15 years one-stop China custom CNC machining parts factory

63 |

Published by VMT at Oct 02 2025 | Reading Time:About 3 minutes

63 |

Published by VMT at Oct 02 2025 | Reading Time:About 3 minutes

The industrial realm, forever pushing boundaries, demands materials that not only perform but genuinely defy conventional limits. In this arena, 7075 aluminum and 4140 steel emerge as titans, each promising unparalleled strengths; but, discerning the truly optimal choice for your critical precision component—that's where genuine expertise becomes not merely useful, but downright indispensable. Errors in material selection, as we have witnessed, lead to nothing short of agonizing project overruns and, honestly, performance compromises that can plague an entire product line.

For those grappling with high-stakes engineering, the fundamental characteristics of these two formidable alloys are, quite frankly, paramount. Understanding their basic distinctions forms the bedrock of any judicious material decision.

Choosing between 7075 aluminum and 4140 steel for precision CNC machining hinges on balancing specific project demands like weight, strength, cost, and environmental resistance. 7075 offers superior strength-to-weight for aerospace and defense, while 4140 provides exceptional hardness and fatigue resistance crucial for heavy-duty industrial applications and tooling. VMT specializes in processing both, ensuring optimal performance.

7075 Aluminum: The Light-Heavyweight Contender

7075 aluminum alloy, a member of the 7xxx series, is unequivocally a high-strength marvel. It's often alloyed with zinc, magnesium, and copper, a formulation that grants it properties approaching those of some steels—a truly remarkable feat for such a lightweight metal! Its designation as an "aluminum" (billet/blank) hints at its common starting form for precision machining. Engineers, especially those fixated on strength-to-weight ratios, frequently gravitate toward this particular alloy, particularly in temper conditions like T6 or T7.

4140 Steel: The Indomitable Workhorse

And then we have 4140 steel, a medium-carbon chromium-molybdenum alloy steel. Its reputation as a robust, incredibly versatile engineering material is, in our experience, entirely well-deserved. Renowned for its excellent toughness, good ductility, and superior wear resistance after appropriate heat treatment, it finds its niche where sheer durability and structural integrity are non-negotiable. Its capacity to be hardened and tempered across a wide range of properties truly sets it apart, allowing for incredible customization to specific application demands.

The Core Distinction: Balancing Mass with Might

The fundamental divergence between these two, it seems to me, boils down to a critical engineering dilemma: how does one balance the imperative for light-weighting with the absolute necessity of supreme strength? 7075 aluminum consistently triumphs in scenarios where minimal mass is paramount, yet significant mechanical stresses are expected. 4140 steel, conversely, is the unchallenged champion when mass is a lesser concern but the absolute highest levels of hardness, fatigue resistance, and impact strength are the non-negotiable requirements—a truly stark contrast in application philosophy.

Delving into the raw numbers and the very fabric of these materials, we uncover the nuanced truths that inform truly expert material selection. It is not just about a single property; it never is, honestly.

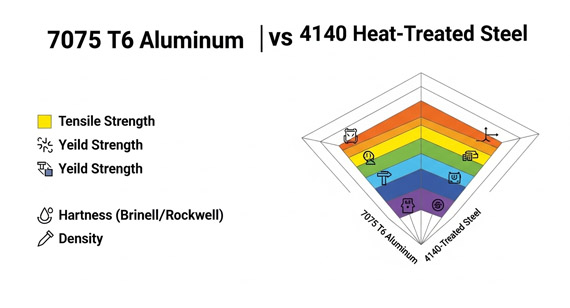

Mechanical Prowess: Strength, Hardness, and Toughness

In matters of pure mechanical performance, a direct comparison reveals fascinating trade-offs. While 7075 aluminum boasts an impressive strength-to-weight ratio, 4140 steel, when properly heat-treated, can achieve significantly higher absolute tensile and yield strengths. Hardness is another key differentiator; 4140 steel, especially after quenching and tempering, is capable of achieving far greater surface hardness, which directly translates into enhanced wear resistance—a critical attribute for many industrial applications. Toughness, however, requires careful consideration for both; 4140 steel generally exhibits excellent toughness, but 7075 aluminum, particularly in its T7 temper, can offer superior fracture toughness compared to its T6 counterpart, especially in the presence of stress corrosion cracking.

