15 years one-stop China custom CNC machining parts factory

294 |

Published by VMT at Nov 13 2024 | Reading Time:About 3 minutes

294 |

Published by VMT at Nov 13 2024 | Reading Time:About 3 minutes

Are you struggling to achieve the perfect surface finish and precision in your CNC machined parts? Frustrated by traditional machining methods that fall short of meeting the stringent requirements of your custom CNC machining projects? You're not alone. Many manufacturers face challenges in delivering high-quality components due to limitations in conventional machining techniques. But what if mastering diamond machining could unlock unparalleled quality and efficiency in your CNC machining services?

Diamond machining utilizes diamond-tipped tools to achieve exceptional surface finishes and ultra-precise dimensions in CNC machined parts. By leveraging the unparalleled hardness and thermal conductivity of diamonds, manufacturers can enhance component quality, extend tool life, and improve overall machining efficiency, making diamond machining an indispensable technique in custom CNC machining.

Now that we've uncovered how diamond machining can revolutionize your CNC machining capabilities, let's delve deeper into why it improves surface quality, explore its advantages, and share essential tips and tricks to master this advanced machining process.

Preface

In the competitive world of manufacturing, achieving superior quality and precision in CNC machined parts is paramount. Industries such as aerospace, electronics, medical devices, and automotive demand components with exceptional surface finishes and tight tolerances. Traditional machining methods often fall short in meeting these rigorous standards, leading manufacturers to seek innovative solutions. Diamond machining emerges as a game-changing technology that addresses these challenges by offering unmatched surface quality, dimensional accuracy, and efficiency in CNC machining services.

Diamond machining involves using diamond-tipped cutting tools in CNC machines to produce components with mirror-like finishes and nanometer-level precision. This technique leverages the unique properties of diamonds—the hardest known natural material—to cut materials that are difficult or impossible to machine with conventional tools. Whether you're operating a CNC machining plant or specializing in custom CNC prototype machining, understanding the tips and tricks of diamond machining can significantly enhance your manufacturing capabilities and set you apart from competitors.

Diamond machining dramatically enhances the surface quality of parts due to several intrinsic properties of diamonds and the precision they enable in the machining process. Diamonds boast a Mohs hardness of 10, making them the hardest natural material known. This exceptional hardness allows diamond tools to maintain an ultra-sharp cutting edge far longer than conventional tools made from carbide or high-speed steel. The sharpness of the cutting edge is crucial in achieving a superior surface finish, as it minimizes microscopic irregularities left on the workpiece during machining.

Furthermore, diamonds exhibit excellent thermal conductivity, which efficiently dissipates heat generated during the cutting process. Excessive heat can cause thermal expansion in both the tool and the workpiece, leading to dimensional inaccuracies and poor surface finishes. By reducing heat buildup, diamond tools maintain dimensional stability and prevent thermal damage to the workpiece.

Another critical factor is the low coefficient of friction between diamond and most workpiece materials. This reduces the force required for cutting and minimizes tool wear, which in turn maintains the integrity of the cutting edge and ensures consistent surface finishes throughout the machining process. Additionally, diamonds are chemically inert with most materials, preventing adverse reactions that could degrade the workpiece surface.

In essence, diamond machining improves surface quality by providing:

These attributes make diamond machining particularly effective for producing components that require high-quality finishes and precise dimensions, such as optical lenses, aerospace parts, and electronic components.

Incorporating diamond machining into CNC machining services offers a multitude of advantages that enhance product quality, operational efficiency, and overall competitiveness. Understanding these benefits is essential for manufacturers looking to optimize their processes and deliver superior CNC machined parts.

Excellent Aluminum Machining

Aluminum and its alloys are widely used in industries like aerospace and automotive due to their lightweight and strength characteristics. However, machining aluminum can be challenging because it tends to adhere to cutting tools, causing built-up edge formation that degrades surface finish. Diamond machining excels in aluminum machining because diamonds have a low affinity for aluminum, significantly reducing built-up edge issues. The result is a smoother surface finish and improved dimensional accuracy.

