15 years one-stop China custom CNC machining parts factory

62 |

Published by VMT at Oct 09 2025 | Reading Time:About 4 minutes

62 |

Published by VMT at Oct 09 2025 | Reading Time:About 4 minutes

A truly calamitous misjudgment in material selection can utterly devastate a meticulously planned project. It's not merely about performance; it's about the very foundational integrity of your critical applications, your reputation, and your financial solvency. Are you absolutely confident your current material choice for corrosive environments protects against unseen, insidious risks, or could a deeper discernment—an exact, precise understanding—avert future catastrophes and preserve your capital? The truth is, it frequently costs far more to rectify a material failure than to preclude it.

Navigating the labyrinthine complexities of high-performance alloys is paramount for engineering resilience. This discourse, my friends, intends to equip you with the strategic insights necessary to decisively choose between 904L and 316L stainless steel, ensuring optimal functionality, unparalleled quality, and judicious fiscal management for your most exigent requirements. A misstep here is an unbelievably foolish assumption; a sagacious selection, on the other hand, yields enduring value.

For critical applications where corrosion resistance is paramount, selecting between 904L and 316L stainless steel mandates an exhaustive technical review. 904L, a super austenitic variant, offers superior resistance to a wider spectrum of aggressive corrosive media, particularly sulfuric acid and chlorides, due to its enriched nickel, molybdenum, and copper content, contrasting with the more widespread, albeit less robust, 316L.

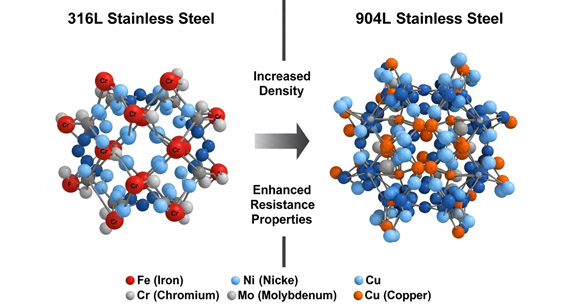

The elemental constitution of an alloy dictates its very essence, its capabilities, its proclivity for success or, indeed, its predisposition to abysmal failure. We must scrutinize these compositions with a meticulous, unforgiving eye. What precisely imbues 904L with its extraordinary resilience, and what, conversely, positions 316L as a ubiquitous workhorse? It is, honestly, a fascinating inquiry.

Chemical Composition: Nickel, Molybdenum, Copper's Decisive Role

The divergence between these two formidable stainless steel grades commences at their atomic blueprint. You see, it's the specific proportions of alloying elements, particularly nickel (Ni), molybdenum (Mo), and copper (Cu), that orchestrate their distinct performance characteristics. 904L, in my estimation, is a metallurgical behemoth, brimming with these crucial constituents. It really does make all the difference, one might say!

Here, let's examine the elemental profiles:

Table: Essential Chemical Composition (Weight %)

| Element | 316L (Approximate) | 904L (Approximate) |

| Chromium (Cr) | 16.0 - 18.0 | 19.0 - 23.0 |

| Nickel (Ni) | 10.0 - 14.0 | 23.0 - 28.0 |

| Molybdenum (Mo) | 2.0 - 3.0 | 4.0 - 5.0 |

| Copper (Cu) | N/A (trace) | 1.0 - 2.0 |

| Carbon (C) | 0.03 max | 0.02 max |

| Manganese (Mn) | 2.0 max | 2.0 max |

| Silicon (Si) | 1.0 max | 1.0 max |

| Phosphorus (P) | 0.045 max | 0.045 max |

| Sulfur (S) | 0.03 max | 0.035 max |

The elevated nickel content in 904L—almost double that of 316L—is directly responsible for its superior austenitic stability and ductility. Meanwhile, the significantly higher molybdenum content in 904L is the primary architect of its enhanced resistance to pitting and crevice corrosion, particularly within chloride-rich milieus. An additional and utterly pivotal inclusion in 904L is copper, which bestows an extraordinary resistance to sulfuric and phosphoric acids.

