15 years one-stop China custom CNC machining parts factory

281 |

Published by VMT at Aug 20 2025 | Reading Time:About 7 minutes

281 |

Published by VMT at Aug 20 2025 | Reading Time:About 7 minutes

Many engineers and product designers struggle when selecting materials for electrical applications. Choosing the wrong metal can lead to high resistance, overheating, or costly failures in critical components. This is especially true for industries relying on precision metal CNC machined parts, where conductivity directly impacts performance. The good news is that by understanding metal conductivity, you can make better choices that improve efficiency, reduce costs, and extend product life.

Most metals conduct electricity because of their free electrons. The best conductors are silver, copper, and gold, followed by aluminum and brass. Factors such as temperature, impurities, and alloying can affect conductivity. For precision applications, CNC machining services can help manufacture conductive parts with the right balance of strength and electrical performance.

Now that we’ve answered the central question, let’s dive deeper. This article will explain what metallic conductivity is, why some metals conduct electricity better than others, and which metals rank highest in performance. We’ll also look at practical applications—from wiring to heat transfer—and how CNC machining factories can support industries that depend on reliable electrical materials.

Metallic conductivity refers to a material’s ability to allow electric current to pass through it. In metals, the outer electrons (valence electrons) are loosely bound and can move freely, forming what is known as an “electron cloud.” This mobility enables metals to conduct both electricity and heat efficiently. Conductivity is usually measured in siemens per meter (S/m) or by comparison to copper (100% IACS = International Annealed Copper Standard).

For manufacturers designing metal CNC machined parts, understanding conductivity is crucial. Poorly chosen materials may cause electrical losses, heating issues, or even equipment failure. This is why industries such as electronics, aerospace, and automotive often consult CNC machining services to ensure that the material’s electrical and mechanical properties meet the intended function.

Metals are highly conductive because their atomic structure allows electrons to move freely. Unlike nonmetals, where electrons are tightly bound, metals feature delocalized electrons in their crystal lattice. This “sea of electrons” allows for minimal resistance, making current flow more efficient. Additionally, metals often have closely packed atoms, which further enhances conduction.

This property not only benefits electrical wiring but also improves thermal conductivity, which is why many conductive metals are used in heat exchangers and cooling systems. When machining these materials into metal CNC machined parts, conductivity must be preserved by minimizing surface oxidation and avoiding contaminants. Experienced CNC machining factories employ advanced processes, such as precision milling and protective coatings, to ensure parts retain their desired conductivity.

In general, all metals conduct electricity, but not equally well. The reason lies in their atomic structure—every metal has free electrons, which allow current to pass through. However, conductivity levels vary widely. For example, silver and copper are excellent conductors, while stainless steel and titanium are much poorer conductors due to their higher resistivity and tendency to form oxides.

This difference is critical in product design. For applications like power transmission, copper and aluminum are widely used because they balance high conductivity with mechanical strength and cost-effectiveness. On the other hand, metals with lower conductivity, such as stainless steel, are often chosen when corrosion resistance or structural integrity is more important than electrical performance. When producing metal CNC machined parts, engineers must carefully evaluate whether conductivity or durability should be prioritized, as the wrong choice can lead to unnecessary costs and reduced efficiency.

For industries that rely on CNC machining services, such as electronics, automotive, and aerospace, understanding the conductivity of different metals helps ensure that the right material is chosen for the application. By consulting experienced CNC machining factories, customers can receive guidance on which metals conduct electricity most effectively while still meeting strength, weight, and cost requirements.

Almost all metals conduct electricity, but their conductivity levels vary significantly. The most conductive metals are silver, copper, and gold, followed by aluminum and brass. Other metals such as iron, zinc, and stainless steel also conduct electricity, but their efficiency is lower. Each metal’s conductivity depends on its electron structure, purity, and how it reacts under different conditions such as temperature or oxidation.

For example, silver is the most conductive metal but is rarely used in wiring due to its high cost. Copper is the most practical choice for electrical wiring and components, offering excellent conductivity and affordability. Aluminum is lighter and less expensive, making it ideal for high-voltage transmission lines. Other metals like brass and bronze are commonly used when moderate conductivity is acceptable but mechanical strength or corrosion resistance is more critical.

When designing metal CNC machined parts, choosing the right conductive material ensures reliability and efficiency in end-use applications. Electronics, automotive, aerospace, and energy industries often rely on CNC machining services to produce conductive parts such as terminals, housings, and connectors. Trusted CNC machining factories can also recommend cost-effective alternatives, ensuring performance without overspending.

Understanding the relationship between electrical conductivity, resistivity, and thermal conductivity of metals is critical in both material science and precision engineering. Conductivity measures how easily a material allows electrons to flow, resistivity is its opposition to current, and thermal conductivity reflects its ability to transfer heat. Together, these properties determine how suitable a metal is for applications such as wiring, heat exchangers, and metal CNC machined parts.

When industries partner with CNC machining services, they need to choose metals that balance conductivity with strength, corrosion resistance, and machinability. For example, copper excels in conductivity, while stainless steel is less conductive but highly resistant to corrosion. By consulting with experienced CNC machining factories, manufacturers can make informed material decisions that save costs and improve product performance.

