15 years one-stop China custom CNC machining parts factory

51 |

Published by VMT at Oct 07 2025 | Reading Time:About 3 minutes

51 |

Published by VMT at Oct 07 2025 | Reading Time:About 3 minutes

I contend that grappling with Nickel-Copper alloys in CNC machining is one of engineering's most vexing and financially perilous endeavors, often culminating in profound consternation and unacceptable scrap. Are you, perchance, confronting the inherent complexities where the margin for error remains razor-thin, and the fiscal repercussions of failure become astronomical? This perpetual struggle—this ceaseless battle against unforgiving material properties—exhausts resources, consumes precious time, and frequently compromises project integrity. Discover precisely how an unwavering commitment to precision, an encyclopedic technical mastery, and a profoundly discerning comprehension of these advanced metallic compositions can indeed transmute your most challenging projects into impeccable, high-performance realities.

For those who regularly contend with superior engineering materials, Nickel-Copper alloys present a formidable yet indispensable choice for extreme environments; mastering their CNC machining ensures component integrity, mitigates tool expenditure, and delivers the requisite precision for critical applications in sectors like marine, aerospace, and chemical processing. Our facility specializes in transforming these challenging materials into high-quality, high-performance parts.

This comprehensive guide delves into the intricate world of CNC machining Nickel-Copper alloys, highlighting their paramount importance, unique advantages, and significant machining challenges. We elucidated critical strategies, including optimal tool selection, cutting parameters, and coolant management, necessary for overcoming material difficulties like work hardening. The article underscores the necessity of stringent quality control, post-processing, and delineates common industrial applications. Finally, it emphasizes our factory's distinct advantages as a source manufacturer, offering unparalleled quality, transparent pricing, and profound technical expertise for precision Nickel-Copper alloy component fabrication.

Fundamentally, Nickel-Copper alloys represent a class of metallic composites predominantly composed of nickel and copper, frequently incorporating minor additions of other elements to augment particular attributes. They are solid solutions, meaning the metals intermix at an atomic level, fostering a unique blend of characteristics. A potent combination, these alloys excel in specific, arduous operational scenarios, performing where ordinary metals would invariably falter. Indeed, the very essence of their utility lies in this atomic commingling.

Their gravitas within industrial spheres cannot be overstated; it is an absolutely irreplaceable truth. These alloys manifest an extraordinary confluence of corrosion resistance, particularly against seawater and various acids, coupled with commendable strength—even at elevated temperatures. They become indispensable constituents within critical infrastructure, components that cannot merely fail without dire consequences. Consider, if you will, the profound reliability mandated in naval propulsion systems. Our collective societal progression, it seems evident to me, often hinges upon the robust performance of such specialized materials.

The genesis of Nickel-Copper alloy deployment dates back to the early 20th century, notably with the advent of Monel, a proprietary alloy pioneered by The International Nickel Company (Inco). Its inception was a direct response to industrial exigencies demanding materials that could withstand the unrelenting assault of corrosive media and substantial mechanical stress. Honestly, the engineers of that epoch, grappling with the limitations of existing metals, must have viewed Monel as nothing short of a metallurgical revelation. A truly pivotal moment for materials science, it undeniably was.

Let's dissect the inherent attributes and inherent detriments of these alloys. They are materials of profound duality, offering immense benefits alongside distinctive processing tribulations. One must approach them with an informed perspective; blind enthusiasm leads inevitably to disappointment and expense.

Nickel-Copper Alloy Advantages

| Attribute | Description |

| Exquisite Corrosion Resistance | Demonstrates formidable resilience against saltwater, hydrofluoric acid, sulfuric acid, and alkalis. |

| Elevated Strength | Retains commendable tensile and yield strength across a broad thermal spectrum. |

| Temperature Stability | Sustains mechanical properties effectively, even when subjected to cryogenic to elevated temperatures. |

| Commendable Weldability | Many variations permit joining via conventional welding methodologies. |

| Non-Magnetic Properties | Certain compositions exhibit non-magnetic characteristics, vital for specific instrumentations. |

