15 years one-stop China custom CNC machining parts factory

156 |

Published by VMT at Dec 10 2024 | Reading Time:About 6 minutes

156 |

Published by VMT at Dec 10 2024 | Reading Time:About 6 minutes

Are you looking for the perfect material for your next custom CNC machining project? Brass may be the solution you’ve been seeking. Its blend of high machinability, corrosion resistance, and aesthetic appeal makes brass an ideal choice for a wide range of industries. However, CNC machining brass requires careful understanding of its properties, the right tools, and the proper techniques to ensure high-quality results. If you're unsure how to approach brass for your custom parts or whether it's the right material for your needs, this comprehensive guide will walk you through everything you need to know.

Brass CNC machining is an excellent choice for producing custom brass parts due to its high machinability, strength, and corrosion resistance. Understanding the unique characteristics of brass, selecting the right alloy, and applying the correct machining techniques will ensure high-quality, durable results for your projects. This guide provides everything you need to know about brass machining, from types and finishes to machining tips.

To fully appreciate why brass is such a favorable material for CNC machining, it's essential to first explore the unique properties of brass that make it a standout choice. From its versatility in design to its ability to withstand corrosion, these characteristics set brass apart. Let’s dive into the reasons why brass is so well-suited for CNC machining.

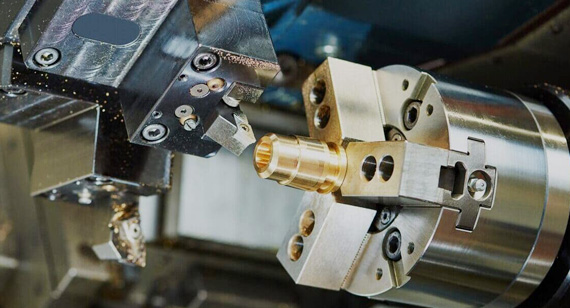

CNC machining brass refers to the process of creating custom brass parts using Computer Numerical Control (CNC) machines. CNC machining involves using automated tools to remove material from a workpiece, creating a part that adheres to precise specifications. Brass, an alloy of copper and zinc, is highly favored for CNC machining due to its excellent machinability, resistance to corrosion, and aesthetic qualities. Brass parts can be used in a variety of applications, from mechanical components to decorative finishes.

CNC machining allows for high-precision production, meaning that even intricate brass components can be fabricated with tight tolerances and minimal human intervention. Through this process, manufacturers can create complex shapes and geometries in brass parts, ensuring that the final product meets specific design requirements. Whether it’s a custom brass connector, a decorative architectural element, or an industrial component, CNC machining makes it possible to craft brass parts with great accuracy and speed.

Brass is renowned for several key characteristics that make it a prime candidate for CNC machining. Below are the properties that make brass suitable for this manufacturing process:

1. Highly Machinable

One of brass’s most valuable features is its excellent machinability. Compared to many other metals, brass is relatively easy to cut, shape, and finish. This is due to its low cutting forces and good chip flow, which allows for faster processing times and less tool wear. Machinability is an essential factor in determining the overall cost and time efficiency of a project, and brass excels in this regard.

2. Corrosion Resistance

Brass is highly resistant to corrosion, making it ideal for applications in harsh environments. It can withstand exposure to moisture, salt, and many chemicals without rusting or degrading, which is particularly valuable in industries such as plumbing, marine, and electrical systems. Its corrosion resistance ensures that parts made from brass will last longer and require less maintenance, providing reliability in critical applications.

3. Plasticity

Brass offers excellent plasticity, meaning it can be easily deformed without breaking. This makes it an excellent choice for manufacturing parts that require shaping or bending. Brass’s plasticity allows for greater design flexibility, making it ideal for intricate and complex geometries in CNC machining.

4. Strength and Hardness

Although brass is softer than steel, it strikes an ideal balance between strength and ductility. The alloy is tough enough to withstand mechanical stresses while being easier to machine than many other metals. Brass’s ability to maintain its form and resist deformation under pressure makes it suitable for various mechanical components, including gears, valves, and fittings.