Mechanical Performance: Strength, Hardness, and Ductility Comparison

Beyond chemistry, the tangible mechanical characteristics are what truly inform design and dictate application suitability. An alloy might possess exemplary corrosion resistance, yet if it crumbles under operational stress, its utility is, well, negligible. We must comprehend the sheer fortitude of each material. Strength matters!

Table: Typical Mechanical Properties (Annealed Condition)

| Property | 316L (Typical) | 904L (Typical) |

| Tensile Strength (MPa) | 485 | 490 |

| Yield Strength (MPa) | 170 | 220 |

| Elongation (% in 50mm) | 40 | 35 |

| Hardness (Brinell) | 149 | 150 |

| Density (g/cm³) | 8.0 | 8.0 |

While their tensile strengths appear somewhat analogous, the discernibly higher yield strength of 904L—the point at which permanent deformation commences—signals its enhanced structural integrity under load. This is a critical factor for components subjected to sustained mechanical stresses. But let's be real, a slightly lower elongation for 904L suggests it's marginally less ductile, a trade-off for its augmented resistance. For high-precision CNC machining, this demands a subtle adjustment in our operational parameters, ensuring the material performs to its absolute zenith.

Cost Impact of 904L vs. 316L

Cost, after all, remains an irrefutable, inescapable consideration in any engineering endeavor. While 904L offers unquestionably superior performance in specific contexts, its procurement is, regrettably, more capital-intensive than 316L. This is an unavoidable reality. One cannot simply disregard the bottom line. Honestly, the material cost difference can be substantial.

The enriched alloying elements—especially the higher nickel and molybdenum percentages—render 904L a significantly pricier commodity. This initial investment, however, must be juxtaposed against the entire lifecycle cost of the component. A cheaper material that necessitates frequent replacement, incurs downtime, or precipitates catastrophic failure is, in the grand scheme of things, an unbelievably foolish economy. We often witness clients make this short-sighted calculation, only to lament it later. We, as your partners, advocate for a holistic financial perspective. Remember, our transparent pricing elucidates these costs from the outset.

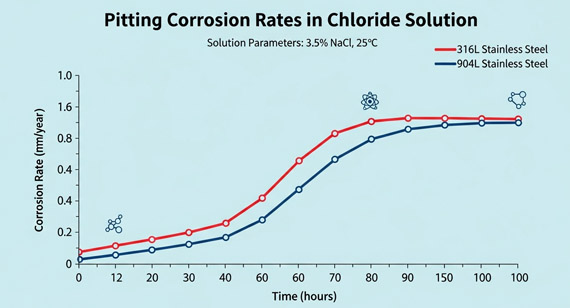

The primary motivation for opting for either 904L or 316L often revolves around their formidable resistance to corrosive media. However, "resistance" is not a monolithic concept; it manifests differently across a spectrum of aggressive environments. One must dissect their capabilities with acute precision.

Pitting and Crevice Corrosion: A PREN Value Scrutiny

Pitting and crevice corrosion are insidious forms of localized attack, often initiating in seemingly innocuous flaws or tight gaps. These phenomena can lead to swift, catastrophic failures, making their mitigation a paramount concern. The Pitting Resistance Equivalent Number (PREN) serves as a robust indicator of an alloy's resistance to these particular modes of deterioration. It is an indispensable metric, truly.

Table: Pitting Resistance Equivalent Number (PREN) Comparison

| Stainless Steel Grade | PREN Value (Typical) |

| 316L | 23 - 28 |

| 904L | 34 - 38 |

The discernibly higher PREN value of 904L, largely attributable to its augmented molybdenum content, underscores its markedly superior resistance to both pitting and crevice corrosion, particularly in chloride-laden environments. This substantial difference is not merely academic; it translates directly into extended operational lifespans and reduced maintenance exigencies in highly aggressive settings. For marine applications or those involving seawater, this distinction is, frankly, monumental.