Silver

Electrical Conductivity: Silver is the most conductive metal (about 63 × 10⁶ S/m, rated 106% IACS).

Resistivity: Very low (1.59 µΩ·cm), making it ideal for precision electronics.

Thermal Conductivity: Silver also has the highest thermal conductivity of all metals (~429 W/m·K).

Because of its superior properties, silver is used in high-end electrical contacts, solar panels, and aerospace applications. However, due to its cost, silver is rarely used in large-scale wiring. In CNC machining, silver is often selected for metal CNC machined parts that demand maximum conductivity, such as connectors or high-frequency components. Specialized CNC machining services can machine silver to precise tolerances without losing its conductive qualities.

Electrical Conductivity: Copper ranks second only to silver, with 100% IACS (58 × 10⁶ S/m).

Resistivity: 1.68 µΩ·cm, making it the standard benchmark for electrical conductivity.

Thermal Conductivity: High (~401 W/m·K), enabling efficient heat dissipation.

Copper is the most widely used conductive metal, applied in power transmission, motors, transformers, and electronic components. It strikes the perfect balance between performance and cost, making it the go-to choice for industries worldwide. When processed into metal CNC machined parts, copper requires skilled handling, as it is soft and can deform if not machined precisely. Reputable CNC machining factories use advanced tooling and cooling techniques to ensure high-quality copper components for both electrical and thermal applications.

Brass

Electrical Conductivity: Brass (an alloy of copper and zinc) has lower conductivity than pure copper, typically around 28% IACS.

Resistivity: 6–7 µΩ·cm, which makes it suitable for moderate-conductivity applications.

Thermal Conductivity: Moderate (~120 W/m·K), depending on the zinc content.

Brass is commonly used in connectors, fittings, and components where both mechanical strength and moderate conductivity are required. It also offers good corrosion resistance, making it a practical choice for marine and plumbing industries. For metal CNC machined parts, brass is highly machinable, allowing CNC machining services to produce detailed components with tight tolerances.

Bronze

Electrical Conductivity: Bronze, primarily a copper-tin alloy, has conductivity around 15% IACS.

Resistivity: ~10 µΩ·cm, higher than brass due to alloying with tin.

Thermal Conductivity: Around 60 W/m·K, lower than brass and copper.

Bronze is not as conductive as copper or brass, but it provides superior wear resistance and durability. It’s often used in bearings, bushings, and marine hardware, where mechanical performance is more important than conductivity. For CNC machining factories, bronze is an excellent material when producing durable parts that must withstand friction and corrosion while still conducting some electricity.

Annealed Copper

Electrical Conductivity: Annealed copper is the reference standard at 100% IACS.

Resistivity: 1.724 µΩ·cm.

Thermal Conductivity: Around 390–401 W/m·K.

Annealed copper is pure copper that has been heat-treated to improve ductility without significantly changing conductivity. It’s widely used in electrical wiring, motors, and transformer windings. For metal CNC machined parts, annealed copper offers the highest combination of conductivity and workability. CNC machining services often recommend it for components where flexibility, conductivity, and machinability are all required.

Gold

Electrical Conductivity: Gold conducts electricity well, at around 70% IACS (45 × 10⁶ S/m).

Resistivity: 2.44 µΩ·cm, slightly higher than copper.

Thermal Conductivity: About 318 W/m·K.

Gold is highly valued for its corrosion resistance. While not as conductive as silver or copper, gold’s resistance to tarnishing makes it ideal for critical components like electrical contacts, aerospace electronics, and medical devices. In metal CNC machined parts, gold is often applied as a plating over copper or nickel components rather than used in bulk due to its high cost. CNC machining factories can prepare precise base components that are later coated with gold for conductivity and longevity.

Electrical Conductivity: Aluminum has about 61% IACS (35 × 10⁶ S/m).

Resistivity: 2.82 µΩ·cm.

Thermal Conductivity: ~237 W/m·K, making it excellent for both electrical and thermal uses.

Aluminum is the second most widely used conductor after copper. Its lightweight nature makes it ideal for overhead power lines, heat exchangers, and electronic housings. For metal CNC machined parts, aluminum offers an excellent balance of conductivity, machinability, and cost-effectiveness. CNC machining services often recommend aluminum for parts requiring high strength-to-weight ratio along with good electrical performance.

Electrical Conductivity: Iron has much lower conductivity than copper or aluminum, around 17% IACS.

Resistivity: 9.71 µΩ·cm.

Thermal Conductivity: ~80 W/m·K.

Iron is not typically chosen for electrical efficiency but is widely used for structural and magnetic applications, such as transformers and electric motors. For metal CNC machined parts, iron is cost-effective and strong, but its poor conductivity limits it to specialized roles. CNC machining factories may use iron when magnetic properties or structural integrity are more critical than electrical flow.

Electrical Conductivity: Carbon steel has relatively poor conductivity, around 3–10% IACS depending on composition.

