15 years one-stop China custom CNC machining parts factory

266 |

Published by VMT at Aug 21 2025 | Reading Time:About 4 minutes

266 |

Published by VMT at Aug 21 2025 | Reading Time:About 4 minutes

Many industries—from electronics to aerospace—rely on copper because of its exceptional conductivity and versatility. But one common question arises among engineers, product designers, and even consumers: is copper magnetic? Misunderstanding copper’s magnetic behavior can lead to design flaws, wasted materials, or unnecessary costs in CNC machining projects. For example, selecting copper under the assumption that it responds to magnets could compromise performance in sensitive equipment. At VMT, where we specialize in Copper CNC machining parts, ensuring clarity on material properties helps prevent costly mistakes and ensures the right choice for each application.

Copper is not magnetic. It is classified as diamagnetic, meaning it weakly repels magnetic fields instead of attracting them. This property comes from its electron structure, making pure copper unsuitable for magnetic applications but highly valuable for conductivity and nonmagnetic environments.

Now that you know the short answer—that copper is not magnetic—it’s important to dive deeper. Understanding why copper lacks magnetism, how it interacts with magnetic fields, and what factors influence its behavior can help engineers, designers, and buyers choose the right material. Let’s explore copper magnetism step by step and see where CNC machining fits into real-world applications.

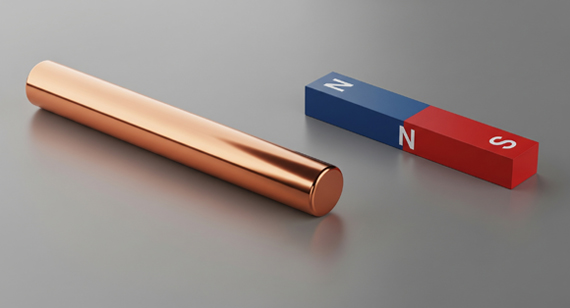

Copper is a reddish-brown metal that has been used for thousands of years in tools, wiring, and industrial equipment. Its standout features are high thermal and electrical conductivity, corrosion resistance, and excellent machinability. These qualities make it a go-to material for CNC machining factories producing precision parts for industries such as electronics, automotive, and aerospace. Unlike ferromagnetic metals such as iron, nickel, and cobalt, copper belongs to the diamagnetic group. This classification influences how it performs in applications where magnetism plays a role.

The direct answer is no, copper is not magnetic under normal conditions. It does not attract to magnets like steel or iron. Instead, copper’s interaction with magnetic fields is minimal and often misunderstood. Its diamagnetism means it slightly repels strong magnetic fields, but the effect is so weak it cannot be detected without specialized instruments. This distinction makes copper an essential choice in applications where magnetic interference must be minimized.

Copper’s lack of magnetism is explained by its electron configuration. In copper atoms, the outer electron shell is fully filled, meaning there are no unpaired electrons to align with an external magnetic field. Materials with unpaired electrons (such as iron) exhibit strong magnetism, while copper remains nonmagnetic. This scientific detail translates directly into practical advantages: copper is ideal for environments where magnetism could cause equipment malfunctions, such as MRI machines or sensitive audio devices.

Although copper is not magnetic in the traditional sense, it still interacts with magnetic fields in fascinating ways. When copper is exposed to a moving or changing magnetic field, it exhibits a phenomenon known as electromagnetic induction. This occurs because copper is an excellent electrical conductor. A moving magnet near copper induces electric currents, called eddy currents, within the metal. These currents then create their own magnetic fields, which oppose the original field according to Lenz’s Law.

This is why a strong magnet falling through a copper tube appears to “float” slowly instead of dropping freely. The eddy currents generated in the copper resist the magnet’s motion, demonstrating that while copper is not magnetic, it can influence and be influenced by magnetic activity. This interaction is extremely useful in applications like magnetic braking systems, induction heating, and transformers, where copper’s conductivity allows for controlled energy transfer without permanent magnetism.

In practical CNC machining applications, this nonmagnetic yet conductive property of copper is highly valuable. Copper CNC machining parts are often chosen for use in electronic shielding, aerospace navigation systems, and precision audio devices, where strong conductivity is needed without the risk of magnetic interference. Unlike ferromagnetic materials, copper ensures that devices remain stable and free from unwanted magnetic distortions.

