15 years one-stop China custom CNC machining parts factory

67 |

Published by VMT at Oct 03 2025

67 |

Published by VMT at Oct 03 2025

The choice between high-performance nickel alloys like Monel and Inconel is a critical engineering decision. Overlooking the nuances can lead to catastrophic project failures, expensive material waste, and compromised operational integrity. We've witnessed firsthand how a misstep here reverberates through an entire system.

This isn't just about material properties; it’s about a deeply informed application, understanding the intricate balance of environment, stress, and cost. Ultimately, it’s about ensuring your components perform flawlessly under immense pressure.

Monel and Inconel are both high-strength, corrosion-resistant nickel alloys vital for demanding applications. Monel, primarily nickel and copper, excels in marine environments, resisting saltwater and acids. Inconel, a nickel-chromium superalloy, withstands extreme heat, pressure, and oxidation, making it indispensable for aerospace and high-temperature industrial uses.

Monel is a series of nickel-copper alloys, truly a workhorse in environments where other metals simply degrade. Its unique composition grants it exceptional resistance to a spectrum of corrosive agents. We frequently turn to it for its proven resilience.

Monel alloys are predominantly composed of nickel (typically 52-67%) and copper (30-32%), with smaller additions of iron, manganese, carbon, and silicon. This specific blend is what dictates its formidable properties. It’s an alloy perfected for specific, harsh conditions.

How is Monel Manufactured?

The manufacturing process for Monel typically involves melting raw materials in a vacuum induction furnace or electric arc furnace. This molten metal is then cast into ingots. Subsequent steps include hot working, such as forging or rolling, followed by cold working and annealing to achieve the desired mechanical properties and shapes. Precision control at every stage is paramount.

While the core nickel-copper blend defines Monel, subtle variations in composition and processing yield distinct types, each optimized for particular applications. It's truly fascinating how minor adjustments unlock entirely new capabilities. Let's dissect them.

Monel 400

Monel 400 is arguably the most common and versatile, renowned for its excellent corrosion resistance in a broad range of media, including seawater. Its ductility and good thermal conductivity make it highly adaptable. This alloy truly shines in marine and chemical processing.

Monel 401

Monel 401 is primarily used for specialized electrical applications. It boasts a very low temperature coefficient of electrical resistivity. This specific property makes it ideal where stable electrical performance is crucial.

Monel 404

Monel 404 is characterized by its exceptionally low permeability and Curie temperature. This makes it invaluable for certain electronic applications where magnetic interference must be strictly controlled. It’s a niche, but absolutely critical, variant.

Monel 405

Often referred to as R-405, this free-machining variant of Monel 400 contains a controlled amount of sulfur. The sulfur acts as a chip breaker, dramatically improving machinability without significant compromise on corrosion resistance. It's a lifesaver for complex, precision parts.

Monel 450

Monel 450, sometimes referred to as Alloy 450, is primarily copper-based with nickel, offering good resistance to corrosion in flowing seawater. It finds specific use in condenser and heat exchanger tubing. Its unique balance of properties is undeniable.

Monel K-500

This is a precipitation-hardened variant of Monel 400, achieved by adding aluminum and titanium. Monel K-500 possesses superior strength and hardness, retaining its non-magnetic properties down to -102°C. Its enhanced mechanical strength is a game-changer for many engineers.

Monel 502

Monel 502, another precipitation-hardenable alloy, offers high strength and good corrosion resistance, similar to K-500. It’s often selected for demanding structural components in corrosive environments. We consider it when extreme durability is non-negotiable.

Every material has its trade-offs, and Monel is no exception. Understanding these facets is fundamental to sound engineering decisions. We must always weigh the benefits against potential limitations for optimal design.

Advantages of Monel

Monel presents a compelling array of benefits that often position it as the preferred material for specific, challenging conditions. Its inherent qualities are truly remarkable.

High Strength

Monel alloys exhibit impressive strength, often exceeding that of many steels, especially at elevated temperatures. This makes it suitable for structural components requiring robust mechanical integrity. It’s a strong contender, without question.

