15 years one-stop China custom CNC machining parts factory

396 |

Published by VMT at Dec 04 2024 | Reading Time:About 5 minutes

396 |

Published by VMT at Dec 04 2024 | Reading Time:About 5 minutes

Imagine embarking on a product development journey only to encounter endless delays, skyrocketing costs, and design inaccuracies that compromise the very essence of your creation. This scenario is all too common in the world of manufacturing, where traditional design methods often fall short of meeting the stringent demands of modern industries. The frustration of iterating countless manual drawings, coupled with the inefficiencies of outdated prototyping techniques, can stifle innovation and hinder progress. Enter Computer-Aided Design (CAD), a transformative technology that not only streamlines the design process but also enhances the precision and efficiency of rapid prototyping. By leveraging CAD, manufacturers can overcome these challenges, ensuring that their products are developed swiftly, accurately, and cost-effectively.

CAD (Computer-Aided Design) revolutionizes rapid prototyping by providing precise digital models, enhancing design accuracy, accelerating production cycles, and enabling seamless integration with CNC machining and other manufacturing technologies. This ensures efficient development and high-quality outcomes in various industries.

Understanding the fundamental aspects of CAD and its pivotal role in rapid prototyping is essential for manufacturers aiming to stay competitive in today’s fast-paced market. Let’s delve deeper into what CAD entails, its applications in rapid prototyping, and the myriad advantages it offers over traditional design methods.

Foreword

In the contemporary manufacturing landscape, the integration of advanced technologies is paramount to achieving efficiency, precision, and innovation. CAD stands out as a cornerstone technology that has revolutionized how products are designed, developed, and brought to market. Particularly in the realm of rapid prototyping, CAD's capabilities extend beyond mere design, facilitating a seamless transition from concept to tangible product. This article explores the essence of CAD, its significant advantages, and its diverse applications in rapid prototyping, highlighting its indispensable role in modern manufacturing.

Definition and Overview

Computer-Aided Design (CAD) is a sophisticated software tool that enables engineers, designers, and architects to create, modify, analyze, and optimize designs digitally. Unlike traditional manual drafting methods, CAD allows for the creation of precise and detailed 2D and 3D models, facilitating a more accurate representation of the final product. CAD software integrates various functionalities, including drafting, modeling, simulation, and visualization, making it an essential tool in the design and manufacturing process.

Evolution of CAD

The evolution of CAD technology has been marked by significant advancements, transitioning from simple 2D drafting tools to complex 3D modeling systems. Early CAD systems were primarily used for creating technical drawings, but modern CAD software encompasses a wide range of capabilities, including parametric modeling, surface modeling, and integrated simulation tools. These advancements have made CAD an indispensable tool in various industries, enabling more efficient and innovative design processes.

Key Features of CAD

CAD has revolutionized the manufacturing industry by enabling more efficient design processes, reducing time-to-market, and enhancing product quality. Its ability to integrate seamlessly with other manufacturing technologies, such as Computer-Aided Manufacturing (CAM) and rapid prototyping, makes it a critical tool in the development of complex and high-precision components. In the energy industry, where components must meet stringent performance and safety standards, CAD's role in ensuring accuracy and reliability is particularly vital.

Enhancing Design Accuracy

One of the primary uses of CAD in rapid prototyping is enhancing design accuracy. CAD software allows designers to create highly detailed and precise models, which can be directly translated into physical prototypes using rapid prototyping technologies. This precision ensures that the prototypes closely match the intended design, reducing the likelihood of errors and misalignments in the final product.

Accelerating the Prototyping Process

CAD significantly accelerates the prototyping process by enabling quick iterations and modifications. Designers can rapidly adjust dimensions, tweak design features, and explore different configurations without the need for extensive manual drafting. This agility allows for faster testing and validation of concepts, shortening the overall product development cycle.

Facilitating Complex Geometries

Rapid prototyping often involves the creation of intricate and complex geometries that are challenging to produce using traditional manufacturing methods. CAD's advanced modeling capabilities make it possible to design and visualize these complex shapes with ease, ensuring that the prototypes are both functional and aesthetically pleasing.

Integration with Manufacturing Technologies

CAD seamlessly integrates with various manufacturing technologies used in rapid prototyping, such as CNC machining, 3D printing, and injection molding. This integration allows for a smooth transition from digital design to physical prototype, minimizing delays and enhancing overall efficiency. For example, CAD models can be directly exported to CAM software for CNC machining, ensuring that the machining process accurately replicates the digital design.