To understand why copper does not respond to magnets like iron or nickel, we need to look closer at its fundamental nonmagnetic characteristics. Copper is classified as a diamagnetic material, meaning that instead of being drawn toward magnetic fields, it slightly repels them. These properties are not just scientific curiosities—they directly affect how copper is used in industries that require precision, stability, and conductivity without magnetic interference. This makes copper and Copper CNC machining parts a top choice for aerospace, electronics, and medical equipment where even a small magnetic response could compromise performance.

Diamagnetism

Diamagnetism is the key reason behind copper’s nonmagnetic behavior. When copper is placed in a magnetic field, tiny circular currents form inside its atoms as electrons adjust their orbits. These induced currents generate magnetic fields that oppose the applied field, causing copper to weakly repel magnets. The effect is extremely subtle—so much so that you won’t notice it without advanced instruments or very strong magnetic setups. However, this diamagnetic response ensures copper remains stable and interference-free in demanding environments.

Electron Configuration

Copper’s electron structure also explains its lack of magnetism. Each atom of copper has a filled 3d orbital and a single electron in the 4s orbital. Since nearly all the electrons are paired, there are no unpaired electrons available to align with an external magnetic field. This is in contrast to ferromagnetic metals like iron, where multiple unpaired electrons create strong magnetic alignment. This filled electron arrangement locks copper into its diamagnetic identity, ensuring it remains nonmagnetic under normal conditions.

Alloying Elements

While pure copper is diamagnetic, its magnetic behavior can change when alloyed with other elements. For instance, when copper is combined with nickel or iron, the resulting alloys may exhibit weak ferromagnetic or paramagnetic properties. This is why materials like Cu-Ni alloys can behave differently than pure copper. The presence of alloying elements alters the balance of unpaired electrons, sometimes introducing magnetic responses that do not exist in copper alone. For engineers and designers, this means verifying the exact alloy composition before selecting copper for magnetic-sensitive applications is essential.

Table: Copper’s Nonmagnetic Properties

| Property |

Description |

Impact on Magnetism |

Practical Tip |

| Diamagnetism |

Copper weakly repels magnetic fields instead of attracting them. | Prevents magnetic interference in sensitive environments. | Ideal for CNC machining parts used in aerospace and medical equipment. |

| Electron Configuration |

Copper’s atoms have filled 3d orbitals and one electron in the 4s orbital, leaving no unpaired electrons. | Lacks unpaired electrons needed for strong magnetism. | Select copper when designing components requiring stability without magnetic attraction. |

| Purity of Copper |

Pure copper retains nonmagnetic properties, while impurities or defects may slightly alter behavior. | High-purity copper remains strictly diamagnetic. | Always request certified material grades from CNC machining factories. |

| Alloying Elements |

Copper alloys (e.g., Cu-Ni, Cu-Fe) can gain weak magnetic responses due to added unpaired electrons. | Magnetic behavior changes depending on alloy composition. | Verify alloy content before ordering CNC machining services to avoid performance issues. |

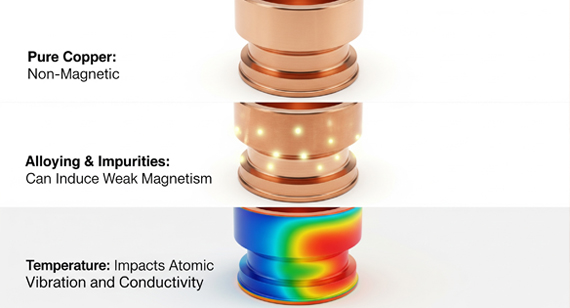

Although copper is generally classified as a nonmagnetic material, certain external and internal factors can subtly influence how it interacts with magnetic fields. These effects do not make copper magnetic in the traditional sense, but they can alter its performance in specific environments. For engineers, designers, and manufacturers working with Copper CNC machining parts, it is critical to understand these influences. Misinterpreting them could lead to unexpected results in sensitive applications, such as electronics, aerospace, and high-precision instruments.

