducing magnetic strength. Cold working, welding, or machining can also introduce residual stresses into the steel, modifying its microstructure and altering magnetic performance. This means that magnetism in steel is not only a matter of chemistry but also how the material is shaped and processed.

Table: Factors Affecting Steel’s Magnetism

|

Factor |

Explanation |

Effect on Magnetism |

Practical Tip |

| Chemical Composition |

Steel’s mix of iron, carbon, chromium, nickel, and other alloys. | Carbon steels are magnetic; high nickel (e.g., austenitic stainless steel) reduces or eliminates magnetism. | Always specify steel grade (e.g., 304 vs. 430 stainless) before CNC machining. |

| Crystal Structure |

The atomic lattice arrangement (BCC or FCC). | BCC (ferritic, martensitic steels) supports magnetism; FCC (austenitic steels) is usually non-magnetic. | Verify final structure after forming—cold working can introduce magnetism in FCC steels. |

| Heat Treatment |

Processes like annealing, quenching, and tempering that change steel phases. | Heating above critical temp can remove magnetism (austenite phase), while cooling can restore it. | Coordinate with CNC machining factories to ensure correct thermal treatment. |

| Microstructural Characteristics |

Grain size, orientation, inclusions, and residual stresses. | Fine, aligned grains improve magnetism; impurities and stresses reduce it. | Use high-quality steel sources to avoid inconsistencies in CNC machining parts. |

To understand steel magnetism, it’s helpful to first review the different categories of magnetic materials. Not all metals behave the same way when exposed to a magnetic field—some are strongly attracted, some are weakly influenced, and others resist magnetism entirely. Scientists classify these behaviors into five main types: diamagnetism, paramagnetism, ferromagnetism, ferrimagnetism, and antiferromagnetism. Knowing these distinctions is essential for selecting materials in engineering, electronics, and CNC machining parts production. For instance, ferromagnetic steels are ideal in motors and transformers, while non-magnetic stainless steels are crucial in surgical or electronic applications.

Diamagnetism

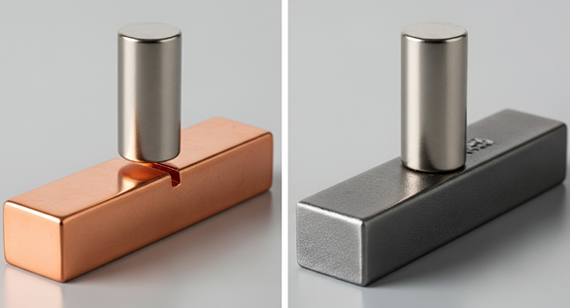

Diamagnetic materials are those that create a weak repulsive force when exposed to a magnetic field. Instead of being attracted, they slightly push away from the magnet. This occurs because the electrons in these materials arrange themselves in a way that cancels out external magnetic influences. Examples of diamagnetic materials include copper, bismuth, gold, and even water.

In industrial settings, diamagnetic behavior is usually negligible, since the effect is very weak. However, it becomes important in high-precision environments like superconductors or advanced magnetic levitation experiments. Since diamagnetic materials do not interfere with magnets, they can also be used as non-magnetic components in sensitive CNC machining parts, especially in electronics and medical devices.

Paramagnetism

Paramagnetic materials are weakly attracted to magnetic fields, but the effect disappears once the external field is removed. This happens because paramagnetic materials have unpaired electrons that align temporarily with the magnetic field, but they do not retain magnetism afterward. Common paramagnetic materials include aluminum, magnesium, and tungsten.

In manufacturing, paramagnetism is often considered “non-magnetic” for practical purposes, since the attraction is so weak. However, understanding it is critical for industries where even minor magnetic influences could disrupt sensitive equipment. For CNC machining factories producing aerospace or medical components, selecting paramagnetic materials ensures reduced risk of unintended magnetic interaction.

Ferromagnetism

Ferromagnetic materials are strongly attracted to magnets and can retain magnetism even after the external field is removed. This is due to their ability to form stable magnetic domains where electron spins align in the same direction. Iron, cobalt, nickel, and most carbon steels fall under this category.

This property makes ferromagnetic steels extremely valuable in electrical and mechanical applications such as transformers, motors, and magnetic storage. For CNC machining services, using ferromagnetic steel ensures parts are suitable for electromagnetic devices or lifting applications. However, the same property can cause issues in environments where magnetic interference must be minimized, such as medical imaging or precision instruments.

