15 years one-stop China custom CNC machining parts factory

25 |

Published by VMT at Oct 27 2025 | Reading Time:About 3 minutes

25 |

Published by VMT at Oct 27 2025 | Reading Time:About 3 minutes

Is inefficient thermal management or inconsistent component quality dimming your lighting product's potential? Discover how the synergy of precision aluminum die-casting and advanced CNC machining is illuminating new possibilities for durability, performance, and design excellence in the modern lighting industry. We confront these vexing issues head-on, offering an unequivocal solution for manufacturers who refuse to compromise on luminosity or longevity. Truly, the stakes are too high for anything less than perfection, I believe wholeheartedly.

When optimal thermal management and exact component quality are paramount for lighting products, the integrated approach of aluminum die-casting and precision CNC machining offers an unparalleled manufacturing solution. This dual process ensures exceptional heat dissipation, tight tolerances, and superior surface finishes, crucial for extending LED lifespan and enhancing product aesthetics.

The article delves into the critical role of aluminum die-casting and CNC machining for high-performance lighting components. It highlights key advantages such as superior thermal management for LEDs, tight precision, enhanced durability, and design freedom, alongside cost-effectiveness for mass production. Discussed are various applications, the integrated manufacturing process, and our factory's commitment to quality, technical expertise, and transparent partnership for streamlined supply chains.

Frankly, it's a perplexing reality that some still hesitate to embrace the inherent superiority of aluminum die-casting and subsequent CNC machining for their lighting components. The advantages are not just incremental; they are utterly transformative, reshaping what’s possible in product design and operational endurance. We're talking about a paradigm shift, honestly, in how these delicate yet robust luminaries function day in and day out.

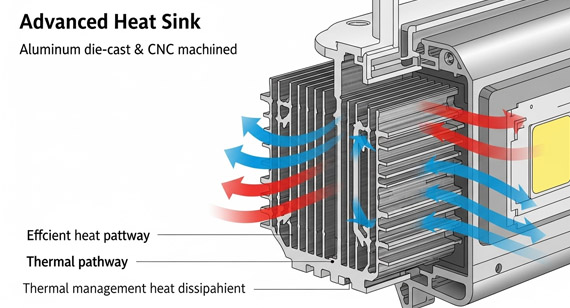

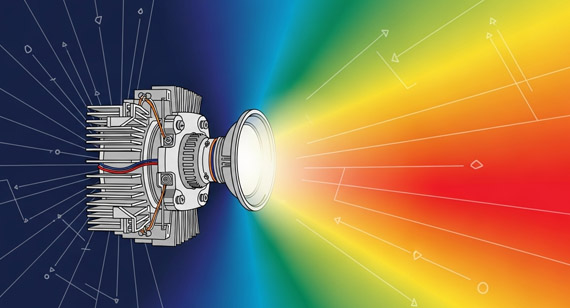

Superior Thermal Management for LEDs

The unrelenting challenge of heat dissipation in LED technology—it’s a veritable dragon that must be slain, and aluminum is our shining lance! Aluminum, with its remarkable thermal conductivity, becomes an almost miraculous conduit for heat transfer away from sensitive LED junctions. When components are fabricated through die-casting, complex geometries, such as numerous, finely pitched fins and intricate internal channels, become utterly achievable for CNC machined LED heat sinks. This isn't just a marginal gain; it reduces thermal impedance significantly, preventing lumen depreciation and forestalling premature failure of the light-emitting diodes—a downright catastrophic outcome for any product, if you ask me.

High Precision & Tight Tolerances Achieved

Achieving truly minute deviations from specified dimensions—this is where the combined prowess of die-casting and CNC machining absolutely shines, I maintain. Initial die-casting establishes near-net shapes with impressive fidelity, but it is the subsequent lighting industry CNC machining that refines these forms to exacting specifications, often within mere microns. We are talking about geometric dimensioning and tolerancing (GD&T) capabilities that ensure flawless assembly, eradicate light leakage, and uphold consistent optical performance. Imagine components fitting together with an almost audible click of perfect congruence! That is the standard we not only aim for but consistently deliver, ensuring precision aluminum casting lighting components that meet the most stringent demands.

