15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

931 |

Published by VMT at Jun 28 2024

931 |

Published by VMT at Jun 28 2024

Detailed Explanation of Electrolytic Coloring Technology

1. What is Electrolytic Coloring?

Electrolytic coloring is a technique that forms an oxide film on the surface of a metal through electrolysis, thereby achieving coloring of the metal surface. This technology is widely used in industries such as construction, home furnishings, and more, due to its uniform coloring, vibrant colors, and excellent corrosion resistance. Particularly in the field of aluminum CNC machining parts manufacturing, electrolytic coloring is an indispensable step.

2. Principle of Electrolytic Coloring Technology

Electrolytic coloring is an electrochemical reaction process. The basic principle is to apply voltage to the metal surface, causing an oxidation reaction and generating an oxide film. This oxide film usually consists of metal oxides, hydroxides, carbonates, and other compounds, with metal oxides being the most common. The coloring principle of electrolytic coloring depends on the type of electrolyte and metal salts used, with different electrolytes and metal salts producing different colors and effects.

3. What is Anodized Aluminum Electrolytic Coloring?

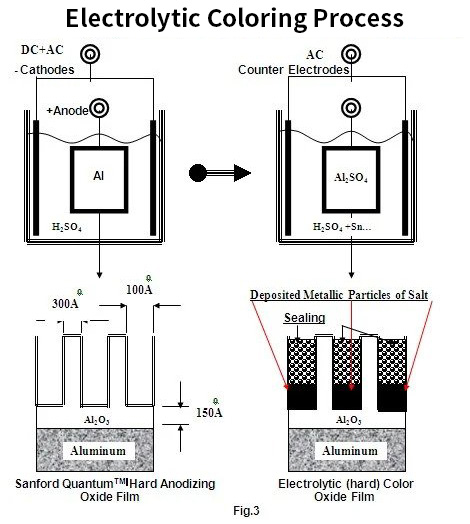

Anodized aluminum electrolytic coloring is an important type of electrolytic coloring technology, mainly targeting aluminum and aluminum alloy materials. During the anodizing process, aluminum is used as the anode and placed in an electrolyte solution such as sulfuric acid. By applying anodic voltage, a dense Al2O3 film is formed on the aluminum surface. This film has a dual-layer structure, including a dense barrier layer and a porous layer with a columnar structure. Subsequently, the anodized aluminum is immersed in a solution containing metal salts. Through electrolytic coloring, metal ions are reduced and deposited at the bottom of the pores in the oxide film, thereby coloring the aluminum and its alloys.

4. What is the Process Flow of Aluminum Electrolytic Coloring?

The process flow of aluminum electrolytic coloring mainly includes the following steps:

Pretreatment: Cleaning, degreasing, and rust removal of the aluminum surface to ensure the quality of the oxide film.

Anodizing: Placing the pretreated aluminum as the anode in an electrolyte solution such as sulfuric acid, applying anodic voltage for electrolysis to form a dense Al2O3 film.

Electrolytic Coloring: Immersing the anodized aluminum in a solution containing metal salts, where metal ions are reduced and deposited at the bottom of the oxide film pores, achieving coloring.

Sealing Treatment: Conducting sealing treatment on the colored aluminum to enhance the corrosion resistance and wear resistance of the oxide film.

5. Equipment for Electrolytic Coloring Technology

The equipment for electrolytic coloring technology mainly includes power supply, electrolytic tank, cathode, and anode. The power supply provides the electrical energy needed for electrolysis, the electrolytic tank contains the electrolyte solution and metal workpieces, and the cathode and anode are the electrodes used in the electrolysis process. Additionally, corresponding electrolyte circulation systems, temperature control systems, and other equipment are required to ensure the stable progress of the electrolytic coloring process.

6. In Which Industries is Electrolytic Coloring Applied?

Electrolytic coloring technology, with its unique advantages, is widely applied in various industries. In the construction industry, it is used to produce copper alloy doors, windows, curtain walls, and other building materials. In the electronics industry, it is used to produce electronic components, conductive films, and more. In the art industry, it is used for the surface coloring and protection of artworks. Additionally, electrolytic coloring technology plays a significant role in the automotive and aerospace fields.