5. Aesthetic Appeal

Brass has a distinct golden hue, making it an attractive choice for parts that require aesthetic value, such as decorative hardware, jewelry, and musical instruments. Its lustrous finish can be maintained through proper surface finishing techniques, making it ideal for both functional and visually appealing applications.

6. Melting Point

Brass has a relatively low melting point compared to many other metals, which reduces energy consumption during the manufacturing process. This feature allows for faster processing and helps in reducing the risk of thermal distortion during machining.

7. Density

Brass has a moderate density, offering a balance between weight and strength. While it is heavier than aluminum, its durability and strength make it an excellent choice for applications where weight is not a major concern but where durability is paramount.

8. Modulus of Elasticity

Brass has a high modulus of elasticity, meaning it is resistant to deformation under stress. This property makes it suitable for applications where parts are subject to bending or twisting forces, ensuring the material maintains its integrity.

9. Electrical and Thermal Conductivity

Brass is an excellent conductor of both electricity and heat, making it particularly useful in electrical components, such as connectors, terminals, and switchgear. Brass’s thermal conductivity also makes it ideal for use in heat exchangers and components that need to dissipate heat efficiently.

10. Resistivity

Brass has relatively low electrical resistivity, which means it can conduct electricity efficiently. This makes it suitable for electrical applications that require low-resistance materials for smooth current flow.

11. Ductility

Brass is ductile, meaning it can be drawn into thin wires or bent into complex shapes without breaking. This property makes it a suitable choice for parts that require elongation or flexibility during operation.

Brass Property Chart

| Property |

Brass |

| Melting point |

885 to 890 ℃ |

| Density |

8.5 g/cm³ |

| Modulus of Elasticity |

97Gpa |

| Thermal Conductivity |

115 W/m-k |

| Electrical Resistivity |

6.3*10-8Ω |

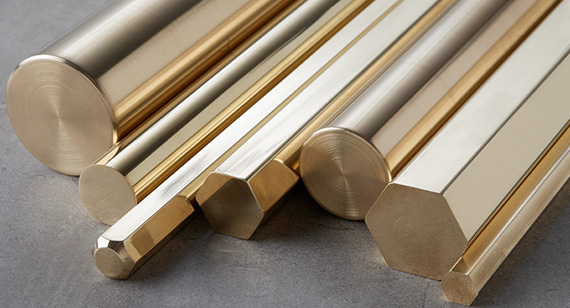

Types of Brass Materials Suitable for CNC Machining

When selecting brass for CNC machining, it’s crucial to understand the different types of brass alloys available. Each type of brass offers unique properties that make it better suited for certain applications. The alloy's composition, machinability, corrosion resistance, strength, and formability all play a role in determining which brass type is best suited for a specific project. Below are some of the most commonly used brass alloys in CNC machining, along with their advantages, disadvantages, and typical applications.

1. Brass C360

Brass C360, often referred to as "Free-Cutting Brass," is one of the most popular alloys for CNC machining. It is composed of approximately 63% copper and 37% zinc, with lead added (up to 2%) to improve its machinability. Brass C360 is known for its excellent cutting characteristics, making it a favorite choice in high-volume manufacturing settings.

Advantages:

Disadvantages:

Applications:

2. Brass C230

Brass C230 is composed of approximately 90% copper and 10% zinc, and it is often referred to as "High-Copper Brass." This alloy offers excellent corrosion resistance, especially in marine environments.

Advantages:

Disadvantages:

Applications:

3. Brass C220

Brass C220 is made up of 85% copper and 15% zinc, offering a balance between strength, machinability, and corrosion resistance. It is commonly used in applications that require a combination of good strength and resistance to wear.

Advantages:

Disadvantages:

Applications:

4. Brass C260

Brass C260, also known as "Cartridge Brass," consists of approximately 70% copper and 30% zinc. It is widely used in various industries due to its good balance of strength, ductility, and formability.

