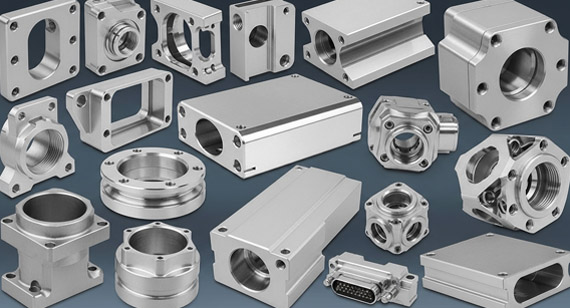

15 years one-stop China custom CNC machining parts factory

47 |

Published by VMT at Oct 24 2025 | Reading Time:About 3 minutes

47 |

Published by VMT at Oct 24 2025 | Reading Time:About 3 minutes

You grapple with material specification, don't you? The gnawing apprehension, that sensation of navigating a perilous labyrinth of nomenclature and physical attributes, is a common plight. Many project stakeholders, perhaps even you, fundamentally misunderstand the disparate nature of material grade and physical dimension; this confusion, indeed, can lead to utterly catastrophic design miscalculations—a veritable quagmire for any manufacturing endeavor. This discourse aims to disentangle that very Gordian knot, providing unblemished clarity and authoritative guidance from VMT, your ultimate partner in high-precision CNC machining.

If you are pondering whether "304 stainless steel" is inherently superior to "16-gauge," you are, quite simply, juxtaposing two entirely distinct characteristics of a metal. 304 stainless steel designates the *composition* and *properties* of the alloy, dictating its performance against corrosion or heat. Conversely, 16-gauge refers solely to the *thickness* of the material, impacting its structural fortitude and weight. Both attributes are critically indispensable, but never interchangeable.

Truly, a material's pedigree, its very molecular makeup, dictates its destiny in an application. When we speak of 304 stainless steel, we’re delving into a realm of atomic architecture—a symphony of chromium and nickel—which confers exceptional, almost miraculous, characteristics upon it. Neglecting this foundation is, frankly, an unbelievably foolish assumption to make during design phases.

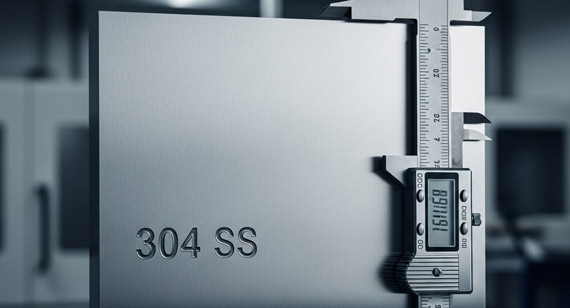

Defining 304 SS: Composition and Properties

At its essence, 304 stainless steel, a venerable member of the austenitic family, comprises roughly 18% chromium and 8% nickel—a formulation that bestows upon it its famed resilience. This specific alloy, for most discerning engineers, represents the bedrock of corrosion resistance; its resistance to oxidation, furthermore, in various ambient environments, is truly remarkable. Non-magnetic in its annealed state, though some magnetism may be induced through cold working, it presents a formidable blend of strength and ductility. Its weldability, one might affirm, is generally excellent, making it a pragmatic selection for myriad fabrication quests. The mechanical characteristics, too, are often a compelling reason for its omnipresent adoption.

Key Benefits of 304 Stainless Steel in Applications

The advantages bestowed by 304 SS are manifold, undeniably prodigious. Foremost amongst them, its superior corrosion endurance means a substantially prolonged operational lifespan for components, mitigating the specter of untimely replacements and warranty claims—a truly mind-blowing miracle for businesses seeking longevity. It exhibits robust resistance to diverse atmospheric conditions, along with many organic and inorganic chemicals. Its formability, allowing for easy deep drawing and bending, renders it profoundly versatile for intricate shapes. Furthermore, this stalwart alloy maintains its structural integrity and aesthetic appeal in a sweeping array of temperature fluctuations. It's truly an all-rounder.