Temperature

Temperature can affect copper’s diamagnetic properties. At room temperature, copper consistently remains nonmagnetic. However, under extremely low cryogenic conditions, copper’s diamagnetic response may become slightly more noticeable due to changes in electron motion. Conversely, at very high temperatures, thermal agitation may weaken its already subtle magnetic interaction. In practice, these changes are minimal, but in aerospace and scientific applications, even small variations can matter.

Alloying Elements

Pure copper is always diamagnetic, but when alloyed with elements such as iron, cobalt, or nickel, its magnetic behavior can change. These metals contribute unpaired electrons to the atomic structure, introducing weak ferromagnetic or paramagnetic responses. For example, copper-nickel alloys may show slight magnetism depending on the ratio of elements. This can be useful in some applications but problematic in others where magnetic neutrality is critical.

Impurities

Impurities in copper can also affect its magnetic response, though usually in very minor ways. Trace amounts of magnetic elements such as iron can introduce localized disturbances in copper’s electron structure. While these impurities rarely make copper noticeably magnetic, they may cause variations in conductivity and electromagnetic performance. For precision applications like electronic shielding or medical equipment, impurity levels must be tightly controlled.

Pressure and Hammering

Mechanical processes like hammering, pressing, or applying high pressure can alter copper’s crystal lattice structure. However, these changes do not affect its fundamental diamagnetic nature. While stress may influence strength or hardness, copper will not become magnetic through mechanical processing. This reliability is one reason copper is widely used in machining and forming applications.

Copper Processing

Similar to mechanical stress, the way copper is processed—whether by casting, forging, or precision CNC machining—does not change its magnetic classification. Processing may improve its mechanical strength, corrosion resistance, or surface finish, but its electron configuration remains unchanged. This makes copper highly predictable and dependable for industries that need stable, nonmagnetic performance.

Applied Magnetic Fields

Even though copper is not magnetic, it can interact strongly with moving or alternating magnetic fields through eddy currents. When a magnet moves near copper, induced currents form inside the metal, creating an opposing magnetic effect. This is not permanent magnetism—it disappears once the external field is gone. However, it is highly useful in applications such as electromagnetic braking, induction heating, and shielding.

Table: Factors Affecting Copper’s Magnetism

| Factor |

Effect on Copper’s Magnetism |

Explanation |

Practical Tip |

| Temperature |

Slight influence | At extremely low temperatures, copper’s diamagnetic response may become more noticeable, but overall magnetism remains weak. | For cryogenic or aerospace projects, always test copper performance under actual operating temperatures. |

| Alloying Elements |

Can increase magnetism | Adding metals like nickel, iron, or cobalt introduces unpaired electrons, creating weak magnetic properties. | Confirm alloy composition before CNC machining—some alloys may not remain nonmagnetic. |

| Impurities |

Minor impact | Trace impurities may disrupt electron balance, but usually don’t make copper magnetic. | Use high-purity copper for electronic shielding or precision CNC machining parts. |

| Pressure & Hammering |

Negligible effect | Mechanical stress can alter crystal structure but doesn’t change copper’s diamagnetic nature. | Mechanical processing won’t make copper magnetic—safe for CNC machining operations. |

| Copper Processing |

No major change | Casting, forging, or CNC machining does not affect copper’s fundamental nonmagnetic state. | Copper parts produced in CNC machining factories remain reliably nonmagnetic. |

| Applied Magnetic Fields |

Temporary induced currents | Moving magnetic fields create eddy currents in copper, which oppose the field but vanish when the field is removed. | Useful in electromagnetic shielding and braking systems—designs can leverage this effect. |

Copper’s combination of high conductivity, corrosion resistance, and nonmagnetic behavior makes it one of the most versatile metals in industry. Although many ask, “Is copper magnetic?”, the answer is consistently no—yet this very property is one of the main reasons copper is so widely used. Its diamagnetic nature prevents interference in sensitive equipment, while its durability ensures long-term reliability. From audio equipment to aerospace systems, electrical devices, and marine hardware, copper’s role is essential. For manufacturers working with CNC machining services, copper offers both design flexibility and reliable performance, making it a preferred material in advanced industries.

