15 years one-stop China custom CNC machining parts factory

367 |

Published by VMT at Nov 15 2024 | Reading Time:About 6 minutes

367 |

Published by VMT at Nov 15 2024 | Reading Time:About 6 minutes

Are you struggling to find the perfect material for your plastic CNC machining parts that can withstand high stress, extreme temperatures, and demanding applications? Frustrated by traditional plastics that fail to meet the rigorous demands of your custom CNC machining projects? You're not alone. Many manufacturers face the challenge of selecting materials that combine durability, versatility, and performance. But what if engineering plastics could be the game-changer your CNC machining services need to elevate your products to the next level?

Engineering plastics are high-performance materials that offer superior mechanical and thermal properties compared to commodity plastics. They are designed for applications requiring enhanced durability, heat resistance, and structural integrity, making them ideal for plastic CNC machining parts in custom CNC machining and CNC prototype machining services.

Now that we've introduced the potential of engineering plastics in transforming your CNC machining projects, let's delve deeper into their definition, characteristics, and the various types available. Understanding these materials will empower you to make informed decisions for your CNC machining plant and elevate the quality of your products.

Preface

In the ever-evolving world of manufacturing, the demand for materials that can meet specific performance criteria is at an all-time high. Traditional plastics often fall short when it comes to applications that require high strength, thermal stability, and resistance to wear and chemicals. This is where engineering plastics come into play. These advanced materials have become a cornerstone in industries ranging from automotive and aerospace to electronics and medical devices. For professionals in custom CNC machining and CNC prototype machining, understanding engineering plastics is crucial for producing high-quality plastic CNC machining parts that meet the stringent demands of modern applications.

Engineering plastics are a group of plastic materials that exhibit superior mechanical and thermal properties compared to standard commodity plastics like polyethylene (PE) and polystyrene (PS). They are designed to withstand mechanical stress, high temperatures, chemical exposure, and other demanding conditions without compromising their structural integrity. Engineering plastics bridge the gap between metals and traditional plastics, offering a combination of lightweight characteristics and high performance.

These materials are used in applications where the properties of standard plastics are insufficient. Engineering plastics can replace metals in certain applications, providing benefits such as reduced weight, improved corrosion resistance, and easier processing in CNC machining services. Common examples of engineering plastics include polycarbonate (PC), acrylonitrile butadiene styrene (ABS), polyamide (PA or nylon), and polyetheretherketone (PEEK).

Engineering plastics are integral to the production of complex and high-precision plastic CNC machining parts. They are favored in custom CNC machining due to their excellent machinability and ability to hold tight tolerances, making them suitable for CNC prototype machining and large-scale production in CNC machining plants.

The primary difference between engineering plastics and ordinary, or commodity, plastics lies in their performance characteristics and applications. While commodity plastics like polyethylene (PE), polypropylene (PP), and polystyrene (PS) are used for high-volume, low-cost products such as packaging, containers, and disposable items, engineering plastics are used for applications requiring enhanced performance.

Key Differences:

For manufacturers specializing in custom CNC machining, the choice between engineering plastics and ordinary plastics hinges on the specific requirements of the application. Engineering plastics are the preferred choice when parts must meet rigorous performance standards, making them ideal for plastic CNC machining parts produced in CNC machining plants.

Engineering plastics offer a host of advantages that make them suitable for a wide range of applications. Their unique properties enable them to outperform ordinary plastics and even replace metals in certain scenarios. Below are some of the key advantages and properties that make engineering plastics a valuable choice for custom CNC machining and CNC prototype machining services.

Thermal Stability up to 120 to 150°C

Engineering plastics can operate effectively at elevated temperatures, typically between 120°C and 150°C, without significant degradation of their mechanical properties. Materials like PEEK can withstand even higher temperatures, up to 250°C. This thermal stability is essential for applications involving high heat, such as automotive engine components, electrical insulators, and industrial machinery parts. In CNC machining services, using materials that maintain integrity under heat ensures that the plastic CNC machining parts will perform reliably in their intended environments.

Excellent Machinability (Wear Resistance, Impact Strength)

Engineering plastics are known for their excellent machinability, allowing for precise and efficient fabrication of complex parts in CNC machining plants. Their wear resistance and impact strength make them suitable for components subjected to mechanical stress and friction. For instance, polyamide (nylon) and POM (acetal) are commonly used for gears, bearings, and bushings due to their low friction and high wear resistance. This machinability translates to cost savings and improved productivity in custom CNC machining.

