15 years one-stop China custom CNC machining parts factory

52 |

Published by VMT at Oct 07 2025 | Reading Time:About 3 minutes

52 |

Published by VMT at Oct 07 2025 | Reading Time:About 3 minutes

Is unpredictable tool wear, inconsistent quality, or skyrocketing costs in nickel-based superalloy machining derailing your critical projects? You're not alone. Discover how leveraging a source manufacturer's deep technical expertise can transform your most challenging superalloy designs into high-performance realities, delivered with unmatched precision and transparent pricing. This endeavor, honestly, requires more than just machinery; it demands an intricate comprehension of metallurgy and mechanics, a truth many overlook until it is too late.

Manufacturing high-performance components from nickel-based superalloys necessitates unparalleled precision and an intimate understanding of these materials' vexing properties. Our dedicated expertise ensures the fabrication of critical parts that meet the most exacting specifications, consistently and reliably. This capability is paramount for industries where failure is simply not an option.

Machining nickel-based superalloys presents formidable challenges due to their unique properties, necessitating advanced strategies, specialized tooling, and rigorous process control. Success hinges on a deep understanding of material characteristics, meticulous planning, optimized cutting parameters, and comprehensive quality assurance. As a source manufacturer, our expertise transforms these inherent difficulties into high-quality, precise, and reliable components.

Nickel-based superalloys, a truly remarkable class of materials, exhibit extraordinary mechanical strength, paramount creep resistance, and exemplary oxidation resistance at elevated temperatures, often exceeding 500°C. Their crystalline structure, typically face-centered cubic, fortified by intricate alloying elements—chromium, cobalt, molybdenum, aluminum, titanium, and niobium, among others—bestows upon them their formidable characteristics. These alloys are not merely metals; they are meticulously engineered compositions, designed for the most demanding environments imaginable.

Key Alloying Elements and Their Roles

| Alloying Element | Primary Contribution |

| Chromium | Oxidation and corrosion resistance |

| Molybdenum | High-temperature strength, creep resistance |

| Aluminum | Gamma prime (γ') strengthening, oxidation resistance |

| Titanium | Gamma prime (γ') strengthening |

| Cobalt | Solid solution strengthening, thermal stability |

| Niobium | Carbide precipitation, creep resistance |

Common Nickel-Based Superalloy Grades

| Alloy Grade | Primary Application Sector | Noteworthy Characteristics |

| Inconel 718 | Aerospace, Oil & Gas, Nuclear | Excellent tensile, creep-rupture strength |

| Hastelloy C-276 | Chemical Processing, Pollution Control | Exceptional corrosion resistance |

| Waspaloy | Gas Turbines, Jet Engines | High strength up to 870°C, good fatigue |

| Rene 41 | Rocket Engines, Turbine Blades | Outstanding high-temperature strength |

Delving into the nature of nickel superalloys reveals a paradox: their exceptional performance attributes make them indispensable, yet these very qualities render their machining an exceedingly formidable task. Imagine, if you will, a material designed to resist virtually everything—that's what we're contending with here!

Unique Material Characteristics & Applications

These alloys possess astounding strength at high temperatures, a low coefficient of thermal expansion for most, and remarkable resistance to oxidation and corrosion, factors that collectively assure their indispensable role across various high-stakes sectors. Consider their application spectrum—ranging from jet engine turbine blades, which endure unfathomable thermal and mechanical stresses; to critical components within nuclear reactors, where integrity is paramount; and even in biomedical implants, demanding biocompatibility and long-term durability. Each application cries out for a material that simply will not yield under duress.

Application Sectors

Key Machinability Challenges of Superalloys

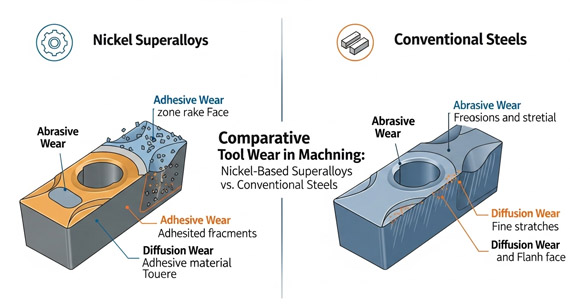

The intrinsic microstructure of nickel superalloys, rich in hard carbide precipitates and intermetallic phases, presents a profound obstacle to conventional machining processes. This leads to exasperating issues: pronounced work hardening, which means the material becomes even harder as you try to cut it; intense heat generation at the cutting zone, threatening both tool and workpiece integrity; and chip characteristics that are notoriously difficult to manage, producing long, stringy, and hot swarf that can wrap around tools and ruin surfaces. This is a battle, truly, for every millimeter.

