15 years one-stop China custom CNC machining parts factory

3 |

Published by VMT at Dec 26 2025 | Reading Time:About 3 minutes

3 |

Published by VMT at Dec 26 2025 | Reading Time:About 3 minutes

Understanding carbon density can feel confusing when you work with different carbon materials, from carbon steel to carbon fiber composites. This uncertainty can lead to design mistakes, unexpected weight issues, or higher machining costs. You need a clear, simple guide that explains carbon material density, how it’s measured, and why it matters for CNC machining parts and performance.

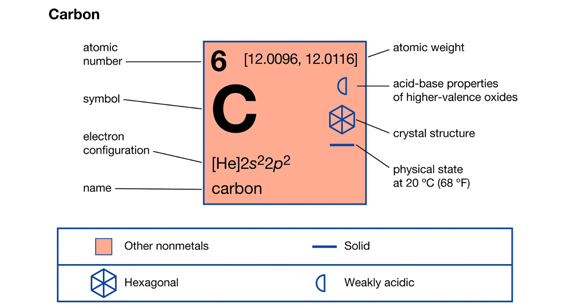

Carbon density refers to the mass of carbon per unit volume, typically expressed as carbon density in g/cm³ or kg/m³. You can calculate it by dividing mass by volume or by using standardized carbon density measurement methods such as Archimedes’ Principle or specific gravity tests. Different carbon materials have different density values based on structure and composition.

Now that you understand the basic meaning of carbon density, you can explore how different forms of carbon behave and why their density values vary so widely. This foundation will help you choose the right carbon material for strength, weight, conductivity, or CNC machining requirements as you read further.

The density of carbon in grams per cubic centimeter (g/cm³) depends on its structure. Most carbon materials fall within a carbon density range of 1.5–3.5 g/cm³. Amorphous carbon is usually around 1.8 g/cm³, graphite ranges from 2.26 g/cm³, and diamond reaches up to 3.51 g/cm³—the highest among carbon allotropes.

When expressed in kilograms per cubic meter (kg/m³), carbon density ranges from 1,500–3,500 kg/m³ depending on the material type. Amorphous carbon typically measures around 1,800 kg/m³, graphite averages 2260 kg/m³, and diamond reaches approximately 3,510 kg/m³, matching its exceptionally strong crystalline structure.

You can calculate carbon density by using the simple formula Density = Mass ÷ Volume. Weigh the carbon sample to get its mass, then measure or calculate its volume based on its shape. For irregular carbon materials, use water displacement or standardized carbon density measurement methods to obtain accurate results without guesswork.

Different types of carbon alloys—especially carbon steels—show a wide carbon material density range because their carbon content directly affects hardness, weight, and machinability. Understanding these density values helps you choose the right material for CNC machining parts, ensuring better strength-to-weight balance, predictable performance, and accurate cost estimation for your project.

| Material Type | Density (g/cm³) | Density (kg/m³) |

| Density of Carbon Steel (General Range) | 7.80 – 7.87 | 7,800 – 7,870 |

| Density of Low Carbon Steel | 7.85 | 7,850 |

| Density of Medium Carbon Steel | 7.85 – 7.87 | 7,850 – 7,870 |

| Density of High Carbon Steel | 7.87 | 7,870 |

Key Takeaways

Understanding carbon density helps you predict how a carbon material will behave in real applications. Density affects strength, weight, thermal behavior, conductivity, and even machining difficulty. When you understand these density differences, you can choose the right carbon material for durability, lightweight performance, heat resistance, or CNC machining parts that must meet strict tolerances.

Carbon Fiber Durability

Carbon fiber’s durability comes from its low density and high tensile strength. Its lightweight structure allows you to build strong components without adding unnecessary mass, making it ideal for aerospace and automotive CNC machining applications.

Carbon Hardness

Carbon hardness increases as density increases. High-density carbon forms—such as diamond-like structures—offer excellent wear resistance, while lower-density forms like graphite remain soft and lubricating. Understanding this helps you choose the right grade for mechanical parts.

Carbon Porosity

Lower-density carbon materials tend to be more porous, affecting strength, water absorption, and chemical resistance. High porosity lowers durability but improves properties like filtration and energy absorption.

Carbon Electrical Conductivity

Electrical conductivity depends heavily on carbon density and structure. Graphite (medium density) conducts electricity well, while carbon fiber and amorphous carbon vary widely. Denser, ordered carbon structures usually produce better conductivity.

Carbon Thermal Conductivity

Thermal conductivity improves with more crystalline and dense forms of carbon. Graphite and diamond conduct heat effectively, while amorphous carbon and some carbon composites offer lower heat transfer.

Carbon Weight

Carbon weight is directly tied to its density and determines how heavy or light your final CNC machined part will be. Lower-density carbon materials reduce weight but may sacrifice hardness or durability.

Energy Storage

Carbon density influences how well the material can store and release energy. Lower-density porous carbons are used in supercapacitors, while denser structures support battery performance and thermal stability.

