15 years one-stop China custom CNC machining parts factory

158 |

Published by VMT at Dec 03 2024 | Reading Time:About 10 minutes

158 |

Published by VMT at Dec 03 2024 | Reading Time:About 10 minutes

In the ever-evolving energy industry, achieving high precision and efficiency in manufacturing complex components is a significant challenge. Companies often struggle with production inefficiencies, increased costs, and the inability to meet stringent quality standards, which can hinder progress and competitiveness. Fortunately, Computer Numerical Control (CNC) machining offers a solution by providing precise, efficient, and versatile manufacturing processes tailored to the energy sector's unique demands.

CNC machining enhances the energy industry by delivering high-precision parts, improving production efficiency, and offering material versatility, which collectively contribute to increased reliability and cost-effectiveness in both renewable and non-renewable energy applications.

To fully appreciate the impact of CNC machining on the energy industry, it's essential to delve into the specific machining methods used, the applications across different energy sectors, and the inherent advantages that make CNC machining an indispensable part of modern energy production.

CNC machining plays a pivotal role in manufacturing the intricate and high-tolerance components required in the energy industry. By utilizing computer-controlled tools, CNC machining ensures that parts are produced with exceptional precision and repeatability, meeting the rigorous standards of sectors like wind, solar, hydroelectric, oil, and gas. The technology enables the production of complex geometries that are often impossible with traditional machining methods, thus facilitating innovation and efficiency in energy systems.

The energy sector encompasses a wide range of industries, including oil and gas, wind, solar, hydroelectric, and nuclear power. Each of these industries relies heavily on complex machinery and components that must withstand extreme conditions and operate with high efficiency. CNC machining has become an indispensable tool in manufacturing these components, thanks to its precision, repeatability, and versatility. By automating the control of machining tools through computer programming, CNC machining ensures that even the most intricate parts are produced to exact specifications.

CNC machining methods are diverse, each offering unique advantages suited to different manufacturing needs. From creating the massive blades of wind turbines to the delicate components of nuclear reactors, these methods play a pivotal role in powering the modern world. The following sections provide an in-depth look at the most commonly used CNC machining methods in the energy sector, highlighting their importance and applications.

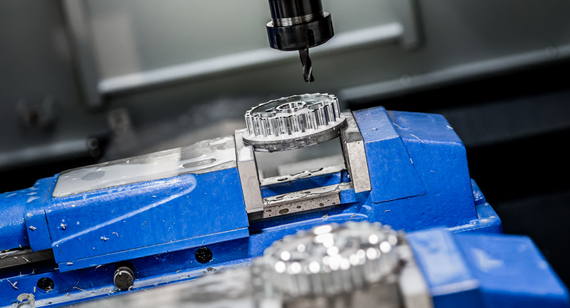

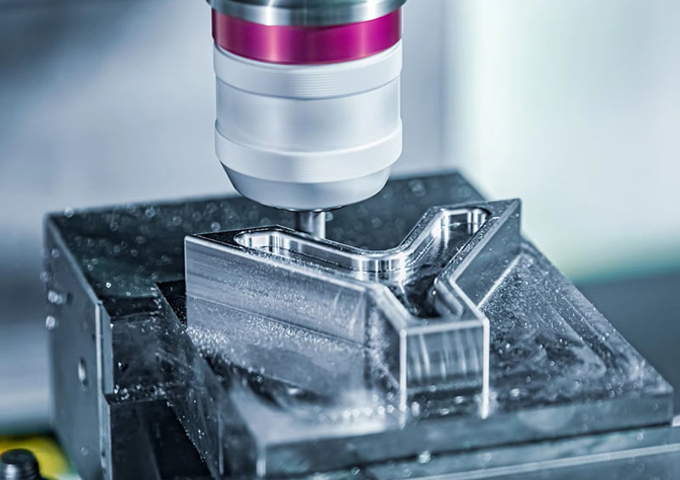

CNC Milling

CNC milling is a subtractive manufacturing process that utilizes computerized controls to operate and manipulate multi-point rotary cutting tools. The process involves removing material from a workpiece to create custom-designed components. CNC milling machines can move along multiple axes (typically three to five), allowing for the production of complex shapes and surfaces with high precision and repeatability. The computerized nature of CNC milling ensures that once a design is programmed into the system, the machine can produce identical parts with minimal human intervention.

CNC milling machines come in various configurations, including vertical and horizontal milling centers. They are equipped with a variety of tools, such as end mills, face mills, and drills, which can be automatically changed during the machining process. This versatility makes CNC milling suitable for producing a wide range of components from various materials, including metals, plastics, and composites.

Applications in the Energy Industry:

Wind Turbines

In the wind energy sector, CNC milling is instrumental in manufacturing critical components of wind turbines. The hubs that connect the blades to the rotor are complex parts requiring high precision to ensure balance and structural integrity. CNC milling machines produce these hubs by precisely removing material to achieve the required dimensions and tolerances.

Additionally, CNC milling is used to fabricate gearbox components within wind turbines. The gearboxes are essential for converting the low rotational speed of the turbine blades into higher speeds suitable for electricity generation. Milling ensures that gears and shafts are machined with the exact tooth profiles and surface finishes necessary for efficient operation and longevity.

Hydropower

Hydroelectric power generation relies on turbines that convert the kinetic energy of flowing water into mechanical energy, which is then converted into electricity. CNC milling is crucial in producing the intricate shapes of turbine blades and casings. The blades must be precisely contoured to optimize water flow and maximize energy conversion efficiency.

Moreover, the casings that house the turbines require tight tolerances and smooth surface finishes to reduce friction and wear. CNC milling allows for the creation of these complex geometries with high accuracy, ensuring the reliability and efficiency of hydroelectric power plants.

Nuclear Energy

In the nuclear energy sector, CNC milling plays a vital role in manufacturing reactor components that must meet stringent safety and performance standards. Components such as control rod drive mechanisms, reactor vessel internals, and fuel handling equipment require precise machining to ensure proper fit and function.

CNC milling enables the production of parts with complex geometries and tight tolerances, which are essential for maintaining the integrity of nuclear reactors. The ability to machine various materials, including stainless steel and exotic alloys used in nuclear applications, makes CNC milling an indispensable process in this industry.