Impact of High-Temperature Strength on Machining

Their retained strength at elevated temperatures—a core advantage in application—becomes a significant detriment during machining. The workpiece maintains its rigidity and hardness even when exposed to the considerable heat generated by the cutting action, necessitating higher cutting forces and accelerating tool degradation. Consequently, this leads to rapid cratering, flank wear, and edge chipping on cutting inserts, resulting in alarmingly brief tool life and, ultimately, exorbitant production costs. It's a cruel irony, isn't it?

Success in machining these formidable materials, honestly, pivots entirely on meticulous pre-operational strategizing. One cannot simply dive in, hoping for the best; that path invariably leads to catastrophic failure and mountains of scrap.

Material Selection and Part Design Considerations

Optimum material selection for a given application is the initial, pivotal decision, influencing everything from manufacturability to ultimate performance. Designing parts with machinability in mind—incorporating generous radii, avoiding overly thin walls, and minimizing deep, narrow pockets—can dramatically mitigate subsequent processing difficulties. Foresight here is absolutely irreplaceable. We've witnessed firsthand the struggles of designs that utterly disregard manufacturing realities.

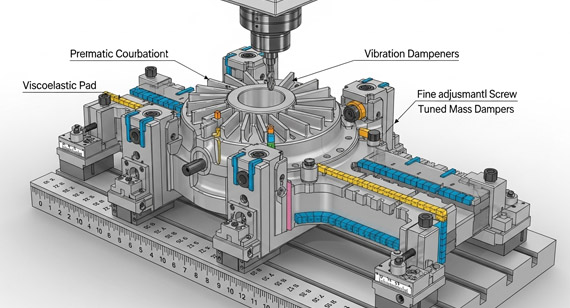

Rigging and Fixturing Best Practices for Superalloys

The sheer forces involved in machining nickel superalloys necessitate exceptionally robust workholding solutions. Rigid fixturing, which minimizes vibration and deflection, is paramount. Think heavy-duty clamps, specialized chucks, and custom jigs designed to dampen harmonics and maintain part stability throughout the entire machining cycle. A stable part, you see, is a precisely machined part—anything less is a recipe for disaster.

Machine Tool Requirements for Superalloy Machining

Our machine tools, let me tell you, are not merely off-the-shelf units. They are substantial, high-rigidity platforms with high spindle power, robust spindle bearings, and superior dampening capabilities, engineered specifically to withstand the intense cutting forces encountered with superalloys. Furthermore, advanced thermal compensation systems are integrated, ensuring dimensional stability even during prolonged, heat-generating operations. The machines themselves are part of the solution, undeniably.

The choice of cutting tools and the specific machining parameters employed constitute the very heart of successful nickel alloy fabrication. These are not merely suggestions; they are mandates, critical to avoiding an abysmal outcome.

Optimized Tool Material Selection and Geometries

Carbide inserts, particularly those with specific coatings like PVD or CVD, are often the workhorses for these materials, exhibiting a fine balance of toughness and wear resistance. However, for particular operations, ceramic tools or even polycrystalline cubic boron nitride (PCBN) might be deployed, especially in finish machining, where their extreme hardness can yield superior surface finishes. The geometry, mind you, matters just as much: sharp, positive rake angles, along with appropriate chip breakers, are critical for minimizing cutting forces and promoting effective chip evacuation. It's a constant quest for the perfect edge.

Tool Material Considerations

Feeds, Speeds, and Depth of Cut Optimization

This is where the magic, or the mayhem, happens. For nickel superalloys, one generally leans towards lower cutting speeds, moderate feeds, and controlled depths of cut. High speeds, unlike with softer materials, catastrophically accelerate tool wear due to the intense heat and chemical reactions. Striking the precise balance—often requiring iterative testing and deep empirical data—is absolutely paramount for both tool longevity and workpiece quality. Too fast, and you incinerate the tool; too slow, and you simply polish the material.

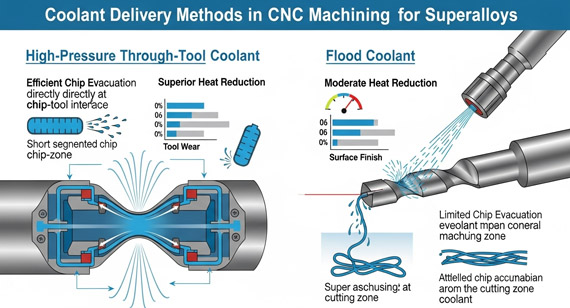

Coolant and Lubrication Techniques for Superalloys

Effective heat dissipation and lubrication are indispensable. High-pressure through-tool coolant, often applied at pressures exceeding 70 bar, delivers the fluid directly to the cutting zone, providing both cooling and efficient chip evacuation. Minimum quantity lubrication (MQL), utilizing an air-oil mist, can also be employed in specific scenarios, reducing environmental impact while still providing critical lubrication. A flood of coolant, however, can be deceivingly less effective than a highly targeted, pressurized stream.

