15 years one-stop China custom CNC machining parts factory

59 |

Published by VMT at Oct 18 2025 | Reading Time:About 5 minutes

59 |

Published by VMT at Oct 18 2025 | Reading Time:About 5 minutes

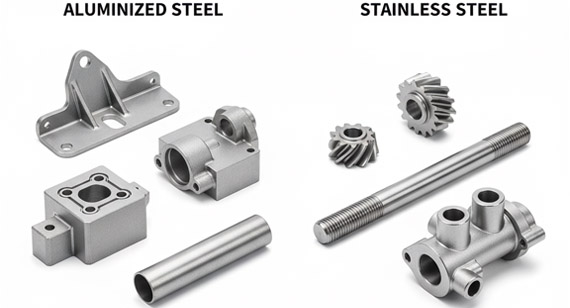

When selecting materials for industrial components, you may struggle to choose between aluminized steel and stainless steel. Both are known for their corrosion resistance, heat resistance, and durability, but they behave differently under specific conditions.

This confusion often leads to higher production costs, reduced part performance, or even premature material failure—especially if the wrong alloy is chosen for high-temperature or corrosive environments.

The good news is that understanding their composition, mechanical properties, and machining characteristics makes it easy to select the right one for your project. In this guide, you’ll discover all the key differences between aluminized steel and stainless steel—from cost and performance to applications and CNC machining suitability.

Aluminized steel is carbon steel coated with an aluminum-silicon alloy for better heat resistance and corrosion protection at high temperatures. Stainless steel, made from chromium-nickel steel, offers superior corrosion resistance, strength, and durability across harsh environments. In short, aluminized steel suits heat applications like exhaust systems, while stainless steel excels in corrosive and long-term structural uses.

Now that you understand the basic difference between aluminized steel and stainless steel, it’s time to explore their characteristics in detail. By comparing their composition, mechanical properties, and applications, you’ll be able to decide which material is more cost-effective and reliable for your CNC machining project.

If you’re looking for custom CNC machining services for either material, check out our page on CNC machining parts and services for more details.

Aluminized steel is a type of carbon steel coated with an aluminum–silicon alloy to enhance its heat and corrosion resistance. This coating provides a strong barrier that protects the underlying steel from oxidation and rust, especially at high temperatures. The result is a material that combines the strength of steel with the protective properties of aluminum.

Aluminized steel is widely used in exhaust systems, ovens, and heat shields, where heat resistance and cost-effectiveness are crucial. It maintains its surface appearance even under continuous heat exposure, unlike plain carbon steel that oxidizes quickly.

Stainless steel is an iron-based alloy that contains at least 10.5% chromium, along with elements like nickel, molybdenum, or carbon to enhance its corrosion resistance, strength, and formability. The chromium reacts with oxygen to form a thin, invisible passive layer that protects the surface from rust and oxidation.

This makes stainless steel ideal for corrosive, moist, and chemical-rich environments—such as food processing, medical equipment, and marine components. Common grades include 304, 316, and 409, each offering a different balance of corrosion resistance, cost, and heat tolerance.

Aluminized steel combines the strength of carbon steel with the protective properties of an aluminum–silicon coating. This coating acts as a barrier against heat and corrosion, making it a popular choice for applications that demand thermal stability and cost efficiency.

Its main benefits include excellent heat reflectivity, resistance to oxidation, and affordability, which make it ideal for automotive exhausts, ovens, and industrial heating equipment. However, its corrosion resistance is limited compared to stainless steel, and once the coating is damaged, the exposed steel can rust quickly.

A detailed table later in the article will list the key advantages and disadvantages of aluminized steel for easy reference.

Table: Aluminized Steel: Advantages and Disadvantages

The following table summarizes the main advantages and disadvantages of aluminized steel for CNC machining and industrial applications.

| Category |

Advantages |

Disadvantages |

| Corrosion Resistance |

Provides moderate corrosion protection through its aluminum–silicon coating. | Coating can wear off or corrode in highly humid or salty environments. |

| Heat Resistance |

Excellent heat reflectivity; performs well up to around 800°C (1470°F). | Prolonged exposure above coating limits can reduce protection. |

| Strength |

Retains the base strength of carbon steel. | Not as strong or ductile as stainless steel at high temperatures. |

| Cost |

More affordable than stainless steel; ideal for budget-sensitive projects. | Shorter service life in corrosive conditions may increase long-term costs. |

| Appearance |

Smooth, reflective surface with good oxidation resistance. | Surface can discolor or dull after prolonged heat exposure. |

| Machinability |

Easy to machine and form; coating offers some wear protection during cutting. | Overheating during machining can damage the aluminum coating. |

| Applications |

Common in exhaust systems, furnaces, and heat shields. | Unsuitable for marine, food-grade, or highly chemical environments. |

Stainless Steel: Advantages and Disadvantages

Stainless steel stands out as one of the most durable and corrosion-resistant materials used in CNC machining and industrial fabrication. Its unique chromium-nickel composition forms a protective oxide layer that prevents rust, even in harsh or wet environments. This makes it ideal for marine, medical, and food-processing applications where hygiene and longevity are critical.

However, stainless steel is generally more expensive and harder to machine than aluminized steel due to its high strength and work-hardening tendency. Despite this, its superior corrosion resistance, heat resistance, and aesthetic finish often justify the higher cost for long-term performance.

A detailed table later in the article will outline the main advantages and disadvantages of stainless steel for quick comparison.

