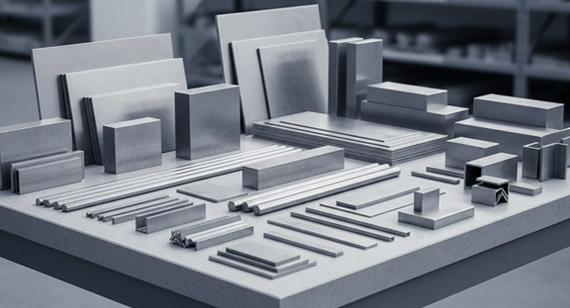

15 years one-stop China custom CNC machining parts factory

71 |

Published by VMT at Sep 30 2025 | Reading Time:About 3 minutes

71 |

Published by VMT at Sep 30 2025 | Reading Time:About 3 minutes

Is your precision component truly made from the optimal stainless steel? The distinction between 410 and 316 stainless steel, though seemingly minor, dictates critical performance and cost implications. An incorrect material selection can lead to significant project delays, expensive rework, and jeopardize product reputation. Today, we delve into the real-world characteristics of these two widely used stainless steels, providing you with a clear, expert guide to make an informed, confident decision.

When choosing stainless steel for precision parts, 410 and 316 represent distinct classes with specific strengths. 410 is a martensitic alloy known for its hardness and strength, particularly after heat treatment, making it suitable for high-wear applications. 316, an austenitic alloy, offers superior corrosion resistance, especially against chlorides, and excellent weldability, ideal for demanding chemical environments. Understanding these core differences is essential for long-term project success.

When your application demands exceptional mechanical strength, hardness, and wear resistance, especially at elevated temperatures, 410 stainless steel often emerges as a primary candidate. This martensitic alloy is designed for environments where robust mechanical performance is paramount.

Martensitic Stainless Steel: 410 Basic Attributes and Advantages

410 stainless steel is a basic martensitic grade, characterized by its iron-chromium composition with approximately 11.5-13.5% chromium. Its martensitic structure, achieved through heat treatment (quenching and tempering), allows it to achieve high levels of strength and hardness. This unique crystalline structure provides the material with its distinctive mechanical properties. The primary advantage of 410 lies in its ability to be hardened and tempered, offering a significant increase in mechanical strength and wear resistance compared to many other stainless steel grades. While it is a stainless steel, its corrosion resistance is moderate, suitable for mild atmospheric conditions or applications where continuous contact with corrosive agents is minimal.

Key Performance Parameters: Strength, Hardness, and Heat Treatment Characteristics

The mechanical properties of 410 stainless steel are highly dependent on its heat treatment. In its annealed condition, it offers good ductility. However, its true potential is unlocked through quenching from high temperatures followed by tempering, which transforms its microstructure into martensite, significantly increasing its tensile strength and hardness. This makes it a preferred choice for parts requiring resilience against abrasion and impact.

Here is a general overview of 410 stainless steel's typical mechanical properties:

Table: Typical Mechanical Properties of 410 Stainless Steel (Heat Treated)

| Property | Metric Value | Imperial Value |

| Tensile Strength | 550-800 MPa | 80-116 ksi |

| Yield Strength (0.2% Offset) | 345-600 MPa | 50-87 ksi |

| Hardness (Brinell) | 180-250 HB | |

| Hardness (Rockwell C) | 35-45 HRC (after tempering) | |

| Elongation | 15-25% | |

| Modulus of Elasticity | 200 GPa | 29 x 10^6 psi |

Typical Application Scenarios: Ideal Choices for 410 Stainless Steel

Given its strength, hardness, and moderate corrosion resistance, 410 stainless steel is widely used in applications where robust mechanical performance is critical, and corrosive conditions are not extreme. Its ability to withstand high temperatures and wear makes it valuable in specific industrial contexts.

