15 years one-stop China custom CNC machining parts factory

291 |

Published by VMT at Sep 28 2024

291 |

Published by VMT at Sep 28 2024

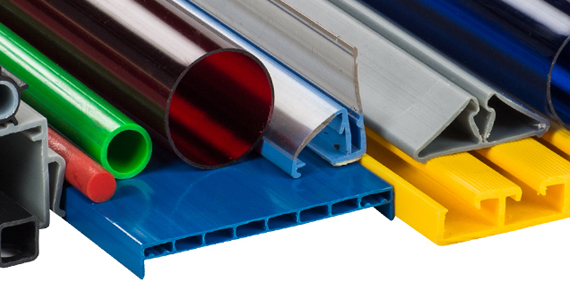

Plastic extrusion is a widely used manufacturing process where raw plastic materials are melted and formed into a continuous profile. This process is highly efficient and can produce a variety of plastic products, including pipes, sheets, wire insulation, and window frames. Plastic extrusion plays a vital role in industries like construction, packaging, automotive, and consumer goods due to its versatility, cost-effectiveness, and ability to produce large volumes of products with consistent quality.

In this article, we will explore the entire plastic extrusion process, discuss its components, and review the different types of extrusion methods. We’ll also cover the advantages, disadvantages, and common applications of plastic extrusion, giving you a complete guide to this critical manufacturing technique. Additionally, we’ll compare plastic extrusion with injection molding to highlight key differences between the two methods.

Plastic extrusion is a continuous process where plastic materials, often in pellet form, are fed into a heated extruder, melted, and then forced through a shaping die to create a long, uniform profile. This profile can then be cut to specific lengths or further processed depending on the final application. Extruded plastic products range from thin films to thick-walled pipes and complex shapes for construction and automotive parts.

This process is ideal for producing high volumes of uniform parts and is used to create products with consistent cross-sectional dimensions. The versatility of plastic extrusion allows manufacturers to work with a wide range of plastics and additives, making it adaptable to various industries and product specifications.

To understand how plastic extrusion works, it’s important to be familiar with the main components of a plastic extruder. Each part plays a crucial role in ensuring that raw plastic is effectively melted, shaped, and cooled to form the desired product.

1. Hopper

The hopper is the starting point of the plastic extrusion process. It’s a large funnel-like container that holds the raw plastic pellets or powder before they enter the extrusion machine. In some cases, the plastic may be pre-mixed with additives, such as colorants, stabilizers, or fillers, in the hopper to modify the properties of the final product.

2. Feed Throat

The feed throat connects the hopper to the extruder’s barrel. It helps to transport the plastic pellets from the hopper into the barrel, where the material will be heated and melted. The feed throat is designed to regulate the flow of material into the barrel to ensure a consistent feeding rate.

3. Crushing Plate

In some extruders, a crushing plate is used to break down larger chunks of plastic material before they enter the barrel. This is particularly useful for recycling operations where plastic scrap needs to be processed alongside virgin material.

4. Barrel

The barrel is the main component where the plastic material is heated, melted, and transported along the extruder. Inside the barrel, a rotating screw moves the plastic forward while it heats up to its melting point. The temperature of the barrel is controlled by a series of heating elements to ensure the plastic reaches the right temperature for extrusion without overheating.

5. Feed Pipe

The feed pipe connects the extruder to the mold, carrying the molten plastic toward the shaping die. The pressure and flow of the plastic through the feed pipe are carefully controlled to prevent defects in the final product.

6. Mold

The mold, or die, is the part of the extruder that shapes the molten plastic into the desired profile. It can be customized to produce different shapes, from simple tubes and sheets to more complex profiles for window frames or automotive parts. The shape of the die determines the cross-sectional geometry of the extruded plastic product.

7. Cooling System

Once the plastic has passed through the die, it must be cooled to solidify into its final shape. The cooling system typically consists of water baths, air cooling, or other cooling methods to quickly cool down the extruded plastic and prevent warping or deformation.

The plastic extrusion process involves several steps to transform raw plastic material into a finished product. Each step is crucial for ensuring that the product has the desired properties, dimensions, and surface finish.

Step 1: Adding Additives

Before the extrusion process begins, additives such as colorants, UV stabilizers, or plasticizers may be mixed with the raw plastic material. These additives enhance the properties of the plastic, such as its color, flexibility, or resistance to environmental factors like UV radiation and heat.

Step 2: Feeding Materials

The raw plastic pellets or powder, along with any additives, are fed into the hopper, which then moves the material into the extruder via the feed throat.

Step 3: Melting Materials

Inside the extruder’s barrel, the plastic material is heated by electric heaters and friction from the rotating screw. As the plastic moves along the barrel, it gradually melts into a thick, viscous liquid.

Step 4: Melt Formation

The melted plastic is transported through the barrel and homogenized by the screw, ensuring a consistent melt without air bubbles or impurities.

