15 years one-stop China custom CNC machining parts factory

241 |

Published by VMT at Nov 02 2024 | Reading Time:About 2 minutes

241 |

Published by VMT at Nov 02 2024 | Reading Time:About 2 minutes

Are you struggling with dull and uneven surfaces on your CNC machined parts? Vapor polishing can transform your components, offering a smooth, shiny finish that enhances both aesthetics and performance. Discover how this innovative process works and how it can benefit your manufacturing projects.

Vapor polishing is a surface treatment technique that uses vaporized solvents to smooth and shine plastic parts. This process enhances optical clarity, improves aesthetics, and is ideal for complex geometries. Whether in medical devices or consumer products, vapor polishing can elevate the quality of your components.

Let’s delve into the world of vapor polishing, exploring its processes, best practices, and applications across various industries.

Introduction

Vapor polishing, also known as vapor polishing, is a specialized technique used primarily to achieve smooth, shiny surfaces on thermoplastics. This process is particularly beneficial for parts manufactured through CNC machining, as it enhances the final appearance while maintaining the integrity of the material. By utilizing vaporized solvents, vapor polishing can effectively remove surface imperfections and improve the overall quality of the product. Understanding this process is essential for manufacturers looking to enhance their offerings and meet stringent aesthetic and functional standards.

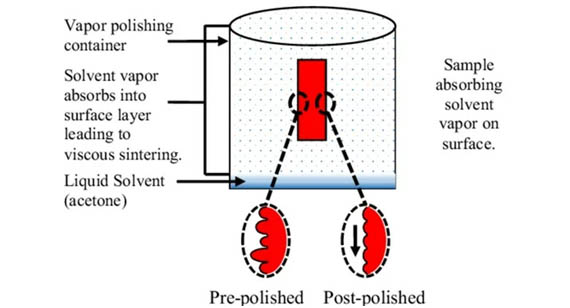

Vapor polishing involves the use of vaporized solvents to smooth the surface of plastic parts. During the process, the workpiece is exposed to solvent vapors, which interact with the surface material. This interaction leads to the melting of the top layer of plastic, effectively leveling out any imperfections and creating a polished finish. Unlike traditional polishing methods that may introduce mechanical stress or require extensive manual labor, vapor polishing offers a gentler approach that is both efficient and effective.

The vapor polishing process is built upon several key steps that ensure optimal results. Understanding these steps is crucial for implementing this technique effectively in your manufacturing operations.

Vapor Polishing Process

Heating Solvents

The first step in the vapor polishing process involves selecting and heating the appropriate solvent. Solvents like acetone, methyl ethyl ketone (MEK), or tetrahydrofuran (THF) are commonly used due to their ability to effectively vaporize and interact with plastic surfaces. Heating the solvent prepares it for vapor generation, allowing it to transition into the gaseous state.

Vapor Generation

Once the solvent reaches the desired temperature, it begins to vaporize, creating a cloud of solvent vapor. This vapor contains the active agents that will smooth the plastic surface upon contact. It’s crucial to control the temperature during this stage to avoid degradation of the solvent or the plastic.

Spraying

The next step involves directing the vapor towards the workpiece. This can be done using specialized equipment that allows for uniform distribution of the vapor over the surface. Proper application is key to ensuring that every part of the workpiece receives adequate exposure to the vapor, leading to consistent results.

Note:

For best results, the entire process should be carefully controlled. Monitoring factors such as temperature, exposure time, and solvent concentration will contribute significantly to the quality of the final finish.

To effectively carry out vapor polishing, following a structured step-by-step guide is essential.

Step 1: Prepare the Part

Before beginning the polishing process, it’s important to clean the part thoroughly. Any dust, grease, or contaminants can affect the quality of the polish.

Step 2: Heating the Solvent

Heat the chosen solvent to its vaporization temperature. Ensure that the heating equipment is suitable for the solvent to avoid any hazards.

Step 3: Vapor Generation

Allow the solvent to generate vapor in a controlled environment, such as a vapor chamber designed specifically for polishing processes.

