15 years one-stop China custom CNC machining parts factory

530 |

Published by VMT at Nov 24 2024 | Reading Time:About 4 minutes

530 |

Published by VMT at Nov 24 2024 | Reading Time:About 4 minutes

Are you struggling to achieve the desired durability, aesthetics, or functionality in your metal products? Frustrated by corrosion, surface defects, or poor adhesion of paints and coatings that compromise the quality of your metal CNC machined parts? You're not alone. Many manufacturers and engineers face challenges in selecting the right metal surface finishing processes, leading to subpar products and customer dissatisfaction. But what if you could transform your metal components with the perfect surface finish, enhancing performance and extending their lifespan?

Metal surface finishing processes are finishings applied to metal surfaces to enhance appearance, improve corrosion resistance, increase durability, and prepare the surface for additional processing like painting or coating. Common methods include plating, anodizing, grinding, polishing, powder coating, sandblasting, and heat finishings, each offering unique benefits for various applications.

Understanding these metal surface finishing processes is crucial for anyone involved in metal CNC machining, custom CNC machining, or working with CNC machined parts. In this comprehensive guide, we'll delve into the basics of surface finishings, explore why they're essential, examine various finishing methods, and provide insights to help you select the right process for your specific needs.

Preface

Metal surface finishing is a critical aspect of manufacturing that directly impacts the performance, longevity, and aesthetics of metal components. Whether you're a CNC machining shop producing custom parts or a manufacturer seeking to enhance your products, understanding surface finishing processes is vital. This guide aims to provide a thorough exploration of metal surface finishes, their importance, and the different methods available, ensuring that your metal components meet the highest standards of quality and functionality.

Surface finishing refers to a variety of processes applied to the surface of a metal to alter its physical, chemical, or mechanical properties. These finishings can improve appearance, enhance corrosion resistance, increase hardness, reduce friction, and prepare the metal for further processing like painting or adhesive bonding. In the context of metal CNC machining and CNC machining services, surface finishings are essential for producing high-quality CNC machined parts that meet specific performance requirements.

Surface finishings can be broadly categorized into two groups:

The choice of surface finishing depends on factors like the type of metal, desired properties, environmental conditions, and the intended application of the part. Surface finishings are integral to industries ranging from aerospace and automotive to electronics and medical devices, where precision and reliability are paramount.

Surface finishing plays a pivotal role in the performance and longevity of metal components. Without appropriate finishing processes, metals can be susceptible to corrosion, wear, and other forms of degradation that compromise functionality. For manufacturers engaged in metal CNC machining and custom CNC machining, surface finishings are not just an optional enhancement but a necessary step to meet industry standards and customer expectations.

Benefits of Surface Finishing Processes Include:

Increase Durability

Surface finishings can significantly enhance the durability of metal parts. Processes like heat finishing and hard plating increase the hardness and wear resistance of the surface, allowing components to withstand mechanical stress and prolonging their service life. This is especially important in applications where parts are subjected to friction, impact, or abrasive conditions.

Improve Corrosion Resistance

Metals are prone to oxidation and corrosion when exposed to environmental elements like moisture, chemicals, and salts. Surface finishings such as anodizing, plating, and passivation form protective layers that shield the metal from corrosive agents. This not only maintains the integrity of the part but also reduces maintenance costs and prevents premature failure.

Eliminate Surface Defects

Surface defects like scratches, pits, and burrs can affect the performance and appearance of metal parts. Finishing processes like grinding, polishing, and sandblasting remove imperfections, resulting in smooth surfaces that meet precise specifications. This is crucial in CNC prototype machining, where exact dimensions and flawless surfaces are required.

Aid Adhesion of Paint and Other Coatings

For paints, adhesives, and other coatings to adhere properly to metal surfaces, the surface must be prepared adequately. Finishings like sandblasting and chemical etching clean and roughen the surface, enhancing adhesion and ensuring that coatings bond effectively. This is vital in applications where coated surfaces provide additional functionalities, such as insulation or aesthetic appeal.

