15 years one-stop China custom CNC machining parts factory

570 |

Published by VMT at Jul 29 2024

570 |

Published by VMT at Jul 29 2024

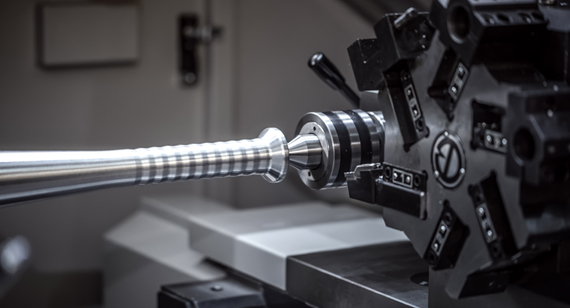

In the vast field of manufacturing, CNC drilling technology has become an indispensable part of modern machining due to its high precision, efficiency, and broad applicability. CNC drilling utilizes computer programming to control the precise movements of machine tools, achieving automated machining from simple to complex hole patterns. This article delves into the CNC drilling process, types, widespread applications, and notable advantages, while also examining the key components of CNC drilling machines, different types of CNC drilling machines, and the diversity of CNC drill bits. Finally, it discusses the cost-effectiveness, time efficiency, and critical factors for successful CNC drilling implementation.

CNC drilling is a technology that uses CNC machines for hole-making processes, integrating computer technology, automation technology, and precision mechanical technology. Through pre-written programs (usually G-codes), CNC machines can precisely control the position, depth, speed, and direction of the drill bit on the workpiece, thus completing high-quality hole-making tasks. Whether it's a single hole, multiple holes, blind holes, or through holes, CNC drilling can achieve extremely high precision and efficiency.

Design and Planning: The starting point of CNC drilling is the design and planning stage. Engineers first use CAD (Computer-Aided Design) software to create a 3D model of the workpiece and determine the position, size, shape, and depth of the holes to be machined. This stage is the foundation for ensuring subsequent machining accuracy.

Programming: Based on the CAD model, programmers use CAM (Computer-Aided Manufacturing) software to generate G-codes. G-codes are the "language" of CNC machines, detailing how the machine should move the drill bit, when to start and stop machining, and various parameter settings during the process.

Setup: Install and secure the workpiece on the machine, and select and install the appropriate drill bit. According to the G-codes, the machine's control system will automatically align the drill bit, ensuring the relative position between the drill bit and the workpiece is accurate.

Drilling: The machine starts machining according to the G-code instructions. The drill bit rotates and feeds at the specified position to form the desired hole. The CNC machine can monitor the machining process in real-time and make adjustments as needed to ensure machining quality.

Monitoring and Adjusting: During the machining process, operators need to closely monitor the machine's operational status to ensure no abnormalities occur. Simultaneously, based on the machining progress and results, adjustments to cutting parameters or G-code optimization may be necessary for better outcomes.

Post-Processing: After machining, perform necessary cleaning and inspection tasks, such as removing burrs, measuring hole diameters and depths, etc. Ensure the machined part meets design requirements before proceeding to subsequent processing or assembly.

Quality Control and Inspection: Use measuring instruments to precisely measure the machined part, verifying its dimensional accuracy and surface quality against standards. Rework or remachining may be necessary if required.

Advantages:

Higher Precision: CNC drilling uses computer control to achieve micron-level machining precision, meeting the demands of high-precision parts.

Wider Applicability: Capable of machining various materials (metals, non-metals, composites) and complex hole shapes and positions.

Higher Repeatability: Once programmed, CNC machines can repeatedly follow the set program, ensuring consistency and stability in machining.

Multifunctionality: With different tools and programming strategies, CNC drilling can perform drilling, reaming, boring, and more.

Limitations:

Initial Investment Cost: CNC machines and their accompanying equipment are relatively expensive, posing an economic burden for small and medium enterprises.

Operational Complexity: Requires skilled personnel for programming and operation, demanding higher technical proficiency from operators.