Moreover, diamond tools enable higher cutting speeds and feeds when machining aluminum, increasing productivity in CNC machining plants. The superior surface quality achieved often eliminates the need for secondary finishing processes, saving time and reducing costs in custom CNC machining.

Carbide Production

Carbide materials are extremely hard and abrasive, posing challenges for conventional cutting tools. Diamond machining is ideal for producing carbide components, such as cutting inserts, wear parts, and tooling. The hardness of diamonds allows them to cut carbide effectively without excessive tool wear. This capability is crucial in manufacturing high-precision carbide parts that are essential in various industrial applications.

Diamond machining ensures tight tolerances and excellent surface finishes in carbide production, enhancing the performance and longevity of the components. CNC machining services that specialize in carbide parts benefit from the efficiency and precision that diamond machining provides.

Diamond Polishing

Diamond polishing is a process where diamond tools are used to achieve ultra-smooth surfaces on workpieces. This technique is particularly valuable in the optics industry for producing lenses, mirrors, and other optical components that require nanometer-level surface finishes. Diamond polishing eliminates micro-irregularities that can scatter light, ensuring optimal optical performance.

In the semiconductor industry, diamond polishing is used to create flat, smooth surfaces on wafers and substrates, which is essential for the fabrication of microelectronic devices. By incorporating diamond polishing into CNC machining services, manufacturers can meet the stringent surface quality requirements of these high-tech industries.

Durability

Diamond tools exhibit exceptional durability due to their extreme hardness and resistance to wear. This longevity translates into extended tool life, reducing the frequency of tool changes and downtime in CNC machining plants. The consistent performance of diamond tools enhances productivity and lowers tooling costs over time.

The durability of diamond tools is particularly advantageous in high-volume production environments where tool wear can significantly impact efficiency and product quality. By maintaining sharp cutting edges for longer periods, diamond tools ensure consistent machining results and minimize variability in custom CNC machining.

Surface Finish

Achieving a superior surface finish is a key advantage of diamond machining. The ultra-sharp cutting edges and low friction properties of diamond tools result in minimal surface roughness and high-quality finishes. This is critical in applications where surface integrity affects the functionality or aesthetics of the component, such as in medical devices, aerospace parts, and consumer electronics.

A smooth surface finish also enhances the mechanical properties of the part by reducing stress concentrations and potential sites for crack initiation. In CNC machining services, delivering parts with exceptional surface finishes can differentiate a manufacturer in a competitive market.

Extended Tool Life

The hardness of diamonds means that diamond tools experience minimal wear compared to conventional tools. This extended tool life reduces tooling costs and maintenance requirements. In addition, longer-lasting tools improve machining consistency, as tool wear can lead to dimensional inaccuracies and surface finish degradation over time.

In custom CNC machining, extended tool life contributes to higher efficiency and cost-effectiveness. Manufacturers can run longer production cycles without interruption, ensuring timely delivery of CNC machined parts.

Unwavering Precision and Accuracy

Diamond machining allows for the production of components with unparalleled precision and accuracy. The stability of diamond tools under cutting forces ensures that tight tolerances are maintained throughout the machining process. This level of precision is essential in industries where component dimensions directly impact performance, such as in aerospace, medical devices, and precision engineering.

By utilizing diamond tools, CNC machining services can meet or exceed customer specifications, enhancing their reputation for quality and reliability. Precise machining also reduces the need for additional finishing or corrective processes, streamlining production workflows.

Quick and Efficient Material Removal

Diamond tools enable efficient material removal while maintaining surface integrity. The sharpness and durability of the cutting edges allow for higher cutting speeds and feeds without compromising quality. This efficiency is particularly beneficial when machining hard or abrasive materials that are challenging for conventional tools.

In CNC machining plants, faster material removal rates increase throughput and reduce production times. This efficiency can lead to significant cost savings and improved competitiveness in custom CNC machining.