Acidic Environments: Sulfuric and Chloride Endurance

Where sulfuric acid reigns or where chloride concentrations soar, 316L, despite its admirable qualities, frequently reaches its operational nadir. This is where 904L truly distinguishes itself, asserting its unchallenged supremacy. It's almost, dare I say, a heroic performance!

Due to its elevated nickel and copper content, 904L exhibits extraordinary resistance to hot dilute sulfuric acid, a condition where 316L would rapidly succumb to corrosive attack. Moreover, its higher molybdenum content significantly bolsters its defense against stress corrosion cracking and general corrosion in chloride-rich solutions, conditions prevalent in many chemical processing operations. This material choice is, without exaggeration, the difference between enduring success and a downright catastrophic failure in such environments. We have observed this firsthand, often rectifying the consequences of suboptimal material choices.

Elevated Temperature and Stress: Performance in Complex Scenarios

Beyond ambient conditions, the interplay of elevated temperatures and mechanical stress introduces an entirely new stratum of complexity to material selection. The integrity of components under such duress is a matter of profound safety and unwavering reliability.

Both 316L and 904L are austenitic stainless steels, retaining their mechanical properties remarkably well at cryogenic temperatures. However, at elevated temperatures, particularly where aggressive corrosive media are also present, the superior alloying of 904L provides a more robust defense against phenomena like intergranular corrosion and stress-accelerated degradation. The structural stability it offers under such composite conditions is, for critical infrastructure, an indispensable trait. It simply outclasses its counterpart, I contend.

Making the judicious choice between these alloys means aligning their intrinsic properties with the specific demands of your operational milieu. It is, to borrow a phrase, a matter of horses for courses. A square peg cannot fit a round hole, even a very good square peg.

316L Stainless Steel Typical Advantageous Application Domains

316L, with its excellent balance of corrosion resistance, mechanical properties, and relative cost-effectiveness, remains an incredibly versatile and widely utilized material. It is a workhorse, a dependable stalwart in countless industries. You will find it almost everywhere, and for good reason.

It finds extensive deployment in marine environments (above the waterline), food and beverage processing equipment, pharmaceutical apparatus where moderate chloride exposure is present, surgical instruments, and architectural applications. For environments with moderate levels of corrosivity, 316L offers a robust and economically viable solution. Its widespread availability and established fabrication protocols also render it a preferred option for many standard applications. Honestly, for many uses, it is perfectly adequate!

904L Stainless Steel Rigorous Conditions and Exclusive Scenarios

When the stakes are high, and the environments are relentlessly aggressive, 904L emerges as the unequivocal champion. This is where compromise is simply not an option, where the cost of failure far eclipses the initial material premium.

904L is the material of choice for highly corrosive chemical processing plants, particularly those handling concentrated sulfuric acid, phosphoric acid, and other highly acidic media. Its application extends to flue gas desulfurization (FGD) systems, demanding environments in oil and gas extraction, pulp and paper processing, and even within pharmaceutical production where extreme cleanliness and resistance to aggressive cleaning agents are paramount. An anecdote springs to mind: a client in the pharmaceutical industry was experiencing unexpected part degradation with 316L in a specific acidic process, leading to expensive maintenance and compliance risks. Collaborating with our engineering team, a detailed analysis revealed the necessity for 904L. Despite the higher initial material cost, our transparent evaluation and precision manufacturing of the 904L components resulted in zero failures over three years, significantly extending equipment lifespan and ensuring uninterrupted, compliant production. This choice, guided by our expertise, transformed a recurring headache into a lasting solution. That’s a powerful illustration, no?

Industry Exemplars: Revelations from Successful Material Choices

The real-world implementation of these materials provides the most poignant testament to their inherent strengths and the sagacity of their selection. We witness these triumphs—and sometimes, regrettably, the missteps—every single day.

