15 years one-stop China custom CNC machining parts factory

62 |

Published by VMT at Sep 29 2025 | Reading Time:About 4 minutes

62 |

Published by VMT at Sep 29 2025 | Reading Time:About 4 minutes

In the extreme environments of modern industry, where corrosion, high temperatures, and immense pressures prevail, material failure can lead to catastrophic financial losses and severe safety hazards. How can you confidently face exposure to sulfuric acid, phosphoric acid, and highly concentrated chloride solutions? This ultimate guide to 904L stainless steel will unveil the secrets of this super austenitic alloy and explain how, through precision machining, it becomes your ultimate defense against the most demanding challenges.

904L stainless steel is a high-alloy super austenitic stainless steel known for its exceptional resistance to various forms of corrosion. Its unique composition, including high levels of nickel, chromium, molybdenum, and copper, provides superior performance in highly aggressive environments, making it a preferred material for critical applications across industries where standard stainless steels fall short.

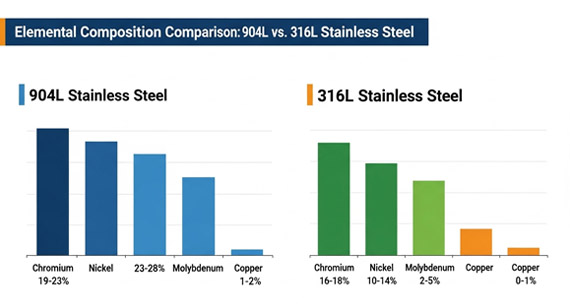

The Unique Chemical Composition and Microstructure of 904L

904L stainless steel's outstanding properties stem directly from its carefully balanced chemical composition. Unlike conventional austenitic stainless steels such as 304L or 316L, 904L incorporates higher percentages of nickel, chromium, molybdenum, and notably, copper. These elements synergistically enhance its resistance to pitting, crevice corrosion, and stress corrosion cracking in a wide array of aggressive media. The microstructure of 904L is predominantly austenitic, ensuring good ductility and toughness, even at cryogenic temperatures. The higher alloying content also contributes to a more stable austenite phase, resisting the formation of deleterious phases at elevated temperatures.

Table: 904L vs. 316L: Key Elemental Composition (Weight %)

| Element | 904L (Typical Range) | 316L (Typical Range) | Purpose in 904L |

| Chromium | 19.0 - 23.0 | 16.0 - 18.0 | Enhances general corrosion and oxidation resistance. |

| Nickel | 23.0 - 28.0 | 10.0 - 14.0 | Improves toughness, ductility, and resistance to stress corrosion cracking. |

| Molybdenum | 4.0 - 5.0 | 2.0 - 3.0 | Significantly boosts pitting and crevice corrosion resistance in chloride environments. |

| Copper | 1.0 - 2.0 | 0.0 - 0.75 | Provides superior resistance to sulfuric and phosphoric acids. |

| Carbon | 0.02 Max | 0.03 Max | Low carbon minimizes sensitization during welding, preventing intergranular corrosion. |

| Manganese | 2.0 Max | 2.0 Max | Deoxidizer, contributes to strength. |

| Silicon | 1.0 Max | 1.0 Max | Deoxidizer, improves fluidity during casting. |

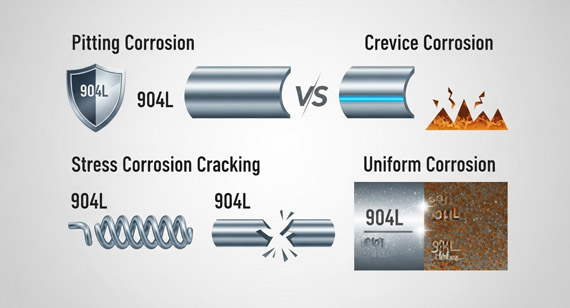

Exceptional Corrosion Resistance: Performance in Acid and Chloride Environments

The elevated levels of chromium, nickel, and molybdenum in 904L are pivotal for its exceptional corrosion resistance, particularly in highly acidic and chloride-rich environments. Chromium forms a stable passive film on the surface, providing primary protection against oxidation. Nickel significantly improves resistance to stress corrosion cracking and general acid attack. Molybdenum is crucial for resisting pitting and crevice corrosion, especially in solutions containing chlorides. Furthermore, the deliberate addition of copper endows 904L with outstanding resistance to reducing acids, such as sulfuric and phosphoric acids, over a wide range of concentrations and temperatures, where other stainless steels would fail. This makes 904L a material of choice for demanding applications in chemical processing and marine environments.