Turning is a machining process where a cutting tool moves linearly while the workpiece rotates on a spindle. The primary purpose of turning is to produce cylindrical parts by removing material from the outer diameter of a rotating workpiece. CNC turning centers, or lathes, automate this process, allowing for high precision and consistency across multiple parts.

CNC turning machines can perform various operations, including facing, threading, grooving, and drilling, often in a single setup. The integration of computer control ensures that complex shapes and features can be achieved with high repeatability. CNC lathes may also be equipped with live tooling, enabling milling operations to be performed without moving the workpiece to a different machine.

Key Parts Manufactured by Turning in the Energy Industry:

Shafts and Rotors for Wind Turbines

In wind turbines, shafts and rotors are critical components that transfer mechanical energy from the blades to the generator. These parts must be manufactured with high precision to ensure balance, reduce vibration, and prevent premature wear. CNC turning allows for the precise machining of these long, cylindrical components, maintaining tight tolerances on diameter and concentricity.

The use of CNC turning in producing wind turbine shafts ensures that they can withstand the immense mechanical stresses and varying environmental conditions they are exposed to. This precision manufacturing contributes to the overall efficiency and reliability of wind energy systems.

Hydropower Turbines

Hydropower turbines consist of various rotating components, such as turbine shafts and runners, which convert the energy of flowing water into mechanical rotation. CNC turning is essential in machining these components to exact specifications. The process ensures that the shafts are perfectly straight and have the required surface finishes to minimize friction losses.

In addition, turning is used to produce the intricate profiles of turbine runners, which are responsible for capturing the energy from water flow. The precision achieved through CNC turning enhances the efficiency of hydropower turbines and extends their operational life.

CNC drilling involves creating holes in a workpiece using rotating drill bits controlled by computer numerical control. The process allows for precise hole placement, depth control, and consistency across multiple parts. CNC drilling machines can handle a variety of hole sizes and can be programmed to drill at specific angles and patterns.

CNC drilling is often integrated into milling or turning centers, enabling multiple machining operations in a single setup. This integration reduces handling and setup times, improving overall production efficiency. The use of CNC control ensures that hole dimensions and positions meet exact specifications, which is critical for assembly and functionality.

Applications and Importance in the Energy Industry:

CNC drilling is widely used in the energy industry to manufacture components that require precise hole patterns for assembly, fluid flow, or structural integrity. Some key applications include:

Flanges and Pipe Fittings: These components require accurately drilled holes for bolts and fasteners to ensure leak-proof connections in pipelines and pressure vessels used in oil and gas, nuclear, and other energy sectors.

The precision and repeatability of CNC drilling are crucial in the energy industry, where component failure due to improper hole placement can lead to catastrophic consequences, including safety hazards and costly downtime.

Grinding is a machining process that uses an abrasive wheel or belt to remove material from a workpiece's surface, achieving a high level of precision and surface finish. The process can produce extremely smooth surfaces and tight tolerances, making it ideal for finishing operations after other machining processes like milling or turning.

CNC grinding machines automate the grinding process, allowing for consistent results across multiple parts. They can perform various grinding operations, such as surface grinding, cylindrical grinding, and centerless grinding, accommodating different shapes and sizes of workpieces. The use of computer control ensures that the grinding parameters are optimized for each specific application.

Key Parts Manufactured by Grinding:

Turbine Blades

In both gas and steam turbines used across various energy sectors, the blades are critical components that must operate under extreme conditions of temperature and stress. After initial machining processes like milling, grinding is employed to achieve the required surface finishes and precise dimensions on turbine blades.

CNC grinding ensures that the blade profiles meet aerodynamic requirements, reducing turbulence and improving efficiency. The process also enhances the surface integrity of the blades, increasing their resistance to fatigue and corrosion. This precision finishing is vital for the reliability and longevity of turbines in power generation.

Bearing Surfaces

Bearings are essential components in rotating machinery, facilitating smooth motion and reducing friction between moving parts. Grinding is used to produce the highly smooth and precise surfaces required on bearing races and journals. CNC grinding machines can achieve the tight tolerances and surface finishes necessary for optimal bearing performance.

In the energy industry, bearings are used extensively in equipment like generators, turbines, and pumps. The reliability of these machines depends heavily on the quality of their bearings. By using CNC grinding, manufacturers ensure that bearing surfaces meet or exceed industry standards, contributing to the overall efficiency and durability of energy systems.

Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM) is a non-traditional machining process that uses electrical discharges (sparks) to remove material from a workpiece. The process involves generating controlled electrical sparks between an electrode and the workpiece, which erode the material in a highly precise manner. EDM is particularly useful for machining hard materials or creating complex shapes that are difficult to achieve with conventional machining methods.

There are two main types of EDM:

EDM does not require physical contact between the tool and the workpiece, eliminating mechanical stresses and enabling the machining of delicate or complex parts.

Applications in the Energy Industry:

Generator Parts

In power generation, especially in nuclear and fossil fuel plants, generators contain components that require high precision and are often made from hard materials like hardened steels or exotic alloys. EDM is employed to machine intricate features in these parts, such as slots, holes, and complex profiles.

For example, rotor and stator components in generators may require precise machining to ensure proper electromagnetic performance. EDM allows manufacturers to create these features with the necessary accuracy and surface finish, enhancing the efficiency and reliability of generators.

Fuel Injection Systems

In engines used for power generation or in the oil and gas industry, fuel injection systems must deliver fuel with extreme precision to optimize combustion and reduce emissions. EDM is used to machine small, precise holes and intricate channels in fuel injector components.

The ability of EDM to machine hard materials and produce complex geometries makes it ideal for manufacturing components like injector nozzles and valves. This precision contributes to improved engine performance, fuel efficiency, and compliance with environmental regulations.

Multi-Axis Machining

Multi-axis machining involves CNC machines that can move tools or workpieces along four or more axes simultaneously. While traditional CNC machines operate on three axes (X, Y, and Z), multi-axis machines add rotational axes (A, B, and C), allowing for more complex machining operations without repositioning the workpiece.

Common types of multi-axis machines include:

Multi-axis machining allows for the creation of complex geometries, improved surface finishes, and reduced setup times.

Key Parts Manufactured by Multi-Axis Machining:

Wind Turbine Parts

Wind turbine components, such as blade hubs, pitch control mechanisms, and complex gearbox housings, often require intricate machining that can only be achieved through multi-axis machining. The ability to machine multiple faces and angles in a single setup enhances precision and reduces production time.