For instance, in the realm of offshore oil and gas, components for subsea equipment and pipelines frequently demand 904L for its unparalleled resistance to seawater and hydrogen sulfide, preventing stress corrosion cracking in incredibly harsh, inaccessible environments. Conversely, a standard pump housing for general industrial water transfer would find 316L perfectly adequate, providing reliable service without the unwarranted expense of 904L. It's about appropriate material deployment, not merely 'better' material. We, as your manufacturing partner, bring this discernment to every project.

The choice of material extends beyond its intrinsic properties; it encompasses the practicalities of transforming raw stock into precision components. Our expertise as a CNC machining factory is particularly salient here. One must consider the manufacturability.

Machinability: Impact on CNC Processes

Both 316L and 904L are austenitic stainless steels, renowned for their toughness and propensity for work hardening during machining. This presents certain challenges for high-precision CNC operations. But let’s be honest, it’s a challenge we relish.

904L, owing to its higher nickel and molybdenum content, is generally considered more difficult to machine than 316L. It exhibits a greater tendency to work harden, necessitating lower cutting speeds, higher feed rates, and robust tooling with sharper cutting edges. Chip control can also be more arduous. Our factory, possessing state-of-the-art multi-axis CNC machines and a cadre of highly experienced machinists, has developed specific protocols and optimized tooling selections to efficiently and precisely process both materials, ensuring exceptional surface finishes and tight dimensional tolerances, even for the most intricate geometries. This is our specialized domain, after all!

Weldability: Strength and Anti-Corrosion Considerations

Welding these sophisticated alloys requires meticulous attention to detail to preserve their corrosion resistance and mechanical integrity. It's not a task for the uninitiated, believe me.

Both materials possess good weldability, but precautions are indispensable to prevent sensitization, which can lead to intergranular corrosion. For 904L, using low carbon content (0.02% max) minimizes sensitization risks. It's crucial to utilize appropriate filler metals that match the composition and properties of the parent material. Post-weld treatment, often involving pickling and passivation, is frequently employed to restore the passive layer and optimize corrosion resistance, especially for 904L components destined for the most aggressive environments. We, as your source manufacturer, guarantee adherence to these stringent welding protocols, ensuring the utmost quality in every fabricated component.

Surface Treatment: Quality and Performance Optimization

The ultimate performance of a stainless steel component is not solely determined by its bulk properties; the integrity and finish of its surface are also profoundly consequential. A flawless surface is, for many applications, non-negotiable.

For both 316L and 904L, precision machining at our facility produces exceptional surface finishes. Beyond that, processes such as passivation are often applied to enhance the native chromium oxide layer, bolstering corrosion resistance. Electropolishing can further reduce surface roughness, making components easier to clean and improving resistance to bacterial adhesion—a critical factor in pharmaceutical and food processing. For 904L, particularly, ensuring the passivation layer is fully developed after any machining or welding is an absolute imperative to unlock its full anti-corrosion potential. It would be an unbelievable foolish assumption to overlook this final, crucial step.

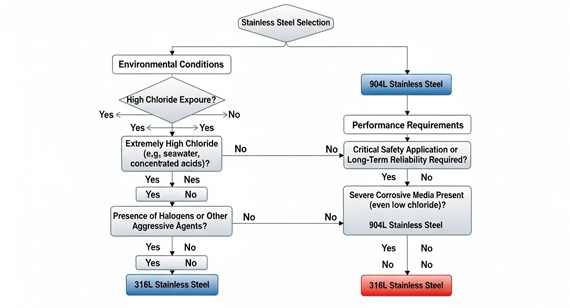

Selecting the consummate material is a systematic undertaking, a deliberate march towards optimized outcomes. It demands a rigorous methodology, a framework for precision. This is how you navigate the quagmire of choices.

Environment Assessment: Corrosive Media, Temperature, Pressure

The initial, and perhaps most pivotal, step involves an exhaustive characterization of the operational environment. You must meticulously identify the corrosive agents present—chlorides, acids, alkalis, their concentrations—alongside the anticipated temperature excursions and pressure profiles. What are the specific conditions, for heaven's sake! What specific dangers lurk?