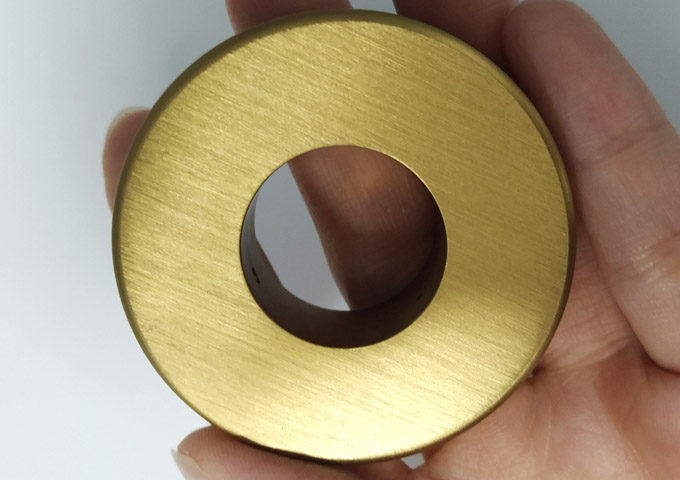

Enhance Aesthetics

Surface finishings can greatly improve the visual appearance of metal parts. Processes like polishing, anodizing, and plating offer various finishes ranging from matte to mirror-like shine, as well as color options. This is important in consumer products, automotive parts, and architectural elements where appearance influences marketability and brand perception.

Improve Chemical Resistance

In environments where metal parts are exposed to harsh chemicals or extreme conditions, surface finishings can provide necessary protection. Coatings like chemical films and specialized platings create barriers that prevent chemical reactions between the metal and its surroundings. This is essential in industries like chemical processing and marine applications.

Improve Conductivity

Certain applications require metal parts to have specific electrical or thermal conductivity properties. Surface finishings can enhance or reduce conductivity as needed. For example, electroplating with metals like copper or silver can improve electrical conductivity, which is crucial in electronic components and connectors.

High Strength, Wear Resistance

By modifying the surface properties through finishings like carburizing or nitriding, metal parts can achieve higher strength and wear resistance without altering the core material. This allows for the production of components that are both robust and lightweight, meeting the demands of advanced engineering applications.

In summary, surface finishing is a critical step in the manufacturing process that enhances the functionality, reliability, and aesthetics of metal parts. For those involved in CNC machining services, understanding and selecting the appropriate surface finishing is key to delivering high-quality products that meet or exceed industry standards.

There is a wide array of metal surface finishing processes available, each designed to achieve specific outcomes. Selecting the right process depends on the material, desired properties, application, and environmental considerations. Below, we explore various types of metal surface finishings commonly used in metal CNC machining and CNC machining shops.

Plating or Conversion Coating

Plating involves applying a thin layer of metal onto the surface of a workpiece to enhance its properties. Conversion coating, on the other hand, chemically alters the surface layer of the metal to form a protective layer. These processes serve to improve corrosion resistance, increase hardness, enhance appearance, and provide other functional benefits.

There Are Two Main Types of Plating:

Electroplating

Electroplating uses an electrical current to reduce dissolved metal cations, allowing them to form a coherent metal coating on an electrode. The workpiece acts as the cathode in an electrolytic cell, and the metal to be plated is the anode. Electroplating is widely used for:

Electroplating requires careful control of the plating bath composition, temperature, current density, and time to achieve the desired thickness and quality.

Electroless Plating

Electroless plating deposits a metal coating on a substrate without the use of an external electrical power source. Instead, it relies on a chemical reduction reaction in an aqueous solution, where the reducing agent supplies the necessary electrons. Common electroless plating processes include:

Electroless plating offers advantages like even coating on complex shapes and internal surfaces, making it valuable for intricate CNC machined parts.

Anodizing

Anodizing is an electrochemical process that converts the metal surface into a durable, corrosion-resistant anodic oxide finish. While commonly associated with aluminum, it can also be applied to titanium, magnesium, and other metals.

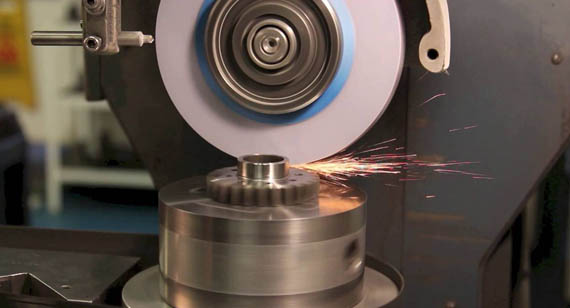

Metal Grinding

Metal grinding is a subtractive process that uses an abrasive wheel to remove material from the surface of a workpiece. It is employed to achieve a specific surface finish, dimensional accuracy, or to prepare the metal for subsequent finishing processes.

Types of Grinding:

Grinding is essential in producing precise CNC machined parts with tight tolerances and specific surface roughness requirements.

Polishing/Grinding

Polishing involves using abrasive materials to produce a smooth and reflective surface. It removes scratches, pits, and other minor imperfections, enhancing both appearance and functionality.

Mechanical Polishing: Uses abrasives like sandpaper, polishing compounds, and buffing wheels.