For instance, the aerodynamic surfaces of blade roots must be machined to exact specifications to ensure proper fitment and performance. Multi-axis machining allows for the continuous contouring of these surfaces, improving the structural integrity and efficiency of the turbine.

Hydropower Components

In hydropower systems, components like turbine runners and wicket gates have complex, curved surfaces that direct water flow efficiently. Multi-axis machining is essential in producing these parts with the required precision and surface finishes.

By utilizing 5-axis machining, manufacturers can produce these components in fewer setups, reducing potential errors from repositioning and improving overall accuracy. This precision contributes to enhanced performance and longevity of hydropower equipment.

Swiss machining, also known as Swiss screw machining, is a specialized type of CNC machining designed for producing small, high-precision parts. In Swiss machining, the workpiece moves longitudinally while being machined, supported by a guide bushing close to the cutting tool. This configuration minimizes deflection and vibration, allowing for the production of parts with tight tolerances and fine features.

Swiss machines often have multiple tool stations and can perform various operations simultaneously, such as turning, milling, drilling, and threading. This capability reduces cycle times and improves efficiency for complex parts.

Key Parts Manufactured by Swiss Machining:

Precision Fuel System Components

In the energy industry, especially in oil and gas and power generation, precision fuel system components are critical for controlling fuel delivery and combustion efficiency. Swiss machining is ideal for producing small, intricate parts like injector needles, valves, and nozzles.

The high precision and surface finish achieved through Swiss machining ensure that these components function reliably under demanding conditions. Accurate fuel metering improves engine performance, reduces emissions, and enhances overall system efficiency.

Electrical Connectors and Contactors

Electrical systems in the energy sector rely on high-quality connectors and contactors to ensure reliable power transmission and control. Swiss machining produces these small, intricate components with the necessary precision and consistency.

Components such as pins, sockets, and terminals require tight tolerances and excellent surface finishes to maintain electrical conductivity and mechanical strength. Swiss machining enables mass production of these parts while maintaining the high quality demanded by energy applications.

Laser cutting is a non-contact manufacturing process that uses a focused laser beam to melt, burn, or vaporize material, resulting in a cut edge. The process is controlled by CNC systems, allowing for precise cutting of complex shapes and patterns. Laser cutting is suitable for various materials, including metals, plastics, wood, and composites.

There are different types of lasers used in cutting, such as CO2 lasers for non-metal materials and fiber lasers for metals. Laser cutting offers high precision, narrow kerf widths, and minimal heat-affected zones, preserving the integrity of the material.

Key Components Manufactured Using Laser Cutting:

Solar Panel Arrays

In the solar energy sector, laser cutting is employed to manufacture components of solar panel arrays, such as photovoltaic cells, frames, and mounting structures. The precision of laser cutting ensures that solar cells are cut to exact dimensions, maximizing the surface area for light absorption and energy conversion.

Additionally, laser cutting is used to create intricate patterns on thin-film solar cells, enhancing their efficiency. The non-contact nature of laser cutting minimizes mechanical stress on delicate materials, preserving their electrical properties.

Wind Turbine Blades

While the primary structure of wind turbine blades is often manufactured using composite lay-up techniques, laser cutting plays a role in producing components like reinforcement structures, internal supports, and aerodynamic enhancements. Laser cutting enables the precise shaping of composite materials and metals used in these applications.

The ability to cut complex shapes with high accuracy contributes to the aerodynamic efficiency and structural integrity of wind turbine blades. This precision enhances the performance and reliability of wind energy systems.

Water Jet Cutting

Water jet cutting is a cold-cutting process that uses a high-pressure jet of water, often mixed with abrasive materials, to erode and cut through materials. Controlled by CNC systems, water jet cutters can cut virtually any material, including metals, composites, stone, glass, and plastics.

The process does not generate heat, eliminating heat-affected zones and preserving the material's properties. Water jet cutting is capable of producing intricate shapes with high precision and smooth edges, reducing the need for secondary finishing operations.

Key Components Manufactured Using Water Jet Cutting:

Hydroelectric Turbine Components

In hydroelectric power systems, water jet cutting is used to manufacture components like turbine blades, casings, and structural supports. The ability to cut thick materials and complex shapes makes water jet cutting ideal for producing these large and intricate parts.

By avoiding thermal distortion, water jet cutting maintains the mechanical properties of materials like stainless steel and specialized alloys used in hydropower equipment. This precision contributes to the efficiency and durability of hydroelectric turbines.

Insulation Materials and Gaskets

Energy systems often require custom-shaped insulation materials and gaskets to ensure proper thermal management and sealing. Water jet cutting allows manufacturers to cut these materials into precise shapes without causing deformation or degradation.

Materials such as rubber, foam, and fibrous insulation can be accurately cut to fit complex geometries in equipment like boilers, turbines, and piping systems. This precision enhances the performance and safety of energy installations.

CNC machining is a cornerstone of modern manufacturing in both renewable and non-renewable energy sectors. Its ability to produce complex, high-precision components from a wide range of materials makes it indispensable for building and maintaining energy infrastructure. Whether it's fabricating massive wind turbine hubs or delicate fuel injector components, CNC machining delivers the accuracy and efficiency required to meet the industry's stringent demands.

The energy sector is characterized by its need for reliability, durability, and performance under extreme conditions. CNC machining methods address these needs by enabling manufacturers to produce parts that meet exact specifications and quality standards. This capability supports innovation and advances in energy technologies, contributing to the global effort toward sustainable and efficient energy production.

CNC Machining in Wind Power

Wind power relies heavily on CNC machining for producing critical components of wind turbines. From the massive hubs and gearboxes to the precision shafts and rotors, CNC machining ensures that each part meets the necessary tolerances and surface finishes. This precision enhances the efficiency and reliability of wind turbines, reducing maintenance costs and increasing energy output.

Hydroelectric CNC Machining

In hydroelectric power generation, CNC machining is essential for manufacturing turbine components, including blades, runners, and casings. The complex geometries and tight tolerances required for optimal water flow and energy conversion are achieved through advanced CNC machining methods like multi-axis milling and turning. This precision contributes to the longevity and efficiency of hydroelectric plants.