Advantages:

Disadvantages:

Applications:

5. Brass C353

Brass C353 is an alloy made from 59% copper and 39% zinc, with lead added to improve machinability. It is often used for applications requiring good machinability and moderate strength.

Advantages:

Disadvantages:

Applications:

6. Brass C464

Brass C464, or "Naval Brass," is a copper-zinc-lead alloy containing around 60% copper, 39% zinc, and 1% tin. It is highly resistant to corrosion, particularly in marine environments.

Advantages:

Disadvantages:

Applications:

7. Brass C770

Brass C770 is a high-copper brass alloy containing 70% copper and 30% zinc. It is known for its excellent corrosion resistance and strength.

Advantages:

Disadvantages:

Applications:

8. Brass C365

Brass C365 is a free-machining brass alloy similar to C360 but with slight modifications to improve strength and durability.

Advantages:

Disadvantages:

Applications:

9. Brass C330

Brass C330 is an alloy composed of approximately 70% copper and 30% zinc. This alloy has a relatively low zinc content compared to other brasses like C360 and C260, which gives it a distinctive set of properties. It is known for its durability, moderate strength, and machinability, making it suitable for a variety of industrial applications.

Advantages:

Disadvantages:

Applications:

10. Brass C385

Brass C385 is a highly versatile alloy composed of about 62% copper, 36% zinc, and 2% lead, similar to the popular C360 alloy. It is known for its exceptional machinability, corrosion resistance, and ease of processing. C385 is used extensively in industries where high volumes of parts need to be manufactured quickly and efficiently.

Advantages:

Disadvantages:

Applications:

11. Brass C443

Brass C443 is a lead-free alloy that contains copper, zinc, and a small amount of tin. This high-copper alloy is designed for use in applications requiring superior resistance to corrosion, particularly in marine and industrial environments. It is also referred to as "Naval Brass" due to its exceptional performance in marine applications.

Advantages:

Disadvantages:

Applications:

Conclusion

Each brass alloy has unique characteristics that make it suitable for different CNC machining applications. Brass C360 stands out for its excellent machinability, making it the go-to choice for high-volume production of fasteners and small mechanical components. On the other hand, Brass C464 excels in high-strength and corrosion-resistant applications, making it ideal for marine environments. For industries that require corrosion resistance and environmental friendliness, Brass C443 offers a lead-free option with great durability, though it may be more challenging to machine.

When selecting the right brass for your CNC machining project, it's essential to consider the material's machinability, strength, corrosion resistance, and specific industry requirements. Whether you need a material for intricate electrical components, marine fittings, or decorative items, understanding the specific properties of each brass alloy will help you make an informed decision, ensuring that your custom brass parts meet the necessary quality and performance standards.

| Common Name |

Description |

Advantages |

Disadvantages |

Applications |

|

| C360 |

Free Machining Brass |

The zinc-copper alloy with the highest machinability. Also has excellent strength thanks to its content of lead. |

Exceptional machinability, excellent strength, and good corrosion resistance. |

Sensitive to acids, possible environmental impact from lead, lead content can cause a cracked surface finish in some instances. |

Electrical equipment, plumbing components, screw machine parts, and musical instruments. |

| C230

±85% Cu ±15% Zn <0.05 Pb |

Red Brass |

It is significantly stronger than yellow-gold colored brass. |

Good machinability can be worked cold or hot. Excellent corrosion resistance. |

Requires careful treatment and cleaning during its use and can be sensitive to corrosion under severe environments. |

Architecture, jewelry, light fixtures, steam iron parts, sprinklers, and decorative parts. |

| C220

±90% Cu ±10% Zn <0.05 Pb |

Commercial Bronze |

Bronze-reddish colored, this brass is widely used in the architectural world. |

Can be worked cold. Fair-to-good machinability relative to C360. Good ductility, strength, and hardness. Excellent corrosion resistance. |

May require annealing if exposed to atmospheres that can induce stress corrosion cracking. |

Architectural uses and weather-stripping. |

| C353

±62% Cu ±36% Zn ±2% Pb + Fe |

High Leaded Brass – Engravers’ Brass |

Known for being both strong and wear-resistant while maintaining good machinability. |