Nickel-Copper Alloy Disadvantages

| Attribute | Description |

| Formidable Machinability | Prone to severe work hardening, engendering rapid tool wear and complicating precision. |

| Elevated Material Expense | These alloys inherently possess a premium price point due to constituent element costs and processing. |

| Density | Possess a comparatively higher density than many ferrous alloys, potentially impacting weight budgets. |

| Thermal Conductivity | Lower thermal conductivity can induce localized heating during machining, contributing to tool degradation. |

A thorough grasp of their intrinsic characteristics is paramount prior to any machining endeavor. Without such foundational cognition, one merely guesses, and guessing, I assure you, proves frightfully costly in this domain.

Common Varieties of Nickel-Copper Alloys

The Monel series stands as the archetypal exemplar. Monel 400, for instance, is a nickel-copper alloy with exemplary resistance to seawater and steam at high temperatures. Then, there's Monel K-500, an age-hardenable variant, deriving its enhanced strength and hardness from aluminum and titanium additions, making it even more of a metallurgical marvel, and simultaneously, a greater machining nemesis. Each variant presents its own set of peculiar demands.

| Alloy Designation |

Primary Characteristics |

Common Applications |

| Monel 400 |

Excellent corrosion resistance, high strength, good ductility. |

Marine engineering, chemical processing equipment, valves, pumps. |

| Monel K-500 |

Age-hardenable for enhanced strength and hardness, non-magnetic. |

Pump shafts, impellers, doctor blades, oil well tools. |

| Monel R-405 |

Free-machining variant of Monel 400 with controlled sulfur addition. |

Meter parts, screw machine products, valve components. |

Physical Attributes of Nickel-Copper Alloys

Understanding the physical makeup provides the scaffolding for comprehending their behavior. This isn't merely academic data; it directly informs tool selection and machining strategy.

| Physical Property | Monel 400 (Typical) | Monel K-500 (Typical) | Unit |

| Density | 8.80 | 8.84 | g/cm³ |

| Melting Range | 1300-1350 | 1315-1350 | °C |

| Thermal Conductivity (RT) | 22 | 16 | W/m·K |

| Electrical Resistivity (RT) | 0.51 | 0.61 | µΩ·m |

| Modulus of Elasticity | 179 | 179 | GPa |

Mechanical Attributes of Nickel-Copper Alloys

Their mechanical fortitude dictates where and how they can be deployed. These figures are not mere digits; they represent the capacity to endure stress, strain, and environmental onslaught.

| Mechanical Property | Monel 400 (Annealed) | Monel K-500 (Age-Hardened) | Unit |

| Tensile Strength | 550 | 1100 | MPa |

| Yield Strength (0.2% offset) | 240 | 790 | MPa |

| Elongation | 35 | 20 | % |

| Hardness (Brinell) | 125 | 275 | HB |

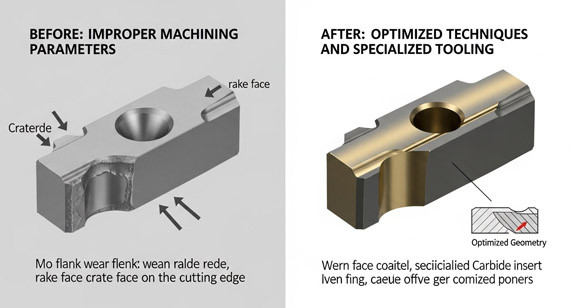

Core Difficulties in Machining Nickel-Copper Alloys

The formidable challenges are legion. Chief among them, undeniably, is their notorious propensity for work hardening—the material becoming progressively tougher as it is cut, rapidly dulling cutting edges. A machinist’s worst nightmare. Then, there are the issues of chip management, which are consistently problematic, and the proclivity for burr formation, demanding meticulous post-processing. Maintaining dimensional accuracy, with such obdurate materials, demands unparalleled control.

Confronting these materials demands a nuanced, aggressive, yet precisely controlled methodological framework. There is no room for complacency.