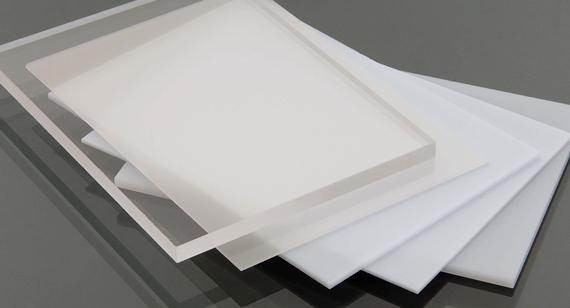

Optical Properties (Translucent and Transparent)

Certain engineering plastics, such as polycarbonate (PC) and polymethyl methacrylate (PMMA or acrylic), offer excellent optical properties, including transparency and clarity. These materials are ideal for applications requiring light transmission, such as lenses, light covers, and display screens. Their ability to be machined into precise shapes and sizes makes them valuable in CNC prototype machining for optical components.

Formability

Engineering plastics exhibit excellent formability, allowing them to be molded, machined, or thermoformed into complex shapes. This versatility is crucial in custom CNC machining, where parts often have intricate designs and tight tolerances. The formability of these plastics ensures that manufacturers can meet specific design requirements without compromising material integrity.

Dimensional Stability

Dimensional stability refers to a material's ability to maintain its dimensions under mechanical stress, temperature changes, and over time. Engineering plastics have low creep and shrinkage rates, ensuring that plastic CNC machining parts retain their shape and size throughout their lifespan. This property is essential in applications where precision and reliability are critical, such as in aerospace and medical devices.

Low Flammability

Many engineering plastics are formulated to be flame-retardant or have low flammability, enhancing safety in applications where fire resistance is necessary. Materials like polycarbonate and certain grades of polyamide are designed to meet stringent flammability standards. This property is particularly important in electrical and electronic components, where preventing the spread of fire is crucial.

Thermal Resistance (Minimum and Maximum Operating Temperatures)

Engineering plastics perform well across a wide temperature range. They retain their mechanical properties at low temperatures and resist deformation or degradation at high temperatures. This thermal resistance makes them suitable for outdoor applications and environments with temperature fluctuations. For CNC machining services, selecting materials with appropriate thermal resistance ensures that the plastic CNC machining parts will function effectively under varying conditions.

Waterproof

Many engineering plastics are inherently waterproof, resisting moisture absorption and preventing degradation due to water exposure. This property is vital for components used in marine environments, plumbing, or outdoor applications. Waterproof materials prevent swelling, warping, or loss of mechanical strength, ensuring longevity and reliability.

Lightweight

Engineering plastics offer a high strength-to-weight ratio, providing comparable or superior mechanical properties to metals at a fraction of the weight. This lightweight characteristic is advantageous in industries like automotive and aerospace, where reducing weight improves fuel efficiency and performance. In custom CNC machining, using lightweight materials can simplify handling and reduce shipping costs.

High Strength

Despite being lightweight, engineering plastics exhibit high tensile and impact strength. Materials like polyamide and polycarbonate can withstand significant mechanical loads, making them suitable for structural components. High-strength plastics allow for the design of robust parts without the added weight of metals.

Reduced Friction and Wear

Engineering plastics like POM (acetal) and PTFE (Teflon) have low coefficients of friction, reducing wear and extending the lifespan of moving parts. They are ideal for bearings, gears, and sliding components. In CNC machining services, using low-friction materials enhances the performance and efficiency of mechanical systems.

Good Chemical Resistance

Engineering plastics resist corrosion and degradation from exposure to chemicals, oils, solvents, and fuels. This chemical resistance is essential in applications involving harsh environments, such as chemical processing equipment, automotive fuel systems, and medical devices. It ensures that plastic CNC machining parts maintain their integrity and functionality over time.

Good Elasticity

Certain engineering plastics exhibit excellent elasticity, allowing them to absorb shocks and vibrations without permanent deformation. This property is beneficial in applications like vibration dampening components, seals, and gaskets. In CNC prototype machining, materials with good elasticity enable the development of parts that can withstand dynamic forces.