Ferrimagnetism

Ferrimagnetic materials are similar to ferromagnetic ones, but their atomic magnetic moments align in opposite directions with unequal strength, resulting in net magnetism. This unique behavior makes ferrimagnetic materials useful in specialized applications such as magnetic recording devices, ferrite cores, and communication equipment.

While ferrimagnetism is less commonly discussed in CNC machining, it’s highly relevant in electrical engineering where components must combine magnetism with electrical insulation. Ferrite materials, often made from iron oxides with other metals, are lightweight and inexpensive, making them ideal for transformers and inductors.

Antiferromagnetism

Antiferromagnetic materials have adjacent atoms with magnetic moments aligned in opposite directions, canceling each other out. This means that, on a macroscopic level, the material exhibits almost no magnetism. Examples include manganese oxide (MnO), chromium, and some rare alloys.

Antiferromagnetic materials are not commonly used in everyday CNC machining parts, but they are important in advanced technologies such as spintronics and magnetic sensors. Their ability to resist external magnetic influences makes them valuable in specialized research and high-performance electronics.

Table: Types of Magnetic Materials

| Type of Magnetism |

Description |

Examples |

Magnetic Behavior |

Practical Tip for CNC Machining |

| Diamagnetism |

Weak repulsion from magnetic fields due to electron orbit realignment. | Copper, Gold, Bismuth, Water | Not attracted to magnets, instead slightly repelled. | Ideal for non-magnetic components in sensitive devices. |

| Paramagnetism |

Weak temporary attraction caused by unpaired electrons. | Aluminum, Magnesium, Tungsten | Attracted only in presence of a strong magnetic field; loses magnetism when removed. | Suitable for “practically non-magnetic” CNC machining parts. |

| Ferromagnetism |

Strong attraction due to aligned magnetic domains; retains magnetism. | Iron, Nickel, Cobalt, Carbon Steel | Strongly magnetic; can become permanent magnets. | Best choice when strong steel magnetism is required (motors, transformers). |

| Ferrimagnetism |

Opposite atomic alignment with unequal strength, resulting in net magnetism. | Ferrites (iron oxides with other metals) | Moderate magnetism; often combined with insulating properties. | Useful for lightweight magnetic parts in electrical/electronic industries. |

| Antiferromagnetism |

Opposite atomic alignment with equal strength, canceling each other out. | Manganese Oxide, Chromium, Special Alloys | Essentially non-magnetic at room temperature. | Relevant for advanced alloys in electronics and magnetic sensors. |

Steel comes in many varieties, each with unique magnetic properties determined by its composition, crystal structure, and processing. While some steels are strongly magnetic, others are only weakly attracted or nearly non-magnetic. This variation can cause confusion, especially in industries that rely on precision materials, such as automotive, aerospace, medical, and CNC machining factories. For example, using non-magnetic austenitic stainless steel in surgical instruments prevents magnetic interference during procedures, while magnetic carbon steel is ideal for motors and transformers. Understanding the magnetic behavior of each steel type ensures proper material selection, optimized performance, and reduced project costs.

Carbon Steel

Carbon steel is one of the most magnetic types of steel because it contains mostly iron and a small percentage of carbon. Its structure is typically body-centered cubic (BCC), which supports strong magnetic domain alignment. This makes carbon steel highly ferromagnetic, able to both attract magnets and retain magnetism.

Carbon steel is widely used in tools, construction materials, and industrial equipment. In CNC machining services, carbon steel parts are often chosen for applications requiring strength and magnetic response, such as gears, shafts, and fasteners. However, the downside is that carbon steel is more prone to corrosion compared to stainless steel.

Ferritic Stainless Steel

Ferritic stainless steels (e.g., grade 430) are magnetic because they contain high chromium but little or no nickel. Their BCC crystal structure allows magnetic domain alignment, similar to carbon steels. Unlike austenitic stainless steels, ferritic stainless steels are always magnetic, even after machining or heat treatment.

They are commonly used in automotive trim, appliances, and industrial equipment where moderate corrosion resistance and magnetism are required. For CNC machining factories, ferritic stainless steel provides a balance between corrosion protection and magnetic properties at a lower cost than nickel-containing alloys.

Martensitic Stainless Steel

Martensitic stainless steels (e.g., grades 410, 420, 440C) are also magnetic due to their BCC or BCT (body-centered tetragonal) crystal structures. These steels contain higher carbon content, making them hardenable by heat treatment while retaining magnetism.

Martensitic steels are widely used in cutlery, turbine blades, and wear-resistant parts. For CNC machining services, martensitic stainless steel is a top choice for applications where hardness, wear resistance, and magnetism are all required. However, their corrosion resistance is lower compared to ferritic and austenitic grades.