Minimizing Tool Wear and Maximizing Tool Life

Achieving acceptable tool life in superalloy machining is an ongoing, truly formidable engineering challenge. Strategies involve tool path optimization to distribute wear evenly, regular insert indexing, and predictive maintenance schedules based on real-time tool monitoring. Honestly, sometimes it feels like a chess match against an exceptionally stubborn opponent. We meticulously track tool performance, gathering data that informs our subsequent strategic adjustments, ensuring we extract every ounce of utility from each cutting edge.

Fabricating parts from nickel superalloys demands not merely a shape, but a precise, immaculate component, devoid of any deleterious subsurface alterations. This requires an almost obsessive attention to detail.

Controlling Dimensional Accuracy and Tolerances

Holding tight dimensional tolerances—often in the micrometre range—is a defining characteristic of high-end superalloy machining. This feat is accomplished through a confluence of factors: the aforementioned rigid machine tools, precise control over cutting parameters, consistent thermal management, and meticulous in-process gaging. Every single variable, one might say, is under the microscope. Variations, however minute, can utterly ruin a critical part.

Surface Finish and Microstructural Integrity

Surface finish, measured in Ra values, is not merely cosmetic; it directly impacts component performance, fatigue life, and corrosion resistance. Achieving mirror-like finishes, crucial for aerospace or medical applications, requires specialized finishing passes, often with light depths of cut and precise tooling. The underlying microstructure must remain untainted; any evidence of heat-affected zones, micro-cracks, or metallurgical degradation renders the part defective. We scrutinize every surface.

Preventing Work Hardening and Residual Stress

Work hardening, that infuriating tendency of superalloys to become harder as they are cut, is combated through sharp tools, correct cutting parameters, and avoiding multiple passes that graze the surface. Residual tensile stresses, a byproduct of improper machining, are equally insidious, significantly reducing fatigue life. Our processes aim to induce compressive residual stresses, which are beneficial, through optimized cutting strategies and sometimes, subsequent surface treatments like shot peening. Preventing these unseen scourges is paramount.

Post-Machining Treatment and Inspection Protocols

Once machined, these parts often undergo various post-processing steps: stress relief heat treatments to alleviate internal stresses, specialized cleaning procedures to remove any surface contaminants, and extensive non-destructive testing (NDT) such as eddy current, ultrasonic, or penetrant inspection to detect any subsurface anomalies. Our multi-stage quality control is nothing short of exhaustive.

Navigating the treacherous landscape of superalloy machining means proactively addressing the common pitfalls that can otherwise lead to utterly calamitous outcomes.

Troubleshooting Chip Control Issues

Stringy, entangled chips are a perennial nuisance. They can scratch finished surfaces, clog tooling, and even pose safety hazards. Effective chip control hinges on optimized tool geometries that induce a tighter curl, combined with precise feed rates and high-pressure coolant to break and evacuate chips swiftly. Sometimes, admittedly, it feels like we are sculpting spaghetti. But we prevail.

Managing Heat Generation and Thermal Stability

Heat is the arch-nemesis of superalloy machining. Without meticulous management, it causes accelerated tool wear, thermal distortion of the workpiece, and even undesirable metallurgical changes. We employ a combination of optimal cutting parameters, advanced cooling techniques, and, in some instances, cryogenic machining to maintain thermal stability throughout the operation. A runaway thermal situation is, in essence, a death knell for the part.

Addressing Vibration and Chatter in Machining

Vibration, or chatter, is a destructive force, leading to poor surface finish, accelerated tool wear, and dimensional inaccuracies. It's an auditory manifestation of process instability. We combat this through rigid machine tools, optimized workholding, selection of tools with high dynamic stiffness, and careful tuning of cutting parameters to avoid resonant frequencies. A stable, quiet cut is invariably a superior cut.

Honestly, the journey to mastering nickel superalloy machining is a relentless pursuit, paved with countless hours of research, development, and, frankly, occasional failures from which we derive invaluable lessons. It seems to me, this is what differentiates a mere machine shop from a genuine expert source.

Leveraging Source Manufacturing for Quality Control

As a dedicated source manufacturer, our control over the entire production lifecycle is absolute—from material procurement, through every single machining operation, to final inspection and certification. This complete oversight allows us to implement a multi-tiered quality management system, ensuring unparalleled traceability and adherence to the most stringent aerospace, medical, and energy sector standards. We don't just make parts; we engineer trust. It's a profound difference, you understand.