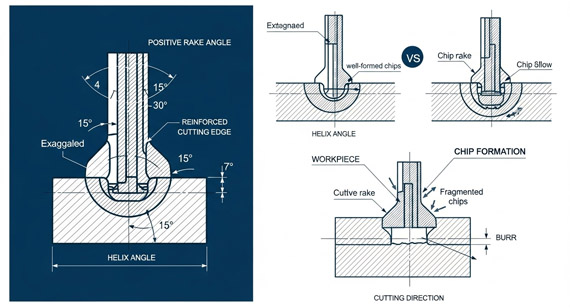

Tool Selection and Geometry Optimization

This element is absolutely paramount; the choice of cutting instrument and its specific configuration dictates success or calamitous failure. We advocate for robust, sharp, positive-rake geometry tooling. Carbide inserts, with appropriate coatings like AlTiN or TiAlN, are indispensable. The larger the nose radius, within sensible limits, often proves beneficial for strength, albeit with implications for surface finish and vibration—a careful equilibrium must be established. Chips must flow.

Cutting Parameter Configuration and Feed Tactics

This is where profound expertise truly distinguishes our endeavors. Low cutting speeds, relatively high feed rates, and a generous depth of cut are typically favored to engage below the work-hardened layer. A shallow cut simply burnishes the surface, making subsequent passes even more arduous. The objective is to sever the material decisively, not merely abrade it. Small, timid cuts are a recipe for disaster.

When setting cutting parameters for nickel-copper alloys, too fast a speed can lead to a dramatic drop in tool life; too slow a speed, and work hardening becomes an insurmountable obstacle. Compared to steel, we use a lower surface feet per minute (SFM) but a relatively high and stable chip load (feed per tooth) to ensure the tool penetrates the work-hardened layer with each cut. This is a delicate but absolutely crucial operation. I believe this technique prevents the tool from simply rubbing and further hardening the surface.

| Parameter |

Recommended Range (Monel 400) |

Rationale for Ni-Cu |

| Surface Feet/Minute (SFM) |

60-120 ft/min |

Minimizes heat generation, reduces thermal shock. |

| Feed per Tooth (FPT) |

0.003-0.007 inches |

Ensures cutting action below work-hardened zone. |

| Depth of Cut (DOC) |

Radial: 0.015-0.030 inches |

Sufficient to engage fresh material, prevents rubbing. |

| Axial: Up to 0.5-1.0xD for roughing |

Maximizes material removal, aids chip evacuation. |

Coolant Management and Chip Control

Effective coolant application is not merely an accessory; it is a critical operational imperative. Flood cooling, often high-pressure, directly targeted at the cutting zone, mitigates heat buildup and assists in chip evacuation. Chip control, often overlooked, is crucial; stringy, tenacious chips can entangle tools, impede cutting, and mar surface finishes. We deploy specialized chip breakers and optimized tool paths to manage these stubborn, ribbon-like metallic strands.

Machine Rigidity and Fixture Design

A substantial, highly rigid machine tool, possessing ample horsepower and robust spindle bearings, is non-negotiable for machining Nickel-Copper alloys. Chatter, that abominable vibration, will destroy tools and finishes with astonishing alacrity. Furthermore, the workholding fixture must be equally unyielding, securely clamping the workpiece to absorb cutting forces and prevent movement. A flimsy fixture. A ruined part.

Our factory approaches these obstacles not as insurmountable barriers but as engineering puzzles awaiting ingenious resolution. It's truly a different mindset.

Tactics for Mitigating Work Hardening

To circumvent work hardening, we meticulously fine-tune cutting parameters and tool geometries. Our strategy involves consistently cutting beneath the previously hardened layer, ensuring the tool always engages virgin, softer material. This often necessitates heavier cuts and precise machine control. Moreover, we judiciously employ sharp, positive-rake inserts to minimize compressive forces and friction, which are significant contributors to undesirable hardening.