Austenitic Stainless Steel

Austenitic stainless steels (e.g., grades 304, 316) are generally non-magnetic due to their face-centered cubic (FCC) crystal structure, which disrupts magnetic domain alignment. They contain high amounts of nickel, which stabilizes the FCC phase and suppresses magnetism.

However, under cold working (bending, forming, machining), austenitic stainless steels can develop partial magnetism because deformation may introduce martensitic structures. This is why sometimes 304 stainless steel appears “slightly magnetic” after processing.

In CNC machining parts, austenitic stainless steels are preferred for corrosion resistance, especially in food processing, marine, and medical industries. The lack of strong magnetism prevents interference with sensitive electronic or medical equipment.

Duplex Stainless Steel

Duplex stainless steels combine both ferritic (magnetic) and austenitic (non-magnetic) phases. As a result, they are partially magnetic, showing weaker magnetism than ferritic steels but stronger than austenitic grades.

Duplex steels are prized for their excellent corrosion resistance and high strength, making them suitable for chemical processing, oil and gas, and marine applications. In CNC machining factories, duplex stainless steel is often chosen for parts that require durability and partial magnetism without full magnetic attraction.

Galvanized Steel

Galvanized steel is carbon steel coated with a thin layer of zinc for corrosion resistance. Since the base material is carbon steel, galvanized steel is strongly magnetic. The zinc coating does not eliminate magnetism but can slightly reduce its surface response depending on thickness.

In applications such as construction, HVAC systems, and automotive parts, galvanized steel offers both durability and magnetism. For CNC machining services, galvanized steel parts may require special cutting tools due to the zinc coating.

Surgical Steel

Surgical steel usually refers to austenitic stainless steels such as 316L, known for their high corrosion resistance and biocompatibility. These steels are generally non-magnetic, which is critical in medical environments where magnetic interference must be avoided.

In CNC machining, surgical steel is widely used for implants, surgical instruments, and medical devices. Its low carbon content and molybdenum addition improve corrosion resistance in bodily fluids. Although non-magnetic, some machining processes may induce weak magnetism, but this is generally insignificant in medical use.

Hot-Rolled Steel

Hot-rolled steel is carbon steel rolled at high temperatures. Its magnetic behavior depends on its composition, but since it is usually plain carbon steel, it is strongly magnetic. However, hot rolling results in a rough surface and residual stresses that may slightly alter magnetic uniformity.

Hot-rolled steel is widely used in construction, structural components, and industrial equipment. In CNC machining services, hot-rolled steel is less common due to its lower dimensional accuracy compared to cold-rolled steel.

Cold-Rolled Steel

Cold-rolled steel is carbon steel that has been processed at room temperature for improved surface finish and dimensional accuracy. Like hot-rolled steel, it is strongly magnetic due to its high iron content. Cold rolling can also enhance magnetic alignment by refining the grain structure.

Cold-rolled steel is used in applications where precision and surface quality are essential, such as automotive panels, appliances, and CNC machining components. Its magnetism makes it useful for parts requiring both mechanical strength and magnetic performance.

Cast Iron

Cast iron is an iron-carbon alloy with a high carbon content (2–4%). It is ferromagnetic due to its iron content, but the presence of graphite flakes or nodules can reduce its magnetic response compared to pure carbon steel.

Cast iron is widely used in machine bases, pipes, and cookware. In CNC machining factories, cast iron parts are common in heavy-duty applications where vibration damping and machinability are more important than strong magnetism.

Wrought Iron

Wrought iron is an iron alloy with very low carbon content and fibrous slag inclusions. It is highly magnetic due to its nearly pure iron composition. Historically used in gates, railings, and tools, wrought iron is less common today, having been replaced by modern steels.

For CNC machining services, wrought iron is rarely used because it is expensive and less consistent than steel. However, its strong magnetism and corrosion resistance (due to slag fibers) make it a unique historical material.