Below, a detailed glimpse into their typical mechanical parameters is presented.

H4: Table 1: Typical Mechanical Properties

| Property | 7075-T6 Aluminum (Typical) | 4140 Steel (Quenched & Tempered) (Typical) |

| Tensile Strength (MPa) | 572 | 1000 - 1200 (approx) |

| Yield Strength (MPa) | 503 | 700 - 1000 (approx) |

| Elongation (%) | 11 | 12 - 20 |

| Hardness (Brinell) | 150 | 217 - 302 (HRC 18-32) |

Physical Attributes: Density, Thermal Conductivity, and Expansion

Their physical properties paint a completely different picture, one that undeniably impacts design choices. Density, of course, is the most obvious; 7075 aluminum is roughly one-third the density of 4140 steel, a staggering difference that forms the foundation of its light-weighting appeal. Thermal conductivity also varies significantly, with aluminum being an excellent conductor of heat, a trait that can be advantageous in heat dissipation applications but a challenge in others. Conversely, 4140 steel, while a conductor, is less efficient, which influences its thermal response during machining and its performance in high-temperature environments.

H4: Table 2: Typical Physical Properties

| Property | 7075-T6 Aluminum (Typical) | 4140 Steel (Typical) |

| Density (g/cm³) | 2.81 | 7.85 |

| Melting Point (°C) | 475 - 635 | 1416 |

| Thermal Conductivity (W/m·K) | 130 | 42.6 |

| Coefficient of Thermal Expansion (µm/m·°C) | 23.6 | 12.2 |

Endurance and Resistance: Corrosion and Fatigue

Corrosion resistance presents another complex layer. 7075 aluminum, despite its "anodizable" nature, can be susceptible to stress corrosion cracking, especially in certain tempers and corrosive environments. Surface treatments like anodizing become absolutely crucial here. 4140 steel, on the other hand, is inherently prone to rust and corrosion if left unprotected, necessitating coatings, plating, or other surface passivation techniques. When it comes to fatigue resistance, both materials are robust, yet the higher absolute strength and toughness of properly heat-treated 4140 steel often give it an edge in applications subjected to repeated cyclic loading.

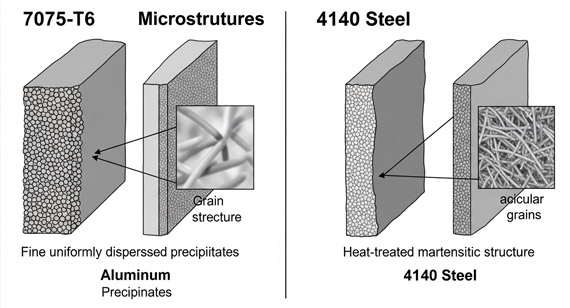

Heat Treatment and Microstructural Responses

The true potential of both alloys is unleashed, without question, through meticulously controlled heat treatment processes. 7075 aluminum's properties are dictated by solution heat treatment and artificial aging, creating fine precipitates within its matrix that impede dislocation movement, hence its strength. 4140 steel undergoes austenitizing, quenching, and tempering to transform its microstructure into tempered martensite, conferring its characteristic balance of hardness and toughness. The specific parameters—temperature, time, quenching medium—are not merely suggestions; they are critical determinants of the final mechanical properties, a nuance our factory deeply understands.

The journey from raw material to a precision-engineered component is fraught with specific challenges for each material, challenges that demand not just skill, but an almost intuitive understanding of their metallurgical quirks. It's truly a dance, you see, between tool and material.