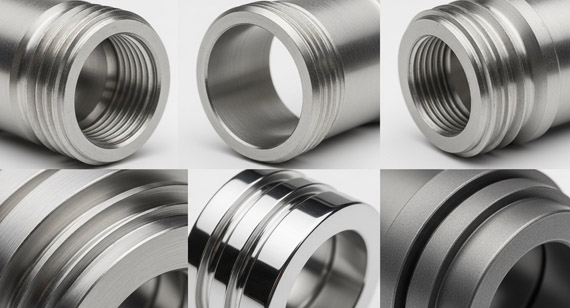

Attaining Exquisite Precision and Surface Finishes

Achieving tight tolerances and a commendable surface finish on these tenacious alloys is an art form, informed by science. We utilize optimized finishing passes with reduced radial engagement and meticulously selected tools. Post-machining operations, such as precision grinding or lapping, are sometimes deployed to achieve exceptionally fine surface specifications. It’s an iterative process, constantly refined by experience.

Prolonging Tool Life and Reducing Expenses

The exorbitant cost of specialized tooling necessitates a rigorous focus on tool life optimization. Through exhaustive testing and empirical data collection, we determine the optimal balance between material removal rate and tool longevity. Employing advanced predictive analytics and real-time monitoring, we anticipate tool wear, enabling timely replacement and averting catastrophic failures. Honestly, nobody desires preventable downtime or scrap.

Troubleshooting and Resolving Common Anomalies

Chatter, excessive burring, or an unacceptable surface finish are not merely defects; they are symptoms demanding diagnostic prowess. Our engineering cadre, possessing decades of cumulative experience, meticulously analyzes chip morphology, acoustic signatures during cutting, and tool wear patterns. This allows for swift identification of root causes and the implementation of corrective adjustments to cutting parameters, coolant delivery, or fixturing.

Wait, I need to clarify that point—identifying the *root cause* is the critical element. Just tweaking settings without understanding why a problem arises is a folly.

The machining concludes, yet the journey toward a perfect component persists. Quality verification and subsequent treatments are indispensable.

Post-Machining Dimensional Inspection Standards

Our metrology department deploys an array of advanced inspection apparatuses, including CMMs (Coordinate Measuring Machines) and optical comparators, to ensure every dimension adheres to the most stringent specifications. We implement statistical process control (SPC) to monitor consistency across production runs, guaranteeing adherence to critical tolerances, often in the micron range. The numbers must validate the precision.

Surface Integrity and Flaw Detection

Beyond dimensional accuracy, the surface integrity of Nickel-Copper alloy components is scrutinized for any indication of thermal damage, micro-cracking, or recast layers that could compromise the material's inherent properties. Non-destructive testing (NDT) methodologies, such as dye penetrant inspection or eddy current testing, are frequently employed to detect even the most minuscule surface or subsurface imperfections. A tiny flaw can lead to tremendous failure.

Cleaning, Deburring, and Finishing Protocols

After machining, components undergo meticulous cleaning processes to eliminate all cutting fluids, chips, and debris. Deburring, often a laborious manual or automated task due to the material's tenacity, is executed with scrupulous attention to detail. Various surface finishing techniques, from electropolishing to passivation, can then be applied to enhance corrosion resistance and refine aesthetic qualities, according to client specifications.

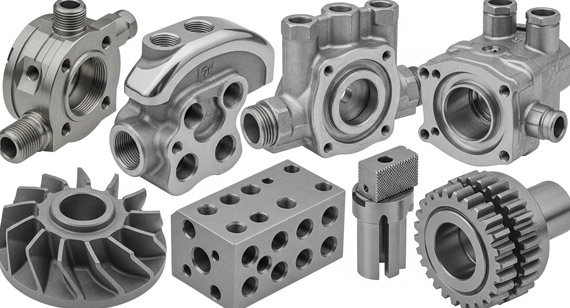

The omnipresence of Nickel-Copper alloys in demanding environments is truly impressive, a testament to their exceptional material characteristics. They are everywhere that performance cannot be compromised.