Good Stiffness

Engineering plastics offer a balance of stiffness and flexibility, providing rigidity where needed while allowing for some flexibility to absorb stress. Materials like polycarbonate and polyamide maintain stiffness under load, which is critical for structural components. This stiffness ensures that parts produced in CNC machining plants meet performance requirements.

Good Durability

The durability of engineering plastics means they can withstand mechanical stress, environmental exposure, and repeated use without significant degradation. This longevity reduces the need for frequent replacements and maintenance, offering cost savings over the product's lifecycle.

Electrical Properties

Many engineering plastics are excellent electrical insulators, making them suitable for electrical and electronic applications. They prevent the flow of electricity, protecting components and users from electrical hazards. Materials like polycarbonate and ABS are commonly used in electrical housings, connectors, and insulating components in CNC machining services.

Sliding Properties

Engineering plastics with good sliding properties reduce friction between moving parts, enhancing efficiency and reducing wear. Materials like PTFE and UHMWPE (Ultra-High-Molecular-Weight Polyethylene) are used in applications requiring smooth movement, such as conveyor systems and sliding bearings.

While engineering plastics offer numerous advantages, they also have certain limitations that manufacturers and designers must consider. Understanding these disadvantages is crucial in selecting the appropriate material for specific applications in custom CNC machining and CNC prototype machining services.

1. Low Temperature Resistance

Some engineering plastics become brittle at low temperatures, losing their impact strength and flexibility. Materials like polycarbonate and ABS may not perform well in extremely cold environments, leading to potential cracking or failure. This limitation requires careful material selection for applications exposed to low temperatures.

2. UV Degradation

Certain engineering plastics are susceptible to degradation when exposed to ultraviolet (UV) light. Prolonged exposure can lead to discoloration, loss of mechanical properties, and surface deterioration. Materials like polyamide may require UV stabilizers or protective coatings if used in outdoor applications.

3. Cost

Engineering plastics are generally more expensive than commodity plastics due to their advanced properties and lower production volumes. The higher material costs can impact the overall budget of a project, especially in large-scale production. Manufacturers must balance performance requirements with cost considerations in CNC machining services.

4. Limited Grades

While there is a variety of engineering plastics available, the selection is still limited compared to commodity plastics. This limitation may restrict the ability to find a material that meets all specific requirements, necessitating compromises or the use of additives and fillers to achieve desired properties.

5. Processing Challenges

Some engineering plastics have higher processing temperatures and require specialized equipment or tooling. Materials like PEEK and PTFE can be difficult to machine due to their high melting points and toughness. These processing challenges can increase manufacturing complexity and costs in CNC machining plants.

6. Environmental Impact

Engineering plastics are derived from petrochemicals and may not be biodegradable, raising environmental concerns. While recycling options exist, the processes can be more complex and less widely available compared to commodity plastics. Environmental regulations and sustainability goals may influence material choices.

7. Limited Transparency

Not all engineering plastics offer optical clarity. Materials like polyamide and PEEK are opaque, limiting their use in applications requiring transparency or translucency. This limitation necessitates the use of specific materials like polycarbonate or PMMA when optical properties are essential.

8. Chemical Compatibility

While engineering plastics generally offer good chemical resistance, they may not be compatible with all substances. Certain chemicals can cause swelling, cracking, or degradation. Material selection must consider the specific chemicals the part will encounter in its application.

9. Low Temperature Brittleness

At very low temperatures, some engineering plastics become brittle and may fail under impact or stress. This brittleness poses risks in applications like cryogenic systems or extreme cold environments, requiring materials specifically designed for such conditions.

Plastic engineering encompasses the development, design, and manufacture of plastic products and components. It involves selecting appropriate materials, designing parts to meet specifications, and employing manufacturing processes like custom CNC machining to produce high-quality plastic CNC machining parts. Understanding the principles of plastic engineering is essential for delivering effective solutions in CNC machining services.

Sourcing the Right Plastic Material for Your Project

Selecting the appropriate engineering plastic is a critical step in product development. Factors to consider include:

Working closely with material suppliers and leveraging expertise in custom CNC machining helps ensure the right material choice for your project.

Plastic Product Design Based on Specifications

Designing plastic parts requires careful consideration of:

Utilizing CAD software and simulation tools aids in optimizing designs for manufacturability and performance in CNC prototype machining.

Manufacturing Plastic Parts

Manufacturing methods for engineering plastics include:

Custom CNC machining offers advantages in producing high-quality plastic CNC machining parts, allowing for customization and quick turnaround times in CNC machining plants.