Enhanced Durability and Longevity

Lighting fixtures often endure harsh conditions—relentless vibrations, fluctuating temperatures, even direct environmental assaults! Aluminum, inherently corrosion-resistant and incredibly robust, forms the foundational bulwark against such abuses. When reinforced by the dense, uniform grain structure achieved through high-pressure aluminum die casting lighting parts processes, these components exhibit exceptional structural integrity. Post-machining further removes any residual porosity, fortifying the material against fatigue and ensuring unparalleled longevity, which is a blessing for end-users and a relief for manufacturers, quite frankly.

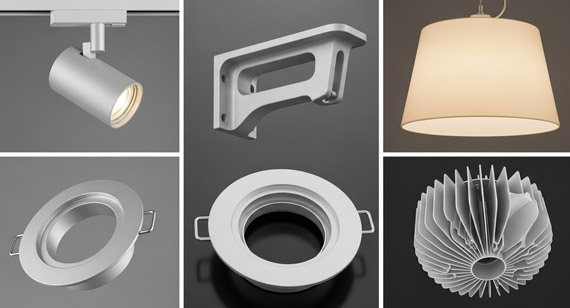

Complex Geometries & Aesthetic Freedom

The constraints of design often feel like creative shackles, do they not? With our integrated process, however, designers find liberation. Die cast aluminum enclosures LED components can feature sweeping curves, intricate internal structures, and sleek, modern contours that are virtually impossible with other manufacturing methods. CNC machining then carves out exquisite details, precise mounting features, and prepares surfaces for a myriad of aesthetic finishes—think anodizing, powder coating, or polishing! The fusion allows for lighting fixture components manufacturing that marries formidable function with breathtaking form, enabling truly innovative product differentiation, a true competitive advantage!

Cost-Effectiveness for Mass Production

"But what about the expense?" one might ponder, and it’s a valid query. While the initial tooling investment for die-casting can seem substantial, its true magic unfurls during mass production. For high-volume aluminum die casting lighting parts, the per-unit cost plummets dramatically, making it an incredibly economical choice. The near-net shapes from casting significantly reduce the material removal required during Aluminum Die-Casting CNC Machining, minimizing machining time and material waste. This translates directly into substantial cost savings, ensuring a superior product without an exorbitant price tag, a truth that delights procurement managers everywhere.

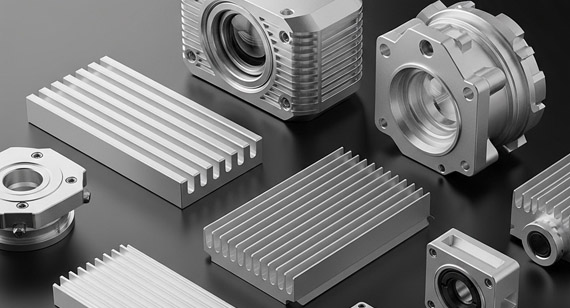

The applications for these masterfully crafted aluminum components are extensive, truly, extending across the entire spectrum of illumination. From the simplest domestic lamp to the most complex industrial luminaire, our CNC Machining Parts for Lighting find their indispensable place, solving critical design and performance dilemmas.

LED Heat Sinks and Thermal Solutions

Absolutely paramount are the heat sinks for LEDs; without them, performance crumbles! Our CNC machined LED heat sinks are not merely pieces of metal; they are meticulously engineered thermal pathways. They guide heat away from the sensitive diode, optimizing temperature management and thereby safeguarding the light source's efficiency and lifespan. Fin densities, flow channels, and mounting surfaces—all are executed with astounding accuracy.

