15 years one-stop China custom CNC machining parts factory

53 |

Published by VMT at Oct 04 2025 | Reading Time:About 3 minutes

53 |

Published by VMT at Oct 04 2025 | Reading Time:About 3 minutes

Understanding 14 Steel Dimensions

The world of CNC machining demands absolute precision. Yet, a fundamental concept like steel thickness, often expressed in "gauge," can frequently lead to confusion. This ambiguity, my friends, is a problem. Misinterpreting gauge specifications can result in costly material waste, critical design flaws, and ultimately, project failure.

In an industry where every micron matters, such errors are not just setbacks; they are catastrophic to lead times and budgets. We’ve seen it firsthand. That's why gaining a definitive, expert-level understanding of 14-gauge steel is not merely beneficial—it is imperative for anyone in manufacturing.

This article serves as your authoritative guide. We will dissect 14-gauge steel, clarifying its precise dimensions, exploring its versatile applications, and detailing the manufacturing considerations that truly matter. Precision, I tell you, is everything.

Standard 14 Steel Thickness (Inches)

14-gauge steel refers to a specific, standardized thickness within the established sheet metal gauging system. It is a critical specification for design and fabrication. This system, originally known as the Birmingham Wire Gauge, assigns a number to a material's thickness.

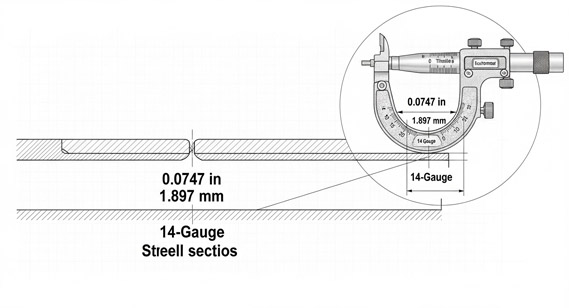

The exact thickness for 14-gauge mild steel is 0.0747 inches. It’s not just a rough estimate; it’s a precise engineering dimension. This value is paramount for accurate part design and predictable structural integrity.

Precise 14 Steel Measurements (Millimeters)

While inches provide the historical context, metric measurements offer universal clarity in our globally connected industry. For 14-gauge steel, that standard 0.0747-inch thickness translates directly.

In the metric system, 14-gauge steel measures exactly 1.897 millimeters. This conversion is crucial for international projects and for seamless integration into modern CAD/CAM software. We at VMT routinely operate in both.

Why the Steel Thickness System Exists: A Brief History

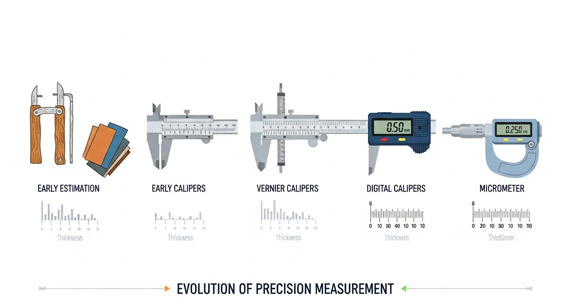

The gauge system, though seemingly counterintuitive with smaller numbers indicating greater thickness, emerged from practical necessity. Early wire and sheet manufacturers needed a quick, consistent way to describe material dimensions. This was before micrometers were commonplace.

It allowed for standardized ordering and fabrication across workshops, long before digital specifications became the norm. Think of it as an early, ingenious form of industrial classification. It simplified commerce, genuinely.

Navigating the nuances of steel thickness is far simpler with clear references. Our comprehensive chart provides the exact conversions you need. This is a foundational piece of data for any engineer or fabricator.

Comprehensive Steel Thickness and Size Comparison Chart

Understanding the gauge system requires a direct comparison. Notice how the gauge number decreases as the thickness increases—an inverse relationship that sometimes catches newcomers off guard. It's a system that truly dictates material properties.

Here is a comprehensive breakdown of common steel gauges and their precise dimensions:

| Gauge | Inches (in) | Millimeters (mm) |

| 20 | 0.0359 | 0.912 |

| 18 | 0.0478 | 1.214 |

| 16 | 0.0598 | 1.519 |

| 14 | 0.0747 | 1.897 |

| 12 | 0.1046 | 2.657 |

| 10 | 0.1345 | 3.416 |

| 9 | 0.1495 |

3.797 |

| 8 | 0.1644 |

4.176 |

| 7 | 0.1793 |

4.554 |

This table provides the definitive specifications. Use it as your go-to reference.