Step 4: Spraying Vapor

Introduce the vapor to the part, ensuring even coverage. Adjust the distance and angle of the spray to maximize exposure.

Step 5: Dwell Time for Optimal Results

Let the vapor sit on the part for a predetermined amount of time, allowing it to interact with the surface effectively. The ideal dwell time may vary depending on the material and desired finish.

Step 6: Controlled Cooling

After the dwell time, carefully cool the part to solidify the surface layer. Rapid cooling can lead to warping or other structural issues.

Step 7: Inspection and Quality Assurance

Inspect the polished surface to ensure it meets the desired quality standards. Any inconsistencies should be addressed before finalizing the product.

Step 8: Finishing and Final Inspection

Once satisfied with the polishing results, conduct a final inspection to confirm that the part is ready for use or further processing.

Selecting the right solvent is crucial for achieving effective vapor polishing results. Various solvents have different properties that influence the polishing process.

Acetone

Acetone is a commonly used solvent due to its effectiveness and quick evaporation rate. It works well on many plastics, providing a shiny finish.

Methyl Ethyl Ketone (MEK)

MEK is another effective solvent that can smooth and enhance the finish of various thermoplastics.

Tetrahydrofuran (THF)

THF is particularly effective for certain types of plastics, providing excellent results in terms of clarity and smoothness.

Dichloromethane (DCM)

DCM can also be used, but it requires careful handling due to its environmental impact and potential health hazards.

Choosing the Right Solvent

The choice of solvent depends on the specific material being polished and the desired finish. It's important to conduct preliminary tests to determine the best solvent for your particular application.

To achieve optimal results in vapor polishing, following best practices is essential.

Solvent Selection

Choose the appropriate solvent based on the material and desired finish. Always refer to manufacturer guidelines for compatibility.

Temperature Control

Maintain precise temperature control throughout the process to prevent damage to the workpiece or solvent degradation.

Safety Considerations

Always prioritize safety by using appropriate personal protective equipment (PPE) and ensuring proper ventilation in the workspace.

Cleaning Parts Before Smoothing

A clean surface is critical for achieving a high-quality finish. Make sure to remove any contaminants before starting the process.

Contact Time

Adjust the contact time based on the specific material and desired finish. Overexposure can lead to adverse effects.

Part Orientation

Ensure proper orientation of the parts during the process for uniform exposure to the vapor.

Part Geometry

Complex geometries may require special consideration in terms of vapor application to ensure even polishing.

Post-Processing

Consider additional post-processing steps, such as additional cleaning or coating, to enhance the final product.

Vapor polishing is particularly effective on various types of plastics, each offering unique properties that can benefit from this finishing technique.

Polycarbonate (PC)

Known for its strength and impact resistance, polycarbonate can achieve excellent clarity through vapor polishing.

Acrylic (PMMA)

Acrylic is highly amenable to vapor polishing, resulting in a glass-like finish that enhances transparency.

Polyetherimide (PEI)

PEI can also be vapor polished, improving its aesthetic appeal and surface quality.

Nylon

Nylon parts benefit from vapor polishing, achieving smoother surfaces that reduce friction.

Acrylonitrile Butadiene Styrene (ABS)

ABS is commonly polished using vapor methods, leading to enhanced surface smoothness and appearance.

Vapor polishing offers numerous benefits, making it a valuable technique in various manufacturing applications.

Enhanced Optical Clarity

The process can significantly improve the optical clarity of plastic parts, making them more visually appealing.

Increased Surface Smoothness

By removing surface imperfections, vapor polishing creates a smoother finish that can enhance product performance.

Improved Light Transmission

Polished parts allow for better light transmission, which is particularly important in applications such as lighting fixtures.

Improved Product Aesthetics

The shiny finish achieved through vapor polishing elevates the overall aesthetic of the product, making it more marketable.

Surface Enhancement

The process can improve surface properties, making parts more resistant to environmental stressors.

Great for Medical Use

The smooth surfaces produced by vapor polishing are ideal for medical devices, where cleanliness and aesthetics are crucial.