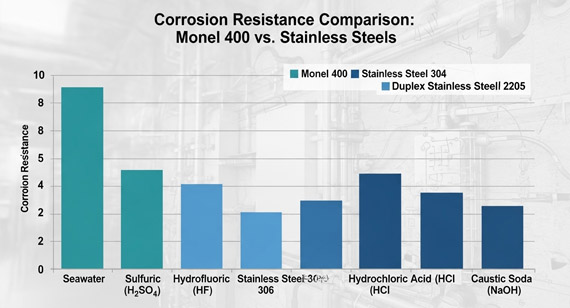

Excellent Corrosion Resistance

Its most celebrated attribute, Monel offers superior resistance to corrosion in various aggressive media, including saltwater, sulfuric acid, and hydrofluoric acid. This property is absolutely paramount for marine and chemical processing.

Yield Strength

With high yield strength, Monel can withstand significant stress before permanent deformation occurs. This is a critical factor in structural applications where component integrity under load is non-negotiable. It truly holds its ground.

Tensile Strength

Monel boasts high tensile strength, meaning it can endure substantial pulling forces without breaking. This characteristic ensures longevity and reliability in applications exposed to significant mechanical tension. Its robustness is often underestimated.

Lower Coefficient of Thermal Expansion

Compared to many other high-performance alloys, Monel has a relatively low coefficient of thermal expansion. This minimizes dimensional changes across varying temperatures, an essential consideration for precision assemblies. It helps maintain tight tolerances.

Weldability

Many Monel grades possess good weldability, allowing for relatively straightforward fabrication into complex shapes. This characteristic is vital for constructing intricate systems and large structures. It simplifies the manufacturing process considerably.

Low and High Temperature Applications

Monel maintains its strength and corrosion resistance across a broad temperature range, from cryogenic conditions to moderately high temperatures. This versatility broadens its application scope significantly. Truly impressive adaptability.

Non-Magnetic

Certain Monel alloys, particularly Monel 400 and K-500, are non-magnetic. This property is crucial for applications sensitive to magnetic interference, such as in electronic equipment or compass housings. It's a specific advantage we leverage often.

Corrosion Resistance of Wrought Nickel-Based Alloys

Monel, as a wrought nickel-based alloy, demonstrates exceptional resistance to various forms of corrosion, including pitting, crevice corrosion, and stress-corrosion cracking. This makes it incredibly reliable in hostile chemical environments. Its resilience is unquestionable.

Disadvantages of Monel

Despite its formidable strengths, Monel does come with certain engineering challenges that demand careful consideration. We must acknowledge these limitations to ensure successful project outcomes.

Fast Work Hardening

Monel alloys work-harden rapidly during machining or cold working, making them challenging to process. This necessitates specialized tools, slower speeds, and frequent annealing cycles. It's a truly frustrating setback if not planned for.

Pitting Corrosion

While generally highly corrosion-resistant, Monel can be susceptible to pitting corrosion in stagnant or low-velocity acidic solutions. This is a localized form of attack that can compromise structural integrity. Vigilance here is absolutely critical.

Galvanic Corrosion

When coupled with less noble metals in an electrolyte, Monel can accelerate galvanic corrosion in the other metal. Engineers must carefully consider material pairings to avoid this destructive phenomenon. It's a silent killer of components.

Expensive

Compared to common engineering materials like stainless steel, Monel is significantly more expensive due to its high nickel and copper content and complex manufacturing. Cost-benefit analysis is absolutely essential here.

Inconel is a family of nickel-chromium-based superalloys, engineered for extreme performance. When components must endure staggering heat, relentless pressure, and aggressive chemical attack simultaneously, Inconel is often our immediate thought. It truly defines "high-performance."

Inconel alloys are primarily composed of nickel (typically 50-70%) and chromium (15-25%), with additions of iron, molybdenum, niobium, and sometimes aluminum and titanium. These precise additions unlock its exceptional high-temperature strength and oxidation resistance. It's an intricate metallurgical marvel.