Audio Equipment

Copper is the gold standard in audio engineering, not because it is magnetic, but because it is nonmagnetic and highly conductive. Speaker coils, amplifier wiring, and precision connectors are almost always made of copper. Its lack of magnetic interference ensures clear sound reproduction without distortion, while its conductivity allows for efficient signal transmission. High-purity copper is especially valued in professional audio equipment where even minor interference can degrade quality. For CNC machining factories, copper is frequently used to produce custom connectors, housings, and structural parts for high-end audio systems.

Aerospace Applications

In aerospace, copper’s nonmagnetic properties are as critical as its conductivity. Navigation systems, avionics, and satellite components must remain unaffected by magnetic fields, and copper ensures this stability. At the same time, copper alloys with excellent strength-to-weight ratios are used in structural components and thermal management systems. For CNC machining parts, aerospace-grade copper must meet strict tolerances and certifications to ensure safety and reliability in extreme conditions. Its resistance to both magnetism and corrosion makes it indispensable in aircraft and spacecraft.

Copper is the backbone of the electrical and electronics industry. Its unmatched conductivity ensures efficient energy transfer in wiring, circuit boards, transformers, and electromagnetic shielding. Importantly, copper’s nonmagnetic nature means it does not interfere with electronic signals, making it ideal for high-frequency applications. For CNC machining factories, copper is commonly processed into bus bars, terminal blocks, and precision connectors. This makes it critical in everything from household electronics to large-scale power systems.

Marine

Marine applications demand metals that resist corrosion, perform well in harsh saltwater environments, and remain stable under variable magnetic conditions. Copper and its alloys, such as brass and bronze, are widely used in propellers, pump components, and underwater connectors. Their resistance to biofouling and seawater corrosion, combined with copper’s nonmagnetic properties, makes them essential for naval vessels and underwater exploration equipment. For CNC machining services, marine copper components must be precisely engineered to ensure reliability and safety in deep-sea conditions.

Table: Applications and Uses of Copper

| Application |

Why Copper is Used |

Examples of Copper CNC Machining Parts |

Practical Tip |

| Audio Equipment |

High conductivity and nonmagnetic properties ensure clear sound with no distortion. | Connectors, housings, precision terminals, amplifier parts. | Use high-purity or oxygen-free copper to maximize sound quality. |

| Aerospace |

Nonmagnetic behavior prevents interference in navigation and avionics; strong alloys add durability. | Heat exchangers, housings, connectors, avionics components. | Choose aerospace-certified copper alloys from reliable CNC machining factories. |

| Electrical & Electronics |

Excellent electrical and thermal conductivity; nonmagnetic nature avoids signal interference. | Bus bars, terminal blocks, circuit connectors, shielding parts. | Ensure precise machining tolerances to maintain electrical efficiency. |

| Marine |

Corrosion resistance and biofouling resistance in saltwater; stable nonmagnetic properties. | Propellers, pump housings, underwater connectors, valve parts. | Select the correct alloy (e.g., bronze or brass) for durability in seawater. |

So, is copper magnetic? The answer is no—pure copper is a diamagnetic material, meaning it weakly repels magnetic fields instead of attracting them. This property, combined with its excellent electrical and thermal conductivity, makes copper one of the most valuable metals across industries. From audio equipment to aerospace systems, electronics, and marine components, copper delivers performance where both conductivity and nonmagnetic stability are essential.

For engineers, designers, and manufacturers, understanding copper magnetism is more than just a scientific curiosity—it’s a practical consideration that impacts product performance and cost. Whether you are designing shielding components for electronics, corrosion-resistant parts for marine use, or precision systems in aerospace, copper ensures stability without the risk of magnetic interference.

In the world of CNC machining services, copper stands out as a reliable and versatile material. At CNC machining factories, copper is transformed into high-precision parts such as connectors, housings, and structural components. Its nonmagnetic behavior ensures that these parts function flawlessly even in the most demanding environments.

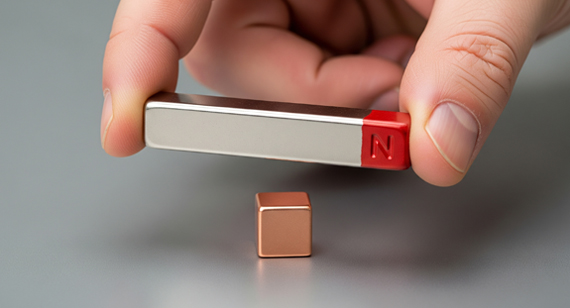

Can a Magnet Attract Copper?