Fixture Housings and Enclosures

Enclosures are more than just shells; they are the armor and the aesthetic soul of a fixture. Our die cast aluminum enclosures LED components offer exceptional structural rigidity, protecting delicate internal electronics from environmental ingress and mechanical stress. Concurrently, their smooth, precise surfaces provide an ideal canvas for various finishes, contributing immensely to the overall visual appeal and brand identity of the final product.

Table: Common Aluminum Alloys for Lighting Components

| Alloy Type | Key Characteristics | Typical Applications in Lighting |

| A380 | Good strength, castability, thermal conductivity | General purpose housings, heat sinks |

| A383 | Excellent fluidity, ideal for intricate thin-walled parts | Complex fixture designs, detailed reflectors |

| A413 | High fluidity, superior leak tightness | Pressure-tight enclosures, outdoor lighting |

| A360 | Good corrosion resistance, strength at elevated temps | Outdoor architectural lighting, industrial applications |

Reflectors and Optical Components

Precision is utterly non-negotiable when it comes to optics. Precision aluminum casting lighting parts can form the foundation for highly accurate reflectors, controlling beam angles and light distribution with exquisite exactitude. Post-machining refines these surfaces to optical-grade smoothness, ensuring minimal light loss and superior photometric performance—a vital factor for both energy efficiency and visual comfort!

Architectural and Commercial Lighting

From grand chandeliers to subtle recessed luminaires, architectural and commercial lighting demands both aesthetic brilliance and steadfast reliability. Our Aluminum CNC Machining Parts for these applications fulfill both criteria, providing sleek, durable housings and intricate internal structures that seamlessly integrate into diverse design schemes. The capability to produce bespoke designs with unparalleled repeatability is a huge asset.

Automotive and Specialty Lighting Components

The automotive sector, particularly, demands components that are not only robust but also exquisitely precise for safety and performance reasons. For headlights, interior ambient lighting, and specialized signaling systems, our CNC Machining Parts are engineered to withstand extreme temperatures, vibrations, and corrosive road conditions while maintaining optical integrity and reliability—an absolute must for modern vehicle illumination.

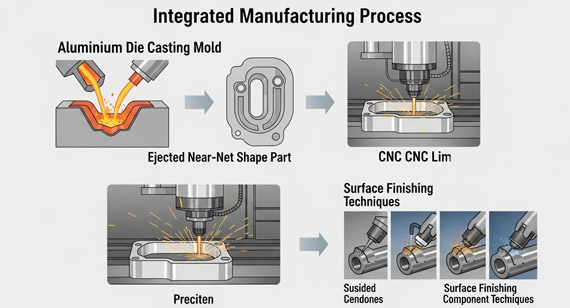

The journey from molten aluminum to a flawlessly finished lighting component is a meticulous dance of engineering and craftsmanship, a process we have mastered to an almost astonishing degree. It's truly a sight to behold, the transformation.

Aluminum Die-Casting Fundamentals for Lighting

It all begins with the aluminum itself, melted to a fluid state and then—whoosh!—injected under immense pressure into precisely engineered steel dies. This high-pressure injection is what gives aluminum die casting lighting parts their characteristic density, exceptional surface finish, and incredible dimensional stability, even before any secondary operations. The mold design, I must say, is an art form in itself, dictating the ultimate success of the part's thermal and structural properties.

Precision CNC Machining Post-Casting

After the casting process, the parts, while already impressive, often require further refinement. This is where Aluminum Die-Casting CNC Machining steps in, utilizing multi-axis milling, drilling, and tapping to achieve micron-level accuracy. Features like precise mounting holes, intricate internal channels for wire routing, or critical optical interfaces are meticulously carved. This ensures every single feature, however small, conforms to the exact engineering blueprint, often improving upon the base cast.

Surface Treatment and Finishing Options

Beyond mere structural integrity, the aesthetic and environmental resilience of lighting fixture components manufacturing often hinges on the final surface treatment. We offer a comprehensive array of finishing options, from utilitarian powder coating for outdoor durability to elegant anodization in various colors for architectural fixtures. Polishing, brushing, and sandblasting also serve to enhance tactile and visual qualities, tailor-fitting the component to its intended environment and design brief.

