15 years one-stop China custom CNC machining parts factory

105 |

Published by VMT at Oct 01 2025 | Reading Time:About 3 minutes

105 |

Published by VMT at Oct 01 2025 | Reading Time:About 3 minutes

The selection of the appropriate stainless steel for precision components is a critical engineering decision. Choosing the wrong material can lead to product performance failures, increased manufacturing costs, and compromised reliability in demanding applications. This article delves into the fundamental technical differences and optimal application scenarios for two commonly specified stainless steel grades, 304 and 410, providing the insights necessary for informed material selection.

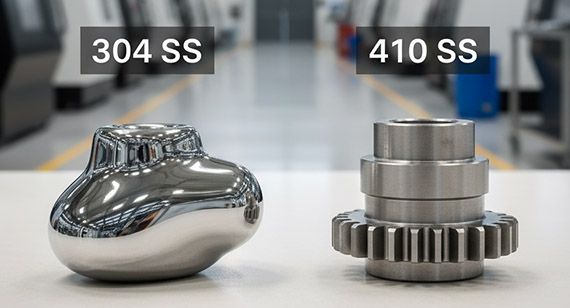

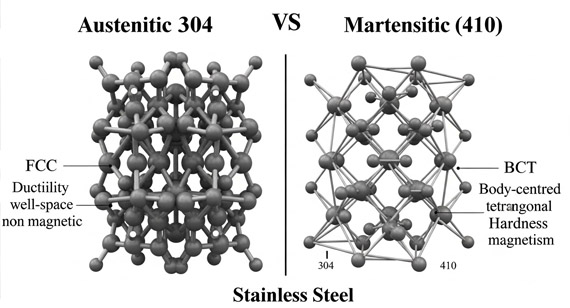

When differentiating between 304 and 410 stainless steel, understanding their core metallurgical classifications is key. 304 is an austenitic stainless steel, known for its excellent corrosion resistance and ductility, while 410 is a martensitic stainless steel, distinguished by its high strength, hardness, and heat treatability. The optimal selection hinges entirely on the specific performance requirements of your application, balancing factors like environmental exposure, mechanical stress, and manufacturing processes.

304 stainless steel is the most widely used austenitic grade, renowned for its versatility across numerous industries. Its balanced chromium and nickel content contribute to its characteristic properties, making it a benchmark for corrosion-resistant applications. Understanding its fundamental composition and mechanical behavior is essential for predicting its performance in diverse environments.

304 Stainless Steel Chemical Composition: Austenitic Base

The austenitic microstructure of 304 stainless steel is primarily due to its significant nickel content, which stabilizes the austenite phase even at room temperature. This composition provides excellent resistance to a wide range of corrosive media.

Table: 304 Stainless Steel Typical Chemical Composition (Weight %)

| Element | Minimum % | Maximum % |

| Carbon | - | 0.07 |

| Silicon | - | 1.00 |

| Manganese | - | 2.00 |

| Phosphorus | - | 0.045 |

| Sulfur | - | 0.030 |

| Chromium | 17.50 | 19.50 |

| Nickel | 8.00 | 10.50 |

| Nitrogen | - | 0.11 |

304 Stainless Steel Mechanical Properties: Strength, Hardness, Ductility

304 stainless steel exhibits a valuable combination of good strength, moderate hardness, and excellent ductility. This makes it highly formable and amenable to various manufacturing processes without excessive work hardening. Its non-magnetic nature in the annealed condition is also a notable characteristic.

