15 years one-stop China custom CNC machining parts factory

3138 |

Published by VMT at Nov 16 2024 | Reading Time:About 6 minutes

3138 |

Published by VMT at Nov 16 2024 | Reading Time:About 6 minutes

Are you struggling with assembling CNC machined parts that don't quite fit together seamlessly? Frustrated by designs that compromise both functionality and aesthetics due to sharp edges and misalignments? You're not alone. Many engineers and manufacturers face challenges in optimizing the performance and safety of their custom CNC machining projects. But what if understanding the role of bevels could revolutionize your approach, enhancing both the efficiency and quality of your CNC machining services?

A bevel is an angled edge or surface that is not perpendicular to the faces of a piece, commonly used in engineering and manufacturing to improve assembly, safety, and aesthetics. Incorporating bevels into CNC machined parts enhances functionality, reduces stress concentrations, and facilitates easier assembly in custom CNC machining processes.

Now that we've highlighted how bevels can be a game-changer in your CNC machining projects, let's delve deeper into what bevels are, why they're essential, and how they can impact your engineering designs. Understanding the types, advantages, and disadvantages of bevels will empower you to make informed decisions in your CNC machining plant, elevating the quality and performance of your products.

Foreword

In the realm of engineering and manufacturing, precision and efficiency are paramount. As industries evolve, the demand for components that are not only functional but also safe and aesthetically pleasing has increased. Custom CNC machining has become a cornerstone in producing intricate parts with tight tolerances. However, the design of these parts often involves more than just dimensions and tolerances; the edges and surfaces play a crucial role in the overall performance of the component. This is where bevels come into play. By understanding bevels—what they are, their types, and their implications—you can enhance the quality of your CNC machined parts, streamline assembly processes, and improve product longevity.

A bevel is an edge of a structure that is not perpendicular to the faces of the piece. In simpler terms, it's an angled cut made along the edge or end of a material. Unlike a straight edge that meets at a 90-degree angle, a beveled edge is typically cut at an angle less than 90 degrees. Bevels are created intentionally to serve specific purposes in engineering and manufacturing, such as reducing sharpness, facilitating assembly, or preparing surfaces for welding.

In the context of CNC machining services, bevels are integral to the design of parts that require precise mating with other components. They can be applied to various materials, including metals, plastics, and composites, and are utilized across numerous industries like automotive, aerospace, construction, and consumer electronics.

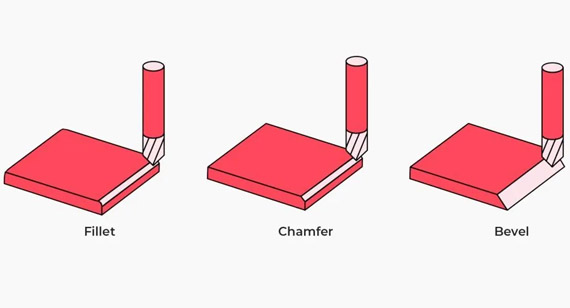

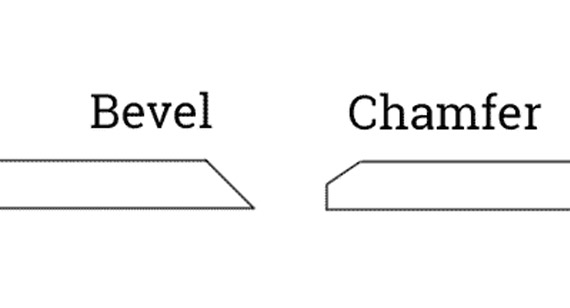

Bevels differ from chamfers and fillets, although they are often confused. A chamfer is a transitional edge between two faces of an object, typically at a 45-degree angle, while a fillet is a rounded corner. Bevels can be at any angle other than 90 degrees and may extend across the entire thickness of a material, offering unique functional and aesthetic benefits in custom CNC machining.

Beveling serves multiple purposes in engineering and manufacturing, making it an essential aspect of component design and fabrication. Here's why beveling is crucial:

Ease of Assembly: Beveled edges can guide parts into place during assembly, reducing the risk of misalignment and damage. This is particularly beneficial in CNC prototype machining, where precision and fit are critical.

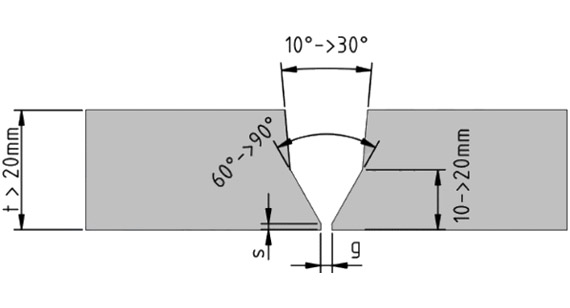

Improved Weld Quality: Beveling prepares the edges of materials for welding by increasing the surface area for the weld, ensuring stronger joints. This is vital in structural applications where joint integrity is paramount.