Conventional Generator CNC Machining

Conventional generators used in fossil fuel and nuclear power plants require high-precision components to operate effectively. CNC machining produces parts like rotor shafts, stator components, and housings with the necessary accuracy. By ensuring that these critical components meet strict quality standards, CNC machining supports the reliability and safety of conventional power generation.

CNC Machining of Hydro Turbines

Hydro turbines convert the kinetic energy of flowing water into mechanical energy for electricity generation. CNC machining plays a vital role in producing the intricate shapes of turbine blades and runners. Techniques like multi-axis milling and precision grinding ensure that these components have the optimal profiles and surface finishes to maximize efficiency and reduce wear.

CNC Machining of Solar Panels

In the solar energy sector, CNC machining is used to manufacture components like panel frames, mounting systems, and tracking mechanisms. Precision machining ensures that these parts fit together seamlessly and can withstand environmental stresses. CNC machining also contributes to the production of photovoltaic cells through processes like laser cutting and micro-machining, enhancing the efficiency of solar panels.

CNC Machining of Non-Renewable Energy Sources

CNC machining is equally important in non-renewable energy sectors like oil and gas, coal, and nuclear power. It produces components such as drilling equipment, pipeline fittings, reactor parts, and fuel system components. The precision and reliability provided by CNC machining are critical for the safe and efficient operation of facilities in these industries.

The renewable green energy industry faces unique challenges, including the need for innovative solutions, sustainable practices, and high-performance components. CNC machining offers numerous benefits that address these challenges, supporting the industry's growth and contribution to a sustainable future.

Ultra-Precision Parts

CNC machining delivers the ultra-precision required for components in renewable energy systems. High-precision parts enhance efficiency, reduce energy losses, and contribute to the overall performance of systems like wind turbines and solar panels.

Applicable to a Wide Range of Materials

The versatility of CNC machining allows manufacturers to work with a variety of materials, including metals, plastics, and composites. This flexibility supports the development of innovative components that leverage advanced materials for improved performance and sustainability.

Efficient and Fast Production

CNC machining automates the manufacturing process, reducing production times and increasing efficiency. This capability enables the renewable energy industry to scale up production to meet growing demand without compromising quality.

Environmentally Friendly Production

CNC machining is inherently precise, minimizing material waste and energy consumption during manufacturing. Additionally, the ability to use sustainable materials and recycle metal scraps aligns with the environmental goals of the renewable energy industry.

Powerful and Effective Technology

The advanced technology of CNC machining supports the production of complex components that are essential for cutting-edge renewable energy solutions. This capability fosters innovation and the implementation of new designs that improve efficiency and reduce environmental impact.

Minimal Environmental Impact

By reducing waste and energy consumption in the manufacturing process, CNC machining contributes to the overall sustainability of the renewable energy industry. This alignment with environmental objectives enhances the industry's credibility and appeal.

Improved Precision and Accuracy

The computer-controlled nature of CNC machining ensures that components are produced with exceptional precision. This accuracy is critical in the energy industry, where parts must operate under extreme conditions and meet stringent safety standards.

Increased Production Efficiency

Automation reduces the potential for human error and allows for continuous operation, increasing production rates without sacrificing quality. CNC machining enables manufacturers to meet tight deadlines and adapt quickly to changing demands.

Increased Component Reliability

High-precision machining results in components that perform reliably over extended periods. This reliability reduces maintenance requirements and downtime, leading to cost savings and improved operational efficiency in energy systems.

Material Versatility

CNC machines can process a wide range of materials, including metals, plastics, and composites. This versatility allows the energy industry to utilize the best materials for each application, enhancing performance and longevity.

Cost-Effectiveness

By reducing waste, minimizing errors, and increasing production speed, CNC machining lowers manufacturing costs. These savings can be passed on to consumers or reinvested in research and development.

Customization and Flexibility

CNC machining allows for easy modification of designs and quick transitions between different components. This flexibility supports customization and rapid prototyping, enabling the energy industry to innovate and adapt to new technologies.

Scalability

CNC machining systems can be scaled to meet production needs, from small batches to mass production. This scalability ensures that manufacturers can respond effectively to market demands and growth opportunities.

Reduced Energy Consumption

Efficient machining processes consume less energy, contributing to cost savings and environmental sustainability. CNC machines are designed to optimize cutting paths and minimize idle times, enhancing energy efficiency.

Enhanced Safety

Automation reduces the need for manual intervention in potentially hazardous machining operations. This reduction in human involvement enhances workplace safety and reduces the risk of accidents.

Innovative Design Implementation

CNC machining supports the production of complex geometries and intricate designs that may not be achievable with traditional methods. This capability fosters innovation and the development of advanced energy technologies.

While CNC machining offers numerous benefits, it also presents challenges that must be addressed to maximize its effectiveness in the energy industry. Understanding these challenges helps manufacturers develop strategies to overcome them and fully leverage the advantages of CNC machining.

Cost

The initial investment in CNC machinery and software can be significant. Additionally, the costs associated with operating and maintaining these machines must be considered. Manufacturers need to assess the return on investment and explore financing options or partnerships to mitigate financial barriers.

Design Complexity

While CNC machining enables the production of complex components, designing such parts requires expertise and careful planning. Designers must consider machining capabilities and limitations to create feasible and efficient designs.

Difficulty Associated with the Selected Material

Some materials used in the energy industry, such as exotic alloys and composites, can be challenging to machine. Issues like tool wear, heat generation, and machining speeds must be managed to ensure quality and efficiency.

The energy industry is at the forefront of technological advancement, striving to meet the world's growing demand for power while transitioning towards sustainable and renewable sources. A significant challenge in this sector is the production of complex, high-precision components that can withstand extreme environments and operational stresses. Traditional manufacturing methods often fall short in meeting these demands, leading to increased costs, production delays, and compromised equipment performance. Fortunately, Computer Numerical Control (CNC) machining offers a solution by providing the precision, efficiency, and versatility required to produce critical components for both renewable and non-renewable energy applications.

Renewable Energy Sector

Renewable energy sources are gaining prominence as the world shifts towards more sustainable practices. CNC machining plays a pivotal role in manufacturing the intricate components required for renewable energy systems. The precision and repeatability of CNC machining ensure that parts meet stringent quality standards, enhancing the efficiency and reliability of these energy solutions. Four major applications of CNC machining in the green energy sector are:

Wind Energy

Wind energy harnesses the kinetic energy of wind to generate electricity, making it one of the fastest-growing renewable energy sources. The efficiency and reliability of wind turbines heavily depend on the quality of their components. CNC machining is instrumental in producing these components with the necessary precision and durability.