Excellent machinability (less than C360), excellent strength, corrosion, and wear resistance. |

Poor to fair cold and hot working. Not ideal for welding. |

Wheels, gears, valve stems, couplings, adapters, watch parts. |

| C464

±59% Cu ± 40 Zn ± 1 Sn + Pb |

Naval Brass |

Well known for its exceptional corrosion resistance thanks to the additions of tin. |

Fair to good machinability compared to the C360. Excellent strength and corrosion resistance, and can be hot worked. |

Prone to dezincification with time, leading to structural cracks on the surface of the alloy. |

Naval applications, wear plates, fasteners, bushings, condenser tubes |

| C770

±55% Cu ±27% Zn 18% Ni |

German Silver / Nickel Silver |

Known for its silvery appearance, yet it does not have silver at all! |

Excellent electrical and thermal conductivity, high strength, excellent formability, and good corrosion resistance. |

Fair machinability compared with C360, poor capacity for being formed hot. |

Electronic applications, battery casings, packaging, lids, musical and ornamental applications. |

| C365

±60% Cu + Ag ±39% Zn ±1% Sn + Pb + Fe |

Brass Plate / Leaded Muntz Metal |

Named after George Fredrick Muntz, who commercialized the alloy following his patent in 1832. |

Good machinability and excellent corrosion resistance and strength (similar to C464). |

Limited cold formability, not recommended for welding. |

Tube sheets for condensers and heat exchangers, baffles, support sheets. |

| C330

±66% Cu ±33.5% Zn ±0.5% Pb |

Low Leaded Brass |

A brass alloy containing relatively low amounts of lead. |

Good strength, good machinability, and strong water corrosion resistance. |

Difficult welding, sensitive to highly corrosive conditions (acids) |

Tubing, ammunition primers, power cylinders, pumps, liners. |

| C385

±56.5% Cu ±40% Zn ±3% Pb <5% Fe |

Architectural Bronze |

Although it is well known as architectural bronze, this alloy is actually a brass! |

Good machinability, great finishes, good corrosion resistance in non-marine conditions. |

Low corrosion resistance in marine conditions, poor cold forming. |

Interior applications, shower doors, bathroom partitions, fireplace lamps, valves. |

| C443

±70% Cu ±29.85% Zn ±0.05% Sn ±0.05% Pb ±0.05% As |

Admiralty Brass |

Also referred to as arsenical brass, this alloy contains tin, lead, and arsenic which together provide good resistance to corrosion in brackish water and saltwater. |

Excellent cold workability for forming and bending and strong corrosion resistance. |

Fair to poor weldability, poor hot formability. |

Condenser tubes, evaporator and heat exchanger tubes, distiller tubing in oil refineries, heater equipment. |

After CNC machining, brass parts may require additional finishing to meet both functional and aesthetic requirements. Below are some popular surface finishes for CNC-machined brass parts:

1. Post-Machining

This process involves removing tool marks, burrs, and sharp edges after machining to ensure the part meets design specifications.

2. Polishing

Polishing is often used to create a smooth, shiny surface and is commonly applied to decorative brass parts like jewelry and hardware.

3. Plating

Plating involves coating the brass part with another material (e.g., nickel, chrome, or gold) to improve its appearance and enhance its resistance to corrosion and wear.

4. Honing

Honing is a finishing process that smooths the surface of brass parts, enhancing their functionality and ensuring precise dimensions for mating components.

5. Powder Coating

Powder coating applies a durable layer to the brass part that enhances its resistance to wear and corrosion. It is often used for industrial components that require additional protection.

When selecting brass for CNC machining, it is important to consider a variety of factors to ensure that the final product meets both performance and cost-effectiveness criteria. Brass alloys are popular in manufacturing because of their excellent machinability, corrosion resistance, and aesthetic appeal. However, not all brass alloys are suitable for every application, and different factors must be weighed to make the best choice for your custom CNC machining project.