Enhanced Component Durability

Components machined with diamond tools often exhibit improved durability due to the superior surface finish and precision achieved. A smoother surface reduces friction and wear in moving parts, extending the component's lifespan. Additionally, precise machining ensures proper fit and function, which is critical in assemblies and systems where component interactions affect overall performance.

By delivering durable components, CNC machining services can enhance customer satisfaction and reduce warranty claims or returns. This reliability strengthens customer relationships and can lead to repeat business and referrals.

Diamond tools possess unique characteristics that make them highly effective in precision machining applications. Understanding these properties is crucial for manufacturers aiming to optimize their CNC machining services using diamond machining.

Hardness

Diamonds are the hardest known material, which allows diamond tools to cut virtually any material with minimal wear. This hardness enables the tool to maintain a sharp cutting edge over extended periods, ensuring consistent performance and surface quality. The exceptional hardness also allows for machining of hard and abrasive materials that would quickly degrade conventional tools.

Thermal Conductivity

Diamonds have the highest thermal conductivity of any material, which helps dissipate heat generated during machining. Efficient heat removal prevents thermal damage to both the tool and the workpiece, maintaining dimensional accuracy and surface integrity. This property is particularly important in high-precision applications where thermal expansion can lead to unacceptable tolerances.

Low Friction Coefficient

The low coefficient of friction between diamond and most materials reduces cutting forces and minimizes heat generation. This results in smoother machining operations and less tool wear. Reduced friction also decreases the likelihood of built-up edge formation, which can negatively impact surface finish and tool life.

Chemical Resistance

Diamonds are chemically inert to most substances, which prevents adverse reactions between the tool and the workpiece material. This inertness maintains the integrity of both the tool and the part, ensuring consistent machining results. However, it's important to note that diamonds can react with ferrous metals at high temperatures, leading to tool degradation. Therefore, diamond tools are typically not used for machining steel or iron.

Diamond tools offer exceptional durability due to their hardness and resistance to wear. The extended tool life reduces tooling costs and minimizes downtime associated with tool changes. In CNC machining plants, this durability enhances productivity and allows for longer uninterrupted production runs.

Factors affecting diamond tool life include:

By carefully managing these factors, CNC machining services can maximize the benefits of diamond tool durability.

Diamond milling is a process that uses diamond-tipped milling cutters to remove material from a workpiece with high precision. This technique is particularly effective for producing components with complex geometries and superior surface finishes. Diamond milling is widely used in industries that require tight tolerances and high-quality finishes, such as aerospace, optics, and electronics.

Principles of Diamond Milling

Understanding the principles of diamond milling is essential for achieving optimal results in CNC machining. Key considerations include cutting edge accuracy, minimizing tool wear, and effective heat management.

Cutting Edge Accuracy

The precision of the diamond tool's cutting edge is critical in diamond milling. A sharp, accurately shaped cutting edge ensures clean cuts and consistent surface finishes. Manufacturers must ensure that diamond tools are properly manufactured and maintained to preserve cutting edge accuracy. Tool alignment and machine calibration in the CNC machining plant also play vital roles in maintaining precision.

Low Wear

Despite their hardness, diamond tools can still experience wear, especially when machining abrasive materials. To minimize wear, it's important to optimize cutting parameters, such as reducing excessive cutting speeds or depths that could overload the tool. Using appropriate coolants or lubricants can also reduce friction and heat, further extending tool life.

Heat Management

Effective heat management is crucial in diamond milling to prevent thermal damage to the tool and workpiece. High temperatures can lead to diamond degradation or graphitization, reducing tool effectiveness. Utilizing coolants, air blasts, or cryogenic cooling techniques helps dissipate heat and maintain optimal machining temperatures.

Comparing diamond milling with traditional machining methods highlights the advantages and considerations of adopting diamond tools in CNC machining services.