No, a magnet cannot attract copper. Pure copper is a diamagnetic metal, which means it slightly repels magnetic fields instead of being pulled toward them. However, when copper is exposed to a moving magnet, it can generate eddy currents that create an opposing magnetic effect. This phenomenon makes it look as if copper interacts with magnets, but the effect disappears once the external magnetic field is removed. For industries producing Copper CNC machining parts, this distinction is critical—copper remains reliably nonmagnetic, which is ideal for sensitive electronics and aerospace applications.

How Conductive is Copper?

Copper is one of the most conductive metals in the world, second only to silver. Its high electrical conductivity (59.6 × 10⁶ S/m at room temperature) makes it the backbone of the electrical and electronics industry. It is used for wiring, circuit boards, transformers, and precision CNC machining parts such as connectors and bus bars. Because copper does not lose much energy in transmission, it is ideal for both large-scale power systems and delicate electronics.

Is a Bullet Magnetic?

Most bullets are not magnetic. Bullets are commonly made of lead or copper-jacketed lead, both of which are nonmagnetic. However, some ammunition may contain steel components, which can make a bullet magnetic. Since copper is often used in bullet casings due to its softness and nonmagnetic properties, copper magnetism does not interfere with firearm performance.

Is a Coin Magnetic?

Most coins are not magnetic because they are made from metals like copper, nickel, or zinc, which are either nonmagnetic or only weakly magnetic. For example, pure copper coins remain nonmagnetic due to their diamagnetic nature. However, some coins may contain ferromagnetic metals such as iron or steel, which would make them magnetic. This varies by country and minting standards.

Does Copper Rust?

No, copper does not rust in the way iron or steel does. Rusting is the oxidation of iron, while copper undergoes a different process. When exposed to air and moisture, copper develops a protective oxide layer, often turning green over time (patina). This patina prevents deeper corrosion, making copper extremely durable in outdoor and marine environments. This durability is one reason why CNC machining services use copper in marine and architectural applications.

What Metals Are Not Attracted by Magnets?

Nonmagnetic metals include copper, aluminum, brass, lead, tin, and precious metals like gold and silver. These metals are either diamagnetic or paramagnetic, meaning they do not respond strongly to magnetic fields. For Copper CNC machining parts, this ensures stability in sensitive environments where magnetic interference could disrupt equipment.

Why Isn’t Stainless Steel Magnetic?

Not all stainless steels are magnetic. Austenitic stainless steels (like 304 and 316) have a crystal structure that prevents unpaired electrons from aligning with magnetic fields, making them nonmagnetic. Ferritic and martensitic stainless steels, on the other hand, are magnetic. The key difference lies in composition and structure. Compared to copper, which is consistently diamagnetic, stainless steel magnetism varies widely.

What Metals Are Magnetic But Don’t Rust?

Some magnetic metals, such as stainless steels with high chromium content, resist rusting while retaining magnetism. Nickel is another example of a magnetic metal that does not corrode easily. Unlike copper, which is nonmagnetic but corrosion resistant, these metals balance both properties. This is important in industries where both durability and magnetism are required.

Is Copper a Hard or Soft Metal?

Copper is classified as a soft metal. It is malleable and ductile, meaning it can be easily shaped, drawn into wires, or machined into precise parts. Its softness is one of the reasons it is widely used in CNC machining factories for connectors, terminals, and custom components. However, alloys like bronze and brass can increase copper’s hardness for structural applications.

What is the Most Magnetic Metal?

The most magnetic metal is iron, followed closely by cobalt and nickel. These metals are classified as ferromagnetic because they have multiple unpaired electrons that align strongly with magnetic fields. Compared to these, copper magnetism is negligible, as copper remains diamagnetic.

What is the Least Magnetic Metal?

The least magnetic metals are strongly diamagnetic, including copper, bismuth, and silver. Among these, copper is the most practical for industrial use due to its conductivity and machinability. This makes copper a preferred choice for CNC machining parts in nonmagnetic environments.

How to Detect Copper?

Copper can be detected using several methods:

For industrial use, CNC machining factories rely on certified suppliers and material testing to confirm copper’s purity before production.