Common Steel Thicknesses in Manufacturing

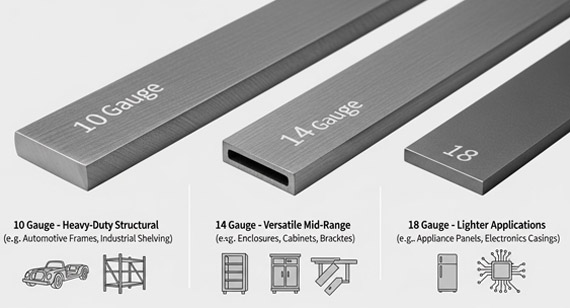

Each gauge thickness possesses a unique utility in manufacturing. Thinner gauges (e.g., 20, 18) are ideal for lightweight enclosures and non-structural panels. They are easily formed.

Thicker gauges (e.g., 12, 10) provide immense structural strength, suitable for heavy-duty frames and machinery. 14-gauge steel, however, strikes a remarkable balance. It’s an incredibly versatile choice.

Factors Affecting Actual Sheet Metal Dimensions

While the nominal gauge thickness is standardized, actual sheet metal dimensions can vary slightly. Manufacturing tolerances, though tight, inherently allow for minor deviations. It’s part of the process.

Material sourcing also plays a role; different mills may have slightly different process controls. Furthermore, post-processing such as annealing or plating can marginally alter final dimensions. Always account for this variability in design.

Choosing the right steel thickness is a critical engineering decision. It’s not just about strength; it’s about balancing performance, weight, and fabrication capabilities. 14-gauge often stands out as a preferred option.

Consider how 14-gauge steel positions itself against common alternatives:

| Gauge | Typical Applications | General Strength/Weight | Workability (Forming/Welding) |

| 16 Gauge | HVAC ducts, appliance panels, light automotive | Moderate strength, lower weight | Excellent, easily formed |

| 14 Gauge | Machine guards, electrical enclosures, structural brackets | Good strength, balanced weight | Very good, versatile |

| 12 Gauge | Heavy-duty enclosures, structural supports, chassis | High strength, significant weight | Good, requires more power |

| Feature |

14-Gauge Steel |

10-Gauge Steel |

18-Gauge Steel |

| Thickness (inches) |

0.0747 |

0.1345 |

0.0478 |

| Thickness (mm) |

1.897 |

3.416 |

1.214 |

| Relative Strength |

Good |

Excellent |

Moderate |

| Relative Weight |

Medium |

Heavy |

Light |

| Formability |

Good |

Moderate |

Excellent |

| Typical Applications |

Enclosures, brackets, panels |

Structural components, heavy frames |

HVAC ducting, appliance casings |

| Cost Consideration |

Moderate |

Higher |

Lower |

This comparison highlights 14-gauge's balanced characteristics. It’s a robust choice without being excessively heavy or difficult to work with.

14-gauge steel is a workhorse in our factory, finding its way into an astonishing array of products. Its balance of strength, formability, and cost-effectiveness makes it genuinely ubiquitous.

Typical Uses and Applications of 14 Steel Components

The sweet spot of 14-gauge steel lies in its ability to provide substantial rigidity without excessive weight or bulk. It excels where moderate load-bearing capacity and robust enclosure capabilities are needed. It’s truly versatile.

Automotive Manufacturing

In automotive production, 14-gauge steel is frequently used for structural brackets, interior components, and specific body panels where enhanced rigidity is required. Its durability is a significant asset here.

Medical Devices

For medical equipment, sterility and structural integrity are paramount. 14-gauge forms robust housings for diagnostic machines, equipment carts, and patient support structures, ensuring both safety and longevity.

Industrial Equipment

From machine guards that protect personnel to durable control cabinets and robust enclosures, 14-gauge steel is a staple in industrial equipment. It withstands harsh operational environments, time and again.

Optical Industry

Precision optical instruments demand stable, rigid chassis. 14-gauge steel provides the necessary structural support for sensitive lenses and sensors, minimizing vibration and maintaining critical alignments. It’s a subtle but vital component.

Electronics

Think robust server racks, telecommunication enclosures, and custom electronics chassis. 14-gauge steel offers excellent protection for sensitive internal components, providing both physical security and often electromagnetic shielding.

Construction

While not for primary structural beams, 14-gauge steel finds its place in lighter framing, flashing, ductwork, and various non-load-bearing architectural elements. Its weather resistance and formability are valued.

Effects of Thickness on Part Strength and Weight

The relationship between thickness, strength, and weight is a fundamental engineering principle. A thicker material, naturally, exhibits greater resistance to bending, torsion, and compressive forces. More material simply means more load-bearing capacity.