Improving Communication and Collaboration

CAD facilitates better communication and collaboration among design teams, engineers, and manufacturers. By providing a common digital platform, CAD enables all stakeholders to view, discuss, and refine the design in real-time, ensuring that everyone is aligned and informed throughout the prototyping process. This collaborative approach enhances the overall quality and effectiveness of rapid prototyping efforts.

Definition and Concept

CAD prototyping refers to the use of Computer-Aided Design software to create detailed digital models that serve as the basis for physical prototypes. This process involves designing a product in a virtual environment, testing and refining the design digitally, and then using rapid prototyping technologies to produce a tangible model based on the CAD design. CAD prototyping bridges the gap between conceptual design and physical production, enabling manufacturers to validate and optimize their designs before committing to full-scale manufacturing.

Benefits of CAD Prototyping

Applications in Various Industries

CAD prototyping is utilized across a wide range of industries, including automotive, aerospace, consumer electronics, and, notably, the energy sector. In the energy industry, CAD prototyping is essential for developing components such as turbine blades, solar panel mounts, and energy storage systems, where precision and performance are critical.

Role in Rapid Prototyping

In rapid prototyping, CAD prototyping plays a foundational role by providing the digital blueprint from which physical prototypes are created. The synergy between CAD software and rapid prototyping technologies, such as 3D printing and CNC machining, allows for the swift transformation of ideas into tangible models. This synergy not only enhances the speed and efficiency of the prototyping process but also ensures that prototypes are highly accurate and reflective of the intended design.

Definition and Overview

Rapid prototyping in CAD refers to the swift creation of physical models based on CAD designs, utilizing various manufacturing technologies to produce prototypes quickly and efficiently. This process allows designers and engineers to evaluate and test their concepts in a tangible form, facilitating better design decisions and reducing the time and cost associated with product development.

Importance in Product Development

Rapid prototyping is a critical phase in product development, as it allows for the validation of design concepts and the identification of potential issues early in the development process. By producing physical prototypes quickly, manufacturers can conduct performance tests, gather feedback, and make necessary adjustments before proceeding to mass production. This iterative process enhances the overall quality and functionality of the final product, ensuring that it meets the desired specifications and market requirements.

Integration with CAD

CAD serves as the foundation for rapid prototyping by providing the detailed digital models that guide the prototyping process. The integration between CAD and rapid prototyping technologies ensures that the transition from design to prototype is seamless and accurate. CAD files can be directly exported to various rapid prototyping machines, such as 3D printers and CNC machines, allowing for the precise replication of digital designs in physical form.

Benefits of Rapid Prototyping in CAD

Rapid prototyping encompasses a variety of technologies that allow for the quick and efficient creation of physical models based on digital designs. CAD is central to these processes, providing the precise digital models that guide the prototyping. Here, we explore the key rapid prototyping technologies where CAD plays a crucial role: Casting, Extrusion, CNC Machining, CNC Turning, and 3D Printing.

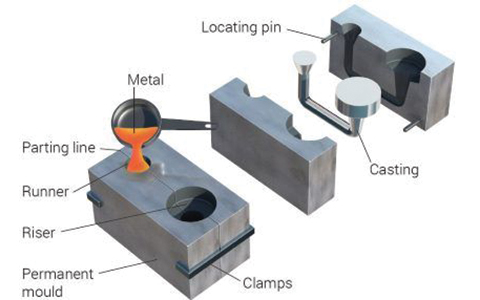

Overview of Casting in Rapid Prototyping

Casting is a traditional manufacturing process that involves pouring liquid material into a mold to create a specific shape once it solidifies. In the context of rapid prototyping, casting allows for the creation of detailed and accurate prototypes from CAD models, particularly useful for producing metal parts.

Role of CAD in Casting

CAD models are essential in designing the molds used in casting. By creating precise digital models, manufacturers can ensure that the molds accurately reflect the desired shape and dimensions of the final product. CAD software enables the design of complex geometries and intricate details that are often challenging to achieve with manual mold-making techniques.

Benefits of Using CAD in Casting

Applications in the Energy Industry

In the energy industry, casting is used to produce components such as turbine blades, engine parts, and structural elements that require high strength and durability. The precision offered by CAD ensures that these components meet the stringent performance and safety standards necessary for energy production systems.