For instance, high chloride concentrations coupled with elevated temperatures (e.g., seawater condensers or heat exchangers) will almost certainly necessitate 904L due to its superior PREN value and resistance to stress corrosion cracking. Conversely, a component exposed to ambient fresh water with minimal corrosive elements would scarcely warrant the premium of 904L. This initial assessment, truly, is the bedrock of intelligent material selection.

Performance Imperatives: Longevity, Reliability, and Safety

Beyond the immediate environmental factors, a deeper introspection into the project's long-term performance objectives is indispensable. What is the expected lifespan? What level of reliability is non-negotiable? Are there inherent safety implications tied to material failure?

If a component's failure could lead to profound financial losses, severe environmental damage, or pose a grave risk to human life—think pressure vessels in chemical plants or critical medical implants—then prioritizing the absolute maximum corrosion resistance and durability, even if it entails a higher initial material outlay for 904L, becomes an ethical and engineering imperative. It is not merely an option; it is a profound obligation. Our factory understands this perfectly.

Cost-Benefit Calculus: Initial Investment and Lifecycle Costs

Now, I just mentioned cost, but wait, I should really emphasize the *long-term* financial ramifications, not just the upfront expense. A true cost-benefit analysis transcends the mere purchase price of the raw material. It must encompass the entire lifecycle.

Consider the cost of maintenance, potential downtime due to failures, the expense of replacements, and any associated regulatory compliance penalties. A material that costs more initially but virtually eliminates these subsequent expenses often presents a superior overall economic advantage. A lifecycle cost analysis, we contend, frequently vindicates the selection of 904L for applications demanding its advanced properties. Our transparent pricing structure helps you perform this exact comparison with clarity, devoid of hidden costs. It is our absolute guarantee.

Expert Guidance: Our Factory's Technical Support

You are not, by any stretch of the imagination, alone in this intricate decision-making process. Leveraging the profound technical expertise of a seasoned manufacturing partner is an utterly invaluable asset.

Our VMT CNC Machining Parts Services Factory personnel possess an intimate, exhaustive understanding of both 904L and 316L, not just their theoretical properties, but their practical behavior during machining, welding, and real-world deployment. We can provide data-driven insights, recommend optimal processing parameters, and collaboratively assist in the selection of the most suitable material for your specific application. This is, after all, our core competency—our very raison d'être. We are a source manufacturer, deeply committed to your project's success. Your queries, honestly, fuel our passion for precision.

Choosing between 904L and 316L stainless steel requires a rigorous, informed assessment, balancing their distinct chemical compositions, mechanical properties, and unparalleled corrosion resistance capabilities against specific environmental exigencies and comprehensive lifecycle costs. 904L's superior performance in highly aggressive, chloride- and acid-rich conditions positions it as indispensable for critical, high-reliability applications, while 316L remains a robust and cost-effective solution for less demanding environments. A strategic approach, supported by deep technical expertise, ensures optimal material selection, minimizing risks and maximizing long-term project value.

1. What is the primary advantage of 904L over 316L stainless steel?

904L’s primary advantage lies in its significantly enhanced corrosion resistance, particularly to highly aggressive media such as hot dilute sulfuric acid and chloride solutions. This superior resilience stems from its higher concentrations of nickel, molybdenum, and the inclusion of copper, which collectively provide a much higher Pitting Resistance Equivalent Number (PREN) and improved resistance to stress corrosion cracking, making it ideal for the most demanding environments.

2. In what scenarios is 316L stainless steel a more appropriate choice than 904L?

316L stainless steel is a more appropriate and economically sensible choice for applications involving moderate corrosive conditions, such as general marine environments (above the waterline), food and beverage processing, pharmaceutical equipment with less aggressive cleaning agents, and architectural components. Its balance of good corrosion resistance, mechanical properties, and lower cost makes it a versatile and widely deployed material for many standard industrial requirements.