Table: 304 Stainless Steel Typical Mechanical Properties (Annealed)

| Property | Metric Value | Imperial Value |

| Tensile Strength | 515 MPa | 75 ksi |

| Yield Strength (0.2% Offset) | 205 MPa | 30 ksi |

| Elongation (in 50mm) | 40% | 40% |

| Hardness (Brinell) | 201 HB max | 201 HB max |

| Hardness (Rockwell B) | 92 HRB max | 92 HRB max |

| Modulus of Elasticity | 193 GPa | 28.0 x 10^6 psi |

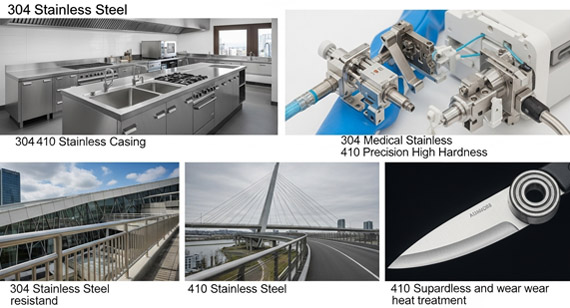

304 Stainless Steel's Typical Applications & Advantages

The excellent corrosion resistance, ease of fabrication, and aesthetic appeal of 304 stainless steel make it a preferred choice for applications where hygiene and visual quality are important, alongside resistance to atmospheric and mild chemical environments. It is a workhorse in many industries.

Table: Common Applications of 304 Stainless Steel

| Industry/Sector | Specific Applications | Key Advantages |

| Food & Beverage | Kitchen equipment, storage tanks, processing units | Excellent corrosion resistance, hygienic, easy to clean |

| Medical | Surgical instruments (non-cutting), hospital sinks | Sterilizable, good resistance to biological fluids |

| Architectural | Building facades, railings, sinks, trim | Aesthetic appeal, atmospheric corrosion resistance |

| Automotive | Exhaust manifolds, trim components | Corrosion resistance to road salts and exhaust gases |

| Chemical | Chemical containers, piping, valves | Resistance to mild acids and alkaline solutions |

| General | Springs, fasteners, woven mesh, pressure vessels | Good formability, weldability |

In contrast to 304, 410 stainless steel belongs to the martensitic family. This classification is crucial, as it implies a fundamentally different set of properties, primarily centered around its ability to achieve high strength and hardness through heat treatment, making it suitable for applications requiring wear resistance and cutting edges.

410 Stainless Steel Chemical Composition: Martensitic Characteristics

The lower chromium content and minimal nickel, combined with a higher carbon content, are characteristic of 410 stainless steel. This composition allows for the formation of martensite upon quenching, which is critical for its hardening capabilities.

Table: 410 Stainless Steel Typical Chemical Composition (Weight %)

| Element | Minimum % | Maximum % |

| Carbon | - | 0.15 |

| Silicon | - | 1.00 |

| Manganese | - | 1.00 |

| Phosphorus | - | 0.040 |

| Sulfur | - | 0.030 |

| Chromium | 11.50 | 13.50 |

| Nickel | - | 0.75 |

410 Stainless Steel Mechanical Properties: Performance Post-Hardening

The defining characteristic of 410 stainless steel is its capacity for hardening and tempering. While in the annealed state it possesses moderate properties, its mechanical performance is significantly enhanced after appropriate heat treatment. It also exhibits ferromagnetic properties.

Table: 410 Stainless Steel Typical Mechanical Properties (Annealed vs. Hardened & Tempered)

| Property | Annealed Metric | Hardened & Tempered Metric | Annealed Imperial | Hardened & Tempered Imperial |

| Tensile Strength | 480 MPa | 690-860 MPa | 70 ksi | 100-125 ksi |

| Yield Strength (0.2% Offset) | 275 MPa | 480-690 MPa | 40 ksi | 70-100 ksi |

| Elongation (in 50mm) | 20% | 14-20% | 20% | 14-20% |

| Hardness (Brinell) | 201 HB max | 200-240 HB | 201 HB max | 200-240 HB |

| Hardness (Rockwell C) | - | 35-42 HRC | - | 35-42 HRC |

410 Stainless Steel Processing & Heat Treatment

410 stainless steel's machinability is generally good, especially in the annealed or lightly tempered condition. However, its high carbon content means that welding requires preheating and post-weld heat treatment to prevent cracking and maintain mechanical integrity. The ability to be hardened through heat treatment is its primary advantage, making it critical to control quenching and tempering processes precisely.