Transparent Pricing and Project Management

We believe in pricing that is not only competitive but entirely transparent. Our detailed quotations break down costs, offering clarity and eliminating unforeseen expenditures. This approach, paired with our proactive project management—including regular progress updates, responsive communication, and contingency planning—ensures your projects remain on schedule and within budget. No hidden fees. No unpleasant surprises. That's our promise.

Case Studies: Complex Superalloy Components

Consider a recent project: an intricate Inconel 718 fuel nozzle for an aerospace client. Their previous suppliers struggled with tool wear and maintaining the precise internal geometries, leading to unacceptably high scrap rates and significant delays. Our solution, after all, involved proprietary micro-tooling, an optimized five-axis simultaneous machining strategy, and real-time thermal compensation. The outcome? Flawlessly machined parts delivered ahead of a demanding schedule, not only meeting but exceeding every stringent specification. We transformed their problem into a truly mind-blowing success.

Partnering for Your High-Performance Needs

Collaborating with us means gaining a partner equipped with deep technical expertise, robust manufacturing capabilities, and an unwavering commitment to quality. We thrive on the challenges presented by advanced materials and complex geometries, continuously innovating to push the boundaries of what's feasible. Your most critical projects—indeed, your vision—deserve nothing less than our full, uncompromised dedication.

1. What are the primary challenges of CNC machining nickel-based superalloys?

The primary challenges stem from their inherent properties: extreme hardness, high-temperature strength, rapid work hardening tendencies, and abrasive microstructures. These factors lead to accelerated tool wear, intense heat generation, and difficult chip control, all of which compromise dimensional accuracy and surface integrity if not managed meticulously. It is an arduous task.

2. Why is tool selection so crucial for machining superalloys?

Tool selection is absolutely paramount because conventional tools cannot withstand the severe conditions. Specialized tool materials like coated carbides, ceramics, and PCBN, combined with optimized geometries that promote chip flow and minimize cutting forces, are essential to achieve acceptable tool life and maintain workpiece quality. Incorrect tooling guarantees catastrophic failure, undeniably.

3. How do you manage heat generation during superalloy machining?

We manage heat generation through a multifaceted approach: employing optimal, lower cutting speeds; utilizing high-pressure, through-tool coolant delivery to the cutting zone for superior cooling and chip evacuation; and, for specific applications, exploring advanced techniques such as cryogenic machining. Thermal management is critical to prevent material degradation and tool failure.

4. What are common nickel-based superalloys you machine?

Our expertise extends to a comprehensive range of nickel-based superalloys, including popular grades such as Inconel 718, Hastelloy C-276, Waspaloy, and Rene 41. Each alloy possesses distinct characteristics and requires a tailored machining approach, which we meticulously develop for every project. This versatility is, frankly, indispensable.

5. What benefits does a "source manufacturer" offer for superalloy machining projects?

As a source manufacturer, we offer complete control over the entire production chain—from material sourcing and process optimization to machining, quality inspection, and certification. This integrated approach ensures consistent quality, full traceability, and efficient project management, significantly de-risking your critical superalloy component projects. You gain unparalleled reliability.

6. How do you ensure the surface integrity of machined superalloy parts?

Ensuring surface integrity involves careful selection of finishing tools and parameters to achieve the required Ra values, avoiding heat-affected zones, and minimizing residual tensile stresses. Post-machining treatments, such as stress relief heat treatments, and rigorous non-destructive testing protocols are also integral to verifying the material's microstructural integrity. We leave absolutely no stone unturned.

7. Can VMT CNC assist with design for manufacturability (DFM) for superalloy components?

Absolutely. Our deep technical expertise includes extensive knowledge in design for manufacturability (DFM) specifically for nickel-based superalloys. We proactively collaborate with your design engineers to optimize part geometries, suggest material alternatives if appropriate, and identify potential machining challenges early in the design phase, thus saving considerable time and cost. Foresight, in our view, is a powerful tool.

8. What is your approach to transparent pricing for complex superalloy projects?

Our approach to transparent pricing is straightforward: we provide detailed, itemized quotations that clearly outline all costs involved, from material and tooling to labor and quality control. We believe in open communication regarding project scope and potential variables, ensuring you have a complete and predictable understanding of your investment. No surprises, ever!

Ready to transform your most demanding nickel-based superalloy designs into high-quality, high-performance components with confidence? As a trusted source manufacturer with deep technical expertise and transparent pricing, we're ready to partner with you. Request a transparent quote today or schedule a technical consultation with our superalloy machining experts to discuss your project's specific needs. We guarantee, your peace of mind is our paramount concern; anything less would be a dereliction of duty.