Common Industrial Uses of 304 SS

Ponder the diverse universe where 304 stainless steel reigns supreme. From kitchen apparatus—sinks, pots, pans—to the intricate vessels of chemical processing plants, its pervasive reach is astonishing. Indeed, architectural facades often benefit from its lustrous, enduring veneer. The food and beverage sector, with its exacting hygiene standards, relies extensively upon 304 SS for containers, piping, and preparation surfaces. You'll find it within the demanding realms of medical instruments and pharmaceutical equipment, too, where cleanliness is paramount. Frankly, almost anywhere durability and a pristine surface are demanded, this material usually makes an appearance.

Now, let's pivot, shall we, to an entirely different, yet equally consequential, attribute—the physical dimension. A material’s heft, its very substantiality, exerts a phenomenal influence over its capacity to withstand external forces. To neglect the profound implications of gauge is to invite structural catastrophe, a veritable downfall!

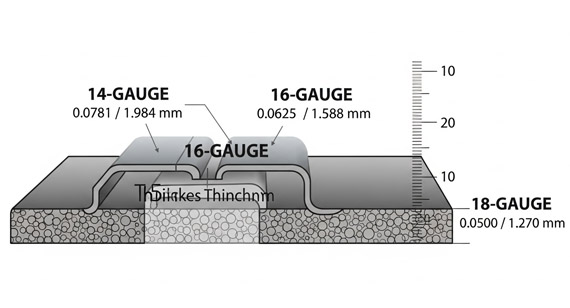

What "Gauge" Means in Stainless Steel Production

What, pray tell, is this "gauge" of which we speak? It is, simply put, a measurement system dictating the thickness of sheet metal. Curiously, it’s an inverse scale: a *lower* gauge number denotes a *thicker* material. Consequently, 16-gauge stainless steel is substantially thicker than, say, 20-gauge, but thinner than 14-gauge. This arcane system, though initially perplexing, is absolutely foundational for engineers specifying sheet metal fabrication. Our team, it must be said, navigates these specifications with unflinching precision.

The Role of 16-Gauge Thickness in Structural Integrity

The robust nature of 16-gauge steel—approximately 1.588 mm or 0.0625 inches thick—renders it exceptionally suitable for applications demanding a moderate degree of rigidity and load-bearing capacity. Its substantial girth contributes significantly to the overall structural integrity of components, preventing unwanted deflection, bending, or outright deformation under stress. This specific thickness, we've observed countless times, often strikes an optimal equilibrium between material expenditure and required physical resilience. It's a judicious middle ground, often.

Practical Implications of Different Gauges

Consider the tangible ramifications of choosing a particular gauge; this decision, you see, directly impacts a part's utility and resilience. For instance, a very thin 18-gauge (approx. 1.27 mm) might suffice for lightweight enclosures or cosmetic panels, where minimal structural load is anticipated. Conversely, a more substantial 14-gauge (approx. 1.984 mm) is often indispensable for heavy-duty frameworks, structural supports, or components subjected to significant impact or abrasive forces. The material’s resistance to impact, vibration damping, and overall perceived durability are all directly proportional to its gauge. Picking correctly? It means everything!

Honestly, the very premise of comparing a material's intrinsic nature to its physical bulk is fundamentally flawed, akin to asking if a car's engine is "better" than its wheelbase. They are interdependent, yes, but never mutually exclusive alternatives. My contention, and it's a firm one, is that this confusion stems from a lack of foundational understanding—a gap VMT seeks to bridge.