Resistivity: ~10–20 µΩ·cm, much higher than copper.

Thermal Conductivity: ~50 W/m·K, significantly lower than copper or aluminum.

Carbon steel is valued for its strength and cost-efficiency rather than conductivity. It is often used in structural parts, mechanical tools, and components requiring high wear resistance. For metal CNC machined parts, carbon steel offers excellent machinability but is rarely chosen for electrical systems where efficient conductivity is needed. Instead, it finds applications in mechanical housings and fixtures. CNC machining factories often recommend carbon steel when strength and durability are prioritized over electrical performance.

Electrical Conductivity: Stainless steel is a poor conductor, with only ~2–3% IACS.

Resistivity: ~60–70 µΩ·cm, very high compared to copper.

Thermal Conductivity: ~16 W/m·K, making it one of the poorest thermal conductors among metals.

Despite its low conductivity, stainless steel is used in industries where corrosion resistance, hygiene, or mechanical properties matter more than electrical flow. Applications include medical devices, food equipment, and aerospace hardware. For metal CNC machined parts, stainless steel is a favorite due to its strength and resistance to corrosion, even though it does not conduct electricity efficiently. CNC machining services often use grades like 304 or 316 stainless steel in parts exposed to harsh environments.

Calcium

Electrical Conductivity: Calcium is a fair conductor but not widely used, around 29% IACS.

Resistivity: ~3.3 µΩ·cm.

Thermal Conductivity: ~200 W/m·K.

Calcium’s conductivity is higher than that of stainless steel, but it is too chemically reactive to be used in most applications. In practice, calcium appears in specialized alloys or as a reducing agent in metallurgy rather than in direct conductive applications. It is not commonly used in metal CNC machined parts, as its reactivity makes it unstable. CNC machining factories typically avoid calcium unless producing research-grade alloys.

Beryllium

Electrical Conductivity: Beryllium has conductivity of about 20–25% IACS.

Resistivity: ~4 µΩ·cm.

Thermal Conductivity: ~200 W/m·K, relatively high.

Beryllium is valued for its stiffness, light weight, and thermal properties, but its toxicity makes handling dangerous. It is usually used in alloy form, such as beryllium copper, which combines high conductivity (20–60% IACS) with excellent strength. In metal CNC machined parts, beryllium copper is popular for springs, connectors, and aerospace components. Experienced CNC machining services are required due to strict safety measures when handling beryllium-containing materials.

Rhodium

Electrical Conductivity: Rhodium conducts moderately well, about 38% IACS.

Resistivity: 4.3 µΩ·cm.

Thermal Conductivity: ~150 W/m·K.

Rhodium is a rare, expensive metal often used for plating due to its corrosion resistance, hardness, and decent conductivity. While not as conductive as copper or silver, it provides durability in high-wear contact points such as electrical connectors. For CNC machining factories, rhodium is rarely machined in bulk; instead, base components are produced by CNC machining services and then plated with rhodium for added longevity.

Magnesium

Electrical Conductivity: Magnesium has conductivity of about 39% IACS.

Resistivity: 4.45 µΩ·cm.

Thermal Conductivity: ~160 W/m·K.

Magnesium is lightweight, with moderate conductivity and excellent machinability. It is often used in aerospace and automotive industries where weight reduction is critical. While not as conductive as copper or aluminum, magnesium alloys provide a balance of strength, conductivity, and lightness. CNC machining services frequently produce magnesium CNC machined parts for housings, enclosures, and components that need both electrical and thermal performance.

Molybdenum

Electrical Conductivity: About 31% IACS.

Resistivity: ~5.7 µΩ·cm.

Thermal Conductivity: ~138 W/m·K.

Molybdenum is best known for its high melting point and strength at elevated temperatures. While its conductivity is moderate compared to copper or aluminum, it is extremely valuable in high-heat environments such as furnace components and aerospace parts. For metal CNC machined parts, molybdenum is difficult to machine due to its hardness, but experienced CNC machining factories can produce critical parts like electrodes or semiconductor components.

Iridium

Electrical Conductivity: ~19% IACS.

Resistivity: 5.3 µΩ·cm.

Thermal Conductivity: ~150 W/m·K.

Iridium is one of the densest and most corrosion-resistant metals. Although its electrical conductivity is lower than silver, copper, or gold, it excels in harsh environments where durability is essential. It is often used in electrical contacts, spark plugs, and high-performance alloys. In CNC machining, iridium is rarely produced in bulk due to cost but can be applied in specialized metal CNC machined parts that demand exceptional longevity.

Tungsten

Electrical Conductivity: ~31% IACS.

Resistivity: 5.6 µΩ·cm.

Thermal Conductivity: ~173 W/m·K.

Tungsten is famous for its high melting point, making it essential for filaments, welding electrodes, and aerospace applications. Its conductivity is moderate but stable at extreme temperatures. For CNC machining services, tungsten presents machining challenges due to its hardness and brittleness. However, CNC machining factories produce tungsten parts for defense, medical imaging, and electronics.

Zinc

Electrical Conductivity: ~27% IACS.

Resistivity: 5.9 µΩ·cm.