How is Inconel manufactured?

Inconel manufacturing involves complex metallurgical processes, often including vacuum induction melting (VIM) followed by vacuum arc remelting (VAR). This ensures ultra-high purity and fine grain structure. Subsequent hot and cold working, along with precise heat treatments, are critical for achieving optimal properties. The complexity is immense.

The Inconel family is vast, with each alloy meticulously designed for specific, often extreme, applications. Their distinct compositions are fine-tuned to tackle unique environmental stressors. We navigate this complexity daily.

Inconel 600

Inconel 600 is a standard engineering material for applications requiring corrosion and heat resistance. It's non-magnetic and exhibits excellent mechanical properties at both cryogenic and elevated temperatures. A truly versatile performer.

Inconel 625

This workhorse superalloy provides high strength and outstanding corrosion resistance across a wide temperature range, particularly against oxidizing and reducing acids. Its excellent fabricability is another significant advantage. We see it everywhere, from jet engines to chemical plants.

Inconel 718

Inconel 718 is a precipitation-hardenable nickel-chromium alloy known for its exceptional high-yield, tensile, and creep-rupture properties at temperatures up to 700°C (1290°F). Its weldability is also quite good for a superalloy. This is a staple in aerospace.

Inconel 825

Inconel 825 is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. It offers excellent resistance to many corrosive environments, including reducing and oxidizing acids, stress-corrosion cracking, and pitting. It's a robust choice for highly acidic conditions.

Inconel’s performance envelope is truly impressive, but it comes with its own set of challenges. Engineers must possess a deep understanding of these characteristics to fully leverage its potential.

Advantages of Inconel

The benefits of Inconel are truly compelling, driving its widespread use in the most demanding industries. Its capacity to perform under extreme duress is unparalleled.

Corrosion resistance

Inconel alloys exhibit outstanding corrosion resistance, particularly to high-temperature oxidation and aggressive chemical media. This is largely due to the stable, passivating oxide layer that forms on its surface. It's an impenetrable shield.

High strength and structural stability

Inconel maintains exceptional strength and structural integrity at extremely high temperatures where many other metals would yield or deform. This makes it ideal for components under intense thermal and mechanical stress. It simply does not buckle.

Oxidation resistance

The chromium content in Inconel forms a robust, protective oxide layer that resists high-temperature oxidation. This property is crucial for components operating in hot, aggressive gas streams. It keeps the surface pristine.

Combined corrosion resistance, mechanical strength, and heat resistance

This triple threat makes Inconel indispensable for critical applications. Few materials can simultaneously offer such a formidable combination of properties. It’s an engineering marvel.

Resistance to creep deformation

Inconel alloys display superior resistance to creep, which is the tendency of a solid material to slowly move or deform permanently under the influence of mechanical stresses. This ensures long-term reliability in high-temperature, load-bearing applications. It holds its shape, relentlessly.

Good fatigue strength

Inconel exhibits excellent fatigue strength, enduring numerous stress cycles without failure. This is vital for dynamically loaded components like turbine blades or engine parts. Its endurance is truly remarkable.

Weldability

While challenging, certain Inconel grades possess good weldability, allowing for complex fabrication. This requires specialized techniques and expert welders, but the results are durable and precise. Precision welding is absolutely crucial here.

Disadvantages of Inconel

Despite its exceptional performance, Inconel presents significant challenges, primarily in its processing. These factors directly impact manufacturability and cost.

Complex manufacturing process

The production of Inconel requires highly controlled processes, including specialized melting and hot working techniques. This complexity contributes directly to its elevated cost and extended lead times. It's an intricate dance of metallurgy.

Machinability: Tool wear and workpiece hardening

Inconel is notoriously difficult to machine due to its high strength, toughness, and rapid work-hardening rate. This leads to extreme tool wear, requiring specialized tooling, low cutting speeds, and expert CNC programming. Machining Inconel is a true test of skill.