Table: 410 Stainless Steel Processing Considerations

| Process | Key Considerations |

| Machinability | Good in annealed state; becomes harder with heat treatment. |

| Weldability | Requires preheating (200-315°C) and post-weld heat treatment (650-760°C) to relieve stress and improve ductility. |

| Heat Treatment | Annealing (815-885°C), Hardening (925-1010°C) followed by oil or air quench, Tempering (200-760°C) to achieve desired hardness/toughness balance. |

| Forgability | Good, typical forging temperatures 900-1200°C. |

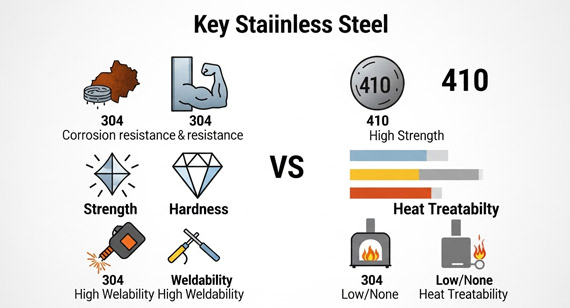

The selection between 304 and 410 stainless steel hinges on a detailed comparison of their performance characteristics. While both are stainless steels, their differing microstructures lead to distinct strengths and weaknesses concerning corrosion resistance, mechanical properties, and manufacturing suitability. Making the correct stainless steel material selection is paramount for long-term product success and cost efficiency.

Corrosion Resistance: 304 vs. 410

When evaluating corrosion resistance, 304 stainless steel generally outperforms 410. The higher chromium and nickel content in 304 forms a more robust passive oxide layer, providing superior resistance to atmospheric corrosion, mild acids, and chlorides. 410, with its lower chromium, offers good resistance in mild environments but is more susceptible to rust and pitting, especially in saline or acidic conditions.

Table: Relative Corrosion Resistance Comparison

| Property | 304 Stainless Steel | 410 Stainless Steel |

| Atmospheric Corrosion | Excellent | Good |

| Pitting Corrosion | Good (moderate) | Poor to Moderate |

| Crevice Corrosion | Good (moderate) | Poor to Moderate |

| Acid Resistance | Good (mild acids) | Poor |

| Chloride Resistance | Moderate | Poor |

Strength & Hardness: Selection for Diverse Conditions

This is where 410 stainless steel truly excels, particularly after heat treatment. Its ability to be hardened to high levels of Rockwell C (HRC) makes it ideal for applications demanding wear resistance, cutting edges, and high tensile strength. 304, being austenitic, cannot be hardened by heat treatment; its strength is primarily derived from cold working.

Table: Strength and Hardness Comparison (Typical Values)

| Property | 304 Stainless Steel (Annealed) | 410 Stainless Steel (Hardened & Tempered) |

| Ultimate Tensile Strength | ~515 MPa | ~690-860 MPa |

| Yield Strength | ~205 MPa | ~480-690 MPa |

| Hardness (Rockwell C) | Non-applicable (typically <92 HRB) | ~35-42 HRC |

| Wear Resistance | Moderate | Excellent |

Weldability, Machinability & Heat Treatment Response Comparison

The processing characteristics of these two grades also differ significantly due to their distinct microstructures. 304 offers excellent weldability without extensive pre/post-weld treatments, and its ductility makes it easy to form. 410 requires more careful welding procedures to avoid cracking and demands precise heat treatment to achieve its optimal mechanical properties. Precision CNC stainless steel machining needs to account for these differences.