Table: Common Applications for 410 Stainless Steel

| Application Area | Specific Components/Uses | Rationale |

| Automotive | Fasteners, shafts, valve components | High strength, wear resistance for moving parts |

| Industrial | Pump and valve parts, cutlery, blades, turbine blades | Abrasion resistance, moderate corrosion |

| Petroleum & Gas | Compressor blades, pressure vessel components | Good strength at elevated temperatures |

| Fasteners | Bolts, screws, nuts | High strength, hardenability |

| General Engineering | Bushings, pins, highly stressed parts | Durability and resistance to wear |

For environments demanding superior corrosion resistance, particularly against chlorides and other aggressive chemicals, 316 stainless steel is the material of choice. Its distinct austenitic structure provides a combination of properties that make it highly versatile across numerous industries.

Austenitic Stainless Steel: 316 Unique Structure and Performance

316 stainless steel belongs to the austenitic family, which is non-magnetic and cannot be hardened by heat treatment. Its composition typically includes 16-18% chromium, 10-14% nickel, and crucially, 2-3% molybdenum. The addition of molybdenum is what sets 316 apart from 304 stainless steel, significantly enhancing its resistance to pitting and crevice corrosion, especially in chloride-rich environments like marine or chemical processing applications. This makes it more robust against a wider range of corrosive media. The austenitic structure also imparts excellent ductility and toughness, even at cryogenic temperatures, and superior weldability.

Key Performance Parameters: Corrosion Resistance, Toughness, and Weldability

The primary strength of 316 stainless steel lies in its exceptional corrosion resistance, superior to that of 410 and even 304. It performs well in acidic, alkaline, and chloride solutions, making it invaluable for chemical processing, marine, and medical equipment. Furthermore, 316 exhibits excellent formability and can be deep drawn, bent, and welded with ease, requiring no post-weld heat treatment in most cases. Its toughness is maintained across a broad temperature range, from cryogenic to moderately high temperatures.

Table: Typical Mechanical Properties of 316 Stainless Steel (Annealed)

| Property | Metric Value | Imperial Value |

| Tensile Strength | 515-620 MPa | 75-90 ksi |

| Yield Strength (0.2% Offset) | 205-310 MPa | 30-45 ksi |

| Hardness (Brinell) | 160-217 HB | |

| Hardness (Rockwell B) | 85-95 HRB | |

| Elongation | 40-50% | |

| Modulus of Elasticity | 193 GPa | 28 x 10^6 psi |

Typical Application Scenarios: 316 Stainless Steel Industry Standard

Due to its enhanced corrosion resistance, especially against chlorides, and good mechanical properties, 316 stainless steel is an industry standard for highly demanding applications. It is frequently specified where longevity and resistance to aggressive environments are non-negotiable.

Table: Common Applications for 316 Stainless Steel

| Application Area | Specific Components/Uses | Rationale |

| Marine | Boat fittings, architectural trim, engine components | Excellent resistance to saltwater corrosion |

| Chemical Processing | Heat exchangers, tanks, pumps, valves | Withstands harsh chemicals, acids, and chlorides |

| Medical & Pharmaceutical | Surgical instruments, implants, pharmaceutical equipment | Biocompatibility, sterilization capability, corrosion resistance |

| Food & Beverage | Food processing equipment, storage tanks, cutlery | Hygienic, resistant to food acids and cleaning agents |

| Aerospace | Structural components, specific fittings | High strength-to-weight ratio, corrosion resistance |

Choosing between 410 and 316 stainless steel requires a detailed understanding of their performance differences across critical parameters. Our factory, as a source manufacturer, brings deep technical expertise to help you navigate these nuances, ensuring your parts perform optimally in their intended environments.

Corrosion Resistance: Who Prevails Against Corrosion?

The most significant differentiator between 410 and 316 stainless steel is their corrosion resistance. 410, being a martensitic grade, offers moderate corrosion resistance, primarily due to its lower chromium content and lack of molybdenum. It is susceptible to pitting and crevice corrosion in chloride-rich or acidic environments. 316, on the other hand, excels in these conditions, owing to its higher nickel and chromium content, and especially the addition of molybdenum.

