15 years one-stop China custom CNC machining parts factory

172 |

Published by VMT at Oct 28 2025 | Reading Time:About 3 minutes

172 |

Published by VMT at Oct 28 2025 | Reading Time:About 3 minutes

3CR13 steel knives offer excellent value for budget-friendly applications, providing good corrosion resistance and machinability for 3CR13 knife manufacturing, making its 3CR13 knife suitability high for utility and kitchen blades with proper heat treatment.

The world of knife steels is complex, often leaving procurement managers and R&D engineers grappling with material choices that balance performance and cost. Is 3CR13 steel the unsung hero or a hidden liability for your product designs? The definitive answer might challenge conventional wisdom and unlock new possibilities for your product line.

At China VMT CNC, we understand the critical decisions involved in selecting materials for precision CNC machining parts. Our deep experience in steel CNC machining parts, including 3CR13, offers unique insights into its true capabilities. This guide will provide a technical deep dive, helping you determine 3CR13 knife suitability and maximize its potential.

Understanding any material begins with its fundamental properties. For 3CR13 steel knives, these characteristics dictate its performance, machinability, and ultimately, its suitability for various knife applications. In our CNC machining factory, we consistently analyze these factors to ensure optimal outcomes.

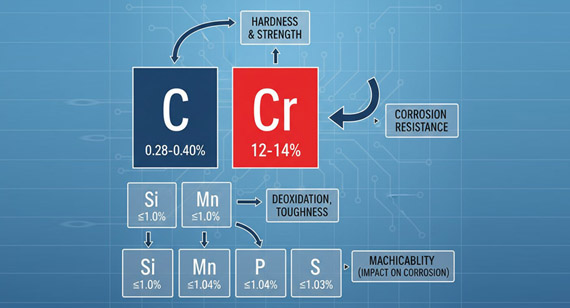

Chemical makeup of 3CR13

3CR13 is a martensitic stainless steel, a classification that provides a balance of hardness and corrosion resistance. Its chemical composition is key to its performance profile in 3CR13 knife manufacturing. Carbon content contributes to hardness, while chromium ensures its stainless properties.

This specific alloy typically contains approximately 0.26-0.35% Carbon, 12-13.5% Chromium, and minor additions of Manganese, Silicon, and other elements. This blend is carefully formulated to achieve the desired balance. The chromium content is sufficient to form a passive oxide layer, granting its corrosion resistance.

Hardness and edge retention

The carbon content in 3CR13, when properly heat-treated, allows it to achieve a respectable hardness. In our experience, we routinely achieve hardness levels in the range of 52-55 HRC for 3CR13 steel knives. This level is sufficient for many practical cutting tasks.

Edge retention is directly related to this hardness. While not on par with premium super steels, 3CR13 offers satisfactory edge retention for everyday use and budget-friendly blades. For a 3CR13 knife, users can expect a decent working edge that is also relatively easy to resharpen.

Corrosion resistance factors

The 12-13.5% chromium content is the primary driver of 3CR13's corrosion resistance. This makes it a stainless steel, suitable for applications where exposure to moisture or mild corrosives is expected. It performs well in kitchen environments and general outdoor use.

However, it's important to manage expectations. While significantly better than non-stainless carbon steels, 3CR13 steel knives are not impervious to all forms of corrosion. Prolonged exposure to harsh chemicals or saltwater without proper cleaning can still lead to pitting or discoloration.

Toughness and grindability

Toughness, the ability to resist chipping or breaking, is a notable advantage of 3CR13. It's generally less brittle than harder, high-carbon steels, making it a more forgiving material for utility knives. This makes it a good choice where impact resistance is valued.

Its relatively lower alloy content also contributes to excellent grindability and machinability. This is a significant factor in 3CR13 knife manufacturing. It allows for efficient shaping and finishing of 3CR13 CNC machining parts, which translates to reduced production costs for our clients.

Every material has trade-offs, and 3CR13 is no exception. Understanding its advantages and limitations is crucial for assessing 3CR13 knife suitability for your specific product line. We help our clients weigh these factors to make informed material selections for their steel CNC machining parts.

Advantages for knife making

One of the primary advantages of 3CR13 steel knives is their excellent corrosion resistance for the price point. This makes it ideal for kitchen knives, fishing knives, or general utility blades that will encounter moisture. It greatly minimizes the risk of rust.

Another benefit is its good toughness. This steel can withstand more abuse without chipping or breaking compared to more brittle, high-hardness alloys. It's a reliable choice for everyday carry (EDC) or utility tasks where absolute edge retention is secondary to durability.