Overview of Extrusion in Rapid Prototyping

Extrusion is a manufacturing process where material is forced through a die to create objects with a fixed cross-sectional profile. In rapid prototyping, extrusion is commonly used for producing consistent, long parts such as pipes, tubing, and frames.

Role of CAD in Extrusion

CAD plays a critical role in designing the dies used for extrusion. By creating accurate digital models of the desired cross-sectional profiles, manufacturers can ensure that the extruded parts meet the required specifications. CAD software allows for the precise control of dimensions and tolerances, ensuring uniformity and consistency in the extruded products.

Benefits of Using CAD in Extrusion

Applications in the Energy Industry

Extrusion is used in the energy industry to produce components such as hydraulic hoses, electrical conduits, and structural frames for renewable energy systems. The ability to create consistent and precise extruded parts ensures the reliability and performance of these components in demanding energy applications.

Overview of CNC Machining in Rapid Prototyping

CNC (Computer Numerical Control) machining is a highly versatile and precise manufacturing process that uses computer-controlled tools to remove material from a workpiece to create the desired shape. In rapid prototyping, CNC machining is used to produce detailed and accurate prototypes from CAD models, suitable for both metal and plastic parts.

Role of CAD in CNC Machining

CAD software is fundamental in CNC machining, as it provides the digital blueprint from which the machining process is guided. By translating CAD models into G-code, CNC machines can execute precise cutting, drilling, and milling operations to produce prototypes that closely match the original design.

Benefits of Using CAD in CNC Machining

Applications in the Energy Industry

In the energy sector, CNC machining is used to produce prototypes and final components such as turbine blades, engine parts, and structural frames. The ability to create high-precision parts ensures that these components perform reliably under the demanding conditions of energy production systems.

Overview of CNC Turning in Rapid Prototyping

CNC turning is a specific type of CNC machining that involves rotating the workpiece on its axis while a cutting tool removes material to create cylindrical or conical shapes. This process is ideal for producing parts like shafts, spindles, and bushings, which are common in various energy applications.

Role of CAD in CNC Turning

CAD models provide the detailed specifications for CNC turning, enabling the creation of precise and accurate parts. By designing components in CAD, manufacturers can ensure that each part meets the exact dimensional and tolerance requirements necessary for their intended use.

Benefits of Using CAD in CNC Turning

Applications in the Energy Industry

CNC turning is utilized in the energy industry to manufacture components such as rotor shafts, turbine spindles, and drive shafts. These parts require high precision and durability to ensure the efficient and reliable operation of energy production systems.

3D Printing

Overview of 3D Printing in Rapid Prototyping

3D printing, also known as additive manufacturing, is a process that builds objects layer by layer based on digital models. In rapid prototyping, 3D printing enables the quick creation of complex and lightweight prototypes, allowing for rapid design iterations and testing.

Role of CAD in 3D Printing

CAD software is essential in 3D printing, as it provides the detailed digital models that guide the printing process. By designing parts in CAD, manufacturers can ensure that prototypes are created with the desired geometries and specifications, allowing for accurate testing and validation.

Benefits of Using CAD in 3D Printing

Applications in the Energy Industry

3D printing is used in the energy industry to create prototypes of components such as turbine blades, solar panel mounts, and energy storage systems. The ability to rapidly produce and test these components allows for faster innovation and optimization of energy systems.

The integration of Computer-Aided Design (CAD) into rapid prototyping processes has revolutionized the manufacturing landscape, offering numerous advantages over traditional design and prototyping methods. CAD provides a digital platform that enhances the accuracy, efficiency, and flexibility of prototyping, making it an indispensable tool in modern manufacturing. This section explores the various advantages of CAD in rapid prototyping, highlighting why it is preferred over manual drawing methods.

Manual drawing has been the cornerstone of design and prototyping for centuries. However, with the advent of CAD technology, the landscape of design and manufacturing has undergone a significant transformation. CAD offers numerous advantages over manual drawing, particularly in the context of rapid prototyping, where speed, accuracy, and efficiency are paramount. Understanding these advantages is crucial for manufacturers seeking to optimize their design and prototyping processes.

1. Productivity

Enhanced Speed and Efficiency

CAD significantly boosts productivity by automating many aspects of the design process that are time-consuming when done manually. Tasks such as drafting, dimensioning, and modifying designs are accomplished much faster with CAD software. This increased speed allows designers to produce more prototypes in less time, accelerating the overall product development cycle.