Key Components Produced for Wind Energy:

Turbine Blades

Gearboxes and Drivetrains

Rotor Shafts

Solar Energy

Solar energy captures sunlight to generate electricity or heat, playing a vital role in the global shift towards renewable energy. CNC machining contributes to the production of solar energy systems by manufacturing components that require high precision and quality.

Key Components Produced for Solar Energy:

Panel Frames

Mounting Brackets and Tracking Systems

Hydroelectricity

Hydroelectric power generates electricity by using the energy of flowing water. CNC machining is essential in producing the complex components required for hydroelectric power plants, ensuring efficiency and reliability.

Key Components Produced by CNC Machining:

Turbine Blades

Gate Valves and Control Mechanisms

Geothermal Energy

Geothermal energy utilizes heat from the Earth's interior to generate electricity or provide heating. CNC machining is vital in manufacturing components that can withstand the extreme conditions found in geothermal applications.

Key Components Produced by CNC Machining:

Casing and Wellhead Equipment

Turbine Components

Biomass Energy

Biomass energy generates power from organic materials like wood, agricultural residues, and waste. CNC machining contributes to the production of equipment that processes biomass into usable energy.

Some Specific Parts Manufactured Using CNC Technology:

Pellet Mill Dies and Rollers

Burner Components

Energy Storage Systems

Energy storage is critical for balancing supply and demand in renewable energy systems. CNC machining plays a significant role in producing components for various energy storage technologies.

Key Components:

Battery Housings and Frames

Heat Exchangers and Cooling Systems

Non-Renewable Energy Sectors

Despite the global push towards renewable energy, non-renewable sources like oil, gas, coal, and nuclear power remain significant. CNC machining is crucial in manufacturing components that ensure the safe and efficient operation of facilities in these sectors.

Oil and Gas Exploration and Production

The oil and gas industry requires equipment that can operate reliably in harsh environments, such as deep-sea drilling or arctic conditions. CNC machining provides the precision and durability needed for these applications.

Key Components:

Drilling Rig Components

Pipe Fittings and Valves

Compressor and Pump Components

Conventional Generators and Turbines

Conventional power plants, including coal and natural gas facilities, rely on turbines and generators to produce electricity. CNC machining is essential in creating components that withstand high temperatures and rotational speeds.

Major Applications Include:

Turbine Blades

Generator Components

Casings and Enclosures

Nuclear Power

Nuclear energy provides a significant portion of the world's electricity. The safety and efficiency of nuclear power plants depend on components manufactured with the utmost precision and quality, which CNC machining delivers.

Key Components Manufactured Using CNC Technology Include:

Fuel Rods

Control Rods

Containment Components

Fossil Fuels

Coal and natural gas remain significant energy sources. CNC machining contributes to the production of equipment that improves the efficiency and environmental impact of fossil fuel power plants.

Key Components:

Turbine Blades and Rotors for Conventional Generators

Pump and Valve Components

Petroleum Refining

Petroleum refining transforms crude oil into usable products like gasoline and diesel. CNC machining is vital in producing equipment that operates under high temperatures and pressures.

Examples of CNC Machined Parts Include:

Pump and Valve Components

Heat Exchanger Components

Fittings and Flanges

Natural Gas Processing

Processing natural gas involves removing impurities and separating components. CNC machining produces the equipment necessary for these complex processes.

Key Components Include:

Compressor and Turbine Blades

Seals and Gaskets

Control Valves

Hydraulic Fracturing Equipment

Hydraulic fracturing, or fracking, extracts oil and gas from shale formations. CNC machining is used extensively in producing equipment that must endure abrasive materials and extreme pressures.

Here Are Some of the Ways CNC Machining Is Used in This Sector:

Component Manufacturing

Customization and Rapid Prototyping

Maintenance and Service Life

Conclusion

CNC machining is integral to the energy industry, providing the precision and reliability required for critical components across both renewable and non-renewable sectors. By enabling the production of complex parts with tight tolerances and excellent surface finishes, CNC machining enhances the efficiency, safety, and sustainability of energy systems worldwide. As the industry continues to evolve, the role of CNC machining will become even more significant, supporting innovation and the global transition towards cleaner energy sources.

CNC (Computer Numerical Control) machining is an essential process for producing high-precision parts across various sectors, including the energy industry. Given the critical nature of components used in energy production, whether renewable or non-renewable, the materials selected for CNC machining are crucial to ensuring the reliability, efficiency, and safety of these components. Each material must meet specific requirements, such as strength, durability, resistance to extreme conditions, and the ability to maintain high performance over prolonged periods of operation.

In this section, we’ll explore some of the most commonly used materials in CNC machining in the energy industry, highlighting their unique properties, applications, and advantages.

Aluminum

Overview and Properties: Aluminum is one of the most commonly used materials in CNC machining, thanks to its excellent strength-to-weight ratio, corrosion resistance, and ease of machining. It is lightweight yet durable, making it an ideal material for components used in both renewable and non-renewable energy systems.

Applications in the Energy Industry:

Advantages:

Stainless Steel

Overview and Properties: Stainless steel is a versatile and durable material known for its high resistance to corrosion and oxidation. Its strength and durability make it suitable for applications that require resistance to high temperatures, pressure, and harsh environmental conditions.

Applications in the Energy Industry:

Advantages:

Titanium

Overview and Properties: Titanium is renowned for its high strength, low weight, and exceptional corrosion resistance. Although it is more expensive than aluminum and stainless steel, titanium’s unique properties make it indispensable in certain energy applications, particularly where high temperatures and extreme environmental conditions are a concern.

Applications in the Energy Industry:

Advantages:

Copper

Overview and Properties: Copper is an essential material in electrical and thermal applications due to its excellent electrical conductivity, heat conductivity, and malleability. It is also highly resistant to corrosion, making it ideal for use in the energy industry, especially in electrical systems.

Applications in the Energy Industry:

Advantages:

Brass

Overview and Properties: Brass, an alloy of copper and zinc, combines the advantages of both metals: the electrical conductivity of copper and the durability of zinc. It is often used for components that need to be durable, corrosion-resistant, and easy to machine.