Electrolytic Polishing

Also known as electropolishing, this process removes material from a metal workpiece using an electrochemical bath. The part serves as the anode, and when an electric current is applied, metal ions are dissolved from the surface.

Advantages:

Applications: Widely used in the pharmaceutical, food processing, and medical industries where cleanliness and smooth surfaces are critical.

Powder Coating

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto electrically grounded parts. The coated parts are then heated in a curing oven, causing the powder to melt and form a uniform, durable finish.

Benefits:

Applications: Used in automotive components, appliances, outdoor equipment, and architectural elements.

Sandblasting

Sandblasting, also known as abrasive blasting, is a process where a stream of abrasive material is propelled against a surface under high pressure to clean, smooth, or roughen it. It is a preparatory step before painting, coating, or other finishing processes.

Purposes:

Typical Sandblasting Machinery Includes:

Sandblasting is versatile and effective, making it a common practice in CNC machining shops for preparing metal surfaces.

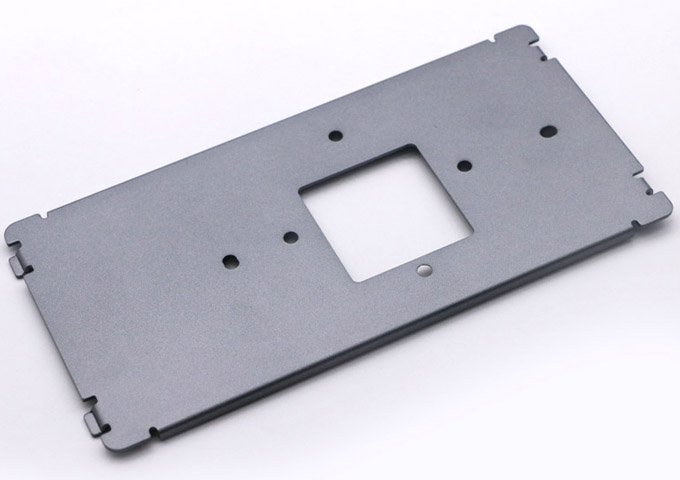

Brushing

Brushing is a surface finishing technique that uses an abrasive belt or wire brush to create a unidirectional satin finish on the metal. It is less reflective than polishing but offers an attractive appearance.

Characteristics:

Applications: Often used in stainless steel appliances, architectural panels, and decorative elements.

Painting

Painting involves applying liquid paint to the metal surface, providing both protective and aesthetic benefits.

Process:

Advantages:

Passivation

Passivation is a chemical finishing that enhances the corrosion resistance of stainless steel and other metals by removing free iron and other contaminants from the surface.

Process:

Benefits:

Applications: Essential in medical devices, food processing equipment, and aerospace components.

Black Oxide

Black oxide is a conversion coating for ferrous materials, stainless steel, copper, and copper-based alloys. It produces a matte black appearance and mild corrosion resistance.

Process:

Chemical Reaction: Metal is immersed in an alkaline aqueous salt solution operating at elevated temperatures.

Benefits:

Applications: Used in tooling, firearms, and decorative hardware.

Chemical Film (Chromate Conversion Coating)

Chromate conversion coating is a type of conversion coating applied to aluminum and its alloys to increase corrosion resistance and prepare surfaces for painting.

Process:

Benefits:

Applications: Aerospace parts, electronic housings, and connectors.

Electroless Nickel Plating

Electroless nickel plating deposits a layer of nickel-phosphorus or nickel-boron alloy on a metal or plastic substrate through autocatalytic chemical reduction.

Advantages:

Applications: Valves, pumps, molds, and electronic components.

Zinc Plating

Zinc plating applies a thin layer of zinc to steel or iron parts to prevent rusting.

Process:

Benefits:

Applications: Fasteners, bolts, and automotive components.

Heat Finishing Finishing

Heat finishing involves controlled heating and cooling of metals to alter their physical and mechanical properties without changing the product shape.

Processes:

Benefits:

Applications: Essential in tool making, automotive parts, and any application requiring specific mechanical characteristics.

Measuring surface finish is critical in verifying that a metal part meets the specified roughness and texture requirements. Accurate measurement ensures functionality, performance, and aesthetics, which are essential in CNC machined parts.

Common Methods to Measure Surface Finish Include:

Using a Surface Roughness Comparator

A surface roughness comparator is a tactile tool that allows an inspector to compare the surface finish of a machined part against standardized samples with known roughness values.

Process:

Advantages:

Limitations:

Using a Surface Profile Scanner

Surface profile scanners, such as profilometers, use a stylus that moves over the surface to measure its roughness.

Types:

Parameters Measured:

Advantages:

Applications: Used in quality control for critical components.