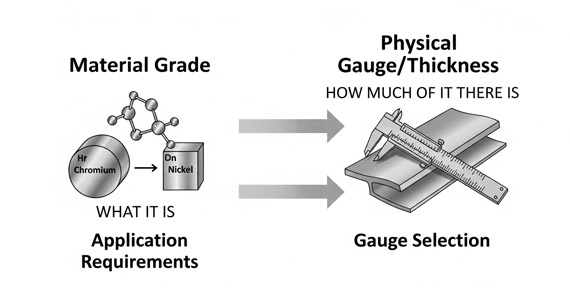

Clarifying the Fundamental Difference: Grade vs. Dimension

Let us be unequivocal: "grade" pertains to the alloy's chemical composition and its inherent metallurgic characteristics—how it interacts with its environment, resists corrosion, or endures heat. "Gauge," on the other hand, is a purely geometric attribute, describing the material's physical thickness or dimension. One dictates *what* the material essentially *is*, the other dictates *how much* of it there physically *is*. You wouldn't, after all, compare the species of an apple to its diameter, would you? The distinction, truly, could not be starker.

The Importance of Context in Material Specification

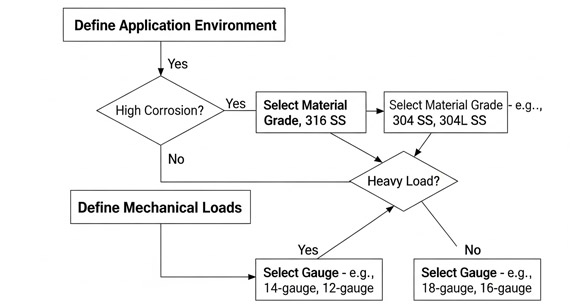

The truly consequential factor in specifying stainless steel is, without a doubt, context. An R&D engineer must first ascertain the operational environment: Will it face corrosive chemicals? Extreme temperatures? High humidity? This dictates the *grade*. Subsequently, the physical demands—load-bearing, impact resistance, stiffness—will then determine the requisite *gauge*. To ignore this sequential, contextual consideration is to invite inevitable failure. It’s a process, one that demands expert oversight, truthfully.

Avoiding Common Misconceptions in Design

One often encounters the misconception that a thicker gauge can compensate for a deficient material grade. Ah, but that is a dangerous gambit! A 14-gauge component made from a lesser-grade steel, susceptible to rapid corrosion, will simply corrode *more slowly*—it will not suddenly gain the intrinsic resistance of 304 SS. Conversely, the most superb 304 SS, if specified too thinly (say, 24-gauge), will buckle under structural stress, notwithstanding its splendid corrosion defiance. We, at VMT, have seen the regrettable consequences of such oversight; costly redesigns, indeed, are never a joyous spectacle.

The sagacious engineer understands that selection is not a haphazard affair; it's a calibrated dance between competing requirements. Often, a procurement manager, in seeking cost efficiency, might overlook a subtle distinction, leading to unforeseen product failures. We must, in our endeavors, always seek the optimal nexus.

Prioritizing Material Grade for Environmental Resistance

When your component is slated for a particularly aggressive milieu—think marine environments, stringent chemical processing, or constant moisture exposure—the material grade assumes paramount, indeed, absolutely irreplaceable, importance. Its very essence, its chemical composition, dictates its survivability. A superlative corrosion-resistant alloy like 304 SS, or even 316 SS for even harsher conditions, becomes the non-negotiable bedrock. The wrong grade, regardless of its thickness, will inevitably succumbs to the ravages of its surroundings. It's a simple, brutal truth.

Prioritizing Gauge for Strength and Durability Requirements

Conversely, when physical stresses dominate the operational landscape—perhaps intense vibrations, significant static loads, or potential impact—the gauge of your chosen material takes center stage. A robust gauge ensures mechanical stability, preventing fatigue failure, structural collapse, or unwanted deflection. Imagine a bracket: if it needs to support substantial weight, its thickness, its inherent rigidity, becomes the pivotal concern. A flimsy, albeit chemically pristine, part is still a failed part.