Step 5: Filtration

In some extrusion processes, the molten plastic passes through a filter to remove contaminants or impurities. This is especially important for products that require high precision and smooth surfaces, such as plastic film or medical tubing.

Step 6: Forming Die

The molten plastic is forced through the die, which shapes it into the desired cross-sectional profile. This could be anything from a flat sheet to a hollow pipe or a more complex geometric shape.

Step 7: Cooling

Once the plastic exits the die, it enters the cooling stage. Depending on the material and product, the plastic may be cooled using air, water baths, or other cooling techniques to solidify it into its final shape.

Step 8: Pulling and Cutting

As the plastic solidifies, it is pulled away from the die at a controlled speed using a pulling mechanism. The extruded plastic is then cut to the desired length or wound onto spools for further processing.

Step 9: Further Processing

In some cases, the extruded product undergoes additional processing, such as surface finishing, printing, or cutting to specific dimensions.

Step 10: Inspection and Quality Control

Finally, the extruded plastic parts are inspected for quality, ensuring that they meet the required specifications for size, shape, and surface finish. Any defective parts are removed, and the batch is prepared for shipment or further processing.

Types of Plastic Extrusion Processes

Plastic extrusion can be adapted to create a wide range of products by using different processes. Below are some of the most common types of plastic extrusion.

1. Pipe Extrusion

This process is used to produce hollow pipes or tubes with consistent wall thickness. It’s commonly used for manufacturing PVC pipes for plumbing, electrical conduits, and other applications.

2. Blown Film Extrusion

Blown film extrusion is used to produce plastic films, such as those used for packaging. In this process, the molten plastic is extruded into a thin tube and inflated with air to create a bubble, which is then flattened and wound onto rolls.

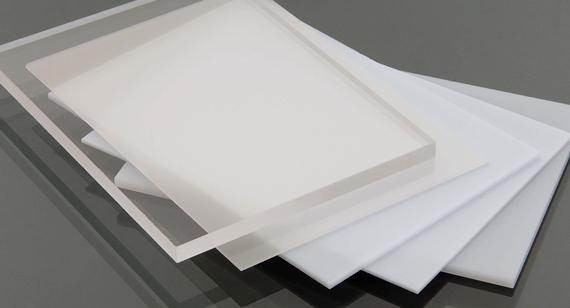

3. Sheet Film Extrusion

In sheet film extrusion, molten plastic is extruded through a flat die to create thin sheets of plastic. This process is widely used for producing plastic sheets for packaging, automotive, and construction applications.

4. Outer Jacket Extrusion

This process is used to create the protective outer layer for cables and wires. The plastic is extruded around the wire or cable, forming a protective insulation layer.

There are two primary types of extruders used in plastic extrusion: single screw extruders and twin screw extruders. Each type has its advantages depending on the material and the product being produced.

Single Screw Extruder

A single screw extruder is the most common type of extruder, using one rotating screw inside the barrel to melt and transport the plastic. It’s ideal for straightforward processes where only one type of material is being extruded, and it’s commonly used in applications like pipe extrusion and sheet film extrusion.

Twin Screw Extruder

Twin screw extruders use two intermeshing screws to transport the plastic material. They offer better mixing and material handling, making them suitable for more complex extrusion processes that involve multiple materials or additives. Twin screw extruders are often used for compounding and producing plastic blends.

Selecting the right material is essential for ensuring that the extruded plastic product meets performance requirements. Some common materials used in plastic extrusion include:

1. ABS (Acrylonitrile Butadiene Styrene)

ABS is a strong, durable plastic commonly used for automotive parts and consumer goods.

2. Acrylic

Acrylic is known for its clarity and is used for products like signs, displays, and windows.

3. PVC (Polyvinyl Chloride)

PVC is a versatile material used in construction for pipes, window frames, and cable insulation.

4. Flexible PVC

Flexible PVC is softer than rigid PVC and is used for products like hose tubing and electrical insulation.

5. Rigid PVC

Rigid PVC is tough and durable, making it ideal for construction applications like pipes and window profiles.

6. CPVC (Chlorinated Polyvinyl Chloride)

CPVC is similar to PVC but with higher temperature resistance, making it suitable for hot water pipes.

7. Mineral Filled Polypropylene

This material is used for lightweight, rigid products in automotive and consumer goods.

8. Polycarbonate

Polycarbonate is a high-strength plastic used in applications like bulletproof windows and optical lenses.

9. Styrene

Styrene is used for disposable products like packaging and cups due to its low cost.

10. TPA (Thermoplastic Alloy)

TPA offers excellent impact resistance and is used for tough, durable parts.

11. Polyethylene

Polyethylene is widely used for products like plastic bags, bottles, and packaging materials.

12. TPV (Thermoplastic Vulcanizate)

TPV is a flexible material used for sealing applications in automotive and construction.

13. Polypropylene

Polypropylene is known for its chemical resistance and is commonly used for packaging and automotive components.

Plastic extrusion has a wide range of applications across various industries. Here are some common products made using plastic extrusion:

1. Wire Insulation

Plastic extrusion is used to create the protective coating around electrical wires and cables.

