15 years one-stop China custom CNC machining parts factory

65 |

Published by VMT at Oct 29 2025 | Reading Time:About 3 minutes

65 |

Published by VMT at Oct 29 2025 | Reading Time:About 3 minutes

Lead's melting point, around 327.5°C, is crucial for designing and machining lead components, directly influencing its thermal properties and safe handling in metallurgy applications.

Lead, a material with ancient roots, presents unique challenges that continue to baffle manufacturers today. Did you know that its deceptively low melting point holds the key to both its utility and its processing difficulties? Discover how mastering this critical property can unlock unparalleled precision and safety in your most demanding applications.

In our experience, a deep understanding of lead's thermal properties is non-negotiable for producing high-quality lead components. This guide delves into the specifics of the lead melting point temperature, its implications for machining lead, and critical safety considerations. We aim to equip you with the knowledge needed for successful lead metallurgy applications.

Pure Lead: The Benchmark Value

Pure lead melting point is precisely defined as 327.5°C (621.5°F). This specific temperature represents the point at which solid lead transitions into its liquid state under standard atmospheric pressure. It is a fundamental material property.

This relatively low lead melting point temperature sets it apart from many other common engineering metals. This characteristic is both a benefit for certain applications and a challenge for others, especially concerning machining lead. Understanding this benchmark is critical for all lead metallurgy applications.

The precise knowledge of this pure lead melting point is essential for thermal processing. It guides everything from casting temperatures to heat treatment protocols, ensuring the material retains its desired microstructure and performance characteristics.

How Melting Point Is Measured

The melting point of lead, or any metal, is typically determined using techniques like Differential Scanning Calorimetry (DSC) or dilatometry. These methods precisely measure the heat absorbed or volume change during phase transitions.

In a manufacturing setting, less precise but practical methods like visual observation in a controlled furnace can also indicate the melting range. However, for critical applications, laboratory-grade measurements confirm the pure lead melting point.

Understanding how this property is measured underpins our ability to verify material specifications. This ensures the lead components we produce conform strictly to required standards, maintaining consistency across batches.

Why This Point Matters for Design

The lead melting point temperature significantly influences component design, particularly for applications involving elevated temperatures or thermal cycling. It dictates material selection for heat sinks or radiation shielding.

Design engineers must account for lead's thermal behavior to prevent structural integrity issues. Using lead components near their melting point can lead to creep or premature failure, compromising overall system reliability.

Therefore, for any lead metallurgy applications, considering the operational temperature range relative to the lead melting point is paramount. This ensures the component performs as intended throughout its service life.

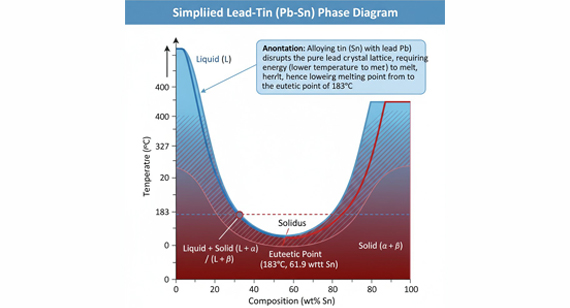

Impact of Alloying Elements

The pure lead melting point can be dramatically altered by the addition of alloying elements. Elements like tin, antimony, and bismuth are commonly added to modify lead's mechanical and thermal properties.

These additions can lower the overall melting temperature, creating a melting range rather than a sharp point. This is often leveraged in soldering applications where a specific lead alloy melting range is desired for processing.

In our experience, controlling the precise alloy composition is critical. It directly impacts the processability and end-use performance of various lead components, necessitating stringent material verification.

Common Lead Alloys and Their Ranges

Many lead alloys exist, each engineered for specific properties and applications. Common examples include lead-tin alloys (for solder), lead-antimony alloys (for batteries), and lead-calcium alloys.

Each of these alloys exhibits a distinct lead alloy melting range, which is critical for their respective manufacturing processes. For instance, a eutectic lead-tin alloy will have a sharp melting point, while others will melt over a range.

