15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

108 |

Published by VMT at Apr 26 2024

108 |

Published by VMT at Apr 26 2024

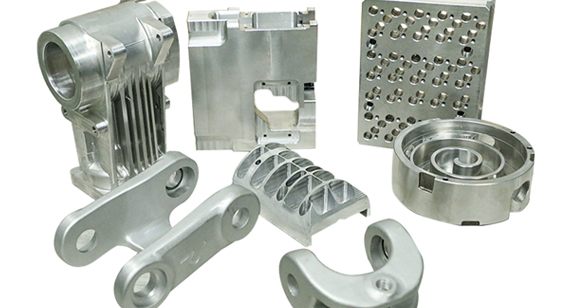

In the field of CNC machining part manufacturing, there are significant differences between precision CNC machined parts and regular CNC machined parts in several aspects. These differences are not only reflected in machining accuracy, quality stability, and process complexity but also in machining equipment, programming difficulty, production efficiency, and many other dimensions. This article will delve into the differences between precision CNC machined parts and regular CNC machined parts from these aspects.

Machining Accuracy and Quality Stability

The core advantage of precision CNC machined parts lies in their extremely high machining accuracy and quality stability. The dimensional accuracy of such parts typically ranges from 0.005 to 0.01mm, or even higher precision levels. In contrast, while regular CNC machined parts also have high precision requirements, they usually cannot achieve such fine levels of precision. This high precision is achieved mainly due to the high-performance precision CNC machining equipment and advanced machining technology. Additionally, precision CNC machined parts also have significant advantages in quality stability, maintaining long-term stable machining quality to meet the demands of high-precision parts.

Process Complexity and Machining Difficulty

Precision CNC machined parts typically have more complex shapes and structures, resulting in more complex machining processes. To meet high-precision machining requirements, precision CNC machining equipment needs to have higher motion accuracy and more stable performance. Moreover, precise programming and strict process control are required during machining to ensure the accuracy and quality of the parts. In contrast, the machining processes for regular CNC machined parts are relatively simpler, with lower requirements for equipment and programming.

Machining Equipment and Programming Techniques

Precision CNC machined parts require the use of high-performance CNC machine tools and advanced programming techniques to achieve high-precision machining. Such equipment is usually equipped with high-precision sensors and control systems to monitor and adjust the machining process in real-time, ensuring the machining accuracy and quality of the parts. Additionally, precision CNC machining also requires the use of more complex programming languages and algorithms to meet the machining requirements of complex-shaped parts. On the other hand, regular CNC machined parts can be produced using more common CNC machine tools and programming techniques, with relatively lower equipment requirements.

Production Efficiency and Cost

Although precision CNC machined parts have significant advantages in machining accuracy and quality stability, their production efficiency is usually lower than that of regular CNC machined parts. This is mainly because precision CNC machining requires longer machining times, more complex process controls, and stricter quality inspections. Additionally, due to the higher cost of precision CNC machining equipment, the machining cost is relatively higher. However, with technological advancements and equipment popularization, the production efficiency and cost control capabilities of precision CNC machining are continuously improving, allowing more enterprises to enjoy high-quality machining services.

Application Fields and Market Demand

Due to their high precision and quality stability, precision CNC machined parts are widely used in aerospace, automotive, electronics, medical devices, and other high-precision industries. These industries have extremely high requirements for part dimensional accuracy, complexity, and surface quality, which can only be met by precision CNC machining. In contrast, regular CNC machined parts are more commonly used in general mechanical manufacturing, home appliances, toys, and other fields with relatively lower precision requirements.

With the continuous development of the manufacturing industry, the market demand for precision CNC machined parts is also increasing. Especially in high-end equipment manufacturing, intelligent manufacturing, and other fields, precision CNC machining technology plays an irreplaceable role. To meet market demand, CNC machining factories need to continuously improve their technical levels and equipment performance, enhance the machining accuracy and quality stability of precision CNC machined parts, while reducing production costs and improving production efficiency.

Development Trends of CNC Machining Services

With the continuous development and expanding application fields of precision CNC machining technology, CNC machining services are also showing some new development trends. On one hand, CNC machining services are evolving towards personalized and customized directions to meet different customers' special requirements for part shapes, sizes, and precision. On the other hand, CNC machining services are gradually realizing intelligent and automated production. By introducing advanced technologies such as robotics and the Internet of Things, production efficiency and machining quality are improved.

Meanwhile, CNC machining services are also exploring new business models and cooperation methods to adapt to the rapidly changing market and diverse customer needs. For example, some CNC machining factories are adopting online platform models to provide customers with more convenient and efficient services. Additionally, some factories collaborate with other enterprises to jointly develop new products and technologies, achieving resource sharing and mutual benefit.

In summary, there are significant differences between precision CNC machined parts and regular CNC machined parts in terms of machining accuracy, quality stability, process complexity, machining equipment, programming techniques, production efficiency, and application fields. With the continuous development of the manufacturing industry and the increasing market demand, precision CNC machining technology will continue to play an important role in promoting CNC machining services to a higher level.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!