Table: 904L Corrosion Resistance Comparison (Relative Scale)

| Corrosion Type | 904L (Rating) | 316L (Rating) | Hastelloy C-276 (Rating) | Key Advantage of 904L |

| Pitting Corrosion (Chlorides) | Excellent | Good | Superior | Higher PREN due to Mo content. |

| Crevice Corrosion | Excellent | Moderate | Superior | Enhanced resistance in stagnant chloride environments. |

| Stress Corrosion Cracking | Very Good | Moderate | Excellent | High Ni content significantly improves SCC resistance. |

| Sulfuric Acid (Reducing) | Excellent | Poor | Superior | Cu addition provides exceptional resistance. |

| Phosphoric Acid | Excellent | Good | Excellent | Effective across various concentrations and temperatures. |

| Intergranular Corrosion | Excellent | Good | Excellent | Low carbon content prevents sensitization. |

Mechanical Properties and General Machining Characteristics of 904L

Beyond its corrosion resistance, 904L stainless steel exhibits good mechanical properties. It offers moderate strength and excellent ductility, making it suitable for forming operations. Its non-magnetic nature in the annealed condition is also an advantage for specific applications. However, these very characteristics, especially its high nickel content, contribute to its machinability challenges. 904L is prone to work hardening during machining, which can lead to rapid tool wear and difficulties in achieving precise tolerances and surface finishes. Proper tooling, machining parameters, and advanced cooling strategies are essential to effectively process this material.

Table: Typical Mechanical Properties of 904L Stainless Steel (Annealed Condition)

| Property | Value (Metric) | Value (Imperial) |

| Tensile Strength (Rm) | 490 MPa (min) | 71 ksi (min) |

| Yield Strength (Rp0.2) | 220 MPa (min) | 32 ksi (min) |

| Elongation (A5) | 35% (min) | 35% (min) |

| Hardness (HB) | 150 - 200 (approx) | 80-95 HRB (approx) |

| Modulus of Elasticity (E) | 195 GPa | 28.3 x 10^6 psi |

| Density | 8.0 g/cm³ | 0.289 lb/in³ |

The exceptional properties of 904L stainless steel position it as an indispensable material in industries facing the most aggressive operational environments. Its ability to withstand severe corrosive attack translates into extended equipment lifespan, reduced maintenance, and enhanced operational safety.

Chemical Processing Equipment: Durable Solutions in Aggressive Acidic Media

In the chemical processing industry, where contact with highly corrosive acids like sulfuric, phosphoric, and acetic acid is routine, materials must offer uncompromising resistance. 904L is widely used for components such as heat exchangers, process piping, storage tanks, and pump and valve parts that handle these aggressive chemicals. Its resistance to both uniform and localized corrosion ensures the integrity of processing equipment, preventing costly leaks and contamination.

Pharmaceutical Industry: Meeting High Purity and Sterile Environment Requirements

The pharmaceutical sector demands materials that not only resist corrosion from cleaning agents and process fluids but also maintain high levels of purity and hygiene. 904L's smooth surface finish capabilities, coupled with its excellent corrosion resistance, make it suitable for pharmaceutical reactors, filtration systems, and piping for sterile product transfer. Its durability against stringent sterilization processes ensures equipment longevity and product safety.

Marine Engineering: Withstanding Seawater Corrosion and High Chloride Environments

Seawater, with its high chloride content, is notoriously corrosive, leading to pitting and crevice corrosion in many standard stainless steels. 904L's high molybdenum content significantly improves its resistance in such environments, making it ideal for marine engineering applications like offshore oil rig components, seawater cooling systems, and propeller shafts, where prolonged exposure to brackish or seawater is unavoidable.

Oil, Gas Extraction, and Pollution Control: High Sulfur and Chloride Applications

The upstream and downstream sectors of the oil and gas industry, as well as pollution control systems, often involve highly corrosive media containing hydrogen sulfide, chlorides, and other aggressive compounds. 904L is employed in sour gas processing plants, exhaust gas desulfurization (FGD) systems, and heat exchangers, where it provides robust protection against these harsh conditions, ensuring reliable and safe operations.

Choosing the correct material for an application is critical, balancing performance, longevity, and cost. While 904L offers superior corrosion resistance, it is important to understand its position relative to other high-performance alloys.

Performance Differences: 904L vs. 316L and 317L

When compared to common austenitic stainless steels like 316L and 317L, 904L presents a significant leap in corrosion resistance, particularly in highly aggressive reducing acids and chloride-rich environments. The higher nickel, molybdenum, and copper content in 904L provide superior resistance to pitting, crevice corrosion, and stress corrosion cracking that 316L and 317L cannot match. While 316L and 317L are cost-effective for moderately corrosive conditions, 904L becomes the economical choice in the long run when facing severe conditions that would cause premature failure in lesser alloys.