Balancing Grade and Gauge for Optimal Performance and Cost

The genuine artistry in material specification, and frankly, where VMT truly shines, lies in striking that delicate balance. One desires an alloy (grade) that can withstand its environmental challenges without premature degradation, *and* one that possesses sufficient physical bulk (gauge) to manage mechanical loads. Over-engineering with an excessively thick or unnecessarily premium grade incurs needless expenditures, while under-engineering invites inevitable, costly failures. Our mission? To guide you to that sweet spot of performance, longevity, and, indeed, cost efficiency. It’s an absolutely vital endeavor.

We've observed a recurring theme: confusion, costly errors, and a pervasive lack of confidence in supplier knowledge. This is where VMT, as a distinguished source manufacturer, offers more than just CNC machining parts services; we offer profound tranquility. Our commitment transcends mere fabrication; we pledge clarity and absolute precision.

How Our Deep Technical Expertise Ensures the Right Choice

VMT's engineering cadre possesses an encyclopedic comprehension of material science—a veritable wellspring of knowledge regarding 304 stainless steel properties, the nuances of 16-gauge stainless steel thickness, and the broader spectrum of stainless steel material selection. Our consultative approach, quite frankly, is unparalleled. We delve into your application's intricacies, dissecting its environmental exposure, mechanical stresses, and aesthetic requisites to pinpoint the absolute ideal material grade vs gauge combination. We are not simply order-takers; we are your technical partners, ensuring your stainless steel application guide becomes a reality.

Transparent Pricing for Custom Material & Gauge Solutions

The vagaries of pricing, alas, can be a major source of apprehension for procurement managers. We at VMT believe in unimpeachable candor. Our quotations for custom 304 stainless steel CNC machining parts and 16-gauge stainless steel CNC machining parts are meticulously itemized, reflecting the actual cost of materials, the intricacies of the CNC machining process, and the scrupulous quality control measures implemented. No hidden fees. No unpleasant surprises. What you see is precisely what you receive—a high-quality, perfectly specified component at a fair, unequivocal price.

Partnering with a Source Manufacturer for High-Quality Parts

When you collaborate with VMT, you're not merely engaging a vendor; you're enlisting a dedicated source manufacturer, one committed to delivering high-quality CNC machining parts without compromise. Our vertically integrated operations permit stringent oversight at every juncture, from raw material procurement to final inspection. This unwavering dedication translates directly into superior 304 stainless steel CNC machining parts, meticulously crafted to your exacting specifications, whether they demand specific thickness or a specific material grade. Our reputation, you see, is built upon this very bedrock of excellence.

Indeed, VMT represents the zenith of stainless steel CNC machining. We transcend the ordinary, delivering extraordinary results that elevate your projects. Our capabilities encompass the full spectrum, from prototype creation to high-volume production, always adhering to the most rigorous standards. We specialize in components demanding the distinctive characteristics of 304 SS, married with the structural fortitude provided by specific gauges like 16-gauge. We absolutely ensure every CNC machining part, every single component, lives up to its immense potential.

So, is 304 stainless steel truly "better" than 16-gauge? A profound realization dawns, doesn't it? They aren't in competition, are they! One speaks of composition, the other of dimension—both pivotal, yet utterly distinct, pillars of proper specification. To truly excel, one must judiciously select the correct material grade for environmental endurance, and then, with equal sagacity, determine the appropriate physical gauge for structural integrity. Overlooking this essential truth is, in my most fervent opinion, a recipe for regrettable outcomes.

This article clarifies the common misconception that 304 stainless steel and 16-gauge are comparable. It distinguishes material grade (304 SS) by its chemical composition and properties like corrosion resistance, from physical gauge (16-gauge) which denotes thickness and structural impact. Emphasizing that both are critical but serve different functions, it advocates for contextual selection to optimize performance, longevity, and cost. VMT's expertise ensures clients make informed decisions, preventing costly errors and guaranteeing high-quality CNC machined parts.