Plastic Product Performance Testing

Ensuring that plastic products meet performance requirements involves testing for:

Quality control processes in CNC machining services ensure that parts meet specifications and function as intended in their applications.

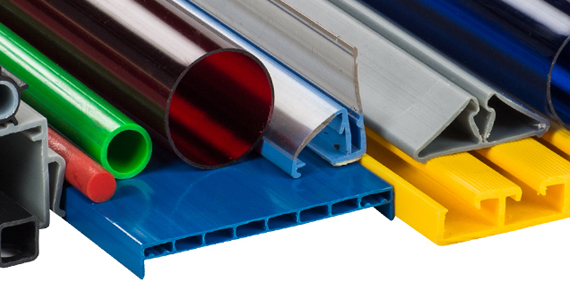

Engineering plastics encompass a variety of materials, each with unique properties suited to specific applications. Below is an overview of some common engineering plastics used in custom CNC machining and CNC prototype machining services.

1. Polycarbonate (PC)

Polycarbonate is a transparent, high-strength plastic known for its impact resistance and optical clarity. It has excellent dimensional stability and can withstand temperatures up to 135°C.

Applications:

Properties:

2. Acrylonitrile Butadiene Styrene (ABS)

ABS is a tough, rigid plastic with good impact resistance and machinability. It is widely used due to its balance of properties and cost-effectiveness.

Applications:

Properties:

3. Polymethyl Methacrylate (PMMA)

Also known as acrylic, PMMA is a transparent plastic with excellent optical properties. It is lighter and more impact-resistant than glass.

Applications:

Properties:

4. Polyphenylene Oxide (PPO)

PPO is a high-temperature engineering plastic with excellent dimensional stability and electrical insulating properties.

Applications:

Properties:

5. Polyoxymethylene (POM)

Also known as acetal or Delrin, POM is a crystalline plastic with high stiffness, low friction, and excellent dimensional stability.

Applications:

Properties:

6. Polyethylene (PE)

PE is a versatile plastic available in various densities, including high-density (HDPE) and low-density (LDPE) forms.

Applications:

Properties:

7. Polypropylene (PP)

PP is a semi-crystalline plastic known for its chemical resistance and fatigue resistance.

Applications:

Properties:

8. Polyamide (PA)

Commonly known as nylon, polyamide offers high strength, toughness, and wear resistance.

Applications:

Properties:

9. Polyetheretherketone (PEEK)

PEEK is a high-performance engineering plastic with exceptional thermal and chemical resistance.

Applications:

Properties:

10. Polytetrafluoroethylene (PTFE)

Known as Teflon, PTFE has excellent chemical resistance and the lowest coefficient of friction among solid materials.

Applications:

Properties:

11. Polyethylene Terephthalate (PET)

PET is a strong, stiff engineering plastic with good dimensional stability and chemical resistance.

Applications:

Properties:

12. Extruded Nylon

Extruded nylon is a type of polyamide produced through extrusion, offering consistent properties and ease of machining.

Applications:

Properties:

Engineering plastics are used across various industries due to their versatile properties. Below are some common applications of plastic engineering products produced through custom CNC machining services.

1. Mechanical Plastic Units

Engineering plastics are used to manufacture mechanical components such as gears, bearings, bushings, and wear plates. Materials like POM, polyamide, and UHMWPE offer low friction and high wear resistance, enhancing the performance and longevity of mechanical systems.

2. Chemical and Heat Resistant Plastic Parts

In chemical processing and high-temperature environments, engineering plastics like PEEK and PTFE are used for seals, gaskets, and components that must resist harsh chemicals and withstand elevated temperatures. Their chemical inertness and thermal stability make them ideal for such applications.

3. Electrical Plastic Parts

Due to their excellent electrical insulating properties, engineering plastics like polycarbonate, PPO, and PET are used in electrical and electronic components. They serve as insulators, connectors, housings, and circuit board materials, ensuring safety and functionality in electrical systems.