2. Pipes

Pipes for plumbing, gas, and electrical conduits are produced using plastic extrusion, particularly with materials like PVC and CPVC.

3. Windows and Doors

Extruded plastic profiles are used in window and door frames, offering durability and weather resistance.

4. Blinds and Shades

Plastic extrusion is used to produce slats for blinds and shades, which require flexibility and strength.

5. Filaments and Fibers

Plastic extrusion is used to create filaments for 3D printing and fibers for textiles.

6. Packaging

Plastic films and sheets used for packaging are produced using extrusion processes like blown film extrusion.

7. Construction

Plastic profiles, pipes, and sheets used in construction are often extruded, providing cost-effective solutions for building materials.

8. Automotive

Plastic extrusion is used to manufacture automotive components, such as trim, seals, and insulation.

9. Consumer Goods

Many everyday plastic items, from containers to toys, are produced using plastic extrusion.

Like any manufacturing process, plastic extrusion has its pros and cons. Understanding these advantages and disadvantages can help you determine if it’s the right process for your project.

Advantages of Plastic Extrusion

Versatility: Plastic extrusion can produce a wide variety of shapes and profiles, from thin films to complex profiles used in construction and automotive applications.

High Volume Production: Extrusion is ideal for continuous production of long parts, making it suitable for high-volume manufacturing.

Economical and Efficient: The process is cost-effective, especially for large production runs, and has relatively low waste compared to other methods.

Post-Extrusion Processing: Extruded products can be easily cut, shaped, or processed further to meet specific requirements.

Relatively Inexpensive: Compared to other manufacturing processes like injection molding, the tooling and setup costs for extrusion are lower.

Design Flexibility: Extrusion allows for the creation of intricate profiles with consistent cross-sections.

Automation and Precision: Modern extruders are highly automated, providing precision and control over product dimensions and quality.

Wide Material Compatibility: A wide range of plastics can be used in extrusion, from PVC to polyethylene.

Surface Finishes and Tolerances: Extrusion can achieve smooth surface finishes and precise tolerances with the right material and process settings.

Disadvantages of Plastic Extrusion

High Initial Setup Cost: While the overall cost is lower for high-volume production, the initial setup costs, including die design and manufacturing, can be high.

Dimensional Variations: Temperature fluctuations during extrusion can lead to slight variations in the dimensions of the final product.

Product Limitations: Extrusion is limited to producing parts with consistent cross-sections, so it may not be suitable for parts that require complex three-dimensional shapes.

Plastic extrusion and injection molding are both popular manufacturing methods, but they are suited to different types of products. While extrusion is ideal for producing continuous profiles like pipes, films, and sheets, injection molding is better suited for creating complex, three-dimensional parts. Injection molding involves injecting molten plastic into a mold, where it cools and solidifies, while extrusion continuously pushes melted plastic through a die to form long shapes.

In summary:

Extrusion is best for producing long, continuous parts with consistent cross-sections.

Injection molding is ideal for producing complex, shaped parts in large volumes.

Plastic extrusion is a versatile, efficient, and cost-effective process used to produce a wide range of products, from pipes and window frames to films and insulation. With its ability to handle a variety of materials and produce parts in large volumes, plastic extrusion plays a key role in industries such as construction, automotive, and packaging. Understanding the process, components, and applications of plastic extrusion will help you make informed decisions when selecting a manufacturing method for your project.

Whether you’re producing high-volume parts or custom CNC-machined components, VMT offers expert CNC machining services and custom CNC machining solutions for a wide range of industries. With our expertise in plastic extrusion CNC machining, we ensure that every part meets the highest standards of quality, precision, and durability.

What are the Types of Plastic Extruders?

There are two main types of plastic extruders: single screw extruders and twin screw extruders. Single screw extruders are commonly used for simple processes, while twin screw extruders are ideal for complex material processing and blending.

What are Extruders Used For?

Extruders are used to melt and shape plastic materials into continuous profiles, such as pipes, sheets, and films, through a shaping die.

How Much Does Plastic Extrusion Cost?

The cost of plastic extrusion varies depending on the material, tooling, and production volume. While the initial setup may be costly, the process is generally economical for high-volume production.

Can Plastic Extrusion Produce Sheets?

Yes, sheet extrusion is a common process used to produce thin plastic sheets for packaging, construction, and automotive applications.

What is the Difference Between Plastic Injection and Plastic Extrusion?

Injection molding is used to produce complex, three-dimensional shapes, while extrusion is ideal for creating long, continuous profiles with consistent cross-sections.

Is Plastic Extrusion Expensive?

Plastic extrusion is relatively inexpensive for high-volume production, but the initial tooling costs can be high. However, its efficiency and low waste make it cost-effective in the long run.

Why Use Plastic Extrusion?

Plastic extrusion is used because it’s a versatile, efficient, and economical way to produce a wide range of plastic products, from pipes and films to complex profiles for construction and automotive applications.