Contact our material specialists today! Stop guessing and start optimizing. Leverage our deep technical expertise for your next project, securing a free consultation and a transparent, high-quality quote tailored to your exact 304 stainless steel and gauge requirements. We are ready!

1. What is the primary difference between stainless steel "grade" and "gauge"?

The fundamental distinction is that 'grade' refers to the chemical composition and intrinsic metallurgical properties of the alloy—how it chemically interacts with its environment, resists corrosion, or endures heat. 'Gauge,' by contrast, is a physical measurement, an inverse scale describing the material's thickness, which primarily dictates its structural fortitude and weight. They are entirely separate parameters, each playing a critical, distinct role.

2. Why is 304 stainless steel so widely utilized in industrial applications?

304 stainless steel is immensely popular due to its exceptional blend of properties. Its approximate 18% chromium and 8% nickel composition confers superior corrosion resistance in diverse atmospheric and chemical conditions. Furthermore, it boasts excellent formability, making it amenable to various fabrication processes, and very good weldability, which simplifies manufacturing. Its robust mechanical properties and aesthetic appeal also contribute to its widespread adoption.

3. How does a material's gauge impact the performance of a CNC machined part?

The gauge, or thickness, of a material profoundly influences a CNC machined part's structural integrity and durability. A thicker gauge generally provides greater rigidity, increased load-bearing capacity, superior impact resistance, and enhanced vibration damping. Conversely, a thinner gauge reduces weight and material cost but offers less structural support. Correct gauge selection is paramount for a part to withstand its intended mechanical stresses without deformation or failure.

4. Can I use a thicker gauge to compensate for choosing a lower-grade stainless steel?

No, absolutely not! This is a dangerous and common misconception. While a thicker gauge might offer greater initial structural rigidity, it cannot magically bestow the intrinsic chemical resistance of a superior material grade. A lower-grade steel, even if thicker, will still be susceptible to the environmental degradation (e.g., corrosion) that its composition predisposes it to, simply at a potentially slower rate. Grade determines environmental performance; gauge determines mechanical robustness.

5. When should I prioritize the material grade over the gauge, or vice versa?

You should prioritize material grade when the component will face aggressive environmental conditions, such as corrosive chemicals, high humidity, or extreme temperatures. The grade ensures chemical resilience. Conversely, prioritize gauge when the primary concern is mechanical performance—such as load-bearing capacity, impact resistance, or the need for a stiff, robust structure. Often, an astute engineer balances both for optimal performance and cost.

6. What specific properties make 304 Stainless Steel ideal for food and beverage applications?

For food and beverage applications, 304 Stainless Steel is coveted for its outstanding corrosion resistance, particularly against various food acids and cleaning agents, which prevents contamination and maintains hygiene. Its smooth, non-porous surface is easy to clean and sanitize, deterring bacterial growth. Additionally, its durability ensures a long service life for equipment, making it a cost-effective and safe choice.

7. What kind of technical expertise does VMT offer for material and gauge selection?

VMT provides comprehensive technical consultation, leveraging our engineers' deep knowledge of material science, metallurgy, and advanced CNC machining. We collaborate with clients to understand their application's specific environmental conditions, mechanical loads, and operational requirements. This holistic approach enables us to recommend the precise material grade (e.g., 304 SS) and appropriate gauge (e.g., 16-gauge) that will optimize component performance, longevity, and overall project cost-effectiveness.

8. How does VMT ensure transparent pricing for custom stainless steel CNC machining parts?

VMT upholds absolute transparency in pricing by providing meticulously itemized quotations. These quotes clearly detail the costs associated with raw material procurement (including specific grade and gauge), the complexities of the CNC machining processes involved, and any subsequent finishing or quality control measures. We eliminate hidden fees and ensure that our clients receive a clear, unambiguous understanding of their investment, reinforcing trust and confidence in our partnership.