However, increased thickness also directly correlates with increased weight and material cost. Engineers must meticulously balance these factors. For many applications, 14-gauge steel offers the optimal compromise, providing ample strength without becoming overly cumbersome or expensive. It’s an astute design choice.

14 Steel Design: Manufacturing Tolerances

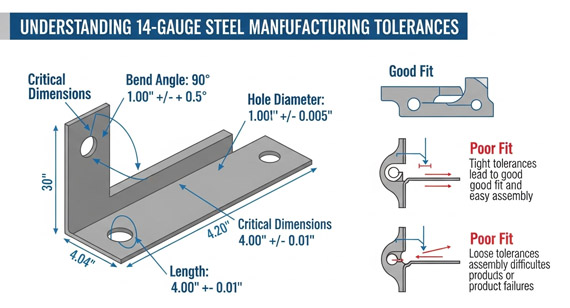

When designing with 14-gauge steel, manufacturing tolerances are absolutely critical. These specified permissible variations in dimensions ensure that parts fit together correctly and function as intended. Without them, assembly becomes a nightmare.

At VMT, we adhere to stringent industry standards, often exceeding them, to maintain exceptional dimensional accuracy. This meticulous approach minimizes tolerance stacks, guaranteeing seamless integration and superior product performance. It's a non-negotiable aspect of our work.

Precision is not merely a goal at VMT; it is our operational ethos, especially when fabricating with materials like 14-gauge steel. Every process is carefully controlled, every measurement verified.

Achieving Dimensional Accuracy in Custom Parts

Achieving sub-millimeter accuracy on 14-gauge steel components relies on advanced CNC machining. Our arsenal includes high-precision laser cutting, CNC bending, and expert welding techniques. Each machine is meticulously calibrated.

Skilled operators, leveraging state-of-the-art software, translate complex designs into physical reality with unparalleled fidelity. Quality control, including coordinate measuring machine (CMM) inspections, ensures every part meets spec.

How Material Sourcing Affects Final Product Quality

The finest machining means nothing without superior raw materials. At VMT, we partner exclusively with certified steel suppliers, ensuring every sheet of 14-gauge steel is of consistent, high quality. Material properties are validated.

Traceability is paramount; we can track every batch of steel to its origin. This rigorous sourcing prevents inconsistencies in material strength, hardness, and chemical composition, which could otherwise compromise the final product.

Partnering for Reliable 14 14-Gauge Steel Structural Projects

When undertaking structural projects with 14-gauge steel, choosing the right manufacturing partner is everything. You need expertise, not just machinery. VMT offers comprehensive engineering support.

Our team collaborates closely with clients from concept to completion, ensuring design manufacturability, optimizing material usage, and delivering components that exceed expectations for strength and durability. We build partnerships, not just parts.

Understanding the cost implications of 14-gauge steel involves more than just its raw material price. It encompasses the entire fabrication journey, from initial processing to long-term performance. It’s a holistic view.

Initial Cost Comparison

On a per-pound basis, 14-gauge steel is generally more expensive than thinner gauges due to its greater material density. However, it is often more cost-effective than much thicker steels for applications where its strength is sufficient. This can save on material.

Long-Term Cost Benefits

The initial investment in 14-gauge steel often yields significant long-term benefits. Its durability reduces maintenance and replacement costs. Its structural integrity can simplify assembly, leading to quicker project completion and less labor. This is true ROI.

Selecting the optimal steel thickness is a critical engineering decision. It directly impacts performance, cost, and manufacturability. There are several key factors we always consider, systematically, I might add.

Strength and Stiffness Requirements

Begin by defining the loads your component will endure. What are the bending moments? What are the shear forces? 14-gauge steel is ideal for applications requiring good, but not extreme, structural integrity and resistance to deflection.

Weight Limitations

Does your project have strict weight targets? Lighter components might necessitate thinner gauges, perhaps reinforced through clever design. However, if some heft is acceptable, 14-gauge offers excellent strength-to-weight.

Cost Budgets

Material cost, processing cost (cutting, bending, welding), and finishing costs all factor in. While 14-gauge is mid-range in material cost, its ease of fabrication can make it a very economical overall choice.

Forming and Manufacturing Complexity

Consider the geometry. 14-gauge steel is quite formable; it handles bending and welding well without excessive springback or distortion. Extremely intricate, small bends might favor thinner material, but 14-gauge is impressively versatile.