Machining Dynamics: Feeds, Speeds, and Tooling

Machining 7075 aluminum is generally considered straightforward, often permitting higher cutting speeds and feeds, which can lead to rapid material removal rates. Its relatively low hardness means less tool wear, a definite advantage for complex, high-volume parts. However, managing chip evacuation and avoiding burr formation—especially with sharp edges or deep pockets—requires diligent strategy. But let's be real, 4140 steel presents an entirely different proposition. Its higher hardness and tensile strength necessitate lower cutting speeds, robust tooling (often carbide), and careful consideration of cutting fluids to manage heat and chip control. Tool wear is a significant factor here, requiring precise tool path optimization and regular tool inspection to maintain dimensional accuracy and surface finish.

H4: Table 3: Typical Machining Characteristics

| Characteristic | 7075 Aluminum | 4140 Steel |

| Machinability | Good to Excellent | Fair to Good |

| Chip Formation | Continuous, often stringy | Strong, discontinuous |

| Tool Wear | Low | Moderate to High |

| Recommended Tooling | HSS, Carbide, Diamond-coated | Carbide, CBN, Coated Carbide |

| Surface Finish Potential | Excellent | Good to Excellent |

Heat Treatment Protocols: Quenching and Tempering

As mentioned, heat treatment is where these materials truly differentiate themselves, and where a source manufacturer like VMT truly shines. For 7075, precise solutionizing and artificial aging are essential to achieve target strengths without inducing distortion. For 4140, the quench-and-temper sequence is absolutely critical. We're talking about specific temperatures, holding times, and quenching media (oil, water, polymer) that determine the final hardness, toughness, and residual stress profile. Incorrect application can lead to cracking, excessive distortion, or, a downright catastrophic failure to achieve desired mechanical properties.

Joining and Surface Treatments

Welding 7075 aluminum is notoriously difficult due to its high crack susceptibility and potential for strength reduction in the heat-affected zone, often requiring specialized techniques or avoiding it entirely for critical structural elements. 4140 steel, while generally more weldable, still demands pre-heating and post-weld heat treatment to prevent hydrogen-induced cracking and to refine microstructures. Surface treatments, however, offer vast possibilities for both. Anodizing (Type II, Type III hardcoat) for 7075 not only enhances corrosion resistance but also dramatically increases surface hardness and wear resistance. For 4140 steel, options range from various platings (nickel, chrome) to nitriding, carburizing, and induction hardening, all designed to create wear-resistant surfaces while retaining a tough core.

Distortion Management and Precision Challenges

Controlling deformation during machining and heat treatment is a constant, almost maddening, battle, especially for complex geometries or thin-walled parts. For 7075 aluminum, residual stresses from manufacturing or prior heat treatments can lead to warping when material is removed unevenly. For 4140 steel, the very nature of its heat treatment—the rapid cooling during quenching—induces significant thermal stresses that, without meticulous control and subsequent tempering, will inevitably lead to distortion or even cracking. Achieving micron-level precision for these demanding materials means considering every step, from raw material selection to final stress relief.

The divergence in properties naturally steers these materials toward distinct, yet equally demanding, applications. Identifying the correct domain for each is a cornerstone of effective engineering.

7075 Aluminum: Aerospace and High-Performance Structures

This alloy is the undisputed champion in sectors where every gram counts but structural integrity cannot be compromised. Think aircraft structural components—wing spars, fuselage frames, landing gear parts—where its superior strength-to-weight ratio is a defining factor. Beyond aviation, it’s a go-to for high-performance sports equipment, robotics, and medical devices where both strength and reduced inertia are critical. The demand for lightweight, robust solutions in these industries is, frankly, insatiable, and 7075 continues to deliver.

4140 Steel: Heavy Machinery, Molds, and Dynamic Components

Conversely, 4140 steel dominates applications demanding resilience against heavy loads, impacts, and abrasive wear. We see it extensively in gears, shafts, connecting rods, and heavy-duty tooling like molds and dies—components where the penalty for failure is often catastrophic downtime or safety risks. Its ability to achieve high core toughness with hardened surfaces makes it ideal for parts subjected to high stress concentrations and fatigue, truly the backbone of robust industrial equipment.

Hybrid Applications and Niche Engineering

Sometimes, a project's demands are so specific, so utterly unique, that neither material alone suffices. We've seen scenarios where 7075 aluminum provides the lightweight main structure, while selectively integrated 4140 steel inserts provide localized wear resistance or bearing surfaces—a truly ingenious hybrid approach that capitalizes on both materials' strengths. Our engineers, you see, excel at identifying such novel solutions for clients with the most intricate engineering requirements.