Streamlined Workflow

CAD integrates various stages of the design process into a single digital platform, facilitating a more streamlined workflow. Designers can easily transition from concept to detailed design, making it easier to manage multiple projects simultaneously. The ability to quickly switch between different design iterations without starting from scratch enhances overall productivity.

Reduced Time-to-Market

With CAD's ability to quickly produce and modify designs, the time required to develop and test prototypes is significantly reduced. This rapid iteration process enables manufacturers to bring products to market faster, gaining a competitive edge in the industry.

2. Accuracy

High Precision and Detail

One of the most significant advantages of CAD is its ability to produce highly precise and detailed designs. CAD software allows for exact measurements and tolerances, ensuring that prototypes closely match the intended specifications. This high level of accuracy minimizes errors and reduces the need for extensive rework.

Consistency

CAD ensures consistency across all design iterations and prototypes. Unlike manual drawing, where human error can lead to inconsistencies, CAD maintains uniformity in dimensions and specifications, ensuring that every prototype meets the same high standards.

Error Detection

CAD software often includes tools for detecting and correcting design errors, such as interference checks and dimensional analysis. These features help identify potential issues early in the design process, preventing costly mistakes and ensuring the integrity of the final product.

3. Readability

Clear and Detailed Documentation

CAD provides clear and detailed documentation of designs, making it easier for team members to understand and implement them. Digital models include comprehensive information on dimensions, materials, and tolerances, facilitating better communication and collaboration among designers, engineers, and manufacturers.

Enhanced Visualization

CAD offers advanced visualization tools, such as 3D rendering and virtual reality, allowing stakeholders to better comprehend complex designs. This enhanced visualization improves decision-making and ensures that everyone involved has a clear understanding of the prototype before production begins.

Comprehensive Design Records

All changes and iterations in CAD are automatically recorded, creating a detailed history of the design process. This comprehensive record-keeping makes it easier to track design changes, maintain version control, and reference past designs when needed.

4. Presentation

Professional Quality Renderings

CAD enables the creation of high-quality renderings and visual presentations of prototypes. These professional-grade visuals are essential for showcasing designs to clients, investors, and other stakeholders, helping to secure buy-in and support for projects.

Interactive Models

With CAD, designers can create interactive models that allow users to explore and interact with the prototype in a virtual environment. This interactivity provides a more engaging and informative presentation, helping stakeholders better understand the functionality and features of the design.

Enhanced Marketing and Sales

The professional presentations and detailed visuals generated by CAD can enhance marketing and sales efforts. Clear and compelling representations of prototypes can attract potential customers and investors, facilitating better market positioning and increasing the likelihood of successful product launches.

5. Follow-up

Seamless Transition to Manufacturing

CAD models can be directly integrated with manufacturing processes, such as CNC machining and 3D printing. This seamless transition from design to production ensures that prototypes are manufactured accurately and efficiently, reducing delays and improving overall workflow.

Easy Modifications

CAD allows for easy modifications and updates to designs based on feedback and testing results. Designers can quickly implement changes and generate new prototypes without the need for extensive manual adjustments, ensuring that the design evolves efficiently in response to user needs and market demands.

Comprehensive Documentation for Manufacturing

CAD provides detailed documentation that supports the manufacturing process, including specifications, materials, and machining instructions. This comprehensive documentation ensures that manufacturers have all the information they need to produce the prototype accurately and efficiently, minimizing the risk of errors and inconsistencies.

6. Sharing and Collaboration

Cloud-Based Collaboration Tools

Many CAD platforms offer cloud-based collaboration tools that allow multiple users to work on the same design simultaneously from different locations. This facilitates real-time collaboration and communication among team members, enhancing the overall design process.

Improved Team Coordination

With CAD, design files can be easily shared and accessed by all relevant stakeholders, ensuring that everyone is working with the latest version of the design. This improved coordination reduces misunderstandings and ensures that all team members are aligned on project goals and requirements.

Integration with Other Tools

CAD software often integrates with other design and manufacturing tools, such as CAM (Computer-Aided Manufacturing) and PLM (Product Lifecycle Management) systems. This integration enhances collaboration by allowing data to flow seamlessly between different stages of the design and manufacturing process, improving overall efficiency and coordination.

