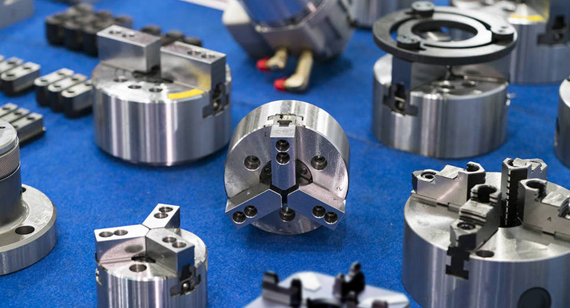

15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

190 |

Published by VMT at Nov 25 2023

190 |

Published by VMT at Nov 25 2023

Choose high-quality drill bits designed specifically for stainless steel. Carbide or cobalt drill bits are often preferred due to their hardness and heat resistance. Proper tool selection ensures efficient cutting and minimizes wear during the drilling process.

Optimal Cutting Speeds:

Stainless steel's hardness requires careful consideration of cutting speeds. Utilize the manufacturer's recommendations for the specific stainless steel alloy being machined. Maintaining an optimal cutting speed prevents overheating, prolongs tool life, and ensures clean, precise holes.

Coolant Application:

Implement an effective coolant strategy to manage heat generated during drilling. Coolants help dissipate heat, reduce friction, and prevent workpiece distortion. Consider using water-soluble or synthetic coolants that are suitable for stainless steel CNC machining.

Peck Drilling Technique:

Employ peck drilling, especially for deeper holes. This technique involves periodically retracting the drill bit during the drilling process to clear chips and prevent chip packing. Peck drilling helps maintain drilling accuracy and prevents tool breakage.

Steady Feed Rates:

Maintain consistent and steady feed rates during the drilling operation. This prevents excessive tool wear and ensures uniform hole quality. Adjust the feed rate based on the drill diameter, material thickness, and the specific requirements of the stainless steel being drilled.

Proper Fixturing and Clamping:

Ensure secure fixturing and clamping of the stainless steel workpiece. This minimizes vibrations and deflections during drilling, contributing to hole accuracy. Use appropriate workholding devices to stabilize the workpiece and optimize the drilling process.

By incorporating these techniques into the CNC machining process for drilling stainless steel, you enhance efficiency, precision, and the overall success of your machining operations.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!