Table: Corrosion Resistance Comparison

| Property | 410 Stainless Steel | 316 Stainless Steel |

| General Corrosion | Moderate; suitable for mild atmospheric and freshwater environments. | Excellent; resists a wide range of corrosive media including acids, alkalis. |

| Pitting & Crevice Corrosion | Susceptible in chloride environments (e.g., saltwater, some chemicals). | Superior resistance, especially due to molybdenum. Ideal for marine and chemical processing. |

| Intergranular Corrosion | Generally good, but can be susceptible if sensitized by improper welding. | Excellent; particularly 316L (low carbon variant) minimizes this risk. |

| Stress Corrosion Cracking | Moderate resistance. | Good resistance, but still susceptible under specific, extreme conditions. |

Mechanical Strength and Hardness: Performance Differences Under Various Conditions

While 316 offers superior corrosion resistance, 410 generally surpasses it in terms of achievable hardness and tensile strength after appropriate heat treatment. This makes 410 suitable for applications where wear and abrasion are significant concerns, whereas 316 offers a balance of strength, ductility, and high corrosion resistance.

Table: Mechanical Strength and Hardness Comparison

| Property | 410 Stainless Steel (Heat Treated) | 316 Stainless Steel (Annealed) |

| Hardness (Rockwell C) | 35-45 HRC | 85-95 HRB (approx. 10-20 HRC equivalent) |

| Tensile Strength | 550-800 MPa (80-116 ksi) | 515-620 MPa (75-90 ksi) |

| Yield Strength | 345-600 MPa (50-87 ksi) | 205-310 MPa (30-45 ksi) |

| Ductility (Elongation) | 15-25% (lower due to hardness) | 40-50% (higher for formability) |

| Impact Toughness | Moderate, can be reduced by high hardness. | Excellent, especially at low temperatures. |

High-Temperature Stability: Which Material Can Endure Extreme Conditions Better

Both 410 and 316 stainless steels exhibit good high-temperature properties, but their specific strengths differ. 410 maintains good mechanical strength at moderately high temperatures, making it suitable for certain high-heat, high-wear applications. 316, on the other hand, offers better creep resistance and retains more strength at higher temperatures than 410, particularly when corrosion is also a factor.

Table: High-Temperature Performance Comparison

| Property | 410 Stainless Steel | 316 Stainless Steel |

| Max Operating Temp. | Up to 650°C (1200°F) for short exposure; Strength degrades above 400°C. | Up to 870°C (1600°F) for continuous service; Maintains better strength at higher temps. |

| Creep Resistance | Moderate, less stable at prolonged high temperatures. | Superior creep resistance, good for long-term high-temperature exposure. |

| Oxidation Resistance | Good up to 700°C (1290°F) in intermittent service. | Excellent up to 870°C (1600°F) in continuous service. |

| Thermal Conductivity | Higher (approx. 24 W/m·K) | Lower (approx. 16 W/m·K) |

Machinability and Weldability: CNC Machining Considerations

When it comes to CNC machining, the inherent properties of each material directly impact process parameters, tool life, and achievable finishes. As a source manufacturer with advanced CNC capabilities, including 5-axis machining, we optimize our processes for both materials.

Table: Machinability and Weldability Comparison

| Property | 410 Stainless Steel | 316 Stainless Steel |

| Machinability | Fair to good in annealed condition, but harder in heat-treated state, requiring more robust tooling. | Good; tendency to work-harden, requiring slower speeds and heavier cuts. Gummy chips can be an issue. |

| Weldability | Good, but requires pre-heating and post-weld heat treatment to prevent cracking and restore ductility. | Excellent; readily weldable by all standard fusion methods. No post-weld annealing required for 316L. |

| Surface Finish | Can achieve good finish, but high hardness can lead to tool wear. | Excellent finish possible due to inherent ductility, but work hardening needs management. |

| Tool Life | Shorter with heat-treated material due to hardness. | Generally good, but sticky chips can reduce tool life if not managed. |

Selecting the right stainless steel extends beyond immediate performance needs; it encompasses a holistic view of initial investment, lifecycle costs, and the value added by your manufacturing partner. Our factory provides transparent, factory-direct pricing, ensuring you receive high-value solutions.