Safety: Sharp edges on machined parts can pose safety hazards to workers during handling and assembly. Beveling eliminates sharp corners, reducing the risk of cuts and injuries in the CNC machining plant.

Stress Distribution: Beveled edges help distribute stress more evenly across a component, minimizing stress concentrations that could lead to failure. This enhances the durability and lifespan of CNC machined parts.

Aesthetic Appeal: Beveling can improve the visual appearance of a product, giving it a finished and professional look. This is important in consumer-facing products where aesthetics influence customer perception.

Functional Enhancement: In some designs, bevels are necessary for the part to function correctly, such as in gears or cutting tools where specific angles are required for optimal performance.

By incorporating bevels into custom CNC machining designs, engineers and manufacturers can address practical challenges and enhance the overall quality and functionality of their products.

Bevels offer a range of advantages that can significantly impact the performance, assembly, and longevity of engineered components. Understanding these benefits is essential for engineers and manufacturers aiming to optimize their designs and manufacturing processes in CNC machining services.

Ease of Assembly

Beveled edges facilitate the alignment and assembly of parts. When components are designed with bevels, they naturally guide each other into the correct position, reducing the time and effort required during assembly. This is especially beneficial in custom CNC machining, where parts often have tight tolerances and complex geometries.

For instance, in the assembly of pipes or tubes, bevels allow for easier insertion and alignment, minimizing the risk of damage or misalignment. This efficiency translates to cost savings in labor and reduced assembly times in the CNC machining plant.

Improved Weld Quality

Beveling is critical in welding processes. By creating an angled edge on the material to be joined, beveling increases the surface area available for the weld. This results in stronger, more durable joints that can withstand greater stresses.

In CNC machined parts that require welding, bevels ensure proper penetration and fusion of the weld material, reducing the likelihood of defects such as porosity or incomplete fusion. Improved weld quality enhances the overall structural integrity of the assembly, which is vital in applications like aerospace, automotive, and structural engineering.

Increased Strength and Function of Parts

Bevels can enhance the mechanical properties of a component by reducing stress concentrations. Sharp corners are common sites for stress accumulation, which can lead to cracking or failure under load. By beveling edges, stress is more evenly distributed across the part, improving its ability to withstand mechanical forces.

In gears and cutting tools, bevels are essential for the proper meshing and cutting action. The specific angles of bevels in these applications are critical for efficient operation and longevity of the parts. Custom CNC machining allows for precise control of bevel angles, ensuring optimal performance.

Safety

Safety is a paramount concern in any manufacturing environment. Sharp edges on machined parts pose risks of cuts and injuries to personnel handling them. Beveling edges reduces these hazards by eliminating sharp corners and creating smoother transitions.

In addition to protecting workers, beveled edges can prevent damage to other components or materials during handling and assembly. This consideration is particularly important in industries where components are frequently manipulated or where cosmetic appearance is important.

Stress Distribution

Bevels play a crucial role in distributing mechanical stress within a component. By modifying the geometry of edges and surfaces, bevels can reduce localized stress concentrations that might otherwise lead to material failure.

In applications involving dynamic loads or high-stress environments, such as in automotive suspension components or aircraft structures, bevels contribute to the durability and reliability of parts. CNC prototype machining allows engineers to experiment with different bevel designs to optimize stress distribution before final production.

Appearance and Durability

Beveled edges contribute to the aesthetic appeal of a product. They provide a finished look that can enhance the perceived quality of the component. In consumer products, such as electronics or appliances, the visual impact of beveled edges can influence customer satisfaction and brand perception.

Moreover, bevels can protect edges from chipping or wear, extending the lifespan of the part. In materials prone to edge damage, such as glass or certain plastics, beveling can prevent cracks from initiating at sharp corners.

While bevels offer numerous advantages, they also come with certain disadvantages that must be considered during the design and manufacturing process. Understanding these drawbacks is essential for making informed decisions in custom CNC machining and ensuring that the final product meets all performance requirements.

Material Loss

Creating bevels involves removing material from the part, which can result in increased material waste and cost. In some cases, the amount of material removed may be significant, particularly for large bevels or in high-volume production runs.