Industries Utilizing Nickel-Copper Alloys

| Industry Segment | Rationale for Selection |

| Marine & Offshore | Unparalleled resistance to seawater corrosion and cavitation, crucial for prolonged saltwater immersion. |

| Chemical Processing | Endures aggressive acids, alkalis, and process fluids, ensuring equipment longevity and safety. |

| Oil & Gas | Resilience in harsh downhole environments, resisting sour gas, chlorides, and elevated temperatures. |

| Aerospace | High strength-to-weight ratio, temperature stability, and corrosion resistance for critical airframe and engine parts. |

| Power Generation | Withstands corrosive steam, elevated temperatures, and high pressures within boilers and heat exchangers. |

Common Nickel-Copper Alloy Components

| Component Type | Typical Application Context |

| Valve Bodies & Fittings | Regulating flow in corrosive fluid systems, ensuring leak-free and reliable operation. |

| Pump Shafts & Impellers | Critical for fluid transfer, demanding resistance to erosion, corrosion, and fatigue. |

| Fasteners & Connectors | Securing assemblies in aggressive environments, where failure is not an option. |

| Heat Exchanger Tubing | Facilitating efficient heat transfer while resisting corrosive fluids on both sides. |

| Marine Propellers | Propulsion systems requiring exceptional strength, cavitation resistance, and saltwater longevity. |

Why repose your confidence in our factory for your most challenging endeavors? It ultimately boils down to expertise, transparency, and an unwavering commitment to unparalleled quality.

The Distinct Advantage of a Source Manufacturer

As an authentic source manufacturer, we wield complete dominion over the entire production continuum—from material procurement to final inspection. This comprehensive control invariably translates into superior quality, predictable lead times, and an elimination of unnecessary intermediary costs. You engage directly with the genesis of your components, eliminating layers of uncertainty.

Unrivaled Quality and Transparent Value

Our commitment to superior craftsmanship is not merely rhetoric; it is woven into the very fabric of our operational ethos. We deliver components that not only satisfy but frequently exceed the most exacting industry benchmarks. Moreover, our pricing structures are utterly transparent, devoid of hidden charges or opaque estimations. You shall always comprehend the precise value proposition.

Profound Technical Acumen and Illustrative Cases

Our cadre of engineers and machinists possess a profound, perhaps even unparalleled, understanding of Nickel-Copper alloy behavior under various cutting conditions. We have successfully navigated myriad projects, transforming seemingly intractable machining challenges into triumphs of engineering. Consultations regarding these previous successes are always available—we have the battle scars, and the victories, to prove it.

Bespoke Solutions and Client Support

Every project, in our estimation, possesses its own idiosyncratic requirements. We do not proffer cookie-cutter solutions. Instead, our approach involves a collaborative engagement with your engineering team to architect bespoke machining strategies precisely tailored to your specific application, tolerances, and performance expectations. Our client support is not merely reactive; it is a proactive, consultative partnership designed for mutual success.

Ultimately, the mastery of CNC machining Nickel-Copper alloys is not for the faint of heart, but rather for those possessing an unwavering technical resolve and an enduring commitment to absolute precision. VMT factory, with its deep-seated expertise, transparent methodologies, and unyielding dedication to delivering high-performance components, stands as your quintessential partner. We empower your critical projects by transforming these demanding materials into reliable, exquisitely crafted realities. Ready to overcome your most demanding Nickel-Copper alloy machining challenges with a trusted, expert partner? Contact our engineering team today for a no-obligation technical consultation and a transparent quote tailored to your specific project needs. Leverage our deep expertise for your next critical component.

1. What distinguishes Nickel-Copper alloys from other high-performance materials in terms of machinability?

Nickel-Copper alloys are particularly infamous for their severe propensity to work harden during machining, a phenomenon where the material becomes significantly tougher and harder as the cutting tool engages it. This necessitates specialized tooling, lower cutting speeds, and higher feed rates to continuously cut below the hardened layer. Furthermore, their relatively low thermal conductivity can lead to localized heat buildup, exacerbating tool wear and potentially compromising surface integrity. These characteristics make them considerably more challenging to machine than many stainless steels or even other nickel-based superalloys without specific strategies.