Material Cost Differences: Comparative Analysis of Initial Investment

Generally, 410 stainless steel is more cost-effective on a per-kilogram basis than 316 stainless steel. The primary reason for this difference is the alloying elements. 316 contains higher percentages of more expensive elements like nickel and, crucially, molybdenum, which significantly enhance its corrosion resistance. Therefore, for projects where the specific high-corrosion resistance of 316 is not strictly necessary, 410 can offer a lower initial material cost. However, this initial saving must always be weighed against the long-term performance requirements.

Lifecycle Costs: Maintenance, Replacement, and Failure Risk Assessment

While 410 may have a lower initial material cost, overlooking the actual application environment can lead to significantly higher lifecycle costs. In corrosive settings, a 410 part might fail prematurely, necessitating expensive replacements, maintenance, and potentially causing downtime for equipment. A 316 part, though more expensive initially, can offer a much longer service life, reducing repair frequency and total cost of ownership. Our DFM (Design for Manufacturability) reports proactively address these concerns, guiding you to a material choice that optimizes long-term value, mitigating risks associated with material failure and ensuring project success. We focus on providing solutions that prevent costly issues down the line.

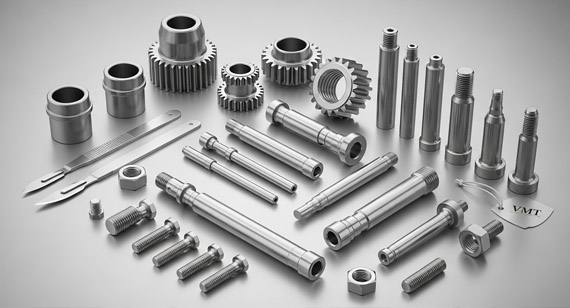

Source Manufacturer Advantage: High-Quality Parts and Transparent Pricing

As a source manufacturer based in Shenzhen, China, VMT CNC Machining Parts Services Factory operates directly, eliminating the markups and complexities associated with trading companies. This allows us to offer transparent, factory-direct pricing for both 410 and 316 stainless steel parts. Our extensive fleet of over 80 advanced CNC machines, including multi-axis centers, ensures efficient and precise machining, regardless of the material's challenges. With ISO9001 and IATF1649 certifications, our full-chain quality control guarantees that every part, whether 410 or 316, meets the highest industry standards. This commitment to quality and efficiency means you receive superior parts and a reliable partnership, making us a trusted choice for demanding sectors like aerospace, medical, and robotics.

Making the optimal material choice is a critical decision that influences product performance, longevity, and overall project economics. At VMT CNC Machining Parts Services Factory, we partner with you to dissect your project's specific requirements, offering expert guidance.

Precise Requirement Analysis: Operating Conditions, Environment, and Expected Lifespan

The selection process for 410 or 316 stainless steel must begin with a thorough analysis of your application's unique demands. Consider the following:

Operating Environment: Is the part exposed to moisture, chemicals (e.g., acids, chlorides, alkalis), extreme temperatures, or abrasive conditions? Highly corrosive or chloride-rich environments strongly favor 316.

Mechanical Stresses: Does the part require high hardness, wear resistance, or significant tensile strength? If so, heat-treated 410 might be more suitable.

Temperature Range: Are there sustained high temperatures or cryogenic conditions? 316 generally performs better at both extremes than 410.

Regulatory Compliance: Does your industry (e.g., medical, food processing) mandate specific material grades or certifications for biocompatibility or hygiene? 316 is often preferred here.

Expected Lifespan: What is the desired service life of the component? Investing in a more corrosion-resistant material like 316 might be more economical in the long run if longevity in harsh conditions is paramount.

Weldability & Fabrication: Are complex welding operations required? 316 is significantly easier to weld without post-weld treatment.

Expert Advice: Customized Material Selection Solutions

Navigating the complexities of material science and application-specific requirements can be challenging. This is where the expertise of VMT CNC Machining Parts Services Factory becomes invaluable. Our team of experienced engineers specializes in providing customized material selection solutions. We don't just process your order; we collaborate with you, offering DFM advice, rapid prototyping (often within 24 hours), and no minimum order quantity (MOQ) services to test and validate your choices. By understanding your specific project parameters, we can recommend whether the high strength of 410 or the superior corrosion resistance of 316, or perhaps another specialized material from our handling expertise (e.g., titanium, various aluminum alloys), will deliver the optimal balance of performance and cost-effectiveness for your precision parts.