Thermal Conductivity: ~116 W/m·K.

Zinc’s moderate conductivity makes it suitable for galvanization and as a base material for alloys like brass. It is not used for high-performance conductive parts but is valuable in protecting steel from corrosion. For metal CNC machined parts, zinc alloys (like Zamak) are easier to machine and widely used in automotive, consumer goods, and hardware industries. CNC machining factories often recommend zinc alloys for cost-effective, corrosion-resistant components.

Cobalt

Electrical Conductivity: ~17% IACS.

Resistivity: ~6.2 µΩ·cm.

Thermal Conductivity: ~100 W/m·K.

Cobalt is more valued for its magnetic properties and wear resistance than its conductivity. It is used in magnets, cutting tools, and high-performance alloys. For CNC machining services, cobalt alloys are difficult to machine due to hardness but provide outstanding durability. Metal CNC machined parts made of cobalt alloys are common in aerospace engines and medical implants.

Cadmium

Electrical Conductivity: ~24% IACS.

Resistivity: 7.3 µΩ·cm.

Thermal Conductivity: ~96 W/m·K.

Cadmium is moderately conductive and often used in electroplating to protect other metals from corrosion. It is not used in bulk for CNC machining due to toxicity and softness. However, cadmium coatings are sometimes applied to metal CNC machined parts in aerospace and defense industries for wear and corrosion protection.

Nickel (Electrolytic)

Electrical Conductivity: ~22% IACS.

Resistivity: ~6.99 µΩ·cm.

Thermal Conductivity: ~90 W/m·K.

Nickel is moderately conductive and highly corrosion resistant. Electrolytic nickel is widely used in plating, batteries, and electronics. It is machinable and often chosen for metal CNC machined parts that require corrosion protection with some conductivity. CNC machining factories also produce nickel alloys (like Inconel) for high-temperature and aerospace applications, though these alloys reduce conductivity compared to pure nickel.

Ruthenium

Electrical Conductivity: ~19% IACS.

Resistivity: 7.1 µΩ·cm.

Thermal Conductivity: ~120 W/m·K.

Ruthenium is a rare platinum-group metal with good conductivity, high hardness, and excellent corrosion resistance. It is often used as a coating on electrical contacts to improve durability and reduce resistance. While pure ruthenium is rarely machined due to brittleness, CNC machining factories often produce copper or nickel parts that are later ruthenium-plated for conductivity and wear resistance.

Lithium

Electrical Conductivity: ~17% IACS.

Resistivity: 9.28 µΩ·cm.

Thermal Conductivity: ~85 W/m·K.

Lithium is lightweight, soft, and highly reactive. While it is conductive, its main applications are in batteries rather than traditional electrical components. Pure lithium is rarely machined into parts because of its reactivity. Instead, it is used in compounds and alloys. CNC machining services typically do not work directly with lithium, but lithium-containing alloys may be processed under controlled conditions.

Platinum

Electrical Conductivity: ~16% IACS.

Resistivity: 10.6 µΩ·cm.

Thermal Conductivity: ~72 W/m·K.

Platinum is not as conductive as copper or silver but is highly valued for its corrosion resistance and stability at high temperatures. It is commonly used in thermocouples, laboratory equipment, and medical devices. For metal CNC machined parts, platinum is rarely used in bulk due to cost but can be precisely machined for critical aerospace, medical, and research applications. CNC machining factories often work with platinum in specialized industries where reliability outweighs cost.

Palladium

Electrical Conductivity: ~16% IACS.

Resistivity: 10.8 µΩ·cm.

Thermal Conductivity: ~72 W/m·K.

Palladium has moderate conductivity but outstanding corrosion resistance, making it useful for plating electronic connectors and circuits. It is also widely used in catalytic converters. In CNC machining, palladium is typically applied as a thin coating rather than bulk-machined. CNC machining services produce base parts that are later palladium-coated for conductivity and corrosion resistance.

Tin

Electrical Conductivity: ~15% IACS.

Resistivity: 11 µΩ·cm.

Thermal Conductivity: ~67 W/m·K.

Tin is moderately conductive and best known for its use in soldering. It creates reliable joints in electrical circuits by bonding conductive metals. In metal CNC machined parts, tin is often used as a coating for copper components to improve corrosion resistance. CNC machining factories frequently recommend tin plating for terminals, connectors, and circuit parts.

Selenium*

Electrical Conductivity: Selenium is a semiconductor, not a good conductor like metals. Its conductivity varies with light exposure.

Resistivity: Extremely high in dark conditions, dropping under illumination.

Thermal Conductivity: Very low (~2 W/m·K).

Selenium is primarily used in photocells, solar panels, and electronics. It is not machined into bulk components due to brittleness. Instead, it is deposited as thin films or coatings. While not relevant for most metal CNC machined parts, selenium has niche applications in electronics that depend on light-sensitive conductivity.

Tantalum

Electrical Conductivity: ~13% IACS.

Resistivity: 13.6 µΩ·cm.

Thermal Conductivity: ~57 W/m·K.