Maintenance Requirements: Regular maintenance and servicing are necessary to ensure the machine's long-term stable operation, increasing operational costs.

CNC drilling technology encompasses various operation types to meet different machining needs:

Spot Drilling: Creating a single hole at a specified location.

Drilling: Basic hole-making operation to form straight holes.

Reaming: Finishing already drilled holes to improve precision and surface quality.

Boring: Enlarging hole diameters and improving hole shape and position accuracy.

Counterboring: Creating a larger diameter flat-bottom hole at the hole's mouth.

Countersinking: Creating a conical recess at the hole's mouth for screws or fasteners.

Tapping: Creating internal threads within holes.

Micro-Drilling: Machining small-diameter holes, typically for precision instruments and electronic devices.

Center Drilling: Providing a centering hole for large hole machining, enhancing subsequent machining accuracy.

Peck Drilling: Using intermittent feed to reduce cutting force, suitable for deep hole machining.

Gun Drilling: A specialized deep hole machining method for long aspect ratio holes.

Vibratory Drilling: Utilizing vibration-assisted cutting to improve efficiency and hole wall quality.

CNC drilling machines, as high-precision, high-efficiency machining equipment, have core components directly affecting machining quality and production efficiency. The main key components include:

Control Panel: The human-machine interface of the CNC drilling machine, allowing operators to input commands, monitor the machining process, and adjust machine parameters. Modern control panels often use touch screen technology for intuitive and convenient operation.

Spindle: A core component responsible for driving the drill bit's rotational movement. The spindle's precision, rigidity, and stability directly influence drilling accuracy and surface quality. It typically uses high-precision bearings and comes with an automatic lubrication system for long-term stable operation.

Drill Bit: The direct tool for CNC drilling, whose shape, material, and geometry determine the hole's shape, size, and surface quality. Different types of drill bits include twist drills, center drills, point drills, and carbide drills. Selecting the appropriate drill bit is crucial for improving machining efficiency and ensuring quality.

Work Table: The component used to install and secure the workpiece, requiring sufficient rigidity and stability to prevent deformation or displacement during machining. The work table also needs flexible adjustment capabilities to accommodate different workpiece sizes and shapes.

Motor: The power source of the CNC drilling machine, driving the spindle and other moving parts. The motor's performance directly impacts machining speed and accuracy. Modern CNC machines often use high-performance servo motors or variable frequency motors for precise speed and position control.

Tool Changer: An essential component for machines requiring multiple hole types or sizes, allowing automatic tool changes during machining. The tool changer needs to be fast, accurate, and reliable, minimizing the impact on machining accuracy.

Cooling System: Reduces cutting temperature, extends tool life, and improves machining quality by spraying coolant onto the cutting area during high-speed drilling. It also aids in chip removal and cutting area cleaning.

Chip Conveyor: Collects and removes cutting chips during drilling to prevent blockages and ensure machining quality. Typically uses suction or dust collection methods to gather and remove chips from the machine.

CNC drilling machines can be categorized based on structure, machining range, and applications to meet different needs. Common types include:

Vertical CNC Drilling Machine: With the spindle perpendicular to the work table, it is suitable for machining holes in medium to small workpieces. It is compact, has a small footprint, and is easy to operate, widely used in mold making and machining.

Radial CNC Drilling Machine: Uses the arm's swing and spindle rotation to machine workpieces, offering a wide range of machining and flexibility, suitable for large workpieces or multi-position hole machining.

Gang Drill Press: Specially designed for multi-hole machining, completing multiple drilling tasks in one setup, significantly improving efficiency, widely used in automotive and aerospace production lines.

Bench CNC Drilling Machine: A small, desktop-mounted CNC drilling machine for small workpieces or simple hole tasks. It is compact, lightweight, and affordable, ideal for small enterprises and personal workshops.

Multi-Spindle Drilling Machine: Equipped with multiple spindles and drill bits, it can simultaneously machine multiple holes, enhancing efficiency and production capacity, suitable for high-volume production.