Applications in the Energy Industry:

Advantages:

Plastics and Composites

Overview and Properties: While metals are commonly used in CNC machining for the energy industry, plastics and composite materials have gained popularity due to their unique properties such as lightweight, resistance to corrosion, and versatility in different applications. Composites, in particular, combine multiple materials to provide enhanced performance for specific applications.

Applications in the Energy Industry:

Advantages:

Nickel Alloys

Overview and Properties: Nickel alloys are known for their excellent resistance to high temperatures and corrosion. They are ideal for demanding applications in high-temperature environments and harsh chemical conditions, making them indispensable in certain sectors of the energy industry.

Applications in the Energy Industry:

Advantages:

Tungsten

Overview and Properties: Tungsten is one of the hardest materials available, known for its high melting point, extreme durability, and ability to resist wear and tear. These characteristics make it an ideal choice for high-stress and high-temperature applications.

Applications in the Energy Industry:

Advantages:

Conclusion

The materials used in CNC machining for the energy industry are carefully chosen based on their ability to meet the demanding requirements of various applications, including strength, heat resistance, durability, and corrosion resistance. From lightweight and versatile materials like aluminum and copper to high-strength alloys like titanium and tungsten, the selection of the right material ensures the longevity, safety, and efficiency of energy systems. With CNC machining continuing to advance, the energy industry can expect even more precise, efficient, and durable components for both renewable and non-renewable energy sectors.

CNC machining has become a vital aspect of the energy industry due to its ability to produce highly precise and complex components required for various energy applications, including renewable and non-renewable energy systems. However, the industry is faced with a range of challenges that impact the efficiency, cost, and scalability of CNC machining processes. From high material costs to maintaining precision and complying with strict regulations, manufacturers must address these issues to meet the increasing demand for high-quality components used in turbines, generators, and other critical infrastructure.

This article will explore the main challenges facing CNC machining in the energy sector, offering insight into material costs, design complexity, machine maintenance, regulatory compliance, and more. By understanding these challenges, industry players can develop strategies to optimize their operations, reduce costs, and maintain the high standards required for energy production systems.

High Material Costs

Overview of the Challenge

One of the most significant challenges facing CNC machining in the energy industry is the high cost of materials required for manufacturing critical components. Energy systems often demand specialized, high-performance materials that can withstand extreme conditions such as high temperatures, high pressures, or corrosion. Common materials used in CNC machining for the energy sector include titanium, stainless steel, nickel alloys, and other specialized metals, all of which come at a premium price.

Impact on CNC Machining

High material costs directly impact the bottom line for manufacturers in the energy industry. The procurement of expensive materials for parts like turbine blades, engine components, and heat exchangers can significantly raise production costs. In addition to the direct expense of raw materials, manufacturers must also consider material wastage, which is particularly problematic when working with high-cost materials that cannot be easily recycled.

Solutions and Strategies

Complex Component Design

Overview of the Challenge

Energy industry components, particularly in renewable energy systems like wind turbines and solar panels, often feature intricate designs that require specialized CNC machining techniques. These components can involve complex geometries, tight tolerances, and highly detailed features that need to be produced with utmost precision.

Impact on CNC Machining

The complexity of energy industry components leads to extended production times, increased tooling requirements, and potential challenges in achieving the desired precision. Components like turbine blades, which have aerodynamic shapes, require sophisticated multi-axis CNC machining to ensure accuracy. Additionally, designing for manufacturability is a key concern, as certain complex features may be difficult or costly to machine.

Solutions and Strategies

Maintaining Accuracy

Overview of the Challenge

Accuracy is critical in the energy industry, where even small deviations in component dimensions can result in costly failures or performance issues. Maintaining high precision throughout the CNC machining process is a major challenge, especially with the high-performance materials typically used in energy systems.

Impact on CNC Machining

Inaccuracies can lead to problems such as poor fits, imbalances in rotating parts, and compromised structural integrity. For instance, components like turbine blades or seals must be manufactured with extremely tight tolerances to ensure that they function correctly under operational stresses. Factors such as tool wear, machine calibration, and thermal expansion can all influence the accuracy of the final product.

Solutions and Strategies

Scalability Issues

Overview of the Challenge

As demand for energy-related components grows, CNC machining operations must scale accordingly. However, scaling up production in the energy sector while maintaining the same level of quality and precision can be difficult.

Impact on CNC Machining

Scaling production can lead to longer lead times, increased operational costs, and logistical challenges. Additionally, producing larger quantities of parts may require more advanced machinery and a more skilled workforce. For example, wind turbine blades require significant machining resources, and scaling production without sacrificing quality or increasing costs is a challenge many manufacturers face.

Solutions and Strategies

Machine Wear and Maintenance

Overview of the Challenge

As CNC machines are subjected to continuous use, wear and tear can affect their performance, especially when machining hard materials at high speeds. Maintenance becomes crucial to ensure that machines are operating at peak efficiency, particularly when machining precision parts for the energy industry.

Impact on CNC Machining

Machine downtime caused by maintenance can lead to delays in production schedules, affecting project timelines. Additionally, worn-out machines may produce parts with defects, resulting in rework or scrapping. The replacement of machine parts and tools also increases operational costs.

Solutions and Strategies

Regulatory Compliance

Overview of the Challenge

The energy industry, especially in sectors like oil and gas, nuclear power, and renewable energy, is heavily regulated to ensure safety, environmental protection, and operational reliability. CNC machining operations must comply with various standards, certifications, and regulations, which can increase operational complexity.

Impact on CNC Machining

Regulatory compliance often requires additional processes, such as documentation, quality checks, and certifications, which can extend production times and increase costs. Furthermore, failure to meet these regulations could result in fines, delays, or safety risks.

Solutions and Strategies

Technology Upgrades

Overview of the Challenge

CNC machining technology is continuously evolving, with new advancements in automation, materials, and machining techniques. However, upgrading to newer technologies often involves significant capital investment and training, which can be a challenge for some companies, particularly those operating on tight margins.

Impact on CNC Machining

Failing to adopt the latest technology may result in a lack of competitiveness, as more advanced machines can provide higher efficiency, improved accuracy, and the ability to process new materials. However, implementing these technologies requires upfront investment and a transition period, during which operations may be temporarily disrupted.