Shortened Lead Times

Vapor polishing can streamline production times, reducing lead times for finished products.

No Mechanical Stress

Unlike mechanical polishing, vapor polishing does not introduce additional stress to the material, preserving its structural integrity.

Complex Geometries

The process is particularly beneficial for parts with complex geometries, allowing for uniform polishing that would be challenging with other methods.

Cost management is a critical aspect of any manufacturing process. Here are some strategies to reduce costs associated with vapor polishing.

Optimize Part Design

Simplifying designs can lead to reduced polishing time and material waste, ultimately lowering costs.

Choose the Right Material

Selecting materials that are more amenable to vapor polishing can save time and reduce solvent consumption.

Batch Processing

Polishing multiple parts in a single batch can improve efficiency and lower overall costs.

Use Automated Equipment

Investing in automated polishing equipment can streamline the process and reduce labor costs.

Outsource to a Specialist Supplier

Working with specialized polishing services can provide cost-effective solutions, particularly for larger production runs.

The lead time for vapor polishing projects can vary based on factors such as the complexity of the parts, the volume being polished, and the availability of equipment. Generally, vapor polishing is a relatively quick process, but planning and scheduling are essential to ensure timely delivery.

Choosing between vapor polishing and manual polishing involves considering several factors:

Applicable Materials

Assess the materials being used to determine which polishing method is more suitable.

Efficiency and Manufacturing Speed

Vapor polishing generally offers faster results, while manual polishing may require more time and labor.

Finish Quality

Vapor polishing typically yields a more consistent finish, while manual methods can vary.

Mechanism of Action

Consider how each method affects the material and what outcomes are desired.

Cost

Evaluate the cost implications of both methods based on the specific project requirements.

Accessibility and Complexity

Some projects may be better suited for vapor polishing due to accessibility issues or complex geometries.

Vapor polishing is utilized in a variety of industries, each benefiting from the enhanced aesthetics and performance of polished components.

In the medical field, vapor polishing ensures that devices are not only functional but also visually appealing and easy to clean.

Food Processing

Equipment in the food processing industry often requires smooth surfaces to meet hygiene standards and improve efficiency.

Consumer Products

From kitchenware to electronic casings, vapor polishing enhances the appeal and functionality of consumer goods.

Automotive components benefit from vapor polishing, achieving both aesthetic and performance enhancements.

In electronics, polished parts can improve heat dissipation and aesthetic appeal.

If you're looking to enhance your CNC machined parts with vapor polishing, consider partnering with a reliable service provider. By utilizing expert techniques and high-quality solvents, you can achieve the smooth, shiny surfaces that elevate your products.

Vapor polishing is a powerful technique that can significantly enhance the quality and appearance of CNC machined parts. By understanding the process, best practices, and applications, manufacturers can leverage this technology to improve their offerings and meet market demands.

Does the workpiece need to be ground first?

While grinding can improve initial surface quality, it is not always necessary. Vapor polishing can effectively smooth out imperfections.

Is the vapor polishing process dangerous?

Safety precautions should always be followed, as solvents can be hazardous. Proper ventilation and PPE are essential.

What is acetone vapor polishing?

Acetone vapor polishing specifically uses acetone as the solvent in the vapor polishing process to achieve smooth finishes on plastic parts.

Is vapor polishing harmful to the environment?

Some solvents can have environmental impacts. It’s crucial to handle and dispose of solvents properly to minimize harm.

How long does it take to prepare for a vapor polishing project?

Preparation time can vary, but thorough cleaning and setup typically take a few hours.

Is vapor polishing a cost-effective process?

Yes, vapor polishing can be cost-effective due to its efficiency and the quality of finish it provides.

Can polycarbonate be smoothed with acetone?

Yes, polycarbonate can be effectively smoothed using acetone vapor polishing.

How long does acetone vapor smoothing usually take?

The process generally takes a few minutes to achieve optimal results, depending on the part and desired finish.

By leveraging vapor polishing technology, manufacturers can enhance their CNC machined parts, ensuring high-quality finishes that meet the demands of various applications.