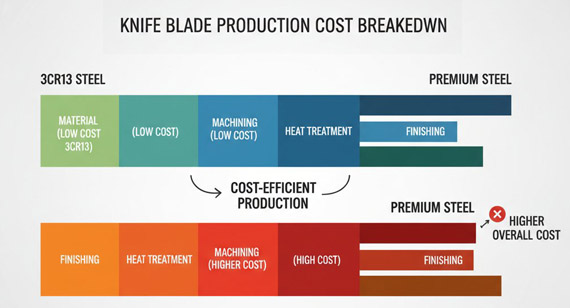

Finally, 3CR13's machinability and ease of heat treatment are significant manufacturing advantages. This contributes to lower production costs for 3CR13 knife manufacturing, allowing for more competitive pricing of finished products. Our CNC machining services leverage this property.

Limitations in knife performance

While good, the edge retention of 3CR13 steel knives is not exceptional compared to premium knife steels. It will require more frequent sharpening if used heavily. This is an important consideration for high-performance applications.

Its maximum achievable hardness is also moderate. For users prioritizing ultimate sharpness and long-lasting edge stability, 3CR13 might not meet the highest expectations. It occupies a specific niche rather than competing with super steels.

Cost-effectiveness in production

The inherent properties of 3CR13, combined with its widespread availability, make it a very cost-effective material. For budget knife steel comparison, 3CR13 consistently emerges as a strong contender. Its lower material cost contributes to affordable end products.

Furthermore, its ease of machining means less tool wear and faster cycle times in our CNC machining factory. This directly impacts the overall cost of producing 3CR13 CNC machining parts. Clients benefit from a favorable balance of performance and economic viability.

In the realm of budget knife steel comparison, 3CR13 often stands alongside other common alloys. Understanding these comparisons helps our clients make informed decisions about 3CR13 knife suitability. We provide data-driven insights for all steel CNC machining parts.

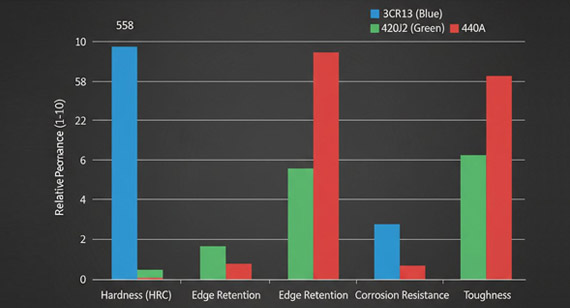

3CR13 vs. 420J2 in knives

Both 3CR13 and 420J2 are entry-level stainless steels. 3CR13 generally offers a slightly higher carbon content, which typically translates to better hardness and edge retention than 420J2. This makes 3CR13 a marginal upgrade in performance.

However, 420J2 might offer marginally better corrosion resistance due to its lower carbon and often higher chromium (though 3CR13 is very close). For most applications, 3CR13 provides a superior balance of properties for 3CR13 steel knives without a significant cost increase. Both are excellent for 3CR13 knife manufacturing where cost is paramount.

3CR13 vs. 440A knife performance

440A is another common stainless steel, often considered a step above 3CR13 and 420J2. It typically has higher carbon and chromium content than 3CR13. This allows 440A to achieve higher hardness and, consequently, better edge retention.

For applications demanding a more durable edge, 440A might be preferred. However, 3CR13 still holds its own in terms of toughness and ease of sharpening. The choice often comes down to the precise performance demands and the budget for the 3CR13 knife manufacturing project.

Here's a quick comparison of common budget steels:

| Property |

3CR13 (Typical) |

420J2 (Typical) |

440A (Typical) |

| Carbon (C) | 0.26-0.35% | 0.15-0.25% | 0.60-0.75% |

| Chromium (Cr) | 12-13.5% | 12-14% | 16-18% |

| Hardness (HRC) | 52-55 | 50-54 | 55-58 |

| Edge Retention | Good | Fair | Very Good |

| Corrosion Resistance | Good | Very Good | Excellent |

| Toughness | Very Good | Excellent | Good |

| Machinability | Excellent | Excellent | Good |

| Relative Cost | Low | Low | Moderate |

Position among budget knife steels

3CR13 steel firmly positions itself as a robust performer within the budget knife steel comparison category. It offers a compelling balance of properties that are often overlooked. It's a significant step up from generic stainless steels in terms of performance.

For manufacturers seeking reliable performance without entering the premium price bracket, 3CR13 provides a cost-effective solution. Our expertise in 3CR13 knife manufacturing ensures clients get the most out of this versatile material. This makes it a smart choice for many mass-produced items.

Choosing the right material means matching its properties to the intended use. 3CR13 knife suitability shines in specific applications where its characteristics are best utilized. Our CNC machining factory can guide clients in this selection process for 3CR13 CNC machining parts.