Susceptible to hydrogen embrittlement, which can affect mechanical properties when exposed to high-pressure or high-temperature hydrogen.

In specific environments, Inconel can be susceptible to hydrogen embrittlement, which can severely compromise its mechanical properties and lead to brittle failure. This is a critical consideration for hydrogen-rich applications. It’s a hidden vulnerability.

The selection of the right alloy is not merely a preference; it’s a rigorous exercise in engineering optimization. We must methodically analyze every variable to ensure the ultimate success and longevity of a project.

Decision Framework: Prioritizing Performance and Cost

Our decision-making always begins with a clear framework: what is the absolute minimum performance required, and what is the maximum acceptable cost? This dual lens helps us narrow down possibilities quickly. Compromise is not an option when performance is critical, but neither is ignoring budget.

The Role of Environment, Stress, and Temperature

These three factors are the bedrock of alloy selection. Is it a corrosive marine environment? Extreme cyclical stress? Sustained high temperatures? Each question guides us toward the alloy engineered for that specific battle. The environment dictates the material.

Collaboration for Expert Material Selection and Precision Machining

Frankly, choosing and machining these advanced alloys demands specialized expertise. Collaborating with a facility like VMT, which possesses deep metallurgical knowledge and advanced CNC capabilities, isn't just an option—it’s often a necessity for optimal results. We bridge the gap between material theory and precision reality.

Understanding the fundamental distinctions in properties between Monel and Inconel is absolutely essential for making informed engineering choices. This is where the rubber meets the road, metabolically speaking.

Monel and Inconel: Chemical Composition

The distinct chemical compositions are the root cause of their differing performance characteristics. A glance at their primary constituents immediately reveals their specialized design intent.

| Element | Monel 400 (Approx. %) | Inconel 625 (Approx. %) |

| Nickel (Ni) | 63 | 60 |

| Copper (Cu) | 31 | - |

| Chromium (Cr) | - | 21.5 |

| Molybdenum (Mo) | - | 9 |

| Iron (Fe) | 2 | 2.5 |

| Niobium (Nb) | - | 3.6 |

| Others | < 1 | < 1 |

Monel and Inconel: Physical Properties

Their physical attributes, such as density and melting point, offer further clues into their suitability for high-performance applications. These are the foundational numbers we work with.

| Property | Monel 400 | Inconel 625 |

| Density | 8.80 g/cm³ (0.318 lb/in³) | 8.44 g/cm³ (0.305 lb/in³) |

| Melting Point | 1300-1350°C (2370-2460°F) | 1290-1350°C (2350-2460°F) |

| Electrical Resistivity | 0.51 μΩ·m | 1.29 μΩ·m |

| Thermal Conductivity | 21.8 W/m·K | 9.8 W/m·K |

Monel and Inconel: Mechanical Properties

For an engineer, mechanical properties are paramount. They dictate how a material will behave under load, stress, and temperature variations. This is where the true performance comparison lies.

| Property | Monel 400 (Annealed) | Inconel 625 (Annealed) |

| Tensile Strength | 550 MPa (80 ksi) | 880 MPa (128 ksi) |

| Yield Strength | 240 MPa (35 ksi) | 460 MPa (67 ksi) |

| Elongation (in 2 in) | 40 % | 40 % |

| Hardness (Brinell) | 125 HB | 200 HB |

| Modulus of Elasticity | 179 GPa (26 x 10³ ksi) | 207 GPa (30 x 10³ ksi) |

The distinct properties of Monel and Inconel naturally lead them to excel in different, yet equally demanding, application sectors. Understanding these specific uses illuminates their strengths.

Monel:Applications and Uses

Monel's exceptional resistance to seawater and various acids makes it indispensable in several key industries.

Offshore Engineering: Used for marine fixtures, pump shafts, valves, and piping in saltwater environments. It resists corrosion from seawater, biofouling, and stress corrosion cracking. Its reliability underwater is paramount.