Table: Key Differentiators: 904L vs. 316L vs. 317L

| Feature / Property | 904L | 316L | 317L |

| PREN (Pitting Resistance Equivalent Number) | High (35-39) | Moderate (23-28) | Moderate-High (28-33) |

| Resistance to Sulfuric Acid | Excellent | Poor to Moderate | Moderate |

| Resistance to Phosphoric Acid | Excellent | Good | Good to Very Good |

| Resistance to Chlorides | Excellent (pitting, crevice, SCC) | Good (pitting, crevice) | Very Good (pitting, crevice) |

| Cost | Higher | Lower | Moderate |

| Work Hardening | High | Moderate | Moderate |

904L vs. Duplex Stainless Steels and Hastelloy: Making the Right Choice

The choice between 904L, Duplex Stainless Steels (e.g., 2205, 2507), and superalloys like Hastelloy (e.g., C-276) depends on the specific demands of the operating environment. Duplex stainless steels offer a combination of high strength and good corrosion resistance, particularly stress corrosion cracking, due to their mixed ferrite-austenite microstructure. They can be a cost-effective alternative to 904L in certain chloride environments where higher strength is also required. However, 904L generally offers superior resistance in strongly acidic, reducing environments due to its copper content. Hastelloy alloys, while significantly more expensive, provide the highest level of corrosion resistance across the broadest range of extremely aggressive media, including highly concentrated strong acids and high-temperature chlorides, making them the choice for the most severe conditions where even 904L might be insufficient.

Table: Material Comparison: 904L vs. Duplex SS (2205) vs. Hastelloy C-276

| Feature / Property | 904L | Duplex SS (e.g., 2205) | Hastelloy C-276 |

| Primary Microstructure | Austenitic | Austenitic-Ferritic (approx. 50/50) | Austenitic (Ni-Cr-Mo alloy) |

| Corrosion Resistance | Excellent (acids, chlorides) | Very Good (chlorides, SCC) | Superior (broadest range of acids, high temps) |

| Mechanical Strength | Moderate | High | Moderate to High |

| Weldability | Good (with proper precautions) | Good | Good (with specific procedures) |

| Cost (Relative) | High | Moderate-High | Very High |

| Suitability for Sour Gas | Good | Excellent | Superior |

How to Select the Most Suitable Stainless Steel Based on Operating Conditions

Selecting the optimal stainless steel requires a thorough understanding of the specific operating conditions. Factors to consider include: the type and concentration of corrosive agents, operating temperature, pressure, presence of chlorides, potential for mechanical stress, required lifespan of the component, and budget constraints. For environments involving strong reducing acids like sulfuric or phosphoric acid, 904L is often the most cost-effective and reliable choice. If high strength is paramount alongside good corrosion resistance in chloride environments, a Duplex stainless steel might be considered. For the most extreme and complex corrosive conditions, especially at high temperatures, superalloys like Hastelloy are indispensable. Consulting with material specialists and performing detailed corrosion analyses are recommended for critical applications.

As a source manufacturer, VMT CNC Machining Parts Services Factory possesses the deep technical expertise required to transform the challenging 904L material into high-precision components. Our advanced equipment and stringent quality controls ensure that the final product meets the most demanding specifications.

904L Stainless Steel's Machining Challenges and Solutions

904L stainless steel's high ductility and tendency to work harden present significant machining challenges. It generates tough, gummy chips that are difficult to break, leading to chip entanglement and poor surface finishes. The work hardening effect also causes rapid tool wear, increasing production costs and decreasing machining efficiency. To overcome these issues, VMT employs specialized machining strategies including: optimized cutting parameters (lower speeds, higher feeds), specific tool geometries (positive rake angles, sharp cutting edges), robust tooling materials (carbides with advanced coatings), and efficient chip evacuation systems. Our engineers provide detailed Design for Manufacturability (DFM) reports, especially for complex structures requiring 5-axis machining, ensuring that designs are optimized for manufacturability without compromising performance.

Key Technologies and Advanced Equipment for CNC Machining 904L

Our facility is equipped with a large fleet of over 80 advanced CNC machines, including high-precision multi-axis CNC machining centers, CNC lathes, and state-of-the-art 5-axis machines. These machines provide the rigidity and precision necessary to machine 904L effectively. The use of advanced CAD/CAM software allows for precise tool path generation and simulation, minimizing errors and optimizing material removal. For 904L, we leverage high-pressure coolant systems to manage heat, improve chip evacuation, and extend tool life, which are critical for maintaining tight tolerances and superior surface finishes on complex 904L components.