Below is a comprehensive guide to the key factors to consider when selecting brass for CNC machining.

1. Time Required to Machine a Part

Time is a critical factor in CNC machining, particularly when you are working with brass alloys. The machining time affects both cost and production schedules. Alloys like Brass C360 are known for their excellent machinability, meaning they can be processed quickly and efficiently, reducing production time and costs. However, alloys like Brass C443 (Naval Brass) are more difficult to machine due to their high strength and reduced machinability, leading to longer machining times.

When considering the time required to machine a part, evaluate the specific brass alloy’s machinability, the complexity of the part’s design, and the number of parts to be produced. Choosing a brass alloy that aligns with your production timelines will help ensure efficiency.

2. Design for Manufacturability

Designing parts with CNC machining in mind is crucial for a smooth and cost-effective manufacturing process. Design for Manufacturability (DFM) focuses on creating designs that can be efficiently produced using the available machinery and technology, minimizing potential issues during machining. For brass, this may involve optimizing the design for tool access, avoiding overly intricate features that require advanced tooling, and ensuring that the part's features are suitable for the selected brass alloy.

If a part has highly detailed features, such as internal threads or complex shapes, it may require specific brass alloys that can hold up to precise machining without excessive tool wear. For example, alloys like Brass C360 are ideal for complex designs because they are easier to machine, while Brass C464 might require additional design adjustments due to its higher strength and lower machinability.

3. Application of Finished Parts

Understanding the final application of the CNC machined brass parts is vital for selecting the appropriate alloy. Brass is used in a wide range of industries, including plumbing, automotive, electrical, marine, and decorative applications. Different brass alloys have varying levels of corrosion resistance, strength, and aesthetic appeal, making some more suitable for specific applications than others.

For example, Brass C360 is often used for small, high-volume parts like fittings and connectors, while Brass C443 is better suited for marine applications, where superior corrosion resistance is required. Be sure to evaluate the environmental and mechanical conditions the parts will be exposed to, such as whether they will be submerged in water or subject to high temperatures.

4. Material Properties

Each brass alloy has unique material properties that influence its behavior during machining and its performance in the finished part. The most important properties to consider when selecting brass for CNC machining are:

Understanding the material properties of the brass alloy will help ensure that the part not only meets performance requirements but can also be machined efficiently.

5. Machining Parameters

The choice of brass alloy directly impacts the machining parameters, including cutting speed, feed rate, and depth of cut. Some brass alloys, like C360 and C385, are more forgiving during machining, allowing for faster cutting speeds and deeper cuts. Others, like C443, require slower cutting speeds and more careful control of machining parameters to avoid tool wear and to maintain the quality of the part.

Choosing a brass alloy that is compatible with your machine tools and allows for optimal cutting parameters is key to ensuring a balance of speed, precision, and quality.

6. Tool Selection and Maintenance

Brass is relatively easy on tools, but selecting the right tool for the job can make a significant difference in machining efficiency and part quality. The hardness and machinability of the selected brass alloy will determine the types of cutting tools required. For example:

Proper tool maintenance is also essential, as brass alloys with higher levels of zinc or other alloying elements can cause tools to wear more quickly. Regular inspection, sharpening, and replacement of tools will help maintain efficiency and precision.

7. Cooling and Lubrication

CNC machining generates a significant amount of heat, and cooling and lubrication are essential to prevent the material from overheating, which can lead to poor surface finish, tool wear, and dimensional inaccuracies. Brass alloys, particularly free-machining alloys like C360, often require less coolant than more challenging alloys, but using the correct coolant can help extend tool life and improve part finish.

For alloys like Brass C443, using the correct type of coolant is essential to prevent excessive tool wear and to maintain a good surface finish. Coolant can also help control the temperature of the workpiece and reduce the risk of warping.

8. Production Volume

The volume of parts to be produced plays a significant role in selecting the right brass alloy. Free-machining alloys like C360 are ideal for high-volume production runs due to their ease of machining and cost-effectiveness. However, if you're manufacturing a small number of high-precision parts or parts for a highly specialized application, you might choose alloys like C464 or C443, which offer superior strength or corrosion resistance, even though they may be more difficult and costly to machine.