Carbon exists in many allotropes and compounds, each with unique structures and properties that directly influence their density. From soft graphite to ultra-hard diamond, understanding the density of these forms is crucial when selecting materials for CNC machining parts, composites, or energy storage applications. Knowing the carbon density value allows you to predict weight, strength, and thermal performance accurately.

| Carbon Material / Allotrope | Density (g/cm³) | Density (kg/m³) |

| Density of Graphite | 2.26 | 2260 |

| Density of Diamond | 3.51 | 3,510 |

| Density of Fullerene (C60) | 1.65 | 1,650 |

| Density of Carbon Nanotubes | 1.3–1.4 | 1,300–1,400 |

| Density of Graphene | 2.31 | 2310 |

| Density of Carbophene | 1.4–1.5 | 1,400–1,500 |

| Density of Buckminsterfullerene | 1.65 | 1,650 |

| Density of Amorphous Carbon | 1.8–2.1 | 1,800–2,100 |

| Density of Lonsdaleite | 3.51 | 3,510 |

| Density of Carbon Fiber | 1.6–2.0 | 1,600–2,000 |

| Density of Carbon Monoxide | 0.00125 | 1.25 |

| Density of Activated Carbon | 0.4–0.5 | 400–500 |

| Density of Carbon Graphite | 2.2 | 2,200 |

| Density of Carbon Allotropes (general) | 1.3–3.5 | 1,300–3,500 |

| Density of Crystalline Carbon | 3.5 | 3,500 |

| Density of Non-Crystalline Carbon | 1.8–2.1 | 1,800–2,100 |

| Density of Carbon Fiber (composite) | 1.6–2.0 | 1,600–2,000 |

| Density of Carbon Composite | 1.5–2.2 | 1,500–2,200 |

| Density of Carbon Black | 1.8–1.9 | 1,800–1,900 |

| Density of Carbon Foam | 0.2–0.5 | 200–500 |

Key Takeaways

Understanding how carbon density compares to other common materials helps you make informed decisions when designing CNC machining parts. Carbon is generally lightweight yet strong, making it an excellent choice for applications where weight reduction is critical. By comparing carbon with metals, plastics, and ceramics, you can evaluate trade-offs in strength, durability, and thermal performance.

| Material | Density (g/cm³) | Density (kg/m³) |

| Density of Carbon | 1.3–3.5 | 1,300–3,500 |

| Density of Aluminum | 2.7 | 2,700 |

| Density of Graphite | 2.26 | 2260 |

| Density of Plastic (general) | 0.9–1.5 | 900–1,500 |

| Density of Ceramics (alumina) | 3.5–3.9 | 3,500–3,900 |

| Density of Titanium | 4.5 | 4,500 |

| Density of Stainless Steel | 7.7–8.0 | 7,700–8,000 |

| Density of Iron | 7.87 | 7,870 |

| Density of Steel | 7.75–8.05 | 7,750–8,050 |

| Density of Copper | 8.96 | 8,960 |

| Density of Brass | 8.4–8.7 | 8,400–8,700 |

| Density of Bronze | 8.7–8.9 | 8,700–8,900 |

| Density of Tin | 7.31 | 7,310 |

| Density of Tungsten | 19.3 | 19,300 |

| Density of Silver | 10.5 | 10,500 |

| Density of Zinc | 7.13 | 7,130 |

| Density of Magnesium | 1.74 | 1,740 |

Key Takeaways

The density of carbon is influenced by multiple factors, from its atomic arrangement to environmental conditions. Understanding these influences helps you select the right carbon material for CNC machining parts, ensuring proper strength, durability, and weight while avoiding unnecessary costs during manufacturing.

Atomic Structure

Carbon density is directly affected by its atomic structure. Crystalline arrangements like diamond and Lonsdaleite produce higher densities, while amorphous carbon or porous forms have lower densities.

Type and Strength of Covalent Bonds in the Material

Strong covalent bonding in carbon increases density. Materials with tightly bonded carbon atoms, such as diamond, have maximum density, while weaker bonding in graphite and carbon foams results in lower density.

Intrinsic Properties of Carbon

Intrinsic properties, such as atomic mass, allotrope type, and electron configuration, determine the base density of carbon. Heavier atomic arrangements lead to higher density values.

Manufacturing Method

The method used to produce carbon materials—whether chemical vapor deposition, sintering, or extrusion—can change porosity and microstructure, affecting density.

Types of Carbon Fibers

Carbon fiber density varies by fiber type: high-modulus fibers are denser than standard modulus fibers. This impacts weight, strength, and stiffness of CNC machined components.

Different Types of Resins

In composites, the resin matrix can alter the overall density. Denser resins increase the composite density, affecting part weight and machining behavior.

Pressure

High pressure during manufacturing can compact carbon particles, increasing density. Low-pressure processes may leave microvoids, reducing density.

Carbon Mass

The total mass of carbon in a given volume directly affects density. Adding fillers or impurities can either increase or decrease density depending on their weight.