Tool Life

Diamond tools offer significantly longer tool life compared to conventional tools, reducing tooling costs and downtime associated with tool changes. The extended durability of diamond tools is particularly beneficial in high-volume production environments.

Surface Treatment

Diamond milling achieves superior surface finishes that often eliminate the need for additional surface treatments or polishing. Traditional machining methods may require secondary processes to achieve similar surface quality, adding time and cost to the production process.

Initial Cost

The initial cost of diamond tools is higher than that of conventional tools. However, the extended tool life and improved efficiency often offset the higher upfront investment over time. Manufacturers must consider the total cost of ownership when evaluating tooling options.

Long-Term Economy

In the long term, diamond machining can be more economical due to reduced tooling costs, improved productivity, and higher product quality. The efficiency gains and cost savings can enhance the competitiveness of CNC machining services.

Material Compatibility

Diamond tools are ideal for machining non-ferrous materials, composites, and certain ceramics. They are not suitable for ferrous metals due to chemical interactions that degrade the diamond. Traditional tools may offer broader material compatibility but may not achieve the same level of precision or surface quality.

Environmental Protection

Diamond machining can contribute to environmental sustainability by reducing waste and energy consumption. The efficiency of the process and the elimination of secondary finishing steps decrease resource usage and emissions in the CNC machining plant.

Diamond machining encompasses various technologies, each suited to specific applications and materials. Key techniques include single-point diamond turning, diamond milling, diamond fly cutting, diamond drilling, diamond grinding, and the use of diamond end mills.

Single Point Diamond Turning

Single-point diamond turning (SPDT) is a precision machining process that uses a diamond-tipped tool to produce components with nanometer-level surface finishes and sub-micron tolerances. The process involves rotating the workpiece on a lathe while the diamond tool removes material in a controlled manner.

Applications of Single Point Diamond Turning

SPDT is widely used in manufacturing optical components, such as lenses and mirrors, as well as precision mechanical parts for aerospace, defense, and medical devices. It is essential for producing components with complex geometries and ultra-smooth surfaces.

Advantages of Single Point Diamond Turning

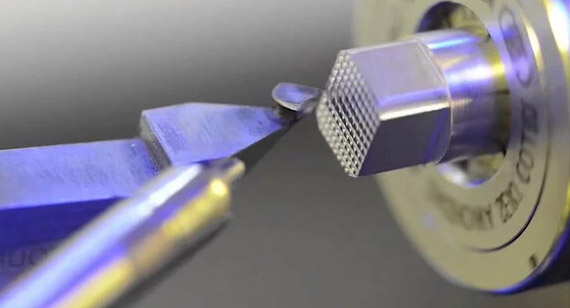

Single Point Diamond Milling Cutter

A single-point diamond milling cutter is a milling tool with a single diamond cutting edge used for precision milling operations. It is designed to produce high-quality surface finishes and precise dimensions in materials like aluminum, copper, and plastics.

Applications of Single Point Diamond Milling Cutter

This tool is used in the fabrication of microfluidic devices, optical molds, and intricate mechanical components. It is particularly effective in custom CNC machining where detailed features and tight tolerances are required.

Advantages of Single Point Diamond Milling Cutter

Diamond Fly Cutting

Diamond fly cutting is a machining process where a diamond tool is mounted on a rotating spindle and moved across the workpiece to produce flat or contoured surfaces with high precision. It is commonly used to create large, highly precise surfaces.

Diamond Fly Cutting Applications

Applications include manufacturing optical flats, precision molds, and components requiring extremely flat surfaces, such as semiconductor wafers.

Diamond Fly Cutting Advantages

Diamond Drilling

Diamond drilling involves using diamond-tipped drill bits to create precise holes in hard or brittle materials. The process is effective for materials like glass, ceramics, composites, and certain metals.

Diamond Drilling Applications

Used in the production of printed circuit boards, medical implants, and precision instruments. Diamond drilling ensures clean, accurate holes without causing cracks or chipping in delicate materials.