Material loss not only affects cost but can also impact the structural integrity of the component. Removing too much material may weaken the part, making it unable to withstand the required loads. Engineers must balance the benefits of beveling with the need to maintain sufficient material for strength.

Less Strength or Structural Integrity

While bevels can enhance stress distribution, they may also reduce the cross-sectional area of a component, potentially decreasing its overall strength. If not properly designed, bevels can introduce weak points in a part where failure may occur under load.

For example, in a load-bearing beam, beveling the edges without considering the impact on structural integrity could lead to premature failure. It's crucial to perform thorough analysis and testing, possibly using CNC prototype machining, to ensure that bevels do not compromise the part's strength.

Not Suitable for All Design Requirements

Bevels may not be appropriate for every application. In some designs, the presence of bevels can interfere with the intended function of the part. For instance, components that require a flat mating surface or a tight seal may be negatively affected by beveled edges.

Additionally, bevels can complicate assembly processes if they cause misalignment or prevent proper engagement between parts. Engineers must carefully consider whether beveling aligns with the design specifications and functional requirements of the component.

Beveled Edges Can Cause Misalignment, Preventing Easy Assembly

While bevels can facilitate assembly in many cases, they can also cause misalignment if not designed correctly. In precise assemblies where components must fit together without gaps or shifts, beveled edges may introduce unintended movement or spacing.

For example, in mechanical systems requiring exact alignment for proper operation, such as precision gearboxes or high-speed machinery, bevels could lead to performance issues or increased wear. Ensuring that bevels are appropriately sized and angled is essential to avoid such problems.

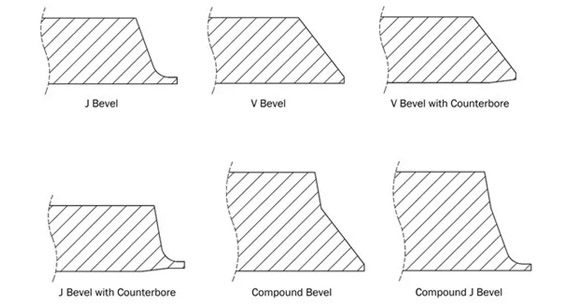

Understanding the different types of bevels is crucial for selecting the right one for your application. Each type serves specific purposes and offers unique advantages and disadvantages. In custom CNC machining, the ability to create precise and varied bevels allows for flexibility in design and functionality.

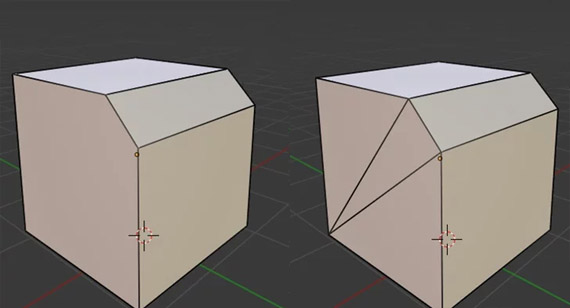

Plain Bevel/V Bevel

A flat bevel, also known as a V bevel, involves cutting the edge of a material at a consistent angle, typically 45 degrees, but it can be any angle less than 90 degrees. This type of bevel is straightforward to produce and is commonly used in welding preparation and aesthetic applications.

Advantages:

Disadvantages:

J-Prep Bevel

A J-prep bevel features a concave, curved profile that resembles the letter "J" when viewed in cross-section. This design increases the surface area for welding, leading to stronger joints with less filler material.

Advantages:

Disadvantages:

J-Prep with Back Bevel

This bevel combines a J-prep bevel on one side with a back bevel on the opposite side. It is used in applications where access to both sides of the joint is possible, and maximum weld strength is required.

Advantages:

Disadvantages:

Compound Bevel

A compound bevel involves multiple angles on the edge of the material, creating a more complex profile. This type is used when specific geometric requirements must be met for assembly or function.

Advantages:

Disadvantages:

Compound J-Prep with Back Bevel

This bevel combines the features of a compound bevel and a J-prep with a back bevel, resulting in a highly specialized edge profile. It is used in critical applications requiring exceptional weld strength and precision.

Advantages:

Disadvantages:

Blade Bevel

Blade bevels are commonly used in cutting tools and blades, where the edge is ground to a specific angle to achieve the desired cutting performance. The bevel angle affects sharpness, durability, and cutting efficiency.

Advantages:

Disadvantages:

Radius Bevel

A radius bevel involves rounding off the edge of a material rather than cutting it at an angle. This type of bevel reduces stress concentrations and improves safety by eliminating sharp corners.

