15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

683 |

Published by VMT at Nov 03 2024 | Reading Time:About 2 minutes

683 |

Published by VMT at Nov 03 2024 | Reading Time:About 2 minutes

Choosing the right helix angle can significantly impact your machining results. Understanding the nuances of helix angles is crucial for optimizing productivity and achieving superior surface finishes.

This guide will help you understand helix angles in machining, including how to select the right angle for your cutting tools. Discover the differences between high, low, and variable helix angles and their applications to enhance machining performance.

Let’s delve deeper into the intricacies of helix angles and their implications for your machining projects.

Introduction

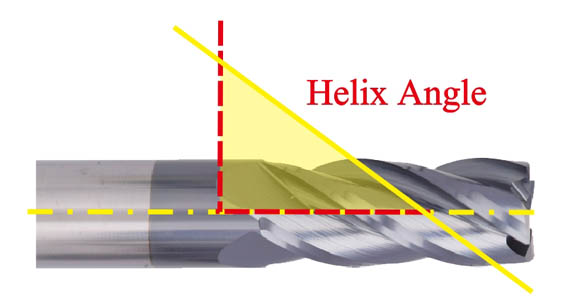

In the world of machining, precision is key. One of the most critical factors influencing cutting performance is the helix angle of cutting tools. The helix angle refers to the angle formed by the cutting edge of the tool relative to the axis of the tool. This angle plays a significant role in chip formation, cutting efficiency, and overall tool performance. Understanding helix angles is essential for selecting the appropriate machining applications and ensuring optimal results.

A helix is a three-dimensional curve that spirals around an axis, forming a shape similar to a spring or a screw thread. In machining, helix angles refer specifically to the design of cutting tools, such as end mills and drill bits, where the cutting edge is designed in a helical pattern. This design is crucial for facilitating the movement of chips away from the cutting area, allowing for smoother operations and improved surface finishes.

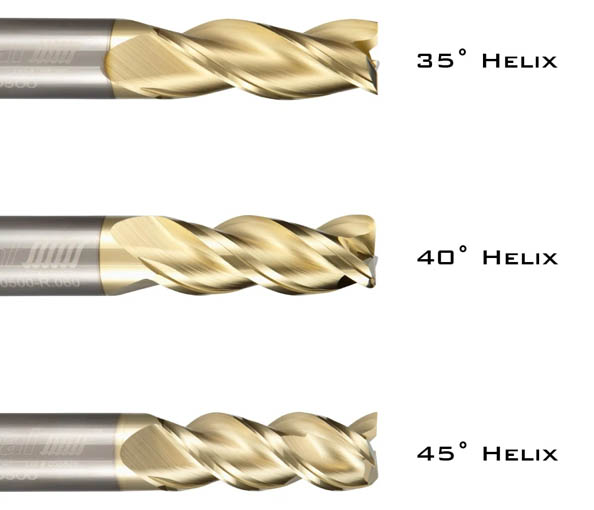

When considering helix angles, there are three primary types to explore:

High Helix: Tools with a high helix angle (generally over 35°) allow for better chip removal and are often used in softer materials. However, they can lead to increased cutting forces, making them less suitable for tougher materials.

Low Helix: Low helix angles (under 30°) are ideal for harder materials, as they offer better stability and control during machining. They can provide improved surface finishes but may struggle with chip evacuation.

Variable Helix: This type combines the benefits of both high and low helix angles. By varying the angle along the cutting edge, these tools can effectively manage chip formation and improve overall machining efficiency.

Advantages and Disadvantages of High Helix

High helix angles enhance chip removal and are suitable for softer materials, promoting faster machining speeds. However, they can generate higher radial forces, leading to instability in harder materials.

Advantages and Disadvantages of Low Helix

Low helix angles provide stability and precision, making them excellent for harder materials. However, their lower chip removal rate can lead to increased heat generation and slower machining speeds.

Advantages and Disadvantages of Variable Helix

Variable helix angles combine the best of both worlds, offering adaptability across different materials and conditions. However, they may be more complex to manufacture and thus could be more expensive.