Table: Available Surface Finishing Options

| Finish Type | Primary Benefit(s) | Typical Appearance | Lighting Application Example |

| Anodization | Corrosion resistance, wear resistance, aesthetic color options | Matte to glossy, opaque color | Decorative LED housings, outdoor luminaires |

| Powder Coating | Excellent durability, chip resistance, wide color range | Uniform, often textured | Industrial light fixtures, outdoor floodlights |

| Polishing | High reflectivity, aesthetic appeal | Mirror-like, shiny | Reflectors, premium architectural lighting |

| Brushing | Aesthetic texture, reduced glare | Subtle, linear texture | Modern fixture housings, trim rings |

| Sandblasting | Matte finish, surface uniformity for painting | Uniform, dull matte | Base for painting, non-reflective surfaces |

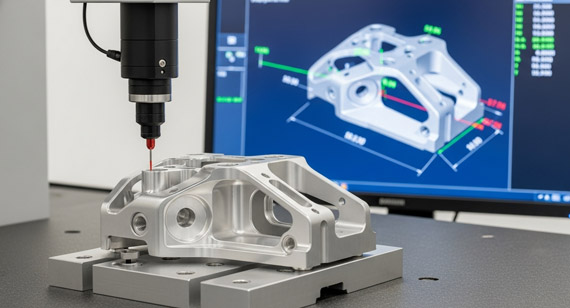

Quality Control and Inspection Standards

Let me be absolutely clear: quality is not an afterthought; it is ingrained into every single fiber of our operation, a non-negotiable imperative! From the initial material inspection of aluminum ingots to the final dimensional validation of CNC Machining Parts, rigorous quality control protocols are implemented at every stage. We leverage advanced metrology equipment, including Coordinate Measuring Machines (CMMs) and optical comparators, to meticulously scrutinize every component, ensuring unfailing adherence to all specifications. Our unwavering commitment to producing high-quality parts is something we, VMT, take immense pride in, an absolute bedrock of our existence.

Choosing the right manufacturing partner is not a trivial decision; it's a monumental choice that can utterly define your project's trajectory. With us, you align with a CNC Machining Factory that offers more than just parts; we provide solutions, a partnership built on trust and technical acumen, which is truly a rare gem in this industry.

Source Manufacturer Advantage & Transparency

We operate as a genuine source manufacturer, which is a distinction of profound importance, offering you a direct line to the production floor—no middlemen, no convoluted communication chains, just absolute clarity. This translates into transparent pricing, enabling you to fully comprehend your costs without hidden fees or obscure markups. This direct engagement fosters a relationship built on trust and mutual understanding, ensuring that your specific needs for CNC Machining Services are met with unwavering dedication.

Unrivaled Quality & Technical Support

"But what if our design needs tweaking?" you might ask. And this is precisely where our deep technical expertise becomes an invaluable asset. Our team of seasoned engineers possesses an encyclopedic knowledge of materials, processes, and DFM (Design for Manufacturability) principles. We don't just execute; we collaborate, offering insightful design optimization suggestions that can enhance performance, reduce costs, or even unlock entirely new design possibilities. It's a truly comprehensive support system, one you deserve.

Streamlined Supply Chain & Timely Delivery

In today's fast-paced market, efficiency is the undisputed monarch! Our integrated manufacturing capabilities, combined with robust logistics, allow us to streamline your supply chain, minimizing complexities and accelerating lead times. We understand that timely delivery is not merely a convenience; it is a critical factor in maintaining your production schedules and getting your innovative products to market when they are needed most—without a moment's hesitation or frustrating delay!

