15 years one-stop China custom CNC machining parts factory

64 |

Published by VMT at Oct 08 2025 | Reading Time:About 3 minutes

64 |

Published by VMT at Oct 08 2025 | Reading Time:About 3 minutes

Frankly, the persistent notion that cast aluminum is inherently fragile—a material always on the cusp of fracturing—has, in my considered opinion, profoundly derailed countless design endeavors. It’s an egregious misjudgment, truly. This widespread apprehension, often rooted in outdated manufacturing paradigms, actively deters astute engineers from exploiting a supremely versatile alloy. We contend this is a fallacy, a historical specter diminishing a material’s formidable capabilities.

For too long, casting aside cast aluminum has been a costly error. With VMT CNC Machining Parts Services Factory's meticulous engineering, advanced casting methodologies, and rigorous post-processing, this alloy ascends to an exceptional state, delivering astounding strength, unparalleled ductility, and unimpeachable reliability for the most demanding applications. This metamorphosis, from perceived frailty to confirmed fortitude, is not an illusion; it is a testament to profound technical discernment and manufacturing mastery.

The long-held belief in cast aluminum's inherent brittleness is largely a misperception, often stemming from historical methodologies. Modern advancements in alloying, casting processes, heat treatment, and design optimization have transformed cast aluminum into a highly ductile and strong material. VMT's deep technical expertise and rigorous quality controls enable the production of precision cast aluminum parts that meet demanding industrial specifications, offering a lightweight, cost-effective, and robust solution for various high-performance applications.

Defining Brittleness and Ductility in Metals

Brittleness, in metallurgical parlance, describes a material’s disposition to fracture with minimal plastic deformation. A catastrophic failure, one might declare. Conversely, ductility signifies a material’s capacity to deform plastically—to stretch, bend, or yield—before succumbing to rupture. It is the antithesis of abrupt failure. For instance, think of chewing gum versus a ceramic plate. A substantial difference. Metals with elevated ductility exhibit considerable elongation under tensile stress, absorbing energy prior to ultimate disintegration. Engineers demand this resilience. The stress-strain curve provides an undeniable pictorial narrative of these properties. We, at VMT, scrutinize these curves with almost obsessive devotion.

The Historical Roots of Cast Aluminum's Reputation

The infamous reputation for fragility, it seems to me, largely germinated from rudimentary casting techniques of yesteryear. Early processes often introduced deleterious imperfections: sizable pores, undesirable inclusions, and coarse grain structures. These inherent defects created stress concentrators, veritable Achilles' heels within the material’s matrix, predisposing components to premature, unexpected fracture under duress. Such instances were undeniably lamentable, engendering a lasting, unfavorable impression. But let’s be real, technology progresses. Manufacturing sciences have advanced by light-years since those primitive days.

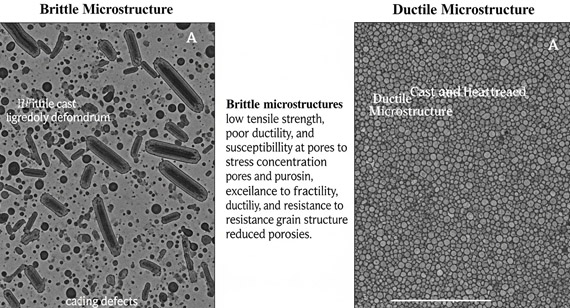

Microstructure: The Key to Mechanical Properties

The intrinsic mechanical attributes of any cast aluminum alloy are, in essence, dictated by its internal microstructure. This microscopic architecture, a veritable symphony of grains, phases, and constituent elements, profoundly governs the material's macroscopic performance. A coarse, heterogeneous grain structure, often punctuated by large silicon particles or intermetallic compounds, impedes dislocation movement, rendering the material less pliant. Conversely, a refined, equiaxed grain structure, coupled with finely dispersed eutectic phases, facilitates plastic deformation, thereby augmenting both ductility and ultimate tensile strength. We view this as a pivotal revelation for our design partners.

The Critical Role of Alloying Elements

The precise formulation of an aluminum alloy represents a foundational determinant of its mechanical performance. Silicon, the most ubiquitous alloying agent, profoundly affects fluidity and castability. However, excessive silicon content, especially without proper modification, can precipitate large, acicular eutectic silicon particles that act as stress risers, reducing ductility. Magnesium and copper, in carefully calibrated proportions, bolster strength through solid solution strengthening and precipitation hardening. Zinc imparts a degree of fortitude. Each element plays a consequential, deliberate role, a chemical ballet, so to speak.