Tantalum has poor conductivity compared to copper but is extremely corrosion resistant, even to strong acids. It is widely used in capacitors, medical implants, and aerospace parts. For CNC machining factories, tantalum is expensive but machinable with care, making it valuable in high-end, corrosion-critical applications.

Niobium

Electrical Conductivity: ~11% IACS.

Resistivity: 15.2 µΩ·cm.

Thermal Conductivity: ~54 W/m·K.

Niobium is moderately conductive but highly valued for its superconducting properties at low temperatures. It is used in superconducting magnets, aerospace alloys, and medical implants. While pure niobium is rarely used in CNC machined parts, it is commonly alloyed with steel to improve strength and toughness. CNC machining factories that serve aerospace and medical industries sometimes machine niobium alloys for specialized applications.

Cast Steel

Electrical Conductivity: Low compared to copper (~2–3% IACS).

Resistivity: ~60 µΩ·cm (varies by alloy).

Thermal Conductivity: ~50 W/m·K.

Cast steel is primarily a structural material, not a conductive one. While it conducts electricity, its resistivity is much higher than copper or aluminum, making it inefficient for wiring or circuits. However, CNC machining services use cast steel extensively for mechanical components, housings, and fixtures where strength and durability matter more than conductivity.

Chromium

Electrical Conductivity: ~7.9% IACS.

Resistivity: 12.7 µΩ·cm.

Thermal Conductivity: ~94 W/m·K.

Chromium is moderately conductive and best known for its excellent corrosion resistance. It is commonly used as a plating material on steel and other metals to improve surface hardness and resistance. In metal CNC machined parts, chromium is not typically used in bulk form but applied as a coating. CNC machining factories often provide chrome plating on steel parts for durability and aesthetics.

Lead

Electrical Conductivity: ~7% IACS.

Resistivity: 20.6 µΩ·cm.

Thermal Conductivity: ~35 W/m·K.

Lead has relatively poor conductivity compared to copper but is still used in specialized applications, such as radiation shielding and batteries. Due to its toxicity, its use in electrical applications has declined. In CNC machining, lead is rarely machined directly, but leaded alloys (like brass with lead) are easier to machine and still used in some industries.

Vanadium

Electrical Conductivity: ~6% IACS.

Resistivity: 20 µΩ·cm.

Thermal Conductivity: ~30 W/m·K.

Vanadium has poor conductivity but is widely used as an alloying element in steels to increase hardness and strength. It is not commonly used in electrical applications. For CNC machining factories, vanadium-containing steels are very common in aerospace and tool industries where wear resistance is critical.

Uranium

Electrical Conductivity: ~4% IACS.

Resistivity: 28 µΩ·cm.

Thermal Conductivity: ~28 W/m·K.

Uranium is weakly conductive and radioactive, making it unsuitable for most commercial conductive applications. It is primarily used in nuclear fuel rather than electrical systems. CNC machining factories do not generally handle uranium due to safety and regulatory restrictions.

Antimony

Electrical Conductivity: ~3% IACS.

Resistivity: 39 µΩ·cm.

Thermal Conductivity: ~24 W/m·K.

Antimony is a poor conductor but is often alloyed with lead to improve hardness in batteries and solders. It is brittle and not used as a bulk material in CNC machining parts. Instead, CNC machining services may process alloys containing antimony for specific industrial needs.

Zirconium

Electrical Conductivity: ~3% IACS.

Resistivity: 42 µΩ·cm.

Thermal Conductivity: ~23 W/m·K.

Zirconium has low conductivity but excellent corrosion resistance, especially in chemical processing and nuclear industries. For CNC machining factories, zirconium alloys are machinable and valuable for specialized chemical equipment, not electrical wiring.

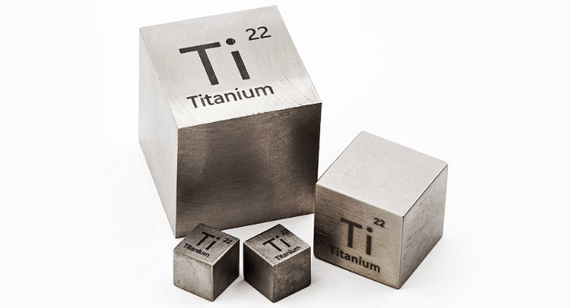

Electrical Conductivity: ~3% IACS.

Resistivity: 42 µΩ·cm.

Thermal Conductivity: ~22 W/m·K.

Titanium is a poor conductor compared to copper or aluminum, but it excels in strength, lightness, and corrosion resistance. It is widely used in aerospace, medical implants, and high-performance engineering applications. In CNC machining factories, titanium alloys are popular for CNC machined parts that require high durability and biocompatibility, but not for electrical conductivity.

Mercury

Electrical Conductivity: ~1% IACS.

Resistivity: 96 µΩ·cm.

Thermal Conductivity: ~8.3 W/m·K.

Mercury is a liquid metal at room temperature and a very poor conductor compared to solid metals. It has been historically used in switches, thermometers, and scientific instruments, though its use has declined due to toxicity. CNC machining services do not handle mercury, but machined housings for scientific equipment may integrate mercury as part of specialized assemblies.