Turret CNC Drilling Machine: Uses a turret tool holder structure for automatic tool changes during machining, improving flexibility and adaptability, widely used in mold making and precision machining.

CNC Deep Hole Drilling Machine: Specialized for deep hole machining, using special drills and techniques for precise deep hole machining, widely used in petroleum, chemical, and aerospace sectors.

Portable CNC Drilling Machine: Small and portable, suitable for on-site machining or repairs, used in shipbuilding, bridge construction, and other field operations, with compact design for easy mobility and installation.

Gantry CNC Drilling Machine: With a gantry frame structure, the spindle moves along the gantry beam while the work table moves along the bed, offering a large machining range and load capacity, suitable for large plates or heavy workpieces, used in heavy machinery, bridge construction, and wind power sectors.

Laser CNC Drilling Machine: Uses high-energy laser beams to create small holes, suitable for non-metallic and hard-to-machine materials, used in electronics, automotive, and aerospace sectors.

High-Precision CNC Drilling Machine: Emphasizes precision and surface quality, equipped with high-precision spindles, guideways, and advanced control systems for micron or even nanometer-level precision, used in precision mold making, optical component processing, and semiconductor manufacturing.

Automatic Loading and Unloading CNC Drilling Machine: With an automatic system to load and unload workpieces, suitable for high-volume, repetitive tasks, improving efficiency and reducing manual intervention.

Five-Axis CNC Drilling Machine: Adds two rotational axes (usually around the X and Y axes) to the three-axis base, allowing complex movements and angle adjustments for complex geometric shapes and angles, used in aerospace and automotive sectors for high-precision parts.

In summary, CNC drilling machines can be categorized by structure, machining range, precision requirements, and automation levels, each type having specific applications and advantages. When selecting a CNC drilling machine, consider the specific machining needs and conditions comprehensively.

CNC drilling employs various types of drill bits, each designed to perform specific functions and suited to different materials and machining conditions. Common types include:

Twist Drill Bits: The most widely used type in industrial manufacturing, suitable for drilling a wide range of materials.

Center Drill Bits: Typically used to create a centering point before drilling, available in various tip angles (e.g., 60°, 75°, 90°).

Carbide Drill Bits: Made of ultra-hard carbide material at the tip or the entire drill body, ideal for machining high-hardness materials.

Indexable Drill Bits: Feature replaceable inserts, enhancing the drill's durability and flexibility.

Coolant-Fed Drill Bits: Designed to supply coolant during drilling to reduce temperature and extend the drill bit's life.

Step Drill Bits: Have gradually increasing diameters along the length, used for creating step holes.

Terms like "spot drilling" and "peck drilling" refer to specific drilling techniques rather than particular types of drill bits.

The main parameters of CNC drilling that directly impact machining quality and efficiency include:

Drill Diameter: The size of the drill bit, usually measured in millimeters (mm).

Drilling Depth: The depth of the hole, also measured in millimeters (mm).

Feed Rate: The speed at which the drill bit advances into the material, generally expressed in millimeters per minute (mm/min).

Spindle Speed: The rotational speed of the cutting tool, typically measured in revolutions per minute (rpm).

CNC drilling can be applied to a wide variety of materials, including but not limited to:

Metal Materials: Such as iron, steel, aluminum, copper, stainless steel, etc.

Non-Metal Materials: Including plastics, wood, ceramics, etc.

Composite Materials: Like carbon fiber composites.

The suitability of materials and the quality of machining depend on the drill bit material, type, and machining conditions.

CNC drilling has extensive applications across multiple industries, including:

Mechanical Manufacturing: Such as automotive, aerospace, and shipbuilding industries that require extensive hole processing.

Electronics Industry: For manufacturing circuit boards and electronic components requiring high-precision hole processing.

Hardware Industry: Including door and window hardware, bathroom hardware, etc., where CNC drilling can meet processing needs.

Medical Device Industry: Such as surgical instruments and diagnostic equipment, where high-precision hole processing is essential.

CNC drilling offers several advantages in terms of cost-effectiveness:

Increased Production Efficiency: Automated control significantly boosts production efficiency.