Table: Magnetic Properties of Different Types of Steel

| Steel Type |

Magnetic Behavior |

Reason |

Applications / CNC Machining Use |

| Carbon Steel |

Strongly magnetic | High iron content, BCC structure | Gears, shafts, fasteners, CNC machining parts requiring magnetism |

| Ferritic Stainless Steel |

Strongly magnetic | Chromium alloy, BCC structure | Automotive trim, appliances, CNC machining services with corrosion resistance |

| Martensitic Stainless Steel |

Strongly magnetic | BCC/BCT structure, high carbon, hardenable | Cutlery, turbine blades, wear-resistant CNC parts |

| Austenitic Stainless Steel |

Generally non-magnetic (may become weakly magnetic after cold working) | High nickel content, FCC structure | Food processing, marine, surgical CNC machining parts |

| Duplex Stainless Steel |

Moderately magnetic (partial) | Mixed ferritic (magnetic) + austenitic (non-magnetic) phases | Oil & gas, chemical processing, CNC parts requiring strength + partial magnetism |

| Galvanized Steel |

Strongly magnetic | Carbon steel core remains magnetic under zinc coating | Construction, HVAC, CNC parts with corrosion resistance |

| Surgical Steel (316L) |

Non-magnetic (very weak if cold-worked) | Austenitic stainless stabilized with nickel + molybdenum | Medical implants, surgical CNC machining parts |

| Hot-Rolled Steel |

Strongly magnetic (less uniform) | Mostly carbon steel with residual stresses | Structural parts, construction, CNC machining when precision not critical |

| Cold-Rolled Steel |

Strongly magnetic (more uniform than hot-rolled) | Refined grain structure from cold processing | Automotive panels, precision CNC machining components |

| Cast Iron |

Magnetic, but weaker than steel | High carbon with graphite reduces magnetic continuity | Machine bases, pipes, CNC parts needing vibration damping |

| Wrought Iron | Strongly magnetic | Nearly pure iron with slag inclusions | Decorative work, historical use; less common in modern CNC machining |

Not all metals are magnetic. While iron, nickel, and cobalt are strongly attracted to magnets, many other metals remain non-magnetic due to their atomic structure and electron configuration. Non-magnetic metals are important in industries where corrosion resistance, electrical conductivity, or non-magnetic properties are critical—such as electronics, aerospace, medical devices, and CNC machining parts.

Below, we explore some of the most common non-magnetic metals and their characteristics.

Aluminum

Copper

Brass (Copper + Zinc Alloy)

Bronze (Copper + Tin Alloy)

Gold

Silver

Zinc

These metals are non-magnetic and are widely used in industries where magnetism must be avoided—such as electronics, MRI machines, aerospace, and precision CNC machining.

Table: Non-Magnetic Metals and Their Properties

| Metal |

Magnetism |

Key Properties |

Common Applications |

CNC Machining Relevance |

| Aluminum |

Non-magnetic | Lightweight, corrosion-resistant, good conductor of electricity & heat | Aerospace, automotive, packaging | Aluminum CNC machining parts |

| Copper |

Non-magnetic | Excellent electrical & thermal conductivity, ductile, corrosion-resistant | Wiring, plumbing, heat exchangers | Copper CNC machining parts |

| Brass (Copper + Zinc) |

Non-magnetic | Strong, corrosion-resistant, golden color | Musical instruments, fittings, bearings | Brass CNC machining parts |

| Bronze (Copper + Tin) |

Non-magnetic | Hard, wear-resistant, excellent corrosion resistance | Bearings, marine hardware, sculptures | Bronze CNC machining parts |

| Gold |

Non-magnetic | Highly corrosion-resistant, ductile, conductive | Jewelry, electronics, aerospace | Precision CNC machining parts |

| Silver |

Non-magnetic | Best electrical conductor, reflective, malleable | Electrical contacts, jewelry, medical devices | Silver CNC machining parts |

| Zinc |

Non-magnetic | Corrosion-resistant, protective coating for steel | Batteries, galvanization, die-casting | Zinc die-cast CNC machining parts |

Steel is one of the most versatile and widely used engineering materials in the world. Its unique combination of strength, durability, machinability, and recyclability makes it indispensable across industries. From automobiles and buildings to medical equipment and renewable energy systems, steel plays a central role in modern technology and infrastructure.

Automotive and Transportation

Construction and Infrastructure

Manufacturing and Tools

Recycling and Waste Management

Renewable Energy

Electromagnets and Transformers

Applications and Uses of Steel – Table

| Industry |

Applications |

Reasons for Use |

| Automotive & Transportation |

Car bodies, chassis, engines, suspension systems, shipbuilding, railway tracks, aerospace parts | High strength-to-weight ratio, crash resistance, formability |

| Electrical & Electronics |

Electrical enclosures, connectors, transformers, motors, magnetic cores | Magnetic properties (silicon steel), conductivity, durability |

| Construction & Infrastructure |

Beams, columns, bridges, pipelines, reinforcement bars | High tensile strength, load-bearing capacity, long-term durability |

| Manufacturing & Tools |

Machine tools, molds, dies, cutting instruments, CNC machined parts | Hardness, wear resistance, machinability, ability to retain sharp edges |

| Recycling & Waste Management |

Shredders, containers, waste processing machines, recycling plants | 100% recyclable, maintains properties after recycling |

| Renewable Energy |

Wind turbine towers, hydro dams, solar mounts, geothermal piping | Structural stability, corrosion resistance, adaptability in renewable systems |

| Medical |

Surgical instruments, implants, hospital beds, diagnostic equipment | Biocompatibility, corrosion resistance, sterilization capability, durability |

| Electromagnets & Transformers |

Magnetic cores, induction coils, transformers, generators | Soft magnetic steels reduce energy losses, improve electrical efficiency |