Best knife types for 3CR13 steel

3CR13 is an excellent choice for utility knives, general-purpose kitchen knives, and outdoor budget blades. Its corrosion resistance makes it ideal for tasks that involve moisture, such as fishing or camping, where cleaning may not always be immediate.

Many everyday carry (EDC) knives also benefit from 3CR13 due to its balance of toughness and ease of sharpening. It provides a reliable blade for common tasks without the worry of excessive chipping or difficult maintenance. This material is very forgiving for daily use.

When to choose 3CR13 for knives

Choose 3CR13 when cost-effectiveness, good corrosion resistance, and moderate edge retention are the primary requirements. It's ideal for products designed for the general consumer market or as an introductory knife for new users.

It's also a strong contender for promotional items or large-scale manufacturing projects where consistent quality at a low price point is critical. Our 3CR13 knife manufacturing expertise ensures high-volume production meets exacting standards. We excel at producing steel CNC machining parts for these applications.

Common 3CR13 knife misconceptions

One common misconception is that 3CR13 is "cheap" and therefore "bad." While it is inexpensive, proper heat treatment and manufacturing can transform it into a highly capable blade for its intended purpose. Many excellent, affordable knives utilize 3CR13 steel.

Another misconception is that it rusts easily. This is untrue; as a stainless steel, it offers good corrosion resistance, far surpassing non-stainless steels. It requires basic care, like any knife, but is not prone to rapid oxidation.

The true potential of 3CR13 steel knives is unlocked through precise manufacturing processes. At China VMT CNC, our expertise in 3CR13 knife manufacturing ensures superior quality from raw material to finished 3CR13 CNC machining parts. We apply stringent controls at every stage.

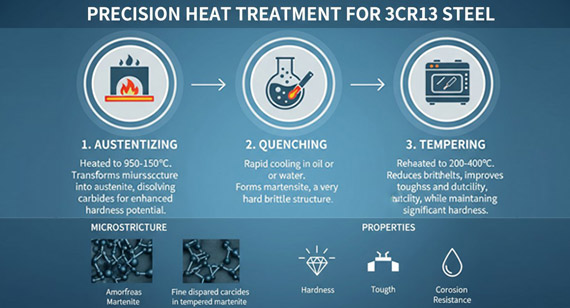

Precision heat treatment for 3CR13

Heat treatment is the single most critical step in optimizing 3CR13's performance. Our metallurgical engineers have developed precise protocols for 3CR13 steel to maximize its hardness, edge retention, and corrosion resistance. This involves controlled heating, quenching, and tempering cycles.

Sub-optimal heat treatment can drastically reduce 3CR13 knife suitability, leading to poor edge retention or brittleness. We utilize advanced furnace technology and strict temperature control to achieve consistent and repeatable results, a hallmark of our CNC machining services.

Machining 3CR13 steel for parts

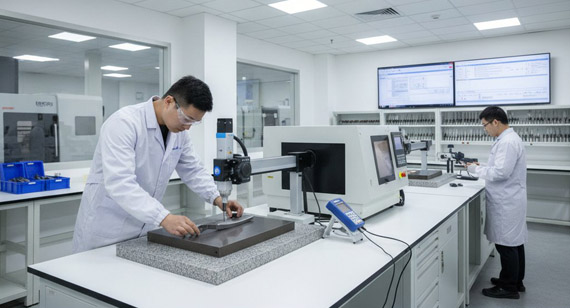

3CR13's excellent machinability is a significant advantage in production. As a leading CNC machining factory, we employ state-of-the-art CNC machining services to precisely shape 3CR13 steel into complex knife components. This includes blade blanks, handles, and other intricate parts.

Our advanced multi-axis CNC machines and optimized cutting parameters ensure tight tolerances and superior surface finishes. This reduces post-machining work and accelerates production cycles for high-volume 3CR13 CNC machining parts. Our engineers are adept at material-specific tooling.

Quality control in 3CR13 knives

Rigorous quality control is paramount in 3CR13 knife manufacturing. We implement comprehensive inspection procedures at every stage, from incoming raw material verification to final dimensional and metallurgical checks. Our ISO-certified processes guarantee consistency.

This includes hardness testing, surface finish analysis, and visual inspections of all 3CR13 CNC machining parts. Our commitment to quality ensures that every component meets the exact specifications and performance requirements for our clients' 3CR13 steel knives.

Choosing China VMT CNC means partnering with a source manufacturer that truly understands 3CR13 steel knives and precision manufacturing. Our deep expertise and integrated CNC machining services offer a distinct advantage for your projects. We are your reliable CNC machining factory.