Table: Processing Characteristics Comparison

| Characteristic | 304 Stainless Steel | 410 Stainless Steel |

| Weldability | Excellent, generally no pre/post-heating required. | Fair, requires preheating and post-weld heat treatment to prevent cracking. |

| Formability | Excellent (highly ductile). | Good in annealed condition, less ductile than 304. |

| Machinability | Good (can be gummy if tools are not sharp). | Good in annealed or tempered conditions, can be challenging when hardened. |

| Heat Treatability | Cannot be hardened by heat treatment. | Can be hardened by heat treatment (quenching and tempering). |

| Magnetic | Non-magnetic (in annealed state). | Ferromagnetic (magnetic). |

Choosing between 304 and 410 stainless steel is not about identifying a "better" material, but rather the "most suitable" one for a given application's demands. Each grade excels in specific environments and fulfills distinct functional requirements. The goal is to match the material's properties to the product's intended use and operating conditions, ensuring optimal performance and longevity. This is critical for effective stainless steel material selection.

Material Choice for Kitchenware, Medical & Architectural

For applications in food processing, medical non-cutting instruments, and architectural elements, 304 stainless steel is overwhelmingly preferred. Its superior corrosion resistance to various food acids, sanitizers, and atmospheric exposure, combined with its ease of cleaning and aesthetic appeal, makes it ideal for these environments where hygiene and visual integrity are paramount.

Table: Applications Favoring 304 Stainless Steel

| Application Area | Specific Needs | Why 304 is Preferred |

| Kitchenware | Hygiene, corrosion to food acids | Excellent resistance to rust, easy to sanitize, non-toxic. |

| Medical Devices | Sterilizability, resistance to bodily fluids | Good corrosion resistance, smooth finish, bio-compatible for non-implants. |

| Architectural | Aesthetic, atmospheric exposure | Resists weathering, retains shine, good formability for complex designs. |

| Dairy & Brewery | Chemical resistance, sanitization | Withstands caustic cleaning solutions, prevents contamination. |

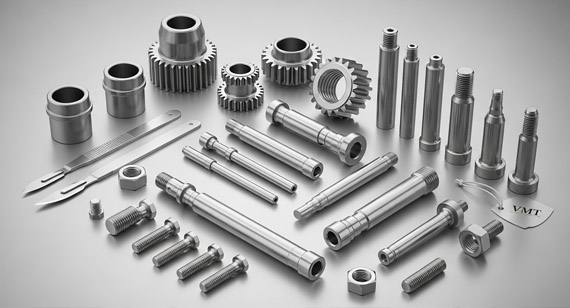

Performance Matching for Tools, Bearings & Valve Components

Conversely, for components requiring high hardness, strength, and wear resistance, such as knives, certain bearings, and critical valve parts, 410 stainless steel, particularly in its heat-treated condition, is the go-to material. Its ability to hold a sharp edge and withstand abrasive forces makes it invaluable where robust mechanical performance is paramount, making it an excellent choice for specialized 410 stainless steel applications.

Table: Applications Favoring 410 Stainless Steel

| Application Area | Specific Needs | Why 410 is Preferred |

| Knife Blades | Sharpness, edge retention | Can be heat-treated to high hardness, holds edge well. |

| Fasteners | High strength, wear resistance | Provides robust mechanical strength, resists stripping. |

| Pump/Valve Parts | Hardness, erosion resistance | Withstands abrasive fluids and high-pressure conditions. |

| Bushings/Shafts | Wear resistance, fatigue strength | Durable under rotational and frictional stresses. |

| Surgical Tools | Sharpness (cutting), sterilization | Can be hardened for cutting, good sterilizability. |

Environmental Factors (Temperature, Media) Affecting Material Selection

Beyond basic mechanical properties, the operational environment is a critical determinant for stainless steel material selection. Factors such as temperature extremes, exposure to aggressive chemicals, and the presence of abrasive media significantly influence the long-term performance and integrity of a component. These environmental demands dictate whether the superior corrosion resistance of 304 or the enhanced hardness of heat-treated 410 is more appropriate.