Diamond Drilling Advantages

Diamond Grinding

Diamond grinding uses diamond-embedded grinding wheels to remove material from a workpiece through abrasion. It is ideal for finishing hard materials and achieving tight tolerances.

Diamond Grinding Applications

Commonly used for sharpening cutting tools, finishing hard surfaces, and machining ceramics and composites. It is essential in industries requiring precise surface finishes and dimensions.

Diamond Grinding Advantages

Diamond End Mill

A diamond end mill is a milling cutter with diamond-tipped cutting edges used for precision milling operations. It combines the cutting action of an end mill with the durability and precision of diamond tooling.

Diamond End Mill Applications

Used in machining graphite electrodes, composite materials, and other abrasive or hard-to-machine materials. Ideal for applications requiring fine details and high-quality finishes.

Diamond End Mill Advantages

Diamond machining utilizes a range of tools tailored to specific applications:

Selecting the appropriate tool involves considering the workpiece material, desired surface finish, and machining process. Proper tool selection is critical for achieving optimal results in custom CNC machining.

Diamond tools are suitable for machining a variety of materials:

It's important to avoid using diamond tools on ferrous metals like steel and iron, as chemical reactions at high temperatures can degrade the diamond.

Diamond machining is unsuitable for:

In such cases, alternative tools like cubic boron nitride (CBN) or carbide are recommended.

Diamond milling is integral to industries requiring high precision and superior surface finishes.

Aerospace

Used for machining components from aluminum alloys and composites, diamond milling ensures tight tolerances and smooth surfaces essential for aerodynamic performance and structural integrity.

Electronics and Semiconductors

Essential for producing silicon wafers, microchips, and optical fibers. Diamond machining achieves the flatness and surface quality required for electronic functionality.

Medical Devices and Equipment

Used in manufacturing surgical instruments, implants, and diagnostic equipment where precision and biocompatibility are critical.

Jewelry and Gem Making

Diamond tools cut and polish gemstones and precious metals, achieving intricate designs and high-quality finishes.

Used for machining engine components, transmission parts, and lighting systems. Diamond machining enhances performance and longevity.

Diamond machining excels in applications requiring exceptional surface quality and precision.

Automotive Light Lens Prototype

Diamond machining produces prototypes with precise geometries and optical clarity, essential for evaluating performance and aesthetics before mass production.

Light Guide Plate

Used in displays and lighting, diamond machining creates microstructures with nanometer precision, improving light distribution and efficiency.

Mastering diamond machining unlocks new levels of precision and quality in CNC machining services. By understanding the unique properties of diamond tools and implementing the tips and tricks outlined in this guide, manufacturers can produce superior CNC machined parts that meet the exacting demands of modern industries.

Whether you're involved in CNC prototype machining or high-volume production, integrating diamond machining into your operations can significantly enhance your capabilities and competitiveness.

At VMT, we specialize in providing advanced diamond machining services tailored to your needs. Our state-of-the-art CNC machining plant is equipped with cutting-edge diamond machining technology, operated by a team of experienced professionals dedicated to excellence.

We offer comprehensive custom CNC machining solutions, from prototyping to large-scale production. Our commitment to quality ensures that your components meet the highest standards of precision and surface finish.

Contact us today to discover how our diamond machining services can elevate your manufacturing projects.

Which Country is Famous for Diamond Machining Cutting?

Japan is renowned for its expertise in diamond machining and ultra-precision manufacturing. Japanese companies have pioneered advancements in diamond cutting technology, particularly in the optics and electronics industries. Other countries with significant capabilities include Germany, Switzerland, and the United States.

Why is Diamond Cutting So Expensive?

Diamond cutting is expensive due to:

Low Volume Production: Custom or precision parts may not benefit from economies of scale.

How is a Diamond Machined?

Diamonds are machined using specialized equipment that can handle their extreme hardness and brittleness. Techniques include:

Careful control of cutting parameters and environmental conditions is essential to prevent damage and achieve the desired outcome.