Germanium

Electrical Conductivity: ~2.1 S/cm (semiconductor, not a true metal).

Resistivity: ~0.47 Ω·cm (varies with doping).

Thermal Conductivity: ~60 W/m·K.

Germanium is not a good conductor by metallic standards but is a critical semiconductor material. It is widely used in electronics, solar cells, and fiber optics. Since it is brittle, CNC machining factories do not process it as bulk material; instead, it is refined for use in wafers and microelectronics.

Silicon

Electrical Conductivity: ~1.6 S/cm (semiconductor).

Resistivity: ~2.3 Ω·cm (varies with doping).

Thermal Conductivity: ~150 W/m·K.

Silicon, like germanium, is a semiconductor rather than a true metal. Its conductivity depends heavily on doping with other elements, making it the backbone of modern electronics. It is not used for structural CNC machining parts, but CNC machining services may fabricate housings and precision components for semiconductor equipment.

| Metal |

Electrical Conductivity (% IACS) |

Electrical Resistivity (10⁻⁸ Ω·m) |

Thermal Conductivity (W/m·K) |

| Silver |

105 | 1.59 | 429 |

| Copper |

100 | 1.68 | 401 |

| Brass |

28 | 6.2 | 120 |

| Bronze |

15 | 8.0 | 75 |

| Annealed copper |

101 | 1.72 | 385 |

| Gold |

70 | 2.44 | 318 |

| Aluminum |

61 | 2.82 | 237 |

| Iron |

17 | 9.71 | 80 |

| Carbon steel |

10 | 15.0 | 50 |

| Stainless steel |

2.5 | 69.0 | 16 |

| Calcium |

29 | 6.0 | 200 |

| Beryllium |

43 | 4.0 | 190 |

| Rhodium |

38 | 4.7 | 150 |

| Magnesium |

39 | 4.45 | 160 |

| Molybdenum |

32 | 5.3 | 138 |

| Iridium |

19 | 8.8 | 150 |

| Tungsten |

31 | 5.6 | 174 |

| Zinc |

28 | 5.9 | 116 |

| Cobalt |

17 | 9.8 | 100 |

| Cadmium |

25 | 6.8 | 97 |

| Nickel (electrolytic) |

22 | 7.0 | 90 |

| Ruthenium |

19 | 8.9 | 117 |

| Lithium |

11 | 9.28 | 85 |

| Platinum |

16 | 10.6 | 72 |

| Palladium |

16 | 10.8 | 72 |

| Tin |

15 | 11.0 | 67 |

| Selenium |

1 | 100.0 | 20 |

| Tantalum |

13 | 13.5 | 57 |

| Niobium |

16 | 10.8 | 54 |

| Cast steel |

8 | 20.0 | 40 |

| Chromium |

8 | 20.0 | 94 |

| Lead |

7 | 21.0 | 35 |

| Vanadium |

9 | 18.0 | 31 |

| Uranium |

6 | 25.0 | 27 |

| Antimony* |

4 | 39.0 | 24 |

| Zirconium |

7 | 23.0 | 22 |

| Titanium |

4 | 42.0 | 22 |

| Mercury |

1 | 95.0 | 8.3 |

| Germanium* |

0.1 | 470.0 | 60 |

| Silicon* |

0.01 | 640.0 | 150 |

Metals with the Highest Electrical Conductivity

Electrical conductivity is usually measured relative to IACS (International Annealed Copper Standard, 100% = pure copper). Here are the top performers:

| Metal |

Electrical Conductivity (% IACS) |

Key Uses |

| Silver (Ag) |

105% | High-end electronics, connectors, RF components, solar panels, satellites |

| Copper (Cu) |

100% | Power cables, wiring, motors, transformers, PCBs |

| Gold (Au) |

~70% | Reliable electrical contacts, connectors in aerospace, medical, telecom |

| Aluminum (Al) |

~61% | Overhead power lines, busbars, lightweight electrical systems |

| Calcium (Ca) |

~29% | Rarely used in pure form, but calcium alloys are used in batteries |

| Beryllium (Be) |

~43% | Beryllium-copper alloys for springs, connectors, aerospace parts |

| Magnesium (Mg) | ~39% | Lightweight electrical housings, aerospace structures |

Detailed Explanation & Uses

Silver (Ag) –

Copper (Cu) –

Gold (Au) –

Aluminum (Al) –

Beryllium (Be) –

Magnesium (Mg) –

Summary:

The electrical conductivity of a metal depends mainly on how easily its electrons can move. Three major factors explain the differences:

1. Number of Free Electrons (Valence Electrons)

2. Atomic Structure & Electron Scattering

In good conductors, the atomic lattice is very uniform, so electrons can travel without bumping into atoms.

In poorer conductors, atoms scatter electrons more due to irregularities.