To fully understand helix angles, it’s essential to consider their geometric features, including:

Central Axis: The imaginary line around which the helix is oriented.

Helix Angle: The angle of the cutting edge relative to the central axis, affecting cutting efficiency and chip removal.

Pitch: The distance between consecutive turns of the helix, influencing the depth of cut and material removal rate.

Number of Turns: The total number of spirals in the helix, impacting the tool’s performance characteristics.

In the context of cutting tools, the helix angle can dramatically influence the performance of the tool. Different materials and machining applications require specific helix angles for optimal results.

Overview of Carbide End Mill Helix Angles

0°: Generally used for specialized applications, providing maximum stability but limited chip removal.

30°: A versatile option, suitable for a range of materials with moderate chip removal capabilities.

35°-40°: This range is popular for aluminum and softer materials, enhancing chip removal while maintaining stability.

37°-45°: Commonly used for general machining applications, offering a good balance of chip removal and stability.

60°: Ideal for precision machining and threading, allowing for fine cuts.

Variable: Offers adaptability, catering to different materials and varying machining conditions.

When selecting cutting tools, the choice between high and low helix angles can be critical:

High Helix Angle Tools

These tools promote efficient chip removal and are best suited for softer materials, enhancing productivity. However, they may compromise stability and are less effective in tougher applications.

Low Helix Angle Tools

Designed for improved stability and control, these tools excel in machining harder materials. While they provide a better surface finish, their slower chip removal rate can lead to increased heat and wear.

Selecting the appropriate helix angle for your machining application involves several considerations:

Productivity Requirements: High productivity applications may benefit from higher helix angles, while stability may be prioritized in more intricate tasks.

Pockets: The depth and design of pockets in the workpiece will influence the choice of helix angle, as deeper pockets may require tools with specific angles for efficient machining.

Thin Walls/Thin Floors: In applications involving thin materials, a low helix angle can provide better control and reduce the risk of deformation.

Tool Life: Choosing the right helix angle can also extend tool life, as proper selection minimizes wear and tear.

Choosing the right helix angle for specific materials can enhance performance and efficiency. Softer materials may favor high helix angles for faster chip removal, while harder materials often benefit from low helix angles to ensure precision and reduce tool wear.

Understanding helix angles in machining is crucial for optimizing performance and achieving superior results. By carefully considering the type of helix angle and its applications, manufacturers can significantly improve productivity, surface finishes, and overall efficiency in their machining processes.

What Does Helix Angle Do?

The helix angle affects chip removal efficiency, cutting forces, and overall tool performance, influencing the quality of the machined surface.

What is the Helix Angle of a Milling Cutter?

The helix angle of a milling cutter can vary based on its design, typically ranging from 0° to 60°.

What is the Difference Between Lead Angle and Helix Angle?

While both angles influence cutting efficiency, the lead angle refers to the angle of the cutting edge relative to the cutting surface, while the helix angle relates to the spiral of the tool.

What is the Use of Helix Angle in Variable Helix End Mills?

Variable helix angles allow for optimized performance across a range of materials and conditions, enhancing chip management and tool stability.

Why is the Helix Angle Important in Machining?

The helix angle is critical in determining the effectiveness of a cutting tool, impacting chip removal rates, surface finishes, and overall machining efficiency.

What is the Difference Between the Helix Angle and the Lead Angle?

The helix angle is the angle of the cutting edge in relation to the tool’s axis, while the lead angle is the angle at which the cutting edge engages the material.

What is the Angle of the Machined Helix?

The angle of a machined helix depends on the design of the cutting tool, with various applications requiring different angles for optimal performance.

What is the Difference Between the Pitch and the Helix Angle?

Pitch refers to the distance between turns of the helix, while the helix angle is the angle formed between the tool's cutting edge and its central axis.

How to Calculate the Helix Angle?

The helix angle can be calculated using trigonometric functions based on the pitch and the diameter of the tool.

How to Measure the Helix Angle of an End Mill?

The helix angle can be measured using precision tools, such as a protractor or specialized measuring devices designed for cutting tools.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!