Solutions and Strategies

Conclusion

CNC machining in the energy industry is not without its challenges, from high material costs and complex designs to regulatory compliance and the need for ongoing technological upgrades. However, by implementing advanced machining techniques, adopting automation, and maintaining rigorous maintenance schedules, manufacturers can overcome these challenges and continue to deliver high-quality, reliable components for the energy sector. As the demand for both renewable and non-renewable energy components grows, the future of CNC machining will rely on innovation, efficiency, and sustainability to meet the evolving needs of the industry.

By staying ahead of the curve, the energy sector can continue to leverage CNC machining to produce the critical parts needed to power the world, all while addressing the unique challenges that come with manufacturing in this dynamic and demanding field.

CNC (Computer Numerical Control) machining has revolutionized industries across the globe, including the energy sector, by providing the precision and efficiency necessary to create complex parts and components. However, with the growing emphasis on sustainability and environmental responsibility, the environmental impact of CNC machining has come into focus. As the energy industry shifts towards cleaner, greener technologies, the manufacturing processes associated with energy production, including CNC machining, must align with these objectives.

While CNC machining can be resource-intensive, it also offers numerous opportunities for minimizing waste, reducing energy consumption, and adopting eco-friendly practices. This article will explore the environmental impact of CNC machining in the energy sector, focusing on sustainable practices, waste reduction, and the role of emerging technologies in creating more environmentally responsible processes.

Eco-friendly Production Practices

Recycling of Metal Scraps

A key environmental benefit of CNC machining lies in its potential for recycling metal scraps, a common byproduct of the machining process. Given the high cost of materials such as titanium, stainless steel, and nickel alloys used in energy production components, recycling is not only environmentally responsible but also economically advantageous.

During CNC machining, metal waste generated from cutting, drilling, and milling operations can be collected and sent for recycling. This scrap material can be melted down and reused, significantly reducing the demand for new raw materials. Many CNC machining companies now have systems in place to capture metal shavings and chips, which are then sold to scrap metal processors or repurposed for new manufacturing.

Impact:

Energy-efficient Machinery

Modern CNC machines are increasingly designed with energy efficiency in mind. By utilizing advanced features like variable-speed drives, improved thermal insulation, and efficient power usage systems, CNC machining shops can significantly reduce their energy consumption. For example, machines that use energy-efficient motors or idle mode when not in use help minimize power usage, especially in large-scale production environments.

Manufacturers in the energy sector are investing in energy-efficient CNC machinery to not only meet their operational goals but also align with global sustainability initiatives. Additionally, energy-efficient machines often require less maintenance, extending their lifespan and further reducing their environmental footprint.

Impact:

Using Sustainable Materials

Sustainable material sourcing is becoming an essential aspect of CNC machining in the energy industry. Materials such as biodegradable plastics, recycled metals, and composites are gaining popularity in production processes. These materials offer the same high-performance characteristics required for energy components—such as strength, corrosion resistance, and durability—while being more environmentally friendly.

For example, using biocomposites or biodegradable plastics in certain components can significantly reduce the environmental impact compared to conventional materials. Additionally, some manufacturers are exploring ways to use more sustainable or renewable resources for energy production components, such as wind turbine blades and solar panel frames.

Impact:

Reducing Material Waste

Precision Machining

One of the most notable environmental benefits of CNC machining is its precision. Unlike traditional machining methods, which often result in significant material waste due to excess cutting and roughing, CNC machines operate with high precision, ensuring that only the necessary amount of material is used to create the final part. This precise cutting minimizes waste and optimizes the use of raw materials.

For example, CNC machining is commonly used to manufacture turbine blades, gears, and other components for the energy industry, where even minor inaccuracies can lead to major performance issues. The precision of CNC ensures that these components are produced with minimal scrap, thus reducing material wastage.

Impact:

Advanced Software

Modern CNC machining is often supported by advanced software systems that optimize cutting paths and machining strategies. These software programs can predict and minimize material waste by generating highly efficient machining plans. By analyzing the geometry of the part and optimizing toolpaths, CNC operators can reduce excess cutting and ensure that parts are made with as little scrap material as possible.

Additionally, software improvements have enabled the integration of simulation tools that help designers and manufacturers visualize the machining process before it even begins. This results in more accurate and efficient machining, with less need for rework or corrections.

Impact:

The energy industry is vast and diverse, spanning both renewable and non-renewable sectors, with each requiring precise and durable components for efficient energy production and distribution. CNC (Computer Numerical Control) machining plays a crucial role in meeting these needs by providing high-precision manufacturing solutions. However, as competition intensifies and sustainability becomes increasingly important, companies are looking for ways to make their operations more cost-effective.

CNC machining is already known for its efficiency and ability to produce complex components with high precision. However, maximizing the cost-effectiveness of CNC machining in the energy sector requires careful attention to various operational strategies. This includes optimizing production cycles, automating processes, leveraging predictive maintenance, procuring materials in bulk, and utilizing multi-tasking equipment. By combining these techniques, energy companies can lower production costs, reduce waste, and improve operational efficiency, all while maintaining the high standards required for energy-related components.

Optimize Production

Optimizing production is one of the most direct ways to enhance the cost-effectiveness of CNC machining in the energy industry. By refining workflows, reducing downtime, and improving machine performance, manufacturers can produce components more efficiently, thus cutting operational costs.

One of the most significant advantages of CNC machining is its ability to run with minimal human intervention once set up. This allows manufacturers to optimize production by:

Maximizing Machine Uptime: By scheduling regular maintenance and using advanced monitoring systems, CNC machines can be kept running for longer periods without the need for frequent downtime.

Impact:

Automate Processes

Automation is a powerful tool for enhancing the cost-effectiveness of CNC machining in the energy industry. By automating routine tasks, energy manufacturers can not only reduce labor costs but also improve consistency and precision, which ultimately leads to fewer defects and less material waste.

Key benefits of automation in CNC machining include:

Impact:

Predictive Maintenance

Predictive maintenance is a technique that allows CNC machines to monitor their condition in real time and predict when maintenance will be required. This approach contrasts with traditional reactive maintenance, where machines are repaired only after they break down, often resulting in costly and extended downtimes.

Predictive maintenance relies on sensors, analytics, and machine learning to monitor machine performance and detect early signs of wear or malfunction. By identifying potential issues before they lead to breakdowns, manufacturers can:

Impact:

Bulk Material Procurement

One of the most significant cost drivers in CNC machining is the price of raw materials, especially for high-performance alloys and metals used in the energy industry. By purchasing materials in bulk, manufacturers can significantly reduce material costs and lower the overall cost per part.