Example: Copper vs. Brass

3. Temperature Effect

Quick Analogy

Think of electricity like cars on a highway:

Summary

Table: Why Some Metals Are More Conductive Than Others

| Metal |

Valence Electrons (Free e⁻) |

Atomic Structure Notes |

Relative Conductivity |

Main Uses |

| Silver (Ag) |

1 | Very low resistivity, minimal electron scattering | ★★★★★ (Highest) | High-end electronics, aerospace, contacts |

| Copper (Cu) |

1 | Stable crystal lattice, excellent electron flow | ★★★★☆ | Wiring, motors, CNC electrodes |

| Gold (Au) |

1 | Resistant to oxidation, stable electron movement | ★★★★☆ | Connectors, microchips, medical devices |

| Aluminum (Al) |

3 | Lightweight, more scattering than Cu | ★★★☆☆ | Power lines, aerospace, automotive |

| Magnesium (Mg) |

2 | Lightweight but higher resistivity | ★★☆☆☆ | Aerospace alloys, lightweight parts |

| Iron (Fe) |

2 | Strong scattering, lattice vibrations | ★★☆☆☆ | Structural steels, machinery |

| Stainless Steel |

Varies (complex alloys) | High scattering due to mixed elements | ★☆☆☆☆ | CNC parts, corrosion-resistant structures |

| Brass (Cu + Zn) |

Mixed | Alloying increases scattering | ★☆☆☆☆ | Decorative parts, low-conductivity fittings |

Key Takeaway:

Electrical conductivity determines how efficiently a metal allows electric current to pass through it. For industries such as CNC machining, electronics, and aerospace, choosing the right material is critical to ensure performance, durability, and cost-effectiveness. Several factors influence conductivity, from the type of material itself to external conditions like temperature and processing methods.

Material

Each metal has a unique number of free electrons available for conduction.

Cross-Sectional Area

A thicker conductor provides more pathways for electrons to move, reducing resistance.

Conductor Length

The longer the conductor, the greater the resistance.

Temperature

As temperature rises, metal atoms vibrate more, causing electron scattering.

Impurities and Defects

Any imperfection in the crystal lattice—such as voids, dislocations, or trapped elements—disrupts electron flow.

Alloying

Mixing metals creates alloys (e.g., brass, bronze, stainless steel) that are stronger but less conductive.

Processing

Manufacturing techniques like annealing, cold working, or CNC machining can alter conductivity.

Key Insight for Customers:

When selecting materials for CNC machined parts, always balance conductivity with strength, corrosion resistance, and cost. Pure metals like copper or silver excel in conductivity, while alloys like stainless steel are preferred for mechanical durability.

Table: Factors Affecting Electrical Conductivity of Metals

| Factor |

Effect on Conductivity |

Example / Notes |

| Material |

Pure metals (Ag, Cu, Au) conduct better than alloys. | Copper wires > Stainless steel. |

| Cross-Sectional Area |

Larger area lowers resistance → improves conductivity. | Thick aluminum power cables vs thin wires. |

| Conductor Length |

Longer length increases resistance → lowers conductivity. | Short copper connections used in electronics. |

| Temperature |

Higher temperature increases atomic vibration → reduces conductivity. | Copper wires heat up → resistance rises. |

| Impurities & Defects |

Impurities and crystal defects scatter electrons → lower conductivity. | High-purity copper vs industrial-grade copper. |

| Alloying |

Mixing metals increases scattering → reduces conductivity compared to pure metals. | Brass, bronze, stainless steel < Pure copper. |

| Processing |

Annealing improves conductivity, cold-working reduces it; machining affects surface contact. | Annealed copper (high conductivity) vs hardened copper. |

Takeaway for Customers:

When choosing materials for CNC machined parts or electrical applications, prioritize pure, well-processed metals like copper or silver if conductivity is critical. For structural strength or corrosion resistance, alloys may be better even though they sacrifice conductivity.

When designing alloys for electrical applications, the goal is usually to improve conductivity while maintaining mechanical strength, corrosion resistance, or other desirable properties. Not all metals are equally effective as additives.

1. Copper (Cu) – The Most Common Conductivity Enhancer

Why: Copper has excellent electrical conductivity (~100% IACS), good ductility, and compatibility with many metals.

Uses:

CNC Machining Insight: Copper-rich alloys are preferred for CNC machined parts that require both strength and electrical performance.

2. Silver (Ag) – High-End Conductivity Booster

Why: Silver is the most conductive metal, but very expensive.

Uses: Specialty alloys for aerospace, medical, or microelectronics where maximum conductivity is critical.

Trade-off: Cost limits wide industrial use, but small additions can significantly improve conductivity.

3. Aluminum (Al) – Lightweight Conductivity Enhancer

Why: Aluminum has ~61% of copper’s conductivity but is much lighter.

Uses: Power transmission lines, busbars, and some aluminum alloys for lightweight conductive CNC parts.