The financial implications of material choice, combined with performance requirements, form an equation that requires rigorous scrutiny. It’s never just about the initial material expense; that would be an unbelievably foolish assumption.

Raw Material Versus Total Machining Costs

Initially, 7075 aluminum typically presents a higher raw material cost per pound than 4140 steel. However, the machining process complicates this simple comparison. Aluminum's superior machinability can translate to faster cycle times and longer tool life, effectively reducing machining labor and tooling costs. Steel, with its inherent hardness, demands more power, slower cuts, and more frequent tool changes, potentially escalating machining expenses. So, a holistic view of the entire production process—from raw billet to finished part—is absolutely essential.

Lifecycle Costs and Maintainability

Beyond initial production, consider the full lifecycle. A lighter 7075 aluminum part might reduce operational energy consumption in moving assemblies, leading to long-term savings. On the other hand, the superior wear resistance of heat-treated 4140 steel might mean fewer replacements and lower maintenance costs over the product's lifespan in harsh environments. We often help clients dissect these long-term financial implications.

Design Imperatives, Performance Weighting, and Risk Mitigation

The ultimate decision invariably loops back to the product's design requirements. Is lightweighting a primary directive, or is absolute strength and extreme durability paramount? What are the critical performance metrics, and how are they weighted? Mitigating risk, for instance, in aerospace applications where failure is unthinkable, often steers towards materials with exceptionally well-understood fatigue properties, requiring extensive testing and rigorous quality control. This is where VMT's IATF1649 certification, for example, becomes a profound differentiator.

Transparent Pricing and Expert Factory Support

Honestly, navigating these complex material decisions without expert guidance is a recipe for potential disappointment. As a source manufacturer, VMT offers not only transparent, factory-direct pricing—eliminating the opaque markups of trading companies—but also, and perhaps more crucially, unparalleled technical support. We provide detailed DFM (Design for Manufacturability) reports, helping clients optimize their designs for the chosen material and process, preventing costly mistakes before they even happen.

Choosing a manufacturing partner means more than just finding someone to cut metal; it means securing a genuine technical ally. Our profound capabilities, rooted in Shenzhen, empower your projects.

Professional Technical Support: Bespoke Material Solutions

Our deep technical knowledge is not just theoretical; it’s forged in decades of practical application across incredibly demanding industries. We don't merely process parts; we partner with you, offering customized material application advice. For instance, if your part requires an unconventional combination of strength and fatigue life, we might recommend specific heat treatment cycles for 4140 or a specific temper of 7075 with a subsequent surface treatment. Our engineers are here to solve your truly intractable material puzzles.

Unwavering Processing Quality: Ensuring Precision

With a colossal fleet of over 80 advanced CNC machines, including the most sophisticated 5-axis centers, our capacity for high-precision machining is, frankly, unrivaled. Whether it's achieving micron tolerances on intricate 7075 aerospace components or maintaining flawless surface finishes on hardened 4140 steel parts, our ISO9001 and IATF1649 certified full-chain quality control ensures every single part meets, and often exceeds, the most stringent specifications. We are obsessed with precision; it's our very lifeblood.

Transparent Pricing: Predictable and Accountable Costs

One of the most frustrating aspects of sourcing in the precision manufacturing world can be the opacity of pricing, can’t it? As a direct source manufacturer, VMT offers transparent, factory-direct pricing. This means no hidden costs, no intermediary markups—just honest, straightforward quotes reflecting the true value of our expertise and service. We believe in building long-term partnerships through absolute clarity and mutual trust, a philosophy that truly makes a difference.

Deep Technical Accumulation: Overcoming Complex Material Challenges

Our collective experience, spanning years and thousands of complex projects, represents a vast reservoir of technical acumen. This isn't just about knowing the textbook definitions; it’s about understanding the subtle ways materials behave under extreme conditions, how they respond to specific tooling, and how to troubleshoot unforeseen challenges. From specialized aluminum alloys to demanding titanium components, we possess the institutional wisdom to navigate the most difficult material selection and processing dilemmas, offering truly robust, dependable solutions.