Chemical Processing: Ideal for heat exchangers, tanks, and piping handling sulfuric and hydrofluoric acids. Monel withstands highly corrosive chemical media where other alloys would fail. This ensures process safety and longevity.

Aerospace: Selected for aircraft structural components, wiring, and fasteners where high strength, low thermal expansion, and non-magnetic properties are required. It performs reliably under varying atmospheric conditions.

Oil and Gas: Utilized in wellhead components, downhole tooling, and piping systems exposed to corrosive brines and sour gas. Its resistance to sulfide stress cracking is invaluable here. It prevents catastrophic failures.

Electronics: Monel 404 is specifically chosen for sensitive electronic components, particularly in transformers and electrical meters. Its low magnetic permeability ensures signal integrity. Precision and stability are key.

Inconel: Applications and Uses

Inconel's ability to withstand extreme temperatures and harsh environments makes it critical for high-stakes applications.

Aerospace: Forms jet engine components, turbine blades, thrust reversers, and exhaust systems. It maintains strength and resists oxidation at blistering temperatures and high stresses. It’s absolutely fundamental to flight.

Heat Treating: Used for furnace components, heat exchanger tubing, and radiant tubes in high-temperature industrial furnaces. It resists thermal fatigue and high-temperature creep. This ensures furnace efficiency and safety.

Nuclear Power: Selected for reactor core components, control rod drive mechanisms, and steam generator tubing. Inconel offers radiation resistance and maintains mechanical properties in aggressive reactor environments. Safety is the ultimate priority.

Automotive and Motorsports: Employed in exhaust systems for high-performance vehicles, turbocharger components, and racing engine valves. It withstands extreme heat and corrosive exhaust gases, boosting performance. Every millisecond counts.

Marine and Offshore Engineering: Utilized for high-temperature and high-pressure components in offshore platforms and marine vessels, especially where fire resistance or extreme heat is a concern. Its robust nature is crucial for survival.

The inherent properties that make these alloys so valuable also make them incredibly challenging and costly to machine. This is a reality we face every day in our shop.

Challenges of CNC Machining Monel Alloy

Monel's tendency to work-harden rapidly presents significant hurdles during CNC machining. Tools dull quickly, demanding lower cutting speeds and depths, and precise coolant application. It's like cutting through hardened butter—if you don't do it just right, you ruin the butter and your knife.

Inconel Machining Expertise

Machining Inconel is an even higher art form. Its extreme hardness and high-temperature strength translate to intense heat generation at the cutting edge. Specialized ceramic or carbide tooling, advanced machine rigidity, and often cryo-cooling are essential. It pushes the boundaries of what's possible in a machine shop.

Material Sourcing and Manufacturing Cost Factors

Both alloys are premium materials, reflecting their complex metallurgical compositions and specialized processing. Sourcing them can involve long lead times and substantial upfront costs. This isn't off-the-shelf steel; it's a specialty item.

When we talk about the bottom line, it's clear: both Monel and Inconel command higher prices than conventional alloys.

However, Inconel generally incurs significantly higher machining costs per part due to its superior hardness and abrasive nature. The increased tool wear, slower cycle times, and the need for specialized equipment contribute to this difference. Monel is challenging, but Inconel is truly the ultimate test.

This is the ultimate question, isn't it? The answer is rarely simple, but we can establish clear guiding principles. It always boils down to balancing critical performance needs with realistic economic constraints.

When to Choose Monel Alloy?

Choose Monel when excellent corrosion resistance to saltwater, sulfuric acid, or hydrofluoric acid is paramount, especially at moderate temperatures. Its good strength and non-magnetic properties are also key drivers. Think marine environments, chemical processing, and some aerospace applications.

When to Choose Inconel?

Opt for Inconel when extreme high-temperature strength, exceptional oxidation resistance, and superior creep resistance are non-negotiable. This is for environments with intense heat, high stress, and corrosive gases. Aerospace, nuclear, and specific high-performance industrial applications immediately come to mind.