Understanding these specific ranges is vital for our precision machining lead operations. It ensures we select the correct material and apply appropriate thermal management strategies to prevent deformation or metallurgical changes.

| Alloy Type |

Nominal Composition |

Melting Range (°C) |

Key Application Examples |

| Pure Lead | 99.9% Pb min | 327.5 | Radiation shielding, ballast weights |

| Lead-Tin Solder (Eutectic) | 63% Sn, 37% Pb | 183 | Electronic soldering, plumbing |

| Lead-Antimony (Battery Grid) | 3-12% Sb, balance Pb | 240-320 | Automotive batteries, cable sheathing |

| Lead-Calcium | 0.07% Ca, balance Pb | ~326 | Maintenance-free batteries |

Impurities Affecting Thermal Behavior

Even minor impurities can significantly impact the lead melting point temperature and overall thermal properties. Elements like copper, iron, or zinc can create undesirable low-melting phases.

These impurities can compromise the structural integrity of lead components, leading to hot tearing during casting or brittle failure in service. They also complicate the precision machining lead process.

At China VMT CNC machining factory, we utilize high-purity lead and rigorously control material inputs. This prevents unforeseen thermal behavior and ensures the consistent quality of our lead components, critical for sensitive applications.

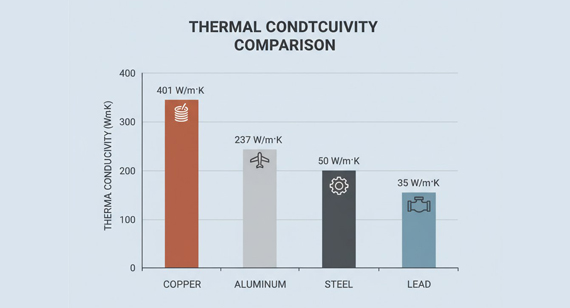

Thermal Expansion and Conductivity

Beyond its melting point, lead exhibits specific thermal expansion and conductivity characteristics. Lead has a relatively high coefficient of thermal expansion compared to steel, meaning it expands and contracts significantly with temperature changes.

It also possesses moderate thermal conductivity, allowing it to dissipate heat reasonably well, but not as effectively as copper or aluminum. These thermal properties of lead are fundamental to its application.

For precision machining lead, understanding these behaviors is crucial. Unmanaged thermal expansion can lead to dimensional inaccuracies and internal stresses in the final lead components.

| Property (at 20°C) |

Pure Lead |

Aluminum (6061) |

Steel (304 Stainless) |

Copper (C11000) |

| Melting Point (°C) | 327.5 | 582-652 | 1370-1427 | 1083 |

| Thermal Conductivity (W/m·K) | 35.3 | 167 | 16.2 | 398 |

| Coefficient of Thermal Expansion (µm/m·°C) | 28.7 | 23.6 | 17.3 | 17 |

| Density (g/cm³) | 11.34 | 2.70 | 8.00 | 8.94 |

Practical Implications for Machining

The thermal properties of lead have profound practical implications when machining lead. The material's low lead melting point and high thermal expansion mean careful control of cutting parameters is essential.

Excessive heat generation during machining can cause localized melting, tool adhesion, and significant dimensional instability. This leads to poor surface finish and difficulty holding tight tolerances for lead components.

In our factory, we actively manage heat. Our engineers select specific coolants, optimal cutting speeds, and feed rates to mitigate these thermal effects, ensuring the integrity and precision of every part.

Heat Dissipation Challenges and Solutions

Due to its moderate thermal conductivity, dissipating heat effectively from lead components during processing can be a challenge. Heat buildup can deform parts or alter their microstructure.

For specific lead metallurgy applications, especially those requiring precise thermal performance, engineered solutions are vital. This includes incorporating fins or other heat exchange features into the component design itself.

During machining, we employ flood cooling and low-speed cutting. These strategies are critical for maintaining a stable temperature, preventing thermal distortion, and ensuring high-quality lead components.

Why Lead is Difficult to Machine

Machining lead presents several unique challenges due to its inherent properties. Its softness means it tends to tear and smear rather than cut cleanly, leading to burring and poor surface finishes.

The low lead melting point means heat generated by friction during cutting can easily cause localized melting or thermal expansion, making it difficult to maintain tight dimensional tolerances. Chip control is also problematic.

In our experience, successful machining lead requires specialized knowledge and tooling. Generic machining strategies often fail to produce the required precision and quality for lead components.

Expert Strategies for Quality Parts

To overcome lead's machining difficulties, our engineers employ a combination of expert strategies. We use extremely sharp, polished tools with high rake angles to promote a shearing action rather than tearing.