Choosing between 7075 aluminum and 4140 steel for precision CNC machining involves a multi-faceted assessment of mechanical, physical, and processing characteristics, intertwined with cost implications and specific application demands. 7075 excels in lightweight, high-strength applications like aerospace, while 4140 steel provides superior absolute strength, hardness, and wear resistance for heavy-duty industrial components. VMT, a Shenzhen-based source manufacturer, provides deep technical expertise, advanced machining capabilities, and transparent pricing to guide clients through this complex decision, ensuring optimal material selection and delivering high-quality, precise components.

Q1: What are the primary advantages of 7075 aluminum over 4140 steel for my project?

A1: The paramount advantage of 7075 aluminum lies in its exceptional strength-to-weight ratio. If your project demands significant strength while simultaneously requiring minimal mass—think aerospace components, high-performance sports equipment, or robotic parts where inertia is a critical concern—then 7075 is, without question, the superior choice. Its machinability is also generally more forgiving, allowing for potentially faster cycle times.

Q2: When should I definitively choose 4140 steel instead of 7075 aluminum?

A2: You should choose 4140 steel when absolute strength, high hardness, superior wear resistance, and resistance to fatigue under heavy, dynamic loads are the primary objectives. It is the preferred material for gears, shafts, heavy-duty tooling, and structural components in industrial machinery where weight is less of a constraint but sheer durability and impact resistance are non-negotiable requirements.

Q3: Can VMT help me with the design for manufacturability (DFM) for parts made from these materials?

A3: Absolutely! Our technical experts provide comprehensive DFM reports. This service helps optimize your part design for the chosen material, ensuring it can be manufactured efficiently, cost-effectively, and to the highest precision standards. It also flags potential issues before production, saving you from costly revisions, a truly valuable service, in our opinion.

Q4: Does VMT offer rapid prototyping services for both 7075 aluminum and 4140 steel?

A4: Yes, we do! VMT understands the urgent demands of product development. We offer rapid prototyping services, with 24-hour service available for urgent projects, catering to both 7075 aluminum and 4140 steel, allowing you to quickly iterate and validate your designs. Our flexible approach also means there's no minimum order quantity (MOQ) for these prototypes.

Q5: How does VMT ensure quality control for such demanding materials?

A5: Our quality control system is, quite frankly, rigorous and full-chain. We hold ISO9001 and IATF1649 certifications, testifying to our unwavering commitment to excellence. From raw material inspection through every stage of machining, heat treatment, and post-processing, our advanced metrology equipment and highly skilled technicians ensure every part meets the most stringent specifications.

Q6: Are there specific surface treatments VMT recommends for these materials to enhance performance?

A6: Indeed! For 7075 aluminum, anodizing (Type II or Type III hardcoat) is highly recommended for improved corrosion resistance and surface hardness. For 4140 steel, options are extensive and include various platings (e.g., nickel, chrome), nitriding, carburizing, or induction hardening, all designed to significantly boost wear resistance and surface durability. Our experts can advise on the optimal treatment for your specific application.

Q7: How does VMT's "source manufacturer" status benefit my procurement process?

A7: Our status as a direct source manufacturer means you're dealing directly with the factory in Shenzhen, China, not an intermediary. This guarantees transparent, factory-direct pricing, eliminates hidden markups, and establishes a direct line of communication with our engineering and production teams. This streamlined process leads to greater cost predictability, enhanced reliability, and superior technical support. It really does cut out so much of the usual hassle.

Q8: Can VMT handle complex 5-axis machining for parts requiring intricate geometries in both 7075 and 4140?

A8: Absolutely. Our state-of-the-art facility boasts a substantial number of high-precision 5-axis CNC machining centers. This advanced capability allows us to process extremely complex structures and intricate geometries in both 7075 aluminum and 4140 steel with exceptional accuracy and surface finish, meeting the most stringent demands of industries like aerospace, medical, and robotics.