4. Low Friction Parts

Components requiring smooth movement and minimal wear, such as sliders, guides, and conveyor parts, utilize engineering plastics with low coefficients of friction. Materials like PTFE and UHMWPE reduce maintenance needs and improve system efficiency.

| Engineering Plastic |

Properties |

Applications |

| Polyethylene |

Versatile, flexible |

Packaging materials, containers |

| Polypropylene |

Chemical resistance, tough |

Automotive parts, medical devices |

| Polycarbonate |

Impact resistance, transparent |

Eyewear lenses, automotive parts |

| ABS |

Toughness, impact resistance |

Consumer goods, electronics |

| Polyamide (Nylon) |

High strength, wear resistance |

Mechanical components, textiles |

| PEEK |

High temperature resistance |

Aerospace, medical, electronics |

| PTFE (Teflon) |

Non-stick, chemical resistance |

Cookware, gaskets, seals |

| PET |

Clarity, barrier resistance |

Beverage bottles, food packaging |

Engineering plastics represent a significant advancement in material science, offering properties that bridge the gap between traditional plastics and metals. For professionals in custom CNC machining and CNC prototype machining, understanding the definition, characteristics, and types of engineering plastics is essential. These materials provide opportunities to design and manufacture high-performance plastic CNC machining parts that meet the demanding requirements of modern industries.

By leveraging the advantages of engineering plastics—such as thermal stability, mechanical strength, chemical resistance, and machinability—manufacturers can produce components that excel in performance and durability. While there are challenges and limitations to consider, the benefits often outweigh the drawbacks, making engineering plastics a valuable choice in CNC machining services.

As technology and material science continue to evolve, engineering plastics will play an increasingly important role in innovative product development. Staying informed about these materials ensures that manufacturers can offer cutting-edge solutions to their clients, maintaining competitiveness in the dynamic field of CNC machining.

What Is the Difference Between Engineering Plastics and Specialty Plastics?

Engineering plastics are materials with enhanced mechanical and thermal properties suitable for structural applications and mechanical parts. Specialty plastics, on the other hand, are designed for specific applications requiring unique properties, such as high optical clarity, biocompatibility, or extreme chemical resistance. Specialty plastics may include certain engineering plastics but are generally tailored for niche markets and applications.

Is Polyurethane an Engineering Plastic?

Polyurethane can be considered an engineering plastic due to its versatile properties, including elasticity, toughness, and resistance to abrasion and impact. It is used in applications like wheels, rollers, seals, and gaskets. However, polyurethane is often classified separately due to its unique chemistry and range of forms, including foams and elastomers.

Which Is Better, LDPE or HDPE?

LDPE (Low-Density Polyethylene) and HDPE (High-Density Polyethylene) differ in density and branching of their polymer chains. HDPE is stronger, stiffer, and more heat-resistant than LDPE, making it better for applications requiring durability and structural integrity. LDPE is more flexible and has better impact resistance, suitable for applications like plastic bags and flexible containers. The choice depends on the specific requirements of the application.

What Is the Difference Between Engineering Plastics and General Plastics?

Engineering plastics offer superior mechanical and thermal properties compared to general, or commodity, plastics. They are used in demanding applications where strength, durability, and performance are critical. General plastics like PE, PP, and PS are used in high-volume, low-cost applications with less demanding performance requirements.

Is HDPE an Engineering Plastic?

HDPE is generally considered a commodity plastic due to its widespread use in packaging, containers, and piping. However, its high strength-to-density ratio and chemical resistance make it suitable for some engineering applications. In certain contexts, HDPE may be classified as an engineering plastic when used in structural or high-performance components.

What Is the Strongest Engineering Plastic?

Polyetheretherketone (PEEK) is one of the strongest engineering plastics, offering exceptional mechanical strength, thermal stability, and chemical resistance. It can operate at high temperatures and withstand significant mechanical stress, making it suitable for aerospace, medical, and industrial applications.

What Are the Strongest Engineering Plastics?

Some of the strongest engineering plastics include:

These materials offer high strength, thermal stability, and chemical resistance for demanding applications.

Which Plastic Is Stronger Than Steel?

Certain engineering plastics reinforced with fibers or fillers can exhibit strength comparable to or exceeding that of steel on a strength-to-weight basis. For example, carbon fiber-reinforced PEEK or polyamide composites offer high mechanical strength while being significantly lighter than steel. However, in absolute terms, steel remains stronger in terms of tensile strength and modulus.

By understanding the intricacies of engineering plastics, manufacturers in custom CNC machining and CNC prototype machining can select the right materials to produce high-quality plastic CNC machining parts. This knowledge ensures that products meet performance requirements, comply with industry standards, and satisfy customer needs, solidifying the role of engineering plastics in advancing manufacturing technologies.