Optimized cutting parameters, including low cutting speeds and high feed rates, are crucial for effective chip formation and reducing heat buildup. We also use copious amounts of high-lubricity cutting fluids.

These strategies, coupled with our deep understanding of lead properties, allow us to achieve exceptional surface finishes and tight tolerances. This results in superior lead components for demanding applications.

Preventing Defects: Tooling and Cooling

Preventing defects like burring, smearing, and thermal distortion is paramount when machining lead. This begins with the careful selection of tooling materials and geometries.

Carbide tools with highly polished edges and specific chip breakers are preferred. These minimize friction and prevent material adhesion, crucial for maintaining surface integrity.

Effective cooling is equally important. We use advanced cooling systems that deliver a consistent flow of coolant to the cutting zone, rapidly dissipating heat and stabilizing the temperature of the lead components.

Health Risks of Lead Exposure

Lead exposure poses significant health risks, affecting various bodily systems, including neurological, cardiovascular, and renal functions. It is a known neurotoxin and can be particularly harmful to children.

Proper handling and processing protocols are therefore not just regulatory requirements but ethical obligations. Minimizing exposure is critical at every stage of manufacturing lead components.

Our factory prioritates employee safety and environmental protection above all else. We ensure that all personnel involved in machining lead are fully aware of these risks and trained in preventative measures.

Regulatory Standards for Lead Usage

The use of lead components is governed by stringent regulatory standards worldwide. These include RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe.

These regulations dictate the permissible levels of lead in certain products and outline comprehensive requirements for handling, storage, and disposal of lead-containing materials.

As a source manufacturer, China VMT CNC is fully compliant with all relevant international and local regulations. We provide lead components that meet the highest safety and environmental standards.

| Standard/Directive |

Scope and Key Requirements |

Impact on Lead Components |

| RoHS Directive (EU) | Restricts the use of specific hazardous substances, including lead, in electrical and electronic equipment (EEE). Maximum 0.1% by weight. | Requires lead-free alternatives or exemptions for certain EEE applications. |

| REACH Regulation (EU) | Regulates the registration, evaluation, authorization, and restriction of chemicals, including lead. Aims to improve human health and environmental protection. | Mandates strict control over lead usage and disclosure in products. |

| OSHA (USA) | Occupational Safety and Health Administration standards for lead exposure in the workplace. Sets permissible exposure limits (PEL). | Requires strict engineering controls, PPE, and monitoring for workers handling lead. |

| EPA (USA) | Environmental Protection Agency regulations concerning lead in air, water, and waste. | Guides lead waste management and emissions control. |

Safe Handling and Processing Protocols

Implementing robust safe handling and processing protocols is fundamental to working with lead. This includes strict adherence to personal protective equipment (PPE) requirements, such as respirators, gloves, and protective clothing.

Our facilities are equipped with advanced ventilation and filtration systems to control airborne lead particles generated during machining lead. Regular air monitoring is conducted to ensure compliance with occupational exposure limits.

All waste materials, including chips and coolant, are collected and disposed of according to strict environmental regulations. We maintain rigorous controls to protect both our workforce and the environment from lead exposure.

Importance of Technical Expertise

When sourcing lead components, the importance of a manufacturer with deep technical expertise cannot be overstated. Lead's unique properties demand specialized knowledge in material science and machining.

A manufacturer with genuine expertise understands the nuances of lead's thermal properties, its machinability, and how to prevent common defects. They can advise on material selection and design optimization for lead metallurgy applications.

Our factory's engineering team possesses decades of experience in working with challenging materials. This ensures that your complex lead component projects are handled with precision and an in-depth understanding of the material.

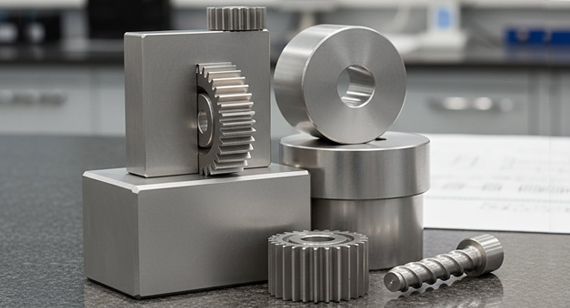

Quality Control and Source Manufacturing

As a source manufacturer, we maintain complete control over the entire production process, from raw material procurement to final inspection. This integrated approach is critical for ensuring the consistent quality of lead components.