Reduced Processing Costs: Higher efficiency leads to lower per-unit production costs.

Enhanced Machining Precision: High-precision hole processing reduces waste, further improving economic benefits.

However, the cost-effectiveness of CNC drilling is influenced by factors like tooling and equipment costs, material expenses, design complexity, production volume, maintenance, and operation. A comprehensive evaluation of these factors is necessary to assess the overall cost-effectiveness in practical applications.

The time required for CNC drilling varies based on several factors, including:

Material Hardness: Harder materials take longer to drill.

Hole Depth and Diameter: Larger and deeper holes require more time.

Machine Speed and Efficiency: Different CNC drilling machines have varying speeds and efficiencies.

Tool Change and Setup Time: Time needed for tool changes and setup also affects the total machining time.

Operator Skill: The skill and experience of the operator influence machining efficiency.

Therefore, it is not feasible to provide a specific time for CNC drilling without considering the actual circumstances.

Important considerations for effective CNC drilling include:

Material Selection: Choose appropriate materials based on processing requirements.

Tool Selection: Select suitable drill bits and other tools based on material and machining needs.

Spindle Speed and Feed Rate: Balance efficiency and precision by setting appropriate spindle speed and feed rate.

Coolant and Lubricant Usage: Use coolants and lubricants to reduce drill bit temperature and extend tool life.

Effective Chip Removal: Ensure timely removal of chips to maintain machining quality and efficiency.

Tool Design Considerations: Consider factors like drill bit diameter, length, and angle.

Programming Details: Accurate programming is the cornerstone of CNC drilling, ensuring process accuracy and efficiency.

CNC drilling services for precision machined parts are an indispensable part of the manufacturing industry. Professional CNC drilling services can meet customer demands for high-precision, high-efficiency hole processing. These services typically encompass the entire process from material selection, tool configuration, and setting machining parameters to final product inspection.

CNC drilling is a high-efficiency, precise machining method with widespread applications in various fields. By selecting the appropriate drill bit type, setting machining parameters, and optimizing the machining process, the efficiency and accuracy of CNC drilling can be ensured, thereby enhancing product quality and market competitiveness.

In practical applications, enterprises should select suitable CNC drilling equipment and tools based on their processing needs and conditions, and focus on operator skill training and equipment maintenance to ensure stable operation and long-term benefits of CNC drilling.

Furthermore, with continuous technological advancements, CNC drilling technology is constantly innovating and evolving. Enterprises should keep abreast of the latest CNC drilling technologies and equipment, actively adopting and applying new technologies to enhance their machining capabilities and market competitiveness.

What is the difference between CNC milling and CNC drilling?

CNC milling involves cutting material to form various shapes and features using a rotating milling cutter. CNC drilling specifically refers to creating round holes in the workpiece, typically using drill bits.

What is the difference between CNC drilling and thread tapping?

CNC drilling involves creating holes in the workpiece, while thread tapping processes the drilled holes to create internal threads for screws or other fasteners. Though both are hole-making processes, their purposes and tools differ.

What is the difference between CNC drilling and CNC lathe?

CNC lathes primarily machine cylindrical parts by rotating the workpiece and moving the tool. CNC drilling focuses on creating holes in the workpiece. Both use CNC technology but have different machining targets and methods.

What is the maximum hole depth achievable by CNC drilling?

The maximum hole depth depends on the drill bit length, machine travel, and material properties. Modern CNC drilling machines can process deep holes, but special drill bits or strategies may be required for particularly deep holes.

What types of drill bits are suitable for deep holes?

Deep hole drilling often uses specialized drill bits like gun drills, BTA (Boring and Trepanning Association) drills, and ejector drills. These drill bits feature special chip removal and cooling systems for efficient deep hole machining.

What is threading in drilled holes?

Threading involves creating spiral grooves on the inner walls of drilled holes, allowing screws or other fasteners to engage. Drilling itself does not create threads; threading is an additional process post-drilling.