Table: Environmental Impact on 304 vs. 410 Performance

| Environmental Factor | Impact on 304 Stainless Steel | Impact on 410 Stainless Steel | Optimal Choice for this Factor |

| Mild Atmosphere | Excellent long-term resistance. | Good, but may show superficial rust over time. | 304 |

| Saltwater/Chlorides | Susceptible to pitting/crevice corrosion over time. | Highly susceptible to pitting/rust. | Neither ideal; consider duplex or super-austenitic for severe conditions. |

| High Temperature | Good strength and oxidation resistance up to ~870°C. | Can soften and lose hardness above ~590°C, good oxidation resistance. | 304 (for general elevated temp), 410 (if hardness needed below ~590°C). |

| Abrasive Wear | Moderate resistance, galls easily. | Excellent resistance after hardening. | 410 |

| Mild Acids (e.g., vinegar) | Excellent resistance. | Poor resistance, likely to corrode. | 304 |

Choosing the correct stainless steel grade is only half the battle; precisely machining it into high-quality components is where true value is created. At VMT CNC Machining Parts Services Factory, we are a source manufacturer, not a trading company, meaning we control the entire process from material sourcing to final inspection. Our deep technical expertise and state-of-the-art equipment ensure that whether you require 304 or 410 stainless steel parts, they are produced to the most demanding specifications. We specialize in precision CNC stainless steel machining for complex components.

Source Manufacturer Advantage: Material Quality & Transparent Pricing

As a source manufacturer based in Shenzhen, China, we offer unparalleled control over the material supply chain. This direct approach guarantees the authenticity and quality of every batch of 304 or 410 stainless steel we use, eliminating risks associated with intermediaries. Our factory-direct model also translates to transparent pricing, providing you with competitive costs without compromising on the superior quality of your CNC machined parts. We prioritize delivering high-value solutions.

Table: Source Manufacturer Benefits for Clients

| Benefit | Description | Client Advantage |

| Guaranteed Material Quality | Direct sourcing, rigorous incoming material inspection. | Assurance of correct material grade and properties. |

| Transparent Pricing | Factory-direct costs, no middleman markups. | Cost-effective solutions, clear understanding of pricing structure. |

| Faster Communication | Direct access to engineering and production teams. | Quicker problem-solving, efficient project management. |

| Accountability | Full responsibility for product quality and delivery. | Reduced risk, reliable partnership. |

Deep Technical Expertise: CNC Precision Machining High-Quality Stainless Steel Parts

Our core strength lies in our deep technical expertise and comprehensive understanding of machining diverse stainless steel grades. With over 80 advanced CNC machines, including high-precision 5-axis centers, we are equipped to handle the unique challenges presented by both 304 and 410 stainless steel. We provide detailed Design for Manufacturability (DFM) reports, ensuring that complex structures are optimized for superior quality and cost-efficiency. Our ISO9001 and IATF1649 certifications underscore our commitment to rigorous full-chain quality control. We offer rapid prototyping services (24-hour options available) and accept no minimum order quantity (MOQ), catering to both small-batch and large-scale projects requiring high-quality CNC machined parts.

Client Success: Optimized Selection & Processing

A notable instance involved a client in the robotics industry who initially specified 304 stainless steel for critical actuator components due to its general corrosion resistance. However, their new robotic arm design required superior wear resistance and hardness for the pivot joints, leading to premature component failure. Our technical team intervened, conducting a thorough DFM analysis. We recommended switching to heat-treated 410 stainless steel for the high-wear components, while retaining 304 for structural elements not subject to direct friction. This optimized stainless steel material selection, combined with our precision CNC machining capabilities and controlled heat treatment processes, significantly extended the lifespan of the actuator, improved the robot's reliability, and ultimately reduced the client's warranty claims. This case exemplifies our role as a trusted partner for demanding industries like aerospace, medical, and robotics.