7. Documentation

Detailed Design Records

CAD provides comprehensive and detailed records of all design aspects, including dimensions, materials, tolerances, and annotations. These detailed records are essential for maintaining consistency and accuracy throughout the prototyping and manufacturing process.

Easy Access and Retrieval

Digital documentation ensures that all design records are easily accessible and retrievable whenever needed. This ease of access facilitates better project management, allowing team members to quickly reference and utilize design information without the need for physical copies.

Regulatory Compliance

In many industries, including the energy sector, maintaining detailed documentation is crucial for regulatory compliance. CAD ensures that all design specifications and changes are accurately recorded, helping manufacturers meet industry standards and regulatory requirements.

Automotive Industry

The automotive industry relies heavily on CAD for designing everything from engine components to entire vehicle bodies. CAD allows for the creation of highly detailed and precise models, enabling the development of complex systems that meet safety and performance standards.

Aerospace Industry

In the aerospace sector, CAD is used to design aircraft components, spacecraft, and related systems. The precision and accuracy provided by CAD ensure that these components meet the stringent requirements necessary for safe and efficient operation in extreme conditions.

Medical Industry

The medical industry utilizes CAD for designing medical devices, prosthetics, and surgical instruments. CAD enables the creation of custom-designed components that meet the specific needs of patients and healthcare providers, enhancing the effectiveness and reliability of medical treatments.

Consumer Electronics

Consumer electronics manufacturers use CAD to design products such as smartphones, laptops, and home appliances. CAD facilitates the development of compact and intricate designs that meet consumer demands for functionality and aesthetics.

Energy Industry

In the energy sector, CAD is essential for designing components used in renewable energy systems, such as wind turbines and solar panels, as well as traditional energy systems like generators and turbines. CAD ensures that these components are designed with precision and efficiency, enhancing the performance and reliability of energy production systems.

Integration of CAD and CAM

CAD and CAM are closely linked technologies that work together to streamline the design and manufacturing process. While CAD is used for designing and modeling components, CAM is used to plan and control the manufacturing processes based on those designs. The integration of CAD and CAM allows for a seamless transition from digital design to physical production, enhancing overall efficiency and accuracy.

Benefits of CAD-CAM Integration

Applications in Rapid Prototyping

In rapid prototyping, the integration of CAD and CAM is particularly valuable. CAD models provide the detailed designs needed for creating accurate prototypes, while CAM software generates the necessary instructions for CNC machines and other manufacturing technologies. This integration ensures that prototypes are produced quickly and accurately, allowing for rapid iteration and testing.

CAD plays a pivotal role in both rapid prototyping and manufacturing, serving as the foundational technology that bridges the gap between design and production. In the context of rapid prototyping, CAD enables the quick creation and modification of digital models, which can then be translated into physical prototypes using various manufacturing technologies. In manufacturing, CAD ensures that production processes are efficient, precise, and scalable, supporting the production of high-quality CNC machining parts for the energy industry and beyond.

1. CAD and CNC Machining

Enhancing Precision and Efficiency

CNC machining relies heavily on accurate digital models to produce precise components. CAD provides the detailed designs that CNC machines follow to cut, drill, and mill materials with high accuracy. This precision is essential for producing components that meet the exact specifications required in the energy industry, where even minor deviations can lead to significant performance issues.

Streamlining the Manufacturing Process

The integration of CAD and CNC machining streamlines the manufacturing process by allowing designs to be directly translated into machining instructions. This reduces the time and effort required to prepare components for production, accelerating the overall manufacturing cycle. Additionally, CAD enables the optimization of tool paths, minimizing material waste and improving the efficiency of the machining process.

Facilitating Complex Designs

CNC machining is capable of producing highly intricate and complex designs that would be difficult or impossible to achieve with manual machining. CAD allows designers to create these complex geometries with ease, ensuring that CNC machines can accurately reproduce the intended shapes and features. This capability is particularly important in the energy industry, where components often feature complex shapes and tight tolerances.

2. CAD and 3D Printing

Enabling Rapid Iteration

3D printing, or additive manufacturing, works seamlessly with CAD to enable rapid iteration of designs. Designers can quickly create and modify CAD models, and these models can be directly printed to produce physical prototypes. This rapid iteration process allows for swift testing and refinement of designs, accelerating the development cycle and enabling faster time-to-market.