9. Tolerances and Dimensions

Precision is crucial in CNC machining, and the brass alloy chosen must be capable of achieving the required tolerances for the part. Alloys like C360 are easier to machine and can achieve tighter tolerances without excessive tool wear. However, stronger alloys like C464 may require additional machining processes and more time to ensure precision.

If your project requires parts with extremely tight tolerances, it’s essential to select a brass alloy that offers both machinability and the ability to hold those tolerances during the machining process.

10. Design Complexity

The complexity of the part design is another critical factor to consider. More complex designs, such as those requiring internal threads, fine details, or multi-axis machining, may require a higher-quality brass alloy with superior strength and ductility. While C360 is easy to machine, alloys like C464 or C443 are more suitable for intricate parts with complex geometries that demand high strength or corrosion resistance.

11. Delivery Time

Lastly, the time required to machine and deliver the parts is an important consideration. Some brass alloys are easier to machine, allowing for quicker turnaround times, while others may require additional processing steps. If quick delivery is essential, choosing a material that can be machined faster—like C360—may be beneficial, especially in industries where lead time is critical.

12. Surface Finish

The desired surface finish of the finished part will influence the selection of brass alloy. Some alloys like C360 provide a smooth, polished surface that requires minimal post-machining finishing, while others, like C443, may require more attention to surface quality due to their higher strength and hardness. It's important to consider whether the part will be used in decorative applications (e.g., jewelry or architectural components), where the finish is critical, or in more industrial applications where surface roughness can be tolerated.

Conclusion

Selecting the right brass alloy for CNC machining involves balancing a wide range of factors. These include the time and cost required for machining, material properties, production volume, and the part’s final application. By understanding each factor and choosing the appropriate brass alloy, you can optimize your machining process for efficiency, quality, and cost-effectiveness. Whether you're working on high-volume production or custom-made parts, considering these factors will ensure that your brass CNC machining project is a success.

Brass, with its distinctive yellow-golden hue and excellent machining properties, is a material commonly used in various industries for producing precision components. Its favorable characteristics—such as corrosion resistance, high machinability, and attractive appearance—make it the material of choice for numerous applications. Below are some of the common uses for brass machined parts:

1. Hinges

Brass is often chosen for making hinges due to its durability, corrosion resistance, and aesthetic appeal. Brass hinges are frequently used in doors, gates, cabinets, and furniture. They provide smooth operation and a high-quality finish. Since brass does not rust easily, it remains functional even in outdoor environments or areas with high humidity.

2. Knobs

Knobs made from brass offer a blend of strength and visual appeal. Brass is an excellent choice for decorative knobs used in a wide variety of applications, including furniture, doors, appliances, and machinery. The metal's ability to retain a polished finish while offering good wear resistance makes it ideal for high-use items like cabinet knobs, handles, and control knobs on machinery.

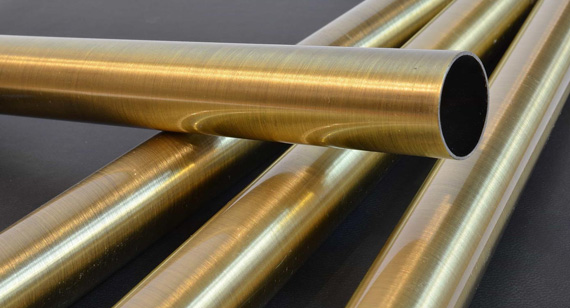

3. Pipes

Brass is frequently used in the production of pipes, particularly in plumbing systems. Brass pipes are highly resistant to corrosion, making them ideal for use in water systems, heating, and gas applications. Their strength and durability ensure that they can withstand high-pressure environments without degradation. Brass pipes are commonly used in both residential and industrial plumbing.