Key Insight for Engineers & Manufacturers

Table: Metals Used to Increase Alloy Conductivity

| Metal |

Electrical Conductivity (% IACS) |

Key Benefits |

Typical Alloy Applications |

Notes for CNC Machining |

| Copper (Cu) |

100 | Excellent conductivity, ductile, widely compatible | Brass (Cu+Zn), Bronze (Cu+Sn), Beryllium-copper alloys | Ideal for CNC machined parts requiring high conductivity |

| Silver (Ag) |

105 | Highest conductivity, corrosion-resistant | Specialty aerospace alloys, microelectronics | Expensive; small additions boost conductivity |

| Aluminum (Al) |

61 | Lightweight, moderate conductivity | Aluminum-copper alloys, power busbars, overhead conductors | Suitable for lightweight CNC machined components |

| Gold (Au) |

~70 | Corrosion-resistant, stable conductivity | Electronic connectors, high-reliability circuits | Rarely used in bulk due to cost; surface plating common |

| Beryllium (Be) |

43 | Adds strength while maintaining reasonable conductivity | Beryllium-copper alloys for springs, relays, aerospace | Must be handled carefully due to toxicity; good for small precision parts |

Customer Tip:

When designing CNC machined parts or alloys for electrical components, copper is usually the most practical metal to enhance conductivity. Silver or gold are used selectively for high-performance or corrosion-resistant applications, while aluminum is excellent when weight savings are critical.

Electrical conductivity is a fundamental property that defines how easily a metal allows electrons to flow. For engineers, designers, and manufacturers, understanding conductivity is critical when selecting materials for metal CNC machined parts, electrical systems, and thermal applications. High conductivity ensures efficiency, safety, and durability in a wide range of applications.

Electrical Wiring

Heat Transfer

Welding and Soldering

Summary:

High electrical conductivity is crucial for:

Selecting the right metals ensures energy efficiency, durability, and performance in CNC machined parts and electrical systems.

Understanding electrical conductivity is essential for selecting the right metals for both industrial and precision applications. Metals like silver, copper, and gold excel in conductivity, making them ideal for CNC machined parts, electrical wiring, connectors, and heat-sensitive components. Alloys can provide additional strength, corrosion resistance, or lightweight properties, but often at the cost of reduced conductivity.

Factors such as material purity, cross-sectional area, length, temperature, alloying, and processing all influence how effectively a metal conducts electricity. Engineers and manufacturers must balance these factors to ensure optimal performance, energy efficiency, and durability in their designs.

For applications where maximum conductivity is critical, metals like copper or silver should be prioritized, while aluminum and specialty alloys are better suited for weight-sensitive or mechanically demanding parts. In CNC machining services, choosing the right conductive material ensures precision, reliability, and long-term performance for both standard and custom components.

By understanding the properties and uses of conductive metals, businesses can make informed decisions that reduce costs, improve efficiency, and enhance the quality of metal CNC machined parts and electrical assemblies.

1. Is gold a better conductor of electricity than copper?

Gold has slightly lower conductivity than copper (~70% IACS vs 100% IACS), but it is highly corrosion-resistant. Gold is preferred in connectors and electronics where reliability is critical, while copper is used for general wiring and power transmission.

2. Is brass conductive?

Yes, brass conducts electricity, but its conductivity (~28% IACS) is much lower than pure copper. It is often used for decorative or mechanical parts rather than high-performance electrical applications.

3. Is copper conductive?

Absolutely. Copper is one of the best electrical conductors (~100% IACS) and is widely used in wiring, motors, transformers, and CNC machined parts.

4. What are the uses of copper?

Copper is used in electrical wiring, busbars, motors, transformers, heat sinks, plumbing, and CNC machined components that require high conductivity and durability.

5. Which material has a conductivity of 98%?

High-purity copper can achieve ~98–100% IACS, making it one of the most conductive commercially available metals.

6. What is a good value for electrical conductivity?

For high-performance applications, metals with >90% IACS (copper, silver) are excellent. For general applications, 50–70% IACS (aluminum, gold) is sufficient.

7. Which metals don't conduct electricity?

Non-metals like rubber, glass, plastics, and ceramics do not conduct electricity. Some metalloids (e.g., silicon, germanium) have very low conductivity.

8. What causes high electrical conductivity?

High conductivity results from free electrons, uniform crystal lattices, low impurities, and minimal electron scattering.

9. What makes metals good conductors?

Metals with loosely bound valence electrons, simple atomic structures, and minimal alloying tend to be excellent conductors.

10. Why do only metals conduct electricity?

Metals have delocalized electrons that can move freely throughout the lattice, unlike non-metals, which have tightly bound electrons.

11. What can increase electrical conductivity?

Using pure metals, reducing impurities, minimizing defects, proper annealing, and adding highly conductive elements (like copper or silver in alloys) can improve conductivity.

12. What determines the conductivity of a metal?

Factors include material type, temperature, alloying, processing, cross-sectional area, and purity.

13. What are the different types of electrical conductivity?

14. What is the difference between electrical conductivity and electrical conductivity?

Often this refers to specific vs. bulk conductivity:

15. How is electrical conductivity measured?

Using instruments like four-point probes, Wheatstone bridges, or conductivity meters, which measure resistance and calculate conductivity.

16. Which metal has the highest thermal conductivity?

Silver has the highest thermal conductivity (~429 W/m·K), followed by copper (~401 W/m·K), making them ideal for both electrical and thermal applications.