Advantages:

Disadvantages:

Beveling requires specific tools and equipment to achieve the desired edge profiles accurately and efficiently. The choice of tools depends on factors such as material type, bevel complexity, production volume, and available resources in the CNC machining plant.

Hand Tools

Hand tools like files, chisels, and hand-held beveling machines are suitable for small-scale or manual beveling tasks. They offer flexibility but are limited in precision and efficiency.

Advantages:

Disadvantages:

Time-consuming and labor-intensive.

Limited precision and consistency.

Power Tools

Power tools, including grinders and handheld beveling machines with electric or pneumatic power, increase efficiency and consistency compared to hand tools.

Advantages:

Disadvantages:

Flame Cutting

Flame cutting uses an oxy-fuel torch to bevel edges, particularly in thick steel plates. It's suitable for large-scale operations but offers less precision compared to machining methods.

Advantages:

Disadvantages:

CNC Machines

CNC machines offer the highest precision and repeatability in beveling. They can produce complex bevel geometries with tight tolerances, essential for custom CNC machining services.

Advantages:

Disadvantages:

Specialized Beveling Machines

Dedicated beveling machines are designed specifically for creating bevels on pipes, tubes, and plates. They can be stationary or portable, offering specialized functions for specific applications.

Advantages:

Disadvantages:

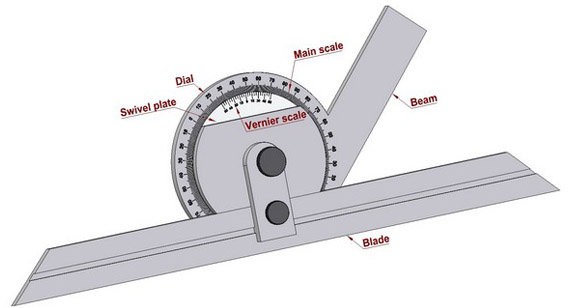

Accurate measurement of bevels is essential to ensure that they meet design specifications and function correctly. Various tools and techniques are used to measure bevel angles, widths, and surface quality in CNC machining services.

List of Tools Used to Measure Bevels:

Universal Vernier Bevel Protractor

A universal vernier bevel protractor is a precision instrument used to measure angles with high accuracy, typically up to 5 minutes of arc.

Advantages:

Disadvantages:

Bevel Protractor with Level

This tool combines a protractor with a level to measure angles in reference to the horizontal plane, useful for ensuring bevels are at the correct angle relative to the part's orientation.

Advantages:

Disadvantages:

Laser Angle Measurement

Laser devices can project a beam along the bevel, allowing for quick and accurate measurement of angles, especially on larger components.

Advantages:

Disadvantages:

A CMM uses a probing system to measure the geometry of physical objects with high precision, ideal for complex bevels in custom CNC machining.

Advantages:

Disadvantages:

To achieve the best results in beveling, it's essential to follow best practices and consider factors that can impact the quality and efficiency of the process. Here are some expert tips to maximize bevel quality in custom CNC machining.

Some Tips from Experts to Maximize Bevel Quality:

Consistency Is Key

Ensure that bevels are consistent across all parts to maintain uniformity in assembly and function. Use standardized setups and programs in CNC machining to replicate bevels accurately in production runs.

Avoid Heating the Workpiece

Excessive heat during beveling can alter the material properties, leading to warping or reduced strength. Use appropriate cutting speeds and cooling methods to minimize heat generation.

Edge Preparation

Proper edge preparation before beveling, such as deburring and cleaning, can improve the quality of the bevel and the performance of subsequent processes like welding or assembly.

Consider Coolants

Using coolants or lubricants during beveling can reduce tool wear, improve surface finish, and prevent overheating of the workpiece.

Selecting the appropriate beveling method depends on several factors, including material type, required precision, production volume, and available resources. Evaluating these factors ensures that the beveling process aligns with project specifications and goals in custom CNC machining.

Workpiece Materials

Different materials require different beveling techniques. For example, hard metals may necessitate CNC machining, while softer materials might be suitable for manual or power tool beveling.

Required Skill Level

Complex bevels or those requiring high precision may need skilled operators and advanced equipment like CNC machines, whereas simple bevels might be handled by less specialized personnel with basic tools.

Project Specifications

Consider the design requirements, including bevel angles, tolerances, and surface finish. Complex designs may dictate the use of advanced beveling methods to meet specifications.

Available Tools and Equipment

Assess the tools and equipment available in your CNC machining plant. Investing in appropriate machinery can improve efficiency and quality but must be balanced against budget considerations.

Bevel Angle and Width

The specific angle and width of the bevel can influence the choice of method. Precise or non-standard angles may require CNC machining, while standard angles might be achievable with simpler tools.