Environment and Climate

Temperature and humidity can slightly affect carbon density by expanding or contracting microstructures. Extreme environments may also alter porosity over time.

Key Takeaways

Accurate carbon density measurement is essential for selecting the right carbon material for CNC machining parts, composites, and energy storage applications. Different methods provide varying levels of precision depending on the carbon type, structure, and intended use. Understanding these methods helps you ensure consistent material performance and avoid costly mistakes.

Archimedes' Principle

This method measures density by submerging a carbon sample in liquid and calculating volume from the displaced fluid. It is ideal for solid, non-porous carbon materials.

Pycnometer Test

A pycnometer measures the density of powders or small carbon samples by filling a precise container and weighing it. This method is suitable for fine carbon powders and composite materials.

Bulk Density Test

Bulk density evaluates the mass per unit volume of porous carbon materials, considering voids between particles. It is useful for activated carbon or carbon black.

True Density Measurement

True density excludes pores and voids, providing the actual material density. Gas pycnometry is commonly used to obtain true density for carbon powders and fibers.

ASTM Density Standards

ASTM provides standardized procedures to measure density for various carbon materials, ensuring global consistency and comparability.

ISO Density Test Methods

ISO standards define density testing methods similar to ASTM but tailored for international regulatory compliance. They cover solids, powders, and composites.

Ultrasonic Measurement

Ultrasonic waves measure density by detecting sound velocity through the carbon material. Denser materials transmit waves faster, making this method non-destructive.

Visual Spark Analysis

This method estimates density by analyzing the intensity and pattern of sparks produced when carbon is exposed to high-energy sparks. It is fast but less precise.

Infrared Absorption

Infrared absorption measures density indirectly by evaluating molecular vibrations and bond density. It works well with composite carbon materials.

X-ray Fluorescence Analysis

XRF analyzes density by measuring elemental composition and mass attenuation of X-rays. It is suitable for carbon composites with added elements or fillers.

OES Sorting (Optical Emission Spectroscopy)

OES evaluates density by analyzing the elemental composition and structure of carbon alloys. It is effective for high-precision carbon steel and composite parts.

Key Takeaways

Understanding carbon density is essential when designing and manufacturing CNC machining parts. Low-density carbon materials, such as carbon fiber and carbon foam, are ideal for lightweight structures in aerospace, automotive, and sports equipment. Medium-density materials, like graphite, are used for electrical components, heat sinks, and mechanical bearings. High-density carbon forms, such as diamond or Lonsdaleite, are applied in cutting tools, wear-resistant surfaces, and high-performance industrial parts.

Guiding Text: For more detailed insights on machining high-density carbon alloys, you can check our CNC Machining Services page, which explains handling and precision techniques for different carbon materials.

Carbon density plays a crucial role in determining the performance, weight, and machinability of carbon materials. From low-density carbon fibers to ultra-dense diamonds, understanding density allows you to select the right material for CNC machining parts, optimize energy efficiency, and ensure durability. By considering factors like atomic structure, manufacturing methods, and environmental conditions, you can achieve precise, cost-effective, and high-performing carbon components.

1. What is the density of a carbon atom nucleus?

The density of a carbon atom nucleus is extremely high, around 2.3 × 10¹⁷ kg/m³, because most of an atom’s mass is concentrated in its nucleus. This is vastly higher than bulk carbon materials.

2. What is the density of pure carbon?

Pure carbon density depends on its allotrope:

3. Is the density of pure carbon the same as its atomic weight?

No. Atomic weight (≈12 u for carbon) is a measure of a single atom’s mass, while density depends on how atoms are packed in a material and its volume.

4. Is the density of carbon low or high?

Carbon density varies:

Compared to metals like steel or tungsten, carbon is generally lighter.

5. What is the density of carbon-12?

Carbon-12 is an isotope with a standard atomic mass of 12 u. Its nuclear density is extremely high (~2.3 × 10¹⁷ kg/m³), but bulk material density depends on how carbon atoms are arranged.

6. What is the density of carbon-14?

Carbon-14 is a radioactive isotope of carbon. Its atomic mass is slightly higher (~14 u), but like carbon-12, its bulk material density depends on the structure of the material (graphite, diamond, etc.).

7. Which type of carbon has the highest density?

Diamond and Lonsdaleite are the densest forms of carbon, with a density of 3.51 g/cm³ (3,510 kg/m³), due to their tightly packed crystalline structures.

8. What are the five elements with the highest density?

The top five densest elements are:

Carbon, even in its densest form, is lighter than all of these.

9. What is the density of carbon dioxide?

At standard temperature and pressure (STP), carbon dioxide gas has a density of approximately 1.98 kg/m³. Its density is much lower than solid carbon due to the gaseous state.

10. What is the density of dry carbon fiber?

Dry carbon fiber typically ranges from 1.6–2.0 g/cm³ (1,600–2,000 kg/m³) depending on the fiber type and manufacturing process. Its low density combined with high strength makes it ideal for lightweight CNC machining parts.