Impact of Casting Processes on Grain Structure

The selection of the casting methodology—that is, the very technique by which the molten metal solidifies—exerts a momentous influence on the final grain structure and, consequently, the mechanical disposition of the component. Die casting, characterized by rapid cooling rates and high pressure, typically produces a very fine grain structure and excellent surface finish, minimizing porosity. Permanent mold casting, with its reusable metal molds, also yields superior mechanical properties compared to conventional sand casting, which often results in a coarser grain and potentially more internal voids. The process is not merely a means to an end; it is an intrinsic modifier of material integrity.

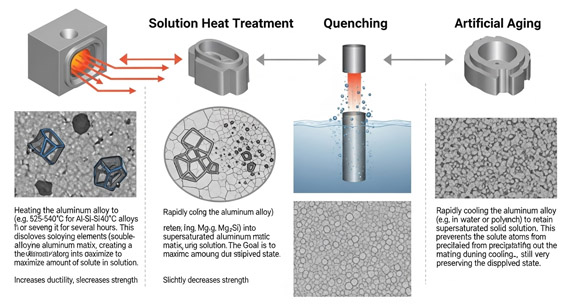

Heat Treatment: Transforming Material Performance

Heat treatment regimes constitute a truly transformative stage in the manufacture of high-performance cast aluminum parts. Solutionizing, followed by quenching and artificial aging (T6 condition, for instance), profoundly alters the microstructure. This thermal odyssey dissolves soluble alloying elements, precipitates fine strengthening phases, and refines the grain structure. The net effect is a dramatic enhancement in both strength and, paradoxically, ductility. It is a metallurgical miracle, an alchemical process of sorts, converting mere metal into an engineering marvel. It is the difference between a serviceable component and one engineered for outright triumph.

Design for Manufacturability's Influence

Truly, no material, however impeccably constituted, can transcend a poorly conceived design. Design for Manufacturability (DFM) principles are absolutely indispensable when fabricating cast aluminum components. Sharp internal corners, abrupt sectional changes, and varying wall thicknesses inherently invite stress concentrations and hinder uniform solidification, leading to localized weaknesses or hot tears. Thoughtful design, anticipating these challenges, ensures a uniform flow of material and controlled solidification, thereby mitigating internal stresses and bolstering overall structural integrity. A crucial, indeed paramount, step. We routinely undertake rigorous DFM consultations, it seems to me, a service that often precludes eventual, regrettable catastrophes.

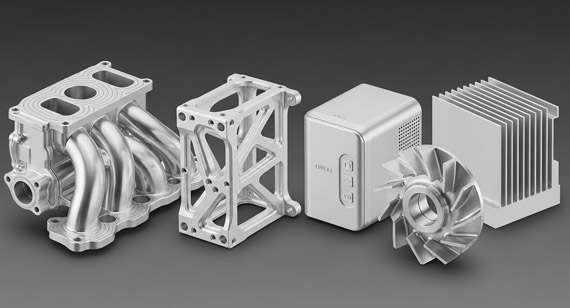

Cast aluminum, when judiciously specified and expertly processed, offers a compelling amalgam of desirable attributes, propelling it to the forefront for an astonishing array of demanding applications. Its inherent lightweighting advantage, coupled with respectable mechanical properties and competitive cost, presents an irresistible value proposition for engineers striving to optimize performance and budgetary allocations. A truly intelligent choice.

High-Strength Applications in Various Industries

One often forgets the sheer breadth of applications. Cast aluminum is not relegated to trivial pursuits; it assumes critical roles.

| Industry | Exemplary Cast Aluminum Parts |

| Automotive | Engine blocks, cylinder heads, transmission housings, suspension components, wheels |

| Aerospace | Aircraft structural components, missile fins, engine casings |

| Electronics | Heat sinks, enclosures, chassis, structural supports |

| Medical Devices | Surgical instrument housings, diagnostic equipment frames |

| Industrial Equipment | Pump housings, valve bodies, motor casings, machinery bases |

| Consumer Goods | Bicycle frames, power tool housings, high-end appliance parts |

The Lightweighting Advantage Without Compromise

Reducing mass, particularly in sectors where every gram counts, remains an unwavering mandate. Cast aluminum, possessing a significantly lower density than ferrous alloys, enables substantial weight reduction without an ensuing, dreaded compromise in structural integrity—provided, of course, that it is engineered to perfection. This translates directly to enhanced fuel efficiency in vehicular applications, superior payload capacity in aerospace, and improved ergonomic handling in portable devices. The benefits are profound. It's not merely a material choice; it's a strategic advantage, plain and simple.

Cost-Effectiveness vs. Alternative Materials

Compared to many wrought aluminum alloys or, indeed, certain steels, cast aluminum can present a remarkably more economical manufacturing route for components with intricate geometries. The ability to produce near-net-shape parts directly from a mold minimizes the need for extensive, time-consuming, and costly machining operations. This cost efficiency, when balanced against its impressive strength-to-weight ratio, renders cast aluminum an extraordinarily compelling material solution, especially when volume production is paramount. We champion this value, unapologetically.