Ultimately, the choice between 410 and 316 stainless steel is not about one being inherently "better," but rather which material is best suited for your specific application's demands.

Choose 410 stainless steel when your primary concerns are high mechanical strength, hardness, wear resistance, and the ability to be heat treated for robust performance, especially in moderately corrosive or high-temperature environments. It often presents a lower initial material cost.

Choose 316 stainless steel when superior corrosion resistance, particularly against chlorides, excellent weldability, and enhanced toughness (even at cryogenic temperatures) are critical. It is the preferred choice for marine, chemical processing, medical, and food-grade applications, offering a higher long-term value despite a greater initial investment.

At VMT CNC Machining Parts Services Factory, we are committed to being more than just a supplier; we are your strategic partner. With our advanced equipment, rigorous ISO9001 and IATF1649 certified quality control, and deep technical expertise, we ensure that your decision leads to high-quality, high-performing components.

Contact our material experts today for a tailored consultation, receive your customized material selection advice, and obtain transparent, factory-direct pricing for your high-quality custom machined parts. Experience the advantage of partnering with a leading source manufacturer for precision CNC machining.

What is the primary difference between 410 and 316 stainless steel?

The primary difference lies in their composition and resulting properties. 410 is a martensitic stainless steel, known for its high strength, hardness, and wear resistance after heat treatment. It contains less chromium and no molybdenum, offering moderate corrosion resistance. 316 is an austenitic stainless steel, characterized by superior corrosion resistance, especially against chlorides, due to its higher nickel and chromium content plus molybdenum. It is more ductile and weldable but cannot be hardened by heat treatment.

Can 410 stainless steel be heat treated?

Yes, 410 stainless steel is specifically designed to be heat treated. It can be hardened by quenching and tempering to achieve high levels of strength and hardness, making it suitable for applications requiring wear resistance and robust mechanical properties. This process transforms its microstructure to martensite.

Why is 316 stainless steel often more expensive than 410?

316 stainless steel is typically more expensive due to its higher alloy content, particularly the presence of nickel and molybdenum. These elements significantly enhance its corrosion resistance, especially against pitting and crevice corrosion in harsh environments, making it a premium material for demanding applications.

Which stainless steel is better for marine applications?

316 stainless steel is overwhelmingly preferred for marine applications. Its molybdenum content provides superior resistance to pitting and crevice corrosion in chloride-rich environments like saltwater, where 410 stainless steel would quickly succumb to corrosion.

Can VMT CNC Machining Parts Services Factory machine both 410 and 316 stainless steel?

Absolutely. As a source manufacturer with over 80 advanced CNC machines, including 5-axis capabilities, we have extensive experience and expertise in precision machining both 410 and 316 stainless steel. Our technical team is proficient in optimizing machining parameters for each material's unique properties to achieve the highest quality and precision.

Is 316 stainless steel suitable for high-temperature applications?

316 stainless steel exhibits excellent high-temperature properties, including good creep resistance and strength retention up to approximately 870°C (1600°F) for continuous service. While 410 can withstand moderately high temperatures, 316 generally offers better long-term stability and corrosion resistance at elevated temperatures.

What are the machinability considerations for these materials?

410 stainless steel is fairly machinable in its annealed condition, but its high hardness after heat treatment requires robust tooling and specific cutting parameters. 316 stainless steel is known for good machinability but can work-harden rapidly, requiring slower speeds and heavier cuts to prevent gummy chip formation and maintain tool life. Our DFM experts provide tailored advice to optimize processing for both.

How does VMT CNC help clients choose between 410 and 316?

We offer comprehensive technical consultation. Our engineers analyze your project's specific operating conditions, environmental factors, mechanical requirements, and budget. We provide detailed DFM reports and can assist with rapid prototyping to validate material choices. Our goal is to ensure you select the most suitable and cost-effective material, leveraging our deep technical expertise and transparent, factory-direct pricing to support your project's success.