Welding Processes: Strategies to Prevent Intergranular Corrosion and Cracking

While this guide focuses on CNC machining, it is important to note that 904L is also readily weldable, but specific procedures are necessary to maintain its corrosion resistance. Low heat input welding methods and the use of matching or slightly over-alloyed filler metals are typically employed. Care must be taken to prevent hot cracking and to avoid conditions that could lead to sensitization and intergranular corrosion in the heat-affected zone. Post-weld treatments, such as passivation, are often applied to restore the passive layer and optimize corrosion resistance of the welded component.

Impact of Surface Treatment and Heat Treatment on 904L Performance

While 904L is inherently highly corrosion resistant, specific surface treatments can further enhance its performance or tailor it for unique requirements. For instance, passivation can clean the surface of free iron particles and rebuild the passive layer, optimizing its inherent corrosion resistance. Electropolishing can achieve an exceptionally smooth, mirror-like finish, which is crucial for pharmaceutical and food processing applications where hygiene and ease of cleaning are paramount. Due to its austenitic structure, 904L is generally not hardened by heat treatment. However, solution annealing (heating to 1090-1150°C followed by rapid cooling) is performed after cold working or welding to restore its optimum ductility and corrosion resistance by dissolving any precipitates and homogenizing the microstructure. Careful control of these processes ensures that the material's properties are fully realized in the final component.

Quality Control and Traceability: Ensuring High-Quality Components

At VMT, rigorous full-chain quality control is an integral part of our manufacturing process for 904L components. Our quality management system is certified to ISO9001 and IATF16949 standards, reflecting our commitment to excellence and continuous improvement. From the moment raw 904L material enters our facility, we implement strict material verification and traceability protocols. Each batch is accompanied by comprehensive material test reports (MTRs) from approved suppliers. During manufacturing, in-process inspections, dimensional checks, and non-destructive testing (NDT) are performed using advanced metrology equipment. Final inspection includes precise dimensional verification, surface finish checks, and, where specified, material performance testing. This meticulous approach ensures that every 904L component leaving our factory meets the highest standards of quality, performance, and traceability.

Engaging VMT as your source manufacturer for 904L components offers a direct path to high-quality parts with transparent pricing, ensuring long-term value for your projects.

Factors Influencing 904L Stainless Steel Pricing

The cost of 904L stainless steel is influenced by several factors. The primary drivers are the market prices of its key alloying elements, particularly nickel, molybdenum, and copper, which are typically higher than those found in standard stainless steels. The manufacturing process for 904L itself is also more complex. Additionally, the form of the material (bar, plate, tube) and the quantity purchased affect the per-unit cost. For precision machined components, the complexity of the part geometry, required tolerances, surface finish specifications, and the number of machining operations contribute significantly to the overall price.

Direct Supply from a Source Manufacturer: Ensuring Quality and Price Advantage

As a source manufacturer, VMT offers factory-direct pricing for 904L machined parts. This eliminates the mark-ups associated with trading companies, providing you with transparent and competitive costs. Our direct engagement means you benefit from direct communication with our technical experts, ensuring that your specifications are fully understood and implemented. We provide comprehensive services from design evaluation to final delivery, including rapid prototyping, with a 24-hour service available for urgent needs. Furthermore, we maintain a no minimum order quantity (MOQ) policy, making high-quality 904L components accessible for projects of all scales, from single prototypes to large production runs.

A Guide to 904L Lifecycle Cost-Benefit Analysis

While the initial material cost of 904L is higher than conventional stainless steels, a comprehensive lifecycle cost-benefit analysis often reveals its superior economic value. In corrosive environments where standard materials fail prematurely, 904L reduces expenses related to frequent replacements, extensive maintenance, downtime, and potential product losses due to contamination or equipment failure. The extended service life and enhanced reliability of 904L components translate into significant long-term savings, improved operational efficiency, and minimized safety risks, making it a highly cost-effective solution for critical applications.

Our 904L Supply and Technical Support Services

VMT is not just a parts supplier; we are a trusted partner for demanding industries. Our dedicated team of engineers provides unparalleled technical support, guiding you through material selection, design optimization (DFM), and process planning for your 904L projects. We leverage our deep technical knowledge and advanced manufacturing capabilities to deliver high-value solutions. From initial consultation to post-delivery support, we ensure a seamless and collaborative experience, reinforcing our commitment to your project's success.