4. Bells

Brass is a traditional material for bells due to its excellent acoustic properties. Brass bells are used in musical instruments, church bells, and even decorative items. Its resonant sound and aesthetic appearance make it an attractive choice for bell manufacturing. The alloy’s ability to maintain a vibrant tone over time is essential in musical and ceremonial applications.

5. Jewelry

The use of brass in jewelry is widespread because of its malleability and attractive color. It can be easily shaped into intricate designs while retaining strength. Brass jewelry is both cost-effective and aesthetically pleasing, making it a popular choice for custom jewelry pieces. It's also commonly used in fashion accessories, charms, bracelets, and rings.

6. Gears

Brass machined gears are widely used in various machinery, especially in applications requiring corrosion resistance, such as water pumps or marine machinery. Brass is often chosen for gears that need to withstand frequent motion and heavy loads. Its wear resistance and ability to retain its shape under stress make it ideal for use in precision gear systems.

7. Door Trims

Brass is also a popular material for door trims, especially for high-end, decorative designs. Brass door trims provide both function and style, offering protection against wear while enhancing the visual appeal of the door. It’s also used in frames, handles, and decorative elements of doors in both residential and commercial settings.

These are just a few examples of the many applications where brass machined parts are used. Whether it's for their aesthetic value, strength, or durability, brass parts are an integral part of various mechanical and decorative components.

Brass is a versatile and reliable material used across several industries for CNC machining, offering a balance of durability, machinability, and visual appeal. Below are the primary industries that make extensive use of brass parts:

1. Plumbing and Heating

Brass has been a staple material in plumbing for decades due to its corrosion resistance and ability to withstand the pressures of water, gas, and heating systems. Brass machined fittings, valves, faucets, and connectors are found in both residential and commercial plumbing. Its excellent machinability also allows for the production of highly accurate and reliable parts.

In the automotive industry, brass is often used for components that require strength, resistance to corrosion, and good electrical conductivity. Components like connectors, bushings, fittings, and radiators are commonly made from brass. The material’s ability to resist oxidation and maintain its form in high-heat environments is ideal for various automotive applications.

Brass is frequently used in the electrical and electronics industries due to its excellent conductivity, both for electricity and heat. It is often used for connectors, terminals, switches, and other electrical components that need to maintain strong electrical performance while also being resistant to corrosion. The material’s thermal properties make it ideal for electronic components exposed to high temperatures.

4. Aerospace Industry

In the aerospace sector, brass is used for a variety of applications, including connectors, fittings, and bushings. It is used in parts that require durability and resistance to corrosion, particularly in harsh environments. Brass is often chosen for its high machinability, allowing for precise parts to be made at lower costs, while still maintaining performance under the extreme conditions typically encountered in aerospace applications.

5. Musical Instruments

Brass has long been the material of choice for many musical instruments, such as trumpets, saxophones, and trombones. Its acoustic properties make it ideal for instruments that need to produce rich, resonant sounds. CNC machining allows for precise shaping of brass into complex geometries required for musical instruments, offering consistency and high-quality finish.

6. Decorative and Architectural Elements

Brass is widely used in architectural applications, from decorative trim and hardware to intricate fittings. It’s used in door handles, window frames, railings, and other decorative elements for both aesthetic appeal and durability. The material’s golden hue adds an element of sophistication, making it a preferred choice in high-end residential and commercial architecture.

7. Marine Industry

Brass is a popular choice in the marine industry for components exposed to salty and corrosive environments, such as boat fittings, propellers, and pumps. Brass alloys like C443 (Naval Brass) are specifically designed for the marine environment, offering outstanding corrosion resistance in seawater. Additionally, brass parts are used in marine applications due to their durability and aesthetic appeal.

Successful brass CNC machining involves understanding the properties of brass and selecting the right processes, tools, and settings for efficient production. Below are some tips to help optimize the CNC machining process for brass:

1. Choosing the Right Brass Grade

Choosing the right brass alloy for your CNC project is the first step toward a successful machining process. Consider the material properties required for your application, such as corrosion resistance, strength, or aesthetic appeal. For high-precision parts, alloys like C360 are ideal, while for marine applications, C443 would be the preferred choice due to its superior corrosion resistance.