At VMT, we pride ourselves on tackling the seemingly impossible machining challenges presented by advanced alloys like Monel and Inconel. Our expertise isn't just theoretical; it's built on years of hands-on experience and a relentless pursuit of precision. We understand the unique metallurgical behaviors of these materials.

Our facility is equipped with state-of-the-art CNC machinery capable of handling the extreme rigidity and precise control required for these superalloys. We invest in the latest tooling technologies—custom inserts, specialized coatings—to minimize tool wear and maintain exacting tolerances. From concept to finished part, our process is meticulously controlled. We optimize every feed, speed, and cutting strategy to overcome Monel's work-hardening and Inconel's formidable strength. Our engineers, truly, are problem-solvers. We deliver components that meet the most stringent specifications, ensuring your projects succeed where others might falter.

A client in offshore engineering required high-pressure valve components for a new deep-sea drilling rig. The operational environment was brutal: constant saltwater immersion, high pressure, and exposure to corrosive brines. Standard stainless steels simply wouldn't suffice; the risk of premature failure was too high.

After meticulous consultation, we advised on Monel 400 for its unparalleled resistance to saltwater corrosion and excellent mechanical strength. Our team then developed a specialized machining program. We utilized specific carbide tooling, employed slower cutting speeds, and implemented multi-stage stress-relief annealing to counteract Monel's rapid work-hardening.

The result? VMT delivered a batch of flawlessly machined Monel 400 valve bodies and stems. These components exhibited exceptional dimensional accuracy and surface finish. The client reported superior performance and extended operational life compared to their previous solutions, a direct testament to precise material selection and VMT’s machining expertise. It proved, once again, that the right material, expertly processed, solves critical problems.

The journey from raw alloy to a precision component is an intricate one, especially with materials like Monel and Inconel. We've dissected their unique strengths, acknowledged their challenges, and laid out a framework for informed decision-making. Ultimately, the choice between Monel and Inconel hinges on a rigorous analysis of your application's environmental demands, mechanical stresses, and thermal profile. It's a complex equation, but one we at VMT are uniquely qualified to help you solve. Our expertise in precision machining these superalloys ensures that your critical components perform exactly as intended, every single time. The stakes are simply too high to leave it to chance.

What is Monel's main advantage?

Monel's paramount advantage is its exceptional corrosion resistance, particularly against saltwater and various acids. It excels in marine and chemical processing environments. This property ensures long-term reliability in harsh conditions.

What is Inconel best used for?

Inconel is best suited for extreme high-temperature applications requiring superior strength, oxidation resistance, and creep resistance. It is indispensable in aerospace, nuclear, and high-performance automotive sectors.

Is Monel magnetic?

Most common Monel alloys, like Monel 400 and K-500, are non-magnetic. This characteristic is crucial for applications sensitive to magnetic interference, such as certain electronic devices.

Why is Inconel so hard to machine?

Inconel is incredibly hard to machine due to its high strength, toughness, and rapid work-hardening properties. It causes severe tool wear and requires specialized tooling and slow cutting speeds.

Which is stronger, Monel or Inconel?

Generally, Inconel alloys exhibit significantly higher strength and structural stability, especially at elevated temperatures, compared to Monel. Inconel is truly a superalloy for extreme conditions.

Can Monel be welded?

Yes, many Monel grades possess good weldability, allowing for fabrication into complex shapes. However, precise welding techniques are necessary to maintain optimal properties and prevent issues.

What is hydrogen embrittlement in Inconel?

Hydrogen embrittlement is when Inconel's mechanical properties degrade due to exposure to high-pressure or high-temperature hydrogen. It can lead to brittle failure and is a critical design consideration.

Why choose VMT for these alloys?

VMT offers specialized expertise and advanced CNC capabilities for machining Monel and Inconel. Our experience ensures precision, efficiency, and component reliability, overcoming the inherent challenges of these materials.