3. How does the cost of 904L compare to 316L, and why?

904L is considerably more expensive than 316L stainless steel. This higher cost is directly attributable to its enriched alloying elements, specifically the much higher percentages of nickel and molybdenum, along with the inclusion of copper. These elements are premium metals, and their increased presence drives up the raw material cost significantly.

4. Can 904L and 316L stainless steels be welded? What are the considerations?

Both 904L and 316L stainless steels possess good weldability. For both, it is crucial to use appropriate filler metals and minimize heat input to prevent sensitization, which can compromise corrosion resistance. For 904L, low-carbon content helps mitigate sensitization risks, and often, post-weld treatments like pickling and passivation are recommended to restore the passive layer and ensure optimal corrosion performance in aggressive service.

5. What is the Pitting Resistance Equivalent Number (PREN), and why is it important for these materials?

The Pitting Resistance Equivalent Number (PREN) is a calculated value used to predict a stainless steel's resistance to pitting and crevice corrosion, particularly in chloride-containing environments. It is derived from the material's chemical composition (specifically chromium, molybdenum, and nitrogen). A higher PREN value indicates superior resistance. For materials like 904L (with a PREN often above 34) and 316L (with a PREN typically 23-28), it is a critical metric for discerning their suitability in environments where localized corrosion is a significant threat.

6. Are there any specific machining challenges with 904L compared to 316L?

Yes, 904L is generally more challenging to machine than 316L stainless steel. Its higher alloy content contributes to increased toughness and a greater propensity for work hardening during cutting. This necessitates adjustments in CNC machining parameters, including slower cutting speeds, higher feed rates, and the use of specialized, robust tooling to manage chip formation effectively and achieve desired surface finishes and dimensional accuracy.

7. How does VMT CNC Machining Parts Services Factory ensure the quality of parts made from these specialized materials?

Our factory ensures exceptional quality through a multi-faceted approach. We start with rigorous material certification and sourcing from reputable suppliers. Our advanced multi-axis CNC machining centers are operated by highly skilled engineers who employ optimized cutting strategies tailored for 904L and 316L. We implement stringent in-process quality control, including precise dimensional inspection and surface finish verification. Furthermore, we adhere to specified post-machining treatments like passivation to maximize corrosion resistance, guaranteeing that every component meets the most exacting performance specifications.

8. What industries most commonly utilize 904L stainless steel components?

904L stainless steel components are predominantly utilized in industries where extreme corrosion resistance is paramount. These include the chemical processing industry (especially for handling sulfuric and phosphoric acids), oil and gas extraction, pharmaceutical manufacturing, flue gas desulfurization (FGD) systems, and specialized marine applications where components are exposed to highly aggressive chloride-rich or acidic environments. Its application is typically reserved for critical components where failure would lead to significant operational, safety, or environmental repercussions.

My conviction is unshakable: the sagacious selection of material forms the absolute bedrock of any enduring engineering triumph. It is a decision that resonates through the entire lifecycle of a product, defining its reliability, its cost-effectiveness, and, ultimately, its legacy. To disregard this foundational truth is to invite inevitable tribulation.

We, at VMT CNC Machining Parts Services Factory, are not merely purveyors of components; we are ardent collaborators, technical advisors, and unwavering champions of precision. Our deep technical expertise as a source manufacturer, coupled with our commitment to transparent pricing and the delivery of high-quality, impeccably machined parts, ensures that you receive not just a product, but the unequivocally correct material solution, flawlessly executed. It’s an irreplaceable partnership.

Stop guessing and start optimizing. Don't let material selection uncertainty compromise your project's inevitable success. Contact our expert engineering team today for a complimentary, in-depth consultation on your 904L or 316L requirements. As a source manufacturer with deep technical expertise and transparent pricing, we provide the precision-machined, high-quality components you desperately need to build with unwavering confidence. Request your custom quote now and ensure the right material for your most critically exacting applications.

Download our comprehensive 'Advanced Stainless Steel Selection Guide' for an even deeper dive into material properties and best practices! It is an indispensable resource.