Our stringent quality control procedures include dimensional inspection, surface finish analysis, and material verification. We adhere to industry standards to guarantee every part meets your exact specifications.

This end-to-end control means greater reliability and traceability for your lead parts. You gain confidence that our products will perform flawlessly in their intended lead metallurgy applications.

Transparent Pricing and Project Success

Transparent pricing is a cornerstone of our service philosophy. We provide detailed quotes that break down all costs, ensuring you understand the investment required for your lead components.

Our commitment to upfront pricing prevents hidden fees and builds trust. We believe that clear communication about costs is essential for long-term partnerships and project success.

This transparency, combined with our technical expertise and quality manufacturing, ensures that your projects are delivered on time, within budget, and to the highest standards.

Ready for a Detailed Consultation?

In our experience, successful projects begin with open communication and a thorough understanding of your unique requirements. We invite you to leverage our deep technical expertise for your next challenge.

Our engineers are ready to discuss your specific lead metallurgy applications, review your designs, and propose optimal manufacturing solutions for your lead components.

Case Study: Advanced Shielding for Medical Imaging

Problem: A client in the medical device industry required highly specialized lead components for a new diagnostic imaging system. These parts demanded exceptional dimensional accuracy, ultra-smooth surface finishes, and specific radiation shielding properties, all while mitigating risks associated with lead's low melting point during manufacturing. Their previous supplier struggled with consistency and thermal deformation.

Our Solution: China VMT CNC's engineering team conducted a detailed analysis of the client's design and material specifications. Leveraging our expertise in machining lead, we developed a tailored process. This involved selecting high-purity lead, optimizing cutting tool geometries, and employing a multi-stage machining strategy with precision-controlled coolant delivery to manage heat and prevent thermal distortion. We meticulously monitored the lead melting point temperature throughout the process to ensure material integrity.

Result: We successfully delivered the complex lead components, exceeding the client's stringent requirements. The parts featured flawless surface finishes and met all dimensional tolerances, significantly improving the imaging system's performance and longevity. Our meticulous process ensured product consistency, proving our ability to reliably produce high-quality lead parts for critical applications.

Call to Action: Ready to tackle your next complex lead component project with confidence? Contact our expert engineering team today for a detailed, transparent quote and a personalized consultation. Leverage our deep technical expertise to ensure your high-quality lead parts are delivered precisely, safely, and on schedule.

What is pure lead's melting point?

The pure lead melting point is approximately 327.5 degrees Celsius (621.5 degrees Fahrenheit). This is a precise benchmark for the material.

It is crucial to consider this temperature for any lead metallurgy applications, especially those involving thermal processes or elevated operating environments.

How do alloys affect lead's melting point?

Alloying elements like tin, antimony, or bismuth can significantly alter the lead melting point. They typically lower it, creating a melting *range* rather than a single point.

This modification of the lead alloy melting range is leveraged in specific applications, such as solders.

Is machining lead challenging?

Yes, machining lead presents unique challenges due to its softness, low lead melting point, and tendency to smear. It requires specialized tooling and techniques.

Without expert strategies, achieving precise lead components with a good surface finish can be very difficult.

What are lead's thermal properties?

Lead exhibits a relatively low melting point, moderate thermal conductivity, and a high coefficient of thermal expansion. These thermal properties of lead impact its behavior.

They are critical considerations for design, manufacturing, and the overall performance of lead components.

What safety risks does lead pose?

Lead exposure carries significant health risks, acting as a neurotoxin and affecting multiple organ systems. Strict safety protocols are essential.

Proper handling, ventilation, and PPE are mandatory when working with lead components.

What regulations apply to lead parts?

Numerous regulations, such as RoHS and REACH, govern the use and presence of lead in components. These ensure environmental and health safety.

Manufacturers must adhere to these stringent standards for lead metallurgy applications.

How is lead component quality ensured?

Quality for lead components is ensured through stringent material selection, optimized machining processes, and comprehensive quality control. A source manufacturer provides end-to-end control.

This guarantees precision, consistency, and compliance with all specifications.

Can lead be used in high-temp applications?

While lead has a low melting point, it can be used in some high-temperature applications if its specific thermal properties are carefully managed. Engineers must account for creep and thermal stability.

Applications typically involve temperatures well below the lead melting point to ensure long-term integrity.