2. Optimizing Tools and Cutting Parameters

Brass is relatively easy to machine, but optimal cutting parameters are still essential to ensure efficiency and precision. Use high-speed steel (HSS) or carbide tools for cutting, as these will maintain sharpness and withstand the forces exerted during machining. Cutting speed, feed rate, and depth of cut should be optimized to prevent excessive tool wear or overheating.

3. Managing Heat Generation

Although brass has good thermal conductivity, excessive heat can lead to dimensional inaccuracies or affect the surface finish. Using the appropriate coolant and managing cutting speeds will help control temperature during machining. In some cases, dry machining may be possible for certain brass grades, but using a coolant can significantly extend tool life and improve surface finish.

To determine if brass is the right choice for your CNC project, evaluate factors like corrosion resistance, machinability, strength requirements, and aesthetic appeal. If you need a part that combines easy machinability with a polished finish and resistance to corrosion, brass is an excellent option. However, if you require a part that must withstand extreme stress or high temperatures, you might need to consider alternative materials.

At VMT (Virtual Manufacturing Technologies), we specialize in custom CNC machining of brass parts. Our advanced CNC machining technology, coupled with our expertise, ensures that your brass parts are manufactured with precision, durability, and a perfect surface finish. Whether you need a single prototype or a large batch of precision-machined brass parts, VMT is committed to delivering high-quality results.

Brass is a versatile and reliable material for CNC machining, offering excellent machinability, corrosion resistance, and aesthetic appeal. From automotive parts to decorative elements and high-performance components for industrial applications, brass is an ideal choice for many industries. By understanding the factors that influence brass CNC machining—such as alloy selection, machining parameters, and surface finish—you can optimize production efficiency and ensure that your parts meet the required specifications. Whether you are looking to manufacture brass components for a single prototype or mass production, VMT provides top-tier CNC machining services for your project needs.

Is brass difficult to CNC machine?

Brass is relatively easy to machine due to its excellent machinability. Alloys like C360 are especially popular for high-precision, high-volume applications.

What is the tolerance range for brass?

Brass can be machined to tight tolerances, typically ranging from ±0.005 mm to ±0.1 mm, depending on the complexity and the alloy chosen.

Are there any disadvantages to CNC machining brass?

One disadvantage is that brass can be prone to tool wear due to its hardness, especially with higher-strength alloys like C464 or C443.

What is the lead time for machining brass?

Lead time varies depending on part complexity and production volume but typically ranges from a few days for prototypes to several weeks for large-scale production runs.

What is the difference between 464 brass and 360 brass?

C464 (Naval Brass) has higher corrosion resistance, making it suitable for marine environments, whereas C360 is more machinable and is often used for high-volume, precision applications.

What is the difference between 260 brass and 272 brass?

C260 (Cartridge Brass) has a higher tensile strength than C272, making it better suited for applications that require more durability. C272 is more machinable and suitable for less demanding applications.

What is the best way to machine brass?

The best way to machine brass involves using high-speed steel (HSS) or carbide tooling, optimal cutting speeds, and proper cooling/lubrication techniques.

What is the difference between 360 brass and 385 brass?

C360 is a free-machining brass alloy with excellent machinability, while C385 is a high-strength alloy that provides better corrosion resistance but is harder to machine.

Is brass harder to machine than aluminum?

Brass is generally easier to machine than aluminum due to its lower hardness, though aluminum is often more forgiving in high-volume production.

What materials are the hardest to CNC machine?

Materials like titanium, high-carbon steels, and certain ceramics are among the hardest to machine due to their strength and hardness.

What are the easiest materials to CNC machine?

Materials like aluminum, copper, and some brass alloys (like C360) are among the easiest to machine due to their relatively low hardness and excellent machinability.

Why use brass instead of bronze?

Brass is often used over bronze for its superior machinability and lower cost, while bronze is preferred in applications requiring higher strength and wear resistance, such as bearings or marine components.