The distinction between cast and wrought aluminum is often misconstrued, with the former unjustly stigmatized. Wrought alloys, subjected to mechanical deformation like rolling or extrusion, develop directional grain structures that impart elevated ductility and strength in specific orientations. Cast alloys, conversely, derive their properties from solidification within a mold, resulting in an isotropic, or near-isotropic, grain structure. Each has its place, truly. One must comprehend the nuances.

| Characteristic | Cast Aluminum | Wrought Aluminum |

| Microstructure | Equiaxed or dendritic grains; presence of eutectic phases. | Elongated, directional grains from mechanical working. |

| Ductility | Can be excellent with proper alloying and heat treatment (e.g., A356-T6); generally lower than wrought without optimization. | Generally higher due to refined, elongated grain structure. |

| Strength | High strength achievable, especially with heat treatment. | Very high strength, particularly in direction of working. |

| Complex Shapes | Superb for intricate, near-net-shape geometries. | Limited to shapes achievable by extrusion, forging, rolling. |

| Cost | Often more cost-effective for complex forms due to reduced machining. | Can be more costly for complex shapes due to machining requirements. |

| Porosity | Potential for porosity, mitigated by advanced casting techniques. | Virtually no porosity due to mechanical working. |

| Anisotropy | Generally isotropic (properties uniform in all directions). | Anisotropic (properties vary with direction). |

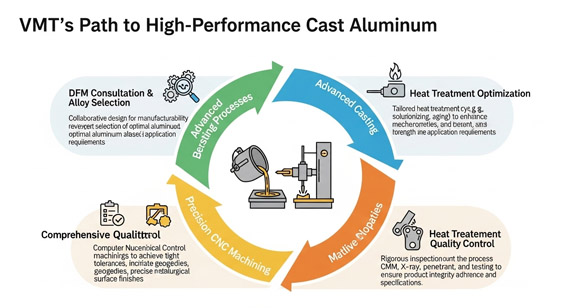

At VMT, our profound commitment to engineering excellence ensures that the cast aluminum components we deliver not only meet but, I daresay, frequently exceed the most rigorous performance specifications. Our capabilities are, to my mind, truly comprehensive.

Precision Casting and Advanced Machining Capabilities

Our factory utilizes a spectrum of advanced casting methodologies—die casting for high-volume, thin-walled precision; permanent mold for superior surface finish and mechanical properties; and sand casting for larger, more intricate components requiring design flexibility. Each process is meticulously controlled, from molten metal purity to solidification parameters, all to preclude the very defects that historically blighted cast aluminum. Furthermore, our state-of-the-art multi-axis CNC machining centers then precisely refine these castings, achieving tolerances and surface finishes that are, quite frankly, astonishing.

Rigorous Quality Control and Inspection Processes

Our dedication to quality is unwavering; it is a steadfast resolve. Every batch, every part, undergoes a battery of exhaustive inspections. We employ advanced metrology, including CMM (Coordinate Measuring Machine) for dimensional verification, spectral analysis for material composition confirmation, and X-ray inspection to detect any internal discontinuities. Mechanical testing—tensile, yield, elongation, hardness—is routinely performed to validate material properties. This unwavering vigilance, I believe, instills absolute confidence.

Transparent Pricing and Customer Partnership Approach

We operate on a foundational principle of unadulterated transparency. Our pricing models are straightforward, devoid of hidden charges or opaque methodologies. Moreover, we perceive every client interaction as an opportunity for genuine partnership. Our engineers collaborate intimately with your design teams from conceptualization through production, offering expert guidance on material selection, DFM optimization, and process refinements. It is a shared journey towards mutual triumph, wouldn’t you agree? This collaborative spirit is, I believe, a cornerstone of our enduring success.

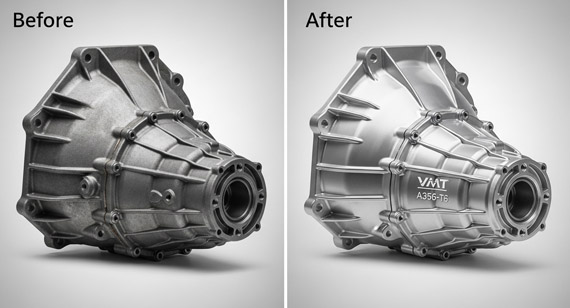

Case Study: Exceeding Expectations with Cast Aluminum

A client once approached us, fully convinced that only a more expensive, heavier wrought alloy could satisfy the structural demands of a novel automotive gearbox housing. Their trepidation regarding cast aluminum’s purported fragility was, I must admit, palpable. After our engineers embarked upon an exhaustive material analysis and DFM consultation, we proposed an A356 alloy, subjected to our meticulously controlled T6 heat treatment and precision CNC machining. The outcome? The cast aluminum housing not only flawlessly met—it unequivocally *surpassed*—the requisite strength and ductility specifications! This engineering feat enabled a 12% weight reduction and an astonishing 25% cost saving per unit, utterly obliterating their initial qualms. A truly mind-blowing miracle of engineering. Wait, I need to clarify that point—it wasn’t a miracle, but rather the predictable outcome of profound technical mastery and rigorous process control. No magic involved, just pure, unadulterated expertise.