Customization and Flexibility

CAD enables the creation of highly customized designs that can be easily adapted for 3D printing. This flexibility is particularly beneficial for producing bespoke components tailored to specific applications in the energy industry, such as custom turbine blades or specialized mounting brackets for solar panels. CAD allows for the easy modification of designs to meet unique requirements without the need for extensive manual adjustments.

Reducing Material Waste

3D printing minimizes material waste by building components layer by layer, using only the necessary amount of material required for the design. CAD plays a crucial role in optimizing the design for additive manufacturing, ensuring that components are both lightweight and strong, while using materials efficiently. This reduction in material waste aligns with the sustainability goals of the green energy industry, promoting more environmentally responsible manufacturing practices.

3. CAD and Vacuum Casting

Creating Detailed Molds

Vacuum casting is a prototyping process that involves creating molds from CAD-designed models and using them to produce accurate replicas of the prototype. CAD ensures that the molds are designed with the necessary precision and detail, enabling the production of high-quality prototypes that closely resemble the final product.

Facilitating Material Selection

CAD allows designers to experiment with different materials in the design phase, ensuring that the chosen materials are suitable for the intended application. This capability is particularly important in the energy industry, where components must meet specific performance criteria, such as resistance to high temperatures and corrosion.

Enhancing Production Speed

By using CAD to design molds and optimize casting processes, manufacturers can significantly enhance production speed. CAD streamlines the design and manufacturing of molds, reducing the time required to produce prototypes and accelerating the overall prototyping process. This speed is essential for rapid iteration and timely project completion in the fast-paced energy sector.

Computer-Aided Design (CAD) has fundamentally transformed the landscape of rapid prototyping and manufacturing, offering unparalleled advantages in precision, efficiency, and flexibility. In the energy industry, where the demand for high-quality, reliable components is ever-increasing, CAD plays a crucial role in ensuring that prototypes and final products meet the stringent requirements necessary for optimal performance and safety.

By leveraging the power of CAD, manufacturers can enhance productivity, reduce costs, and streamline their production processes, all while maintaining the highest standards of accuracy and quality. Whether through integration with CNC machining, 3D printing, or vacuum casting, CAD continues to be an indispensable tool in the pursuit of innovation and excellence in the energy sector.

As the industry evolves, the continued advancements in CAD technology will further empower manufacturers to create more sophisticated and efficient energy systems, driving progress towards a more sustainable and energy-efficient future. Embracing CAD and its associated technologies is not just a strategic advantage but a necessity for those looking to thrive in the competitive and dynamic landscape of the energy industry.

1. What software do I use for CAD?

Popular CAD software includes AutoCAD, SolidWorks, CATIA, Siemens NX, and Fusion 360. The choice depends on the specific needs of your project, industry requirements, and personal or organizational preferences.

2. What are the advantages of 3D CAD drawings over 2D?

3D CAD drawings provide a more comprehensive and realistic representation of designs, allowing for better visualization, improved accuracy, easier modification, and more efficient communication among team members compared to 2D drawings.

3. What are the limitations of CAD?

While CAD offers numerous advantages, it can be limited by the complexity of software learning curves, high initial costs for advanced software and hardware, potential over-reliance on digital models without physical testing, and the need for regular updates and maintenance.

4. What are the advantages of CAD?

Advantages of CAD include increased productivity, higher accuracy, enhanced readability, professional-quality presentations, improved collaboration, comprehensive documentation, and seamless integration with manufacturing processes.

5. Why should I use CAD before making any 3D prototypes?

Using CAD before creating 3D prototypes allows for precise design planning, easy modifications, and thorough testing in a virtual environment. This ensures that the prototypes are accurate, reduces material waste, and accelerates the overall development process.

6. What are the advantages and disadvantages of AutoCAD?

Advantages of AutoCAD include its versatility, extensive toolset, wide industry adoption, and robust support and resources.

Disadvantages include its high cost, steep learning curve for beginners, and potential over-reliance on manual input without automation capabilities found in more specialized CAD software.

By understanding the multifaceted advantages and applications of CAD in rapid prototyping, especially within the energy industry, manufacturers can harness this powerful technology to drive innovation, enhance efficiency, and maintain a competitive edge in the evolving market landscape.

By understanding the multifaceted advantages and applications of CAD in rapid prototyping, especially within the energy industry, manufacturers can harness this powerful technology to drive innovation, enhance efficiency, and maintain a competitive edge in the evolving market landscape.