Conclusion

Steel is one of the most versatile and widely used materials in modern industry. Its unique combination of strength, durability, machinability, and recyclability makes it indispensable across fields such as automotive, construction, electronics, energy, medical, and manufacturing. Different grades of steel—carbon steel, stainless steel, tool steel, and silicon steel—are carefully selected based on their mechanical and magnetic properties to meet industry-specific requirements. As technology advances, steel continues to play a critical role in building stronger infrastructure, enabling renewable energy solutions, advancing medical technologies, and supporting sustainable development.

Steel is more than just a structural material—it is a complex alloy whose magnetic properties depend on factors such as chemical composition, crystal structure, heat treatment, and microstructure. While carbon steel, ferritic, and martensitic stainless steels are generally magnetic, austenitic stainless steels and certain specialized alloys remain non-magnetic due to their atomic arrangements. Understanding these differences is crucial for industries ranging from automotive and construction to medical devices and electronics, where magnetic behavior often determines suitability.

Equally important is the distinction between magnetic and non-magnetic metals such as aluminum, copper, brass, and gold, which find roles in applications where non-magnetism is essential. Steel’s adaptability, recyclability, and wide-ranging applications—from transformers and tools to renewable energy systems—make it one of the most indispensable materials in modern engineering.

By mastering the relationship between steel’s structure and its magnetism, engineers, manufacturers, and researchers can make informed choices, ensuring that the right steel or metal is used for the right purpose—balancing performance, safety, and sustainability in every field.

How Can I Identify Magnetic Steel?

You can identify magnetic steel by using a simple magnet test. If the magnet sticks strongly, the steel is likely carbon steel, ferritic, or martensitic stainless steel. If it shows little or no attraction, it may be austenitic stainless steel or another non-magnetic alloy.

Is Steel's Magnetism Permanent?

No, most steel is not permanently magnetic. It can become temporarily magnetized when exposed to a strong magnetic field, but only certain types, like hardened martensitic steels, can retain magnetism for longer periods.

Can a Magnet Attract Steel?

Yes, magnets can attract most types of steel, particularly carbon steels and magnetic stainless steels. However, some stainless steels, such as austenitic grades (304, 316), are not magnetic.

Why doesn't a magnet attract stainless steel?

Not all stainless steels are magnetic. Austenitic stainless steels have a face-centered cubic (FCC) crystal structure, which prevents unpaired electrons from aligning, making them essentially non-magnetic.

Is all stainless steel magnetic?

No. Only ferritic and martensitic stainless steels are magnetic. Austenitic stainless steels, the most common type, are usually non-magnetic unless cold worked.

Can a magnet attract titanium?

No. Titanium is generally non-magnetic, making it useful for medical implants, aerospace, and marine applications where magnetism could interfere with performance.

How can I tell if metal is stainless steel or galvanized?

Galvanized steel has a distinct spangled, matte-gray coating of zinc, while stainless steel has a smoother, shinier surface. Magnetism can help too—most galvanized steels are magnetic, while some stainless steels are not.

What grades of stainless steel can be attracted by magnets?

Ferritic (e.g., 430) and martensitic (e.g., 410, 420) stainless steels are magnetic. Austenitic grades like 304 and 316 are generally non-magnetic unless cold worked.

Does the shape of steel affect its magnetism?

Shape does not change whether steel is magnetic, but it can affect how a magnetic field interacts with the steel. For example, thin sheets may show weaker attraction compared to thicker pieces.

Are all types of steel magnetic?

No. While carbon steel, ferritic, and martensitic stainless steels are magnetic, austenitic stainless steels and some specialty alloys are non-magnetic.

Can a magnet attract hardened steel?

Yes. Hardened steel, such as tool steel, is magnetic. In fact, certain hardened steels can even retain permanent magnetism.

What metal looks like gold and is non-magnetic?

Brass and bronze often resemble gold but are non-magnetic. They are commonly used in decorative items, musical instruments, and fittings.