At VMT, we specialize in transforming raw 14-gauge steel into highly precise, custom CNC machined components. Our facility is equipped with cutting-edge technology designed for this exact purpose. We excel at complex geometries.

From intricate laser-cut blanks to precision-formed enclosures and expertly welded assemblies, our capabilities ensure your 14-gauge steel projects are executed to the highest standards. Partner with us for unwavering quality and reliability.

A client approached VMT requiring a durable, precisely manufactured housing for sensitive industrial sensors. The housing needed to withstand harsh factory environments while maintaining tight internal tolerances for component fit. 14-gauge steel was the chosen material.

Our engineers collaborated with the client to refine the design, optimizing for both strength and manufacturability using 14-gauge steel. We employed advanced laser cutting for the initial profile, ensuring crisp edges and exact hole placements. Precision press braking followed, creating accurate bends for the enclosure.

The components were then expertly welded, forming a seamless, robust structure. Rigorous quality checks, including CMM inspections, verified every critical dimension. The resulting 14-gauge housing provided exceptional protection, dimensional stability, and a long operational lifespan for the sensors, exceeding client expectations. It was a testament to meticulous planning and execution.

Understanding 14-gauge steel's precise dimensions (0.0747 inches or 1.897 mm) is fundamental for design success and manufacturing accuracy. This article explored the gauge system's origins, provided comprehensive conversion charts, and compared 14-gauge with other thicknesses to highlight its versatile applications in industries from automotive to enclosures. We discussed critical design considerations, the importance of manufacturing tolerances, and the impact of material sourcing on final product quality. Furthermore, we delved into fabrication costs, emphasizing the long-term value of precision. VMT as an expert CNC machining factory, stands ready to deliver high-quality, exact-specification 14-gauge steel parts, ensuring reliability and confidence for your projects through meticulous engineering and transparent processes.

The clarity surrounding 14-gauge steel thickness—its 0.0747 inches, its 1.897 millimeters—is not merely academic. It is the very bedrock of project success, an unyielding metric in the world of high-stakes manufacturing. We've dissected the numbers, explored the applications, and illuminated the pathways to precision.

We at VMT don't just understand these dimensions; we embody them in every cut, every bend, every finished part. Our commitment is to eliminate ambiguity, to replace uncertainty with the hard data of meticulous engineering. This is our promise.

Don't compromise on precision. If your project demands high-quality 14-gauge steel parts with exact dimensions, contact our engineering experts today for a free, no-obligation technical consultation. Or, get a transparent, detailed quote tailored to your specific manufacturing needs.

What's 14-gauge steel thickness?

14-gauge steel has a standard thickness of 0.0747 inches, which converts to approximately 1.897 millimeters. This precise measurement is crucial for accurate design and fabrication in engineering projects.

What is 14 gauge steel?

14-gauge steel refers to sheet metal with a standardized thickness within the gauge system. It's a robust yet versatile material, favored for applications requiring good structural integrity without excessive weight. It is neither extremely thick nor extremely thin.

What are 14 gauge steel's dimensions?

The precise thickness of 14-gauge mild steel is 0.0747 inches. In the metric system, this translates to 1.897 millimeters. These exact dimensions are crucial for accurate engineering design.

Is 14 gauge steel strong?

Yes, 14-gauge steel offers very good strength and rigidity. It's significantly stronger than thinner gauges (like 18 or 20 gauge) while remaining highly formable. It is suitable for many load-bearing and protective applications.

What is 14 gauge steel used for?

14-gauge steel is widely used in automotive, medical, industrial equipment, optical, electronics, and light construction sectors. Common components include machine guards, electrical enclosures, structural brackets, and various housings. Its versatility is truly impressive.

How does gauge affect cost?

Generally, thicker steel (lower gauge number) has a higher material cost per square foot. 14-gauge steel sits in the mid-range; it is more expensive than thinner gauges but can be more cost-effective than very thick steel where its strength is sufficient.

Can 14 gauge steel be welded?

Absolutely. 14-gauge steel is highly weldable using common welding processes like MIG, TIG, and stick welding. Its thickness provides good material for strong, stable weld joints, making it suitable for structural assemblies.

How is 14 gauge measured?

14-gauge steel is measured using micrometers or calipers to determine its precise thickness in inches or millimeters. The gauge system itself is a historical standard, with each gauge number corresponding to a specific, non-linear thickness.

What is VMT's role?

VMT specializes in precision CNC machining of 14-gauge steel, offering services from laser cutting and bending to welding and assembly. We ensure custom components meet stringent dimensional accuracy and quality standards for demanding applications.