Ready for Your Project: Partner with VMT

Whether your project demands the superior corrosion resistance and ductility of 304 stainless steel or the high strength and hardness achievable with heat-treated 410, VMT CNC Machining Parts Services Factory possesses the expertise, equipment, and quality systems to deliver exceptional results. Our factory-direct approach ensures not only high-quality CNC machined parts but also transparent pricing and a partnership built on trust and technical excellence.

This article provided a comprehensive technical comparison between 304 and 410 stainless steel, detailing their distinct chemical compositions, mechanical properties, and processing characteristics. We explored their optimal application scenarios, highlighting that the choice depends on balancing corrosion resistance, strength, hardness, and environmental factors. As a source manufacturer, VMT CNC Machining Parts Services Factory offers deep technical expertise and advanced CNC precision machining capabilities for both 304 and 410 stainless steel, ensuring high-quality parts, transparent pricing, and tailored solutions for complex projects across demanding industries.

1. What is the primary difference between 304 and 410 stainless steel?

The primary difference lies in their metallurgical classification and resulting properties. 304 is an austenitic stainless steel, known for excellent corrosion resistance and ductility, but it cannot be hardened by heat treatment. 410 is a martensitic stainless steel, which offers good corrosion resistance in mild environments but can be hardened to very high strength and hardness through heat treatment, making it suitable for wear-resistant applications and cutting edges.

2. Which stainless steel is better for corrosion resistance, 304 or 410?

304 stainless steel generally offers superior corrosion resistance compared to 410, particularly in more aggressive environments or those involving mild acids and chlorides. Its higher chromium and nickel content forms a more stable passive layer. While 410 provides good resistance in mild atmospheric conditions, it is more susceptible to rust and pitting in corrosive settings.

3. Can both 304 and 410 stainless steel be machined by CNC?

Yes, both 304 and 410 stainless steel can be precisely machined using CNC techniques. However, their machinability characteristics differ. 304 can be somewhat "gummy" and requires sharp tooling to prevent work hardening. 410 is generally more readily machinable in its annealed or tempered state but becomes significantly harder and more challenging to machine after full hardening. Our facility is equipped with advanced CNC machinery and expertise to handle both grades effectively.

4. Is 410 stainless steel magnetic? What about 304?

Yes, 410 stainless steel is ferromagnetic, meaning it is magnetic. This is due to its martensitic microstructure. In contrast, 304 stainless steel is typically non-magnetic in its annealed condition because of its austenitic microstructure. However, 304 can become slightly magnetic after significant cold working due to localized martensite formation.

5. What applications are best suited for 410 stainless steel due to its hardness?

410 stainless steel is ideally suited for applications requiring high hardness, strength, and wear resistance, especially after heat treatment. Common applications include knife blades, fasteners, pump and valve components (e.g., shafts, seats), bushings, and certain surgical instruments where a sharp edge or robust mechanical performance is critical.

6. Does VMT provide design consultation for material selection?

Absolutely. As a source manufacturer with deep technical expertise, VMT offers comprehensive design consultation, including Design for Manufacturability (DFM) reports. Our engineers work closely with clients to evaluate product requirements, environmental factors, and cost considerations to recommend the most suitable stainless steel grade (304, 410, or other specialized alloys) and optimize the design for precision CNC machining.

7. What kind of quality control measures does VMT implement for stainless steel parts?

VMT adheres to rigorous full-chain quality control protocols, supported by ISO9001 and IATF1649 certifications. This includes strict incoming material inspection, in-process monitoring during CNC machining, and comprehensive final inspection using advanced metrology equipment like CMMs and optical comparators. We ensure every part meets specified tolerances and material properties.

8. Can I get rapid prototyping services for parts made from 304 or 410 stainless steel?

Yes, VMT offers rapid prototyping services for both 304 and 410 stainless steel components, with 24-hour service available for urgent requirements. We understand the importance of quick turnaround times for product development and validation, and our advanced equipment and streamlined processes enable us to deliver high-quality prototypes efficiently, without any minimum order quantity restrictions.