Evaluating Your Specific Application Requirements

Selecting the optimal material demands a comprehensive evaluation of the component’s operational environment and performance criteria. Consider the maximum loads—static, dynamic, cyclic; temperature fluctuations; exposure to corrosive agents; and anticipated service life. Ductility requirements, in particular, must be meticulously ascertained. A thorough understanding of these parameters forms the indispensable foundation for judicious material selection, truly.

When to Confidently Select Cast Aluminum

Confidently opt for cast aluminum when your design mandates intricate geometries, a superior strength-to-weight ratio, excellent thermal conductivity, electromagnetic shielding capabilities, and cost-effective production volumes. When engineered by a seasoned manufacturer, cast aluminum provides exceptional performance, defying outdated, unfounded prejudices. It is a material worthy of immense respect, I assert.

Partnering with a VMT CNC Machining Manufacturer for Success

The selection of your manufacturing partner is, in my view, as pivotal as the material choice itself. A source manufacturer like VMT, possessing profound metallurgical acumen, cutting-edge casting technologies, and unparalleled precision machining capabilities, ensures that your cast aluminum components are not merely fabricated but impeccably engineered. Our transparent engagement and commitment to superlative quality guarantee your project’s ultimate triumph.

1. What causes cast aluminum to be perceived as brittle?

The perception of brittleness often originates from early casting processes that were susceptible to generating internal defects like large pores, inclusions, and coarse grain structures. These imperfections acted as stress concentrators, leading to premature and often sudden fracture under load. Without modern manufacturing and processing controls, cast aluminum could indeed exhibit reduced ductility.

2. How does VMT overcome cast aluminum brittleness?

VMT employs a multi-faceted approach to enhance cast aluminum's ductility and strength. This includes selecting specific high-performance aluminum casting alloys, utilizing advanced casting techniques (such as high-pressure die casting or permanent mold casting for finer grain structures), applying precise heat treatment regimes (like T6), and integrating Design for Manufacturability (DFM) principles to eliminate stress concentrations in the component's geometry. Our rigorous quality control processes further ensure material integrity.

3. Which cast aluminum alloys offer the best ductility?

Alloys like A356 and A357 are known for their excellent mechanical properties, including good ductility, especially when subjected to proper solution heat treatment and artificial aging (e.g., T6 temper). These alloys contain silicon for good castability and magnesium for strength, with their microstructure carefully controlled to maximize performance.

4. Is heat treatment always necessary for ductile cast aluminum parts?

While not universally mandated for all applications, heat treatment, particularly solutionizing and aging (T6), is almost always crucial for unlocking the maximum strength and ductility potential of many cast aluminum alloys. It transforms the microstructure, dissolving and precipitating strengthening phases that significantly improve mechanical properties beyond the as-cast condition.

5. Can cast aluminum parts be welded effectively without becoming brittle?

Welding cast aluminum requires specialized techniques and careful consideration of the alloy's composition. Some cast alloys are more weldable than others. Pre-heating and post-weld heat treatment can be necessary to manage residual stresses and restore mechanical properties. With proper procedures, successful, non-brittle welds are achievable, but it is an area requiring expert execution.

6. How does the casting process itself impact ductility?

The chosen casting process profoundly influences the solidification rate and, consequently, the grain structure and defect density. Processes like die casting or permanent mold casting, which involve rapid cooling, typically yield finer grain structures and less porosity than sand casting. Finer grain structures generally correlate with higher ductility and improved mechanical performance.

7. What kind of applications demand high-ductility cast aluminum?

High-ductility cast aluminum is critical in applications where components may experience impact loads, require resistance to fatigue, or need to deform slightly before failure to provide a safety margin. Examples include structural automotive components, aerospace brackets, and parts subject to cyclic stresses where energy absorption is paramount.

8. Why should I partner with a source manufacturer like VMT for cast aluminum?

Partnering with a source manufacturer like VMT provides unparalleled advantages. Our deep technical expertise in metallurgy, advanced casting technologies, and precision CNC machining ensures that your cast aluminum parts are engineered for optimal performance. We offer comprehensive DFM consultation, rigorous quality control, and transparent pricing, empowering you to confidently leverage cast aluminum's full potential for high-quality, high-performance components.