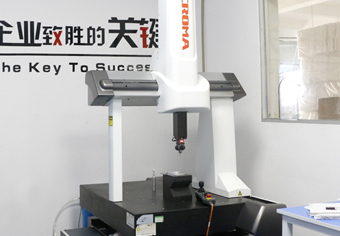

Using a Coordinate Measuring Machine (CMM)

A CMM is a device that measures the geometry of physical objects by sensing discrete points on the surface with a probe.

Process:

Probe Contact: Touches various points to create a 3D map.

Benefits:

Considerations:

Surface finish roughness charts provide visual and numerical representations of different surface textures, correlating specific roughness values with machining processes.

Common Parameters Include:

Surface Roughness Chart References

Surface roughness charts are essential tools for engineers and machinists in:

For example, a machined part requiring a smooth finish might specify an Ra value of 0.8 µm, indicating the need for fine grinding or polishing. Conversely, a rougher finish with an Ra of 6.3 µm might be acceptable for non-critical surfaces.

Understanding these charts ensures that all stakeholders, from designers to machinists, are aligned on the surface finish expectations.

Choosing the appropriate surface finishing process is a critical decision that affects the performance, cost, and success of a metal component. Several factors must be considered to ensure that the selected process aligns with the specific needs of the application.

Materials

Speed

Appearance

Environmental Impacts

Applications

Cost

By carefully evaluating these factors, manufacturers and engineers can select the most appropriate surface finishing process, ensuring optimal performance and cost-effectiveness.

Metal surface finishing processes are indispensable in modern manufacturing, significantly enhancing the functionality, durability, and aesthetics of metal components. Whether involved in metal CNC machining, custom CNC machining, or operating a CNC machining shop, understanding the various surface finishings is crucial. From plating and anodizing to grinding and polishing, each process offers unique benefits tailored to specific applications and requirements.

By selecting the appropriate surface finishing, manufacturers can produce CNC machined parts that not only meet but exceed industry standards and customer expectations. This comprehensive guide serves as a valuable resource, providing the knowledge needed to make informed decisions in the complex world of metal surface finishing.

At VMT, we specialize in providing high-quality CNC prototype machining and CNC machining services, offering a wide range of metal surface finishing options to meet your specific needs. Our experienced team understands the importance of surface finishings in enhancing the performance and appearance of your metal components.

Our Services Include:

By choosing VMT, you gain a partner committed to delivering excellence in every aspect of metal CNC machining and surface finishing. Contact us today to discuss your project requirements and discover how we can help bring your ideas to life.

How Do I Define Surface Finish?

Surface finish refers to the texture and quality of a surface, characterized by its roughness, waviness, and lay. It describes the microscopic peaks and valleys on a material's surface, affecting appearance, friction, wear, and how the part interacts with other components. Surface finish is typically quantified using parameters like Ra (average roughness) and measured with specialized equipment like profilometers.

What Is the Best Surface Finish for Steel?

The best surface finish for steel depends on the application and desired properties. For corrosion resistance, galvanizing or applying a zinc coating may be suitable. For aesthetic appeal and wear resistance, processes like electropolishing or chrome plating might be preferred. In applications requiring high precision and smoothness, grinding or superfinishing can achieve finishes with low Ra values.

What Is Metal Surface Finish?

Metal surface finish encompasses the various finishings and processes applied to a metal's surface to alter its texture, appearance, and physical properties. It includes mechanical processes like grinding and polishing, chemical finishings like passivation and anodizing, and coating methods like plating and painting. The goal is to enhance the metal's functionality, durability, and aesthetics for specific applications.

How Do I Paint Metal Without Leaving Brush Marks?

To paint metal without leaving brush marks:

What Factors May Affect My Surface Finish?

Several factors can affect surface finish:

What Are the Main Causes of Uneven Surfaces?

Uneven surfaces can result from:

How Do I Check the Surface Finish of Metal?

To check the surface finish:

What Is the Difference Between Surface Roughness and Surface Finish?

What Is a 0.4 Micron Surface Finish?

A 0.4-micron surface finish refers to a surface roughness average (Ra) of 0.4 micrometers. This indicates a very smooth surface with minimal deviations. Achieving such a fine finish typically requires precision machining processes like superfinishing, lapping, or polishing. This level of smoothness is often required in applications like optical components, high-precision bearings, and sealing surfaces.

By thoroughly understanding metal surface finishes and the various processes involved, you can make informed decisions that enhance the quality and performance of your metal components. Whether you're involved in metal CNC machining, producing custom CNC machined parts, or seeking reliable CNC machining services, selecting the right surface finishing is essential for success.