Bulk procurement of materials allows manufacturers to:

Impact:

Leverage Multi-tasking Equipment

The energy industry often requires the production of complex parts, such as turbine blades, generator components, and valve assemblies. Traditionally, producing these parts would require several different machines for each operation, such as milling, turning, and drilling. However, multi-tasking CNC machines are capable of performing multiple operations on a single machine, which reduces setup time, minimizes machine downtime, and maximizes efficiency.

Multi-tasking equipment, such as CNC turning centers with integrated milling, drilling, and tapping functions, offers several advantages:

Impact:

Conclusion

CNC machining offers significant cost-saving benefits to the energy industry, especially when optimized through strategies such as production optimization, automation, predictive maintenance, bulk material procurement, and the use of multi-tasking equipment. By implementing these techniques, manufacturers can improve their operational efficiency, reduce waste, and lower costs while maintaining the high levels of precision and quality required for energy-related components.

As the energy industry continues to grow, particularly in the renewable sector, the role of cost-effective manufacturing processes like CNC machining will become increasingly critical. By leveraging the full potential of CNC technology, energy producers can ensure that they remain competitive, sustainable, and efficient in the years to come.

As the world moves towards more sustainable and environmentally conscious energy production, the role of CNC machining in the green energy industry is evolving. CNC machining, which has been a cornerstone of precision manufacturing across various industries, is increasingly finding its place in the renewable energy sector. As the demand for more efficient, cost-effective, and environmentally friendly solutions grows, CNC machining will play a pivotal role in shaping the future of green energy.

CNC machining offers the energy industry numerous advantages, including high precision, material flexibility, and scalability. The rapid advancements in technology, combined with new production techniques and innovative energy systems, are pushing CNC machining to be even more efficient, sustainable, and cost-effective. As renewable energy sectors such as wind, solar, hydro, and geothermal continue to grow, CNC machining will be instrumental in meeting the increasing demand for high-quality, durable components for these energy systems.

Technological Advances in CNC Machining

The future of CNC machining in the green energy industry is being shaped by several technological advances that promise to enhance efficiency, precision, and sustainability. These innovations not only improve the performance of machining processes but also align with the growing demand for environmentally friendly manufacturing solutions.

Automation and Robotics

Automation and robotics are two of the most transformative technologies driving the future of CNC machining. The integration of robotics with CNC machines allows for more flexible, precise, and faster manufacturing processes. This is particularly important in the green energy sector, where demand for renewable energy components is growing rapidly, and the need for scalability and reduced production times is critical.

Additive Manufacturing

Additive manufacturing (3D printing) is increasingly being used in conjunction with CNC machining, offering opportunities to create more complex parts with less material waste. In the green energy industry, this can be particularly advantageous for producing lightweight, custom-designed components that are difficult or costly to create using traditional machining methods.

Intelligent CNC Machine Tools

The integration of intelligent CNC machine tools represents another key development in the future of machining for the energy industry. These advanced tools use artificial intelligence (AI) and machine learning (ML) algorithms to optimize manufacturing processes in real time. By continuously monitoring performance data, these machines can adapt their behavior to improve precision, reduce cycle times, and extend tool life.

Emerging Energy Fields and CNC Machining

As the green energy sector expands, new technologies and energy systems are emerging that will require advanced CNC machining solutions. Some of the most promising emerging energy fields include hydrogen energy and ocean energy, both of which will present unique challenges and opportunities for precision manufacturing.

Hydrogen Energy Systems

Hydrogen is considered a clean and efficient alternative to fossil fuels, and its potential in energy production is immense. Hydrogen energy systems require complex components such as fuel cells, hydrogen storage tanks, and various types of piping and valves that can withstand high pressures and corrosive environments. CNC machining will be key in producing these components with the precision needed for safety and reliability.

Ocean Energy

Ocean energy, which includes wave, tidal, and ocean thermal energy, is another area where CNC machining will be crucial. The infrastructure needed to harness energy from the ocean, such as tidal turbines and wave energy converters, involves the production of large, durable components that must be resistant to harsh marine environments.

As a leading provider of CNC machining services, VMT is well-equipped to support energy projects, including those in the renewable energy sector. Our advanced CNC machining capabilities, combined with our commitment to quality, precision, and sustainability, make us the ideal partner for energy companies looking to manufacture components for wind, solar, hydro, and emerging energy systems.

At VMT, we understand the unique demands of the energy industry and offer tailored solutions to meet the specific requirements of each project. Whether you need precision components for wind turbines, solar panels, or cutting-edge hydrogen systems, VMT has the expertise and technology to deliver superior results.

The future of CNC machining in the green energy industry looks promising, with technological advancements such as automation, robotics, additive manufacturing, and intelligent machine tools leading the way. As renewable energy sectors continue to expand, CNC machining will play an essential role in manufacturing the precise, durable components required for efficient energy production.

With the rise of emerging energy fields like hydrogen and ocean energy, CNC machining will become even more vital in meeting the challenges of producing high-performance parts for these innovative technologies. By leveraging the latest advances in machining technology, companies can optimize production, reduce costs, and contribute to the growth of a sustainable energy future.

1. How does CNC machining support green energy projects?

CNC machining provides the precision and efficiency needed for producing high-quality components in renewable energy systems, such as wind turbines, solar panels, and hydrogen fuel cells.

2. What is the role of automation in CNC machining for energy projects?

Automation in CNC machining allows for faster production times, higher precision, and reduced human error, making it ideal for manufacturing energy components in large quantities.

3. How does additive manufacturing benefit CNC machining in the energy sector?

Additive manufacturing allows for the creation of complex, custom-designed parts with less material waste and faster prototyping, which is particularly valuable in the development of energy systems.

4. What are some emerging energy technologies that will rely on CNC machining?

Emerging technologies such as hydrogen energy systems and ocean energy will require precision machining for components like fuel cells, turbines, and storage systems.

5. Why choose VMT for CNC machining in energy projects?

VMT offers advanced CNC machining capabilities, expertise in manufacturing precision components, and a commitment to sustainability, making us the ideal partner for energy projects.

By incorporating these technological advances and emerging energy fields, the future of CNC machining in the green energy industry holds tremendous potential for innovation and sustainability.