7. Electrolytic Coloring of Aluminum CNC Machining Parts

In the field of aluminum CNC machining parts manufacturing, electrolytic coloring technology holds high application value. Through electrolytic coloring, the surface of aluminum CNC machined parts can be colored to enhance their decorative and corrosion-resistant properties. Moreover, electrolytic coloring technology can be customized according to customer requirements to produce aluminum CNC machined parts with different colors and effects, meeting personalized needs.

8. Value of Custom CNC Machining and Electrolytic Coloring Services

Custom CNC machining and electrolytic coloring services have significant value in modern manufacturing. CNC machining factories can provide customized CNC machining services according to customer requirements, producing aluminum CNC machined parts that meet customer specifications. By combining electrolytic coloring technology, the appearance quality and performance of the parts can be further enhanced, meeting customers' pursuit of high-quality products. Additionally, custom CNC machining and electrolytic coloring services can improve production efficiency, reduce production costs, and shorten delivery times.

9. Conclusion

As an advanced surface treatment technology, electrolytic coloring has broad application prospects in the field of aluminum CNC machining parts manufacturing. Through electrolytic coloring technology, the surface of aluminum CNC machined parts can be colored, enhancing their decorative and corrosion-resistant properties. By combining custom CNC machining services, the individual needs of customers for high-quality products can be met. Therefore, mastering electrolytic coloring technology and custom CNC machining service capabilities is of great importance to modern manufacturing enterprises.

10. Frequently Asked Questions

Can electrolytic coloring replace traditional thermal coloring processes?

Electrolytic coloring technology has many advantages over traditional thermal coloring processes, such as uniform coloring, vibrant colors, and corrosion resistance. However, each has its characteristics and application scenarios, and they cannot completely replace each other. When choosing a coloring process, specific requirements and material properties should be comprehensively considered.

What should be noted during the electrolytic coloring process?

During the electrolytic coloring process, it is important to control the composition, temperature, and concentration of the electrolyte to ensure the quality of the oxide film and coloring effect. Additionally, the stability of the power supply, the cleanliness of the electrodes, and the safe operation of the equipment must also be considered.

How should colored aluminum CNC machined parts be maintained?

Colored aluminum CNC machined parts need proper maintenance to extend their service life and maintain their appearance. Maintenance measures include regular cleaning, avoiding scratches and collisions, and keeping them dry. Additionally, avoid contact with strong acids, strong alkalis, and other chemicals to prevent damage to the oxide film and coloring layer.

What impact does electrolytic coloring technology have on the performance of aluminum CNC machined parts?

Electrolytic coloring technology not only imparts rich colors to aluminum CNC machined parts but also significantly enhances their corrosion resistance, wear resistance, and UV resistance. The oxide film formed by electrolytic coloring effectively blocks environmental corrosion on the substrate, thereby extending the service life of aluminum CNC machined parts.

Is sealing treatment required after electrolytic coloring of aluminum CNC machined parts?

Yes, sealing treatment is typically required after electrolytic coloring of aluminum CNC machined parts. Sealing treatment can further improve the corrosion resistance and wear resistance of the oxide film while reducing color loss and wear due to friction and scratches. Sealing treatment usually involves the use of sealants containing organic silicon, inorganic salts, and other components.

How to choose the appropriate electrolytic coloring process and equipment?

Choosing the appropriate electrolytic coloring process and equipment requires consideration of multiple factors, such as material characteristics, product requirements, production scale, and equipment performance. It is recommended that enterprises thoroughly understand the features, advantages, and disadvantages of different processes and equipment, and make a comprehensive consideration based on their actual situation. Additionally, professional advice and guidance can be obtained from electrolytic coloring technology suppliers or service providers.

Through the answers to the above questions, readers will have a deeper understanding of electrolytic coloring technology and its application in aluminum CNC machining parts manufacturing. In practical applications, enterprises should choose appropriate electrolytic coloring processes and equipment based on their needs and conditions, and strictly follow the process flow and operating procedures to ensure product quality and performance.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!