Exploring 904L's Application Potential in Emerging Fields

The inherent properties of 904L stainless steel position it for growth in several emerging fields. As industries like renewable energy (e.g., concentrated solar power with molten salt systems), advanced battery technologies, and specialized waste treatment evolve, the demand for materials capable of operating under increasingly aggressive conditions will rise. 904L's combination of corrosion resistance, high-temperature stability, and good mechanical properties makes it a strong candidate for these innovative applications. Continuous research into further optimizing its composition and processing techniques will likely expand its utility.

Environmental and Sustainability Considerations in Material Selection

The longevity and durability of 904L stainless steel contribute significantly to sustainable engineering practices. By providing components with extended service life, it reduces the need for frequent replacements, thereby minimizing material consumption, manufacturing energy, and waste generation. Its high recyclability also supports circular economy principles. As environmental regulations become more stringent and industries prioritize sustainable solutions, materials like 904L, which offer long-term reliability and reduced environmental impact throughout their lifecycle, will become increasingly vital.

This ultimate guide has thoroughly explored 904L stainless steel, a super austenitic alloy, detailing its unique chemical composition, exceptional corrosion resistance in challenging environments, and mechanical properties. We've highlighted its critical applications across chemical processing, pharmaceuticals, marine engineering, and oil/gas, and provided a comprehensive comparison with other high-performance alloys. As a source manufacturer, VMT offers unparalleled expertise in precision machining 904L, overcoming its inherent challenges through advanced technology and rigorous quality control. Our transparent, factory-direct approach ensures high-value, durable components, making 904L a strategic and cost-effective choice for your most demanding projects, aligning with future trends in sustainability.

1. What is the primary advantage of 904L stainless steel over 316L?

The primary advantage of 904L over 316L is its significantly enhanced corrosion resistance, especially in highly aggressive reducing acids like sulfuric and phosphoric acids, and in chloride-rich environments. This is due to 904L's higher nickel, molybdenum, and notably, copper content, which improve its resistance to pitting, crevice corrosion, and stress corrosion cracking.

2. In which specific environments does 904L stainless steel excel?

904L stainless steel particularly excels in environments involving highly concentrated sulfuric acid, phosphoric acid, and other reducing acids. It also performs exceptionally well in solutions with high chloride concentrations, suching as seawater or industrial brine, where it resists pitting and crevice corrosion more effectively than standard austenitic stainless steels.

3. Is 904L stainless steel difficult to machine, and how does VMT address this?

Yes, 904L stainless steel is considered challenging to machine due to its high ductility and tendency to work harden. VMT addresses these difficulties by utilizing specialized CNC machining strategies, including optimized cutting parameters, specific tool geometries, robust carbide tooling with advanced coatings, high-pressure coolant systems, and leveraging our 5-axis machining capabilities for complex geometries.

4. What quality certifications does VMT hold for manufacturing 904L components?

VMT CNC Machining Parts Services Factory adheres to rigorous quality management systems, holding ISO9001 and IATF16949 certifications. These certifications underscore our commitment to consistent quality, process control, and continuous improvement throughout the manufacturing of 904L and other precision machined parts.

5. Can 904L stainless steel be used for high-temperature applications?

While 904L offers good corrosion resistance at elevated temperatures, its primary strength lies in resisting corrosion in aggressive chemical environments rather than exceptionally high temperatures alone. Its austenitic structure provides good high-temperature strength, but specific temperature limits depend on the corrosive medium present. For extreme high-temperature and corrosive conditions, superalloys like Hastelloy might be more suitable.

6. Does VMT offer rapid prototyping services for 904L parts?

Yes, VMT provides rapid prototyping services for 904L stainless steel components. We understand the urgency of new product development and offer a 24-hour service option to expedite the creation of prototypes, allowing for quick design validation and iteration.

7. What is the significance of 904L's copper content?

The copper content in 904L stainless steel (typically 1.0-2.0%) is highly significant. It provides the alloy with its exceptional resistance to reducing acids, specifically sulfuric and phosphoric acids, across a wide range of concentrations and temperatures. This makes 904L a unique and highly effective material for these particular chemical processing applications.

8. How does purchasing 904L from a source manufacturer like VMT benefit the client?

Purchasing 904L from a source manufacturer like VMT offers several key benefits: factory-direct pricing without intermediary mark-ups, ensuring transparent and competitive costs; direct access to deep technical expertise and engineering support for design optimization and problem-solving; full traceability and rigorous quality control from raw material to finished product; and flexible order quantities, including no MOQ, to accommodate diverse project needs.

Your next critical project deserves the highest standards in material and machining services. Contact our 904L stainless steel technical consultants today to receive personalized material selection advice, precision machining solutions, and a transparent, detailed quotation. We are committed to safeguarding your success with the robust capabilities and exquisite craftsmanship of a leading source manufacturer.