High-quality 3CR13 steel components

We pride ourselves on delivering high-quality 3CR13 CNC machining parts that consistently meet design specifications. Our advanced manufacturing capabilities, combined with our material science knowledge, ensure optimal performance for your 3CR13 steel knives. We never compromise on precision.

We understand that even budget materials can yield exceptional results with the right processes. Our focus is on maximizing the inherent strengths of 3CR13 through expert machining and heat treatment. This ensures your final product stands out in the market.

Transparent pricing for 3CR13 projects

Transparency is a cornerstone of our business philosophy. We provide clear, itemized quotes for all 3CR13 knife manufacturing projects, ensuring procurement managers have a full understanding of costs. There are no hidden fees or surprises with our CNC machining services.

Our efficient production methods and direct sourcing of materials allow us to offer competitive pricing without sacrificing quality. This makes us an ideal partner for cost-conscious clients seeking reliable production of steel CNC machining parts.

Deep technical expertise for knives

Our team of R&D engineers and metallurgists possesses deep technical expertise in stainless steels, including 3CR13. We offer consultation services to help clients optimize their knife designs, material selection, and heat treatment protocols for 3CR13 knife suitability.

We provide data-driven recommendations and work collaboratively to solve complex manufacturing challenges. This expert guidance is invaluable, especially when aiming to get the best possible performance from specific materials. Our CNC machining factory is built on knowledge.

After a thorough technical analysis, the verdict on 3CR13 steel knives is clear. It is a highly capable and cost-effective material when understood and processed correctly. Its 3CR13 knife suitability is excellent for a wide range of applications.

Recap: Is 3CR13 good for knives?

Yes, 3CR13 is indeed good for knives, particularly for utility, kitchen, and budget outdoor applications. It offers a commendable balance of corrosion resistance, toughness, and ease of sharpening, especially when optimized through precision 3CR13 knife manufacturing.

While it won't outperform premium super steels in edge retention, its value proposition is unmatched for its intended market segment. With expert CNC machining services and meticulous heat treatment, 3CR13 steel knives deliver reliable and satisfactory performance.

Ready to unlock the true potential of 3CR13 steel for your knife production? Leverage our expertise.

Get a transparent 3CR13 quote

Contact China VMT CNC today for a transparent, detailed quote on your 3CR13 CNC machining parts. Our team will provide all the information you need. We ensure clarity from the outset for your steel CNC machining parts.

Consult our engineers for knife materials

Invite our expert engineers for an in-depth technical consultation on your 3CR13 steel requirements. We're here to optimize your material selection and manufacturing processes. Let us guide your 3CR13 knife manufacturing project.

What is 3CR13 steel primarily used for?

3CR13 steel is primarily used for manufacturing budget-friendly knives, utility tools, and various steel CNC machining parts. Its balance of corrosion resistance and good toughness makes it ideal for these applications. It also finds use in certain medical instruments and general hardware.

How does 3CR13 compare to 440C?

3CR13 is a lower-carbon stainless steel compared to 440C. 440C offers significantly higher hardness and edge retention due to its higher carbon content. However, 3CR13 is generally tougher and easier to sharpen than 440C, making it more forgiving.

Is 3CR13 prone to rust?

No, 3CR13 is a martensitic stainless steel and offers good corrosion resistance due to its chromium content. It is significantly more resistant to rust than non-stainless carbon steels. Proper care, like drying after use, is still recommended.

Can 3CR13 steel be sharpened easily?

Yes, 3CR13 steel knives are known for being relatively easy to sharpen. Its moderate hardness means it responds well to standard sharpening tools. This makes it a user-friendly choice for individuals who prefer straightforward maintenance.

What HRC can 3CR13 achieve?

With proper heat treatment, 3CR13 steel can typically achieve a hardness range of 52-55 HRC (Rockwell Hardness C scale). This level provides a good balance of edge retention and toughness for its common applications. Our 3CR13 knife manufacturing processes aim for this range.

Is 3CR13 suitable for high-end knives?

No, 3CR13 is not typically suitable for high-end or premium knives where ultimate edge retention and exotic properties are desired. It excels as a value-oriented material. For premium knives, higher-alloyed steels are generally preferred.

What are the benefits of CNC machining 3CR13?

CNC machining 3CR13 steel offers benefits such as excellent precision, consistent quality, and efficient production due to its good machinability. This allows for complex geometries and tight tolerances in 3CR13 CNC machining parts. Our CNC machining services leverage these advantages.

How does China VMT CNC ensure quality for 3CR13 parts?

China VMT CNC ensures quality through stringent material verification, precise heat treatment protocols, advanced multi-axis CNC machining, and comprehensive quality control inspections at every stage. We adhere to ISO standards to deliver reliable 3CR13 CNC machining parts.