Bevels, chamfers, and fillets are all methods of modifying the edges of a part but serve different purposes and have distinct geometries.

Understanding the differences helps engineers select the appropriate edge modification for their design requirements in custom CNC machining.

A bevel is an angled edge that connects two surfaces, not necessarily at a standard angle, and can extend across the entire thickness of the material. A chamfer is a specific type of bevel, usually at a 45-degree angle, that creates a transitional edge between two faces.

Key Differences:

A bevel is an angled flat surface, while a fillet is a rounded surface connecting two faces. Bevels modify the edge by cutting it at an angle, whereas fillets smooth out the corner by adding a radius.

Key Differences:

In gear systems, beveling is critical for proper meshing and efficient power transmission. Bevel gears have teeth cut on an angular or conical surface, allowing them to transmit motion between intersecting axes.

Benefits:

Custom CNC machining enables the precise manufacturing of bevel gears, enhancing the performance of mechanical systems.

Bevels are employed across various engineering applications to enhance functionality, safety, and aesthetics. Understanding these applications helps engineers and manufacturers leverage beveling effectively in custom CNC machining services.

Weld Preparation

Beveling is essential in preparing edges for welding, ensuring strong and reliable joints. It increases the surface area for the weld and allows for better penetration and fusion.

Pipe and Tube Beveling

In piping systems, beveling facilitates the assembly and welding of pipes and tubes. It ensures proper alignment and joint strength, critical in industries like oil and gas, plumbing, and chemical processing.

Cutting Tools

Bevels are fundamental in the design of cutting tools like drills, end mills, and blades. The bevel angle influences cutting efficiency, durability, and performance.

Industry Applications

Architecture/Home Improvement

Bevels are used in decorative elements, furniture, and fixtures to enhance aesthetics and safety. Beveled edges on glass, countertops, and flooring reduce sharpness and add visual appeal.

Understanding bevels—their definition, types, advantages, and disadvantages—is crucial for engineers and manufacturers aiming to optimize their designs and manufacturing processes. Bevels play a significant role in enhancing the functionality, safety, and aesthetics of CNC machined parts. By carefully considering the application of bevels in custom CNC machining, professionals can improve assembly efficiency, product performance, and overall quality.

Whether you're engaged in CNC prototype machining or large-scale production in a CNC machining plant, incorporating bevels effectively can set your products apart in a competitive market. Balancing the benefits and drawbacks of beveling ensures that you make informed decisions that align with your project's goals and specifications.

What Is the Purpose of Beveling?

The purpose of beveling is to create an angled edge on a material to facilitate assembly, improve weld quality, enhance safety by removing sharp edges, distribute stress more evenly, and improve the aesthetic appearance of a component.

What Is the Role of Beveling?

Beveling plays a role in preparing materials for welding, easing assembly processes, reducing stress concentrations, enhancing the functionality of mechanical parts, and improving safety and aesthetics in engineering and manufacturing applications.

What Is the Most Important Parameter in Beveling?

The most important parameter in beveling is the bevel angle, as it determines how the beveled edge will function in assembly, welding, stress distribution, and overall performance of the part.

What Is the Purpose of Bevel Edge Preparation?

Bevel edge preparation is performed to ready the edges of materials for welding or assembly, ensuring proper alignment, optimal weld penetration, and strong, reliable joints.

Why Is It Called Chamfer?

The term "chamfer" originates from the French word "chanfrein," meaning beveled edge. A chamfer specifically refers to a transitional edge between two faces of an object, usually cut at a 45-degree angle.

What Is the Difference Between a Taper and a Chamfer?

A taper is a gradual decrease in diameter or thickness over a length of a part, creating a conical shape. A chamfer is an angled cut on the edge or corner of a part, creating a beveled edge at a specific angle, typically 45 degrees.

What Is the Difference Between a Chamfer and a Countersink?

A chamfer is a beveled edge on the external corner of a part, while a countersink is a conical hole cut into a material to allow the head of a screw or bolt to sit flush or below the surface.

What Is the Difference Between a Bevel and an Angle?

A bevel refers to an angled edge or surface that is not perpendicular to the faces of the piece, specifically applied to the edge of a material. An angle is a more general term that describes the space between two intersecting lines or surfaces, measured in degrees.

By incorporating bevels thoughtfully into your designs and manufacturing processes, you can enhance the quality and functionality of your CNC machined parts. Understanding the nuances of beveling empowers you to make informed decisions, optimizing your custom CNC machining services to meet the evolving demands of engineering and manufacturing.