2. What specific tooling materials and coatings are recommended for CNC machining Monel K-500?

For machining Monel K-500, a particularly challenging age-hardenable variant, robust carbide inserts are unequivocally recommended. The carbide substrate itself should be tough, with specific grades designed for difficult-to-machine materials. Coatings like AlTiN (Aluminum Titanium Nitride) or TiAlN (Titanium Aluminum Nitride) are highly favored due to their superior hot hardness and oxidation resistance, which help to mitigate the intense heat generated at the cutting edge. Furthermore, positive rake angles and sharp cutting edges are paramount to facilitate chip flow and minimize compressive forces.

3. How do you prevent excessive burr formation when machining Nickel-Copper alloys?

Preventing excessive burr formation on tenacious Nickel-Copper alloys requires a multifaceted approach. It begins with optimal tool geometry, utilizing sharp cutting edges and positive rake angles to shear the material cleanly. Optimized cutting parameters—adequate feed rates and depths of cut—are crucial to ensure a clean severing action rather than tearing. Employing climb milling whenever feasible can also reduce burr size. For intricate features, dedicated deburring operations, which can range from manual techniques to automated processes like vibratory finishing or electrochemical deburring, are frequently necessary.

4. What are the typical lead times for custom Nickel-Copper alloy components?

Typical lead times for custom Nickel-Copper alloy components exhibit considerable variation, profoundly influenced by the component's complexity, the required material grade's availability, the batch volume, and any specialized post-processing or certification requirements. Simple parts in readily available material might be produced in a few weeks, while highly intricate components demanding specific material certifications or exotic Monel variants could necessitate several months. We provide a detailed project timeline following an in-depth technical consultation and design review, ensuring transparent communication regarding schedules.

5. Can Nickel-Copper alloys be welded after CNC machining, and what considerations are there?

Indeed, most Nickel-Copper alloys, including Monel 400 and K-500, possess commendable weldability, permitting various joining methodologies post-machining. However, crucial considerations abound. Preheat is often unnecessary for Monel 400 but might be beneficial for heavier sections of K-500. Specific filler metals, carefully matched to the base alloy, are mandatory to maintain corrosion resistance and mechanical properties of the weldment. Strict adherence to welding procedures, including interpass temperature control and post-weld cleaning, is essential to prevent hot cracking and ensure metallurgical integrity.

6. How does your factory ensure the integrity of critical properties, like corrosion resistance, after machining?

Our factory maintains the integrity of critical properties through a rigorous combination of process control and post-machining verification. We meticulously manage cutting parameters to avert thermal damage or unintended material alterations such as surface recast layers or micro-cracking, which could compromise corrosion resistance. During post-processing, appropriate cleaning and passivation techniques are applied if required. Finally, non-destructive testing (NDT) methods like eddy current or dye penetrant inspection are often deployed to confirm surface integrity, alongside material certifications, guaranteeing the inherent corrosion resistance of the alloy remains unblemished.

7. What kind of quality control documentation do you provide for Nickel-Copper alloy parts?

For Nickel-Copper alloy components, particularly those destined for critical applications, our factory provides comprehensive quality control documentation packages. These typically encompass material certifications (MTRs - Material Test Reports) tracing the raw stock, dimensional inspection reports (CMM data, first article inspection reports), surface finish measurements, and often non-destructive testing (NDT) reports. Certificates of Conformance (CoC) are always issued, affirming that all components meet the specified design and quality requirements. Additional documentation can be furnished upon request, aligning with client-specific regulatory or industry standards.

8. Why should we choose a source manufacturer like VMT for Nickel-Copper alloy machining?

Opting for a source manufacturer like VMT for your Nickel-Copper alloy machining projects bestows a distinct array of unparalleled advantages. We possess complete vertical integration, allowing us precise control over every facet of the production sequence—from material acquisition to the ultimate quality verification. This eliminates reliance on external subcontractors, ensuring consistent quality, superior communication, and significantly reduced lead times. Our direct engagement translates into more transparent pricing, direct access to our profound technical expertise for problem-solving, and a more streamlined, reliable partnership. It ultimately equates to a higher caliber component and a more predictable project trajectory.