Here at VMT CNC Machining Parts Services Factory, located in China, we truly embrace the mantle of precision and innovation in lighting industry CNC machining. Our commitment to unparalleled quality, backed by years of specialized experience in Aluminum Die-Casting CNC Machining for the most demanding industries, positions us as your quintessential partner. We pride ourselves on delivering not just parts, but absolute confidence and unshakeable reliability to our clients, every single time. Honestly, we refuse to settle for anything less than perfection, and neither should you, our esteemed client!

The confluence of aluminum die casting lighting parts and high-precision CNC machining is not just another manufacturing option; it is, quite frankly, the definitive path forward for anyone serious about creating truly exceptional lighting products. This integrated approach solves the persistent problems of thermal management, precision, durability, and aesthetic versatility, providing a competitive edge that is simply insurmountable by lesser methods. To ignore its immense power would be an unbelievably foolish assumption in today's fiercely competitive market. So, let us collaborate, let us create, and together, let us illuminate the future!

Q1: What are the primary benefits of using aluminum die casting lighting parts for LED fixtures?

A1: The primary benefits are superior thermal conductivity, which is crucial for dissipating heat from LEDs to prolong their lifespan and prevent lumen depreciation. Additionally, aluminum die casting provides excellent structural integrity, corrosion resistance, and the ability to form complex geometries with a good surface finish, which can then be refined by CNC machining.

Q2: How does CNC machined LED heat sinks improve the performance of lighting products?

A2: CNC machined LED heat sinks significantly improve performance by creating precise, intricate fin structures and internal channels that maximize surface area for heat exchange. This reduces thermal resistance, keeps the LED junction temperatures lower, and ensures consistent light output, color stability, and extended operational life for the entire luminaire.

Q3: Can precision aluminum casting lighting components meet strict aesthetic requirements?

A3: Absolutely. Precision aluminum casting lighting components, when followed by advanced CNC machining and a range of surface treatments (like anodizing, powder coating, polishing), can achieve exceptionally high aesthetic standards. This allows for intricate designs, sleek finishes, and seamless integration into various architectural and product designs.

Q4: What is the typical lead time for lighting fixture components manufacturing using your combined process?

A4: The typical lead time for lighting fixture components manufacturing varies significantly based on part complexity, volume, and specific surface finishing requirements. Generally, initial tooling for die-casting can take several weeks, followed by production runs which can be quite rapid, often measured in days or a few weeks for large volumes. We encourage clients to discuss their specific project timelines with our team for an accurate estimate.

Q5: Is your factory capable of supporting custom die cast aluminum enclosures LED designs?

A5: Yes, indeed! Our CNC Machining Factory specializes in supporting custom die cast aluminum enclosures LED designs. We possess deep technical expertise in design for manufacturability (DFM) and can work closely with your R&D engineers and product designers from concept to final production, ensuring that your unique specifications are met with precision and efficiency.

Q6: How does your source manufacturer advantage benefit clients looking for CNC Machining Services?

A6: As a source manufacturer, we offer clients a direct, transparent relationship with the production facility. This eliminates middlemen, leading to clearer communication, faster problem resolution, more transparent pricing, and greater control over the manufacturing process. It fundamentally simplifies the supply chain for our CNC Machining Services.

Q7: What quality control measures are in place for Aluminum Die-Casting CNC Machining parts?

A7: For Aluminum Die-Casting CNC Machining parts, we implement stringent quality control at every stage. This includes raw material inspection, in-process checks on casting parameters, comprehensive dimensional verification using CMMs and optical comparators post-CNC machining, and final surface finish inspections. Our commitment ensures high-quality parts consistently.

Q8: What kind of technical support does VMT offer for new lighting projects?

A8: VMT offers extensive technical support for new lighting projects, encompassing DFM consultation, material selection guidance, prototype development, and process optimization recommendations. Our team acts as a collaborative extension of your engineering department, helping to refine designs for optimal performance, manufacturability, and cost-effectiveness from the earliest stages.

Ready to illuminate your product's potential with precision-engineered aluminum components? Contact our technical experts today for a free consultation and a transparent quote on your next lighting project.