Table: Stainless Steel: Advantages and Disadvantages

The following table lists the main advantages and disadvantages of stainless steel in CNC machining and industrial applications.

| Category | Advantages | Disadvantages |

| Corrosion Resistance | Exceptional corrosion resistance due to the chromium oxide passive layer; ideal for wet and chemical environments. | May still corrode in chloride or acidic environments without proper grade selection (e.g., 304 vs. 316). |

| Heat Resistance | Maintains strength and oxidation resistance at high temperatures. | Prolonged heat exposure can cause scaling or loss of surface luster. |

| Strength and Durability | High tensile strength and wear resistance for demanding applications. | Difficult to cut or form due to hardness and work-hardening behavior. |

| Cost | Offers long-term value through durability and low maintenance. | Higher initial material and processing cost than aluminized steel. |

| Appearance | Attractive, bright, and easy-to-clean surface finish suitable for decorative and hygienic applications. | Susceptible to fingerprints and smudges without surface treatment. |

| Machinability | Produces precise, clean finishes with proper tools and cutting fluids. | Can cause rapid tool wear and requires slower machining speeds. |

| Applications | Used in marine, medical, food processing, and structural components. | Not ideal for cost-sensitive projects or non-corrosive environments. |

When comparing aluminized steel vs. stainless steel, the key differences come down to their chemical composition and how this affects their mechanical, thermal, and corrosion-resistant properties. Both are designed to perform in demanding conditions, but they achieve durability in different ways.

Aluminized steel relies on its aluminum–silicon coating to resist oxidation and heat, while stainless steel uses its chromium–nickel alloy base to form a self-healing passive film that protects against corrosion. Understanding these fundamental differences helps you choose the right material for your CNC machining parts based on your project’s working temperature, exposure level, and required lifespan.

Aluminized Steel vs. Stainless Steel: Chemical Composition

The chemical composition of each material defines its key performance characteristics. Aluminized steel consists of a carbon steel core coated with an aluminum–silicon alloy (typically 90% aluminum and 10% silicon), offering strong heat reflectivity and oxidation resistance.

Stainless steel, on the other hand, contains iron, chromium (10.5–20%), and often nickel (8–12%), providing superior corrosion protection through a stable oxide layer that regenerates when scratched.

A detailed table later will compare the major chemical components of both materials, highlighting the elements that influence corrosion resistance, heat resistance, and machinability.

Table: Aluminized Steel vs. Stainless Steel: Chemical Composition

The following table compares the typical chemical composition of aluminized steel and common stainless steel grades used in CNC machining and manufacturing applications.

| Element |

Aluminized Steel (Type 1 Coating) |

Stainless Steel (304 Grade) |

Effect on Properties |

| Iron (Fe) |

Balance (base metal) | Balance (base metal) | Provides structural strength and rigidity. |

| Carbon (C) |

0.05–0.20% | ≤ 0.08% | Increases hardness and strength but reduces ductility and corrosion resistance. |

| Aluminum (Al) |

~90% (coating) | — | Forms an oxidation-resistant barrier and improves heat reflectivity. |

| Silicon (Si) |

~10% (coating) | ≤ 1.00% | Enhances coating adhesion and improves oxidation resistance. |

| Chromium (Cr) |

— | 18–20% | Key element for corrosion resistance; forms a passive oxide layer. |

| Nickel (Ni) |

— | 8–10.5% | Improves ductility, corrosion resistance, and formability. |

| Manganese (Mn) |

≤ 1.00% | ≤ 2.00% | Increases toughness and hardenability. |

| Phosphorus (P) |

≤ 0.04% | ≤ 0.045% | Small amounts increase strength but can reduce ductility. |

| Sulfur (S) |

≤ 0.05% | ≤ 0.03% | Improves machinability but may lower corrosion resistance. |

| Other Elements |

Trace amounts | May contain Mo, N | Molybdenum (Mo) improves pitting resistance; nitrogen (N) enhances strength. |

Aluminized Steel vs. Stainless Steel: Physical Properties

The physical properties of aluminized steel and stainless steel determine how they perform under heat, stress, and environmental exposure. These characteristics—such as density, melting point, thermal conductivity, and corrosion resistance—play a major role in selecting the right material for CNC machining, forming, or fabrication.

Aluminized steel excels in heat reflection and thermal stability, while stainless steel provides superior corrosion resistance and mechanical strength across a wide temperature range. Understanding these differences will help you choose the right alloy for your project’s working conditions.

Aluminized Steel vs. Stainless Steel: Physical Properties Comparison Table

| Property |

Aluminized Steel |

Stainless Steel (304 Grade) |

Remarks / Performance Insight |

| Density (g/cm³) |

7.70–7.85 | 7.93 | Stainless steel is slightly denser but offers higher strength. |

| Melting Point (°C) |

~660°C (Al coating) / 1370°C (core steel) | 1400–1450°C | Stainless steel has a higher melting range, suitable for extreme heat. |

| Thermal Conductivity (W/m·K) |

25–30 | 16.2 | Aluminized steel transfers heat more efficiently, ideal for exhaust and heating components. |

| Electrical Resistivity (Ω·m) |

0.6 × 10⁻⁶ | 0.72 × 10⁻⁶ | Both have similar resistivity; stainless steel resists scaling at higher voltages. |

| Thermal Expansion Coefficient (10⁻⁶/K) |

12–13 | 17.2 | Stainless steel expands more with heat, which must be considered during precision CNC machining. |

| Corrosion Resistance |

Moderate (depends on coating integrity) | Excellent due to chromium oxide layer | Stainless steel provides longer-term corrosion protection. |

| Magnetic Properties |

Slightly magnetic (depends on core steel type) | Generally non-magnetic (austenitic types) | Ferritic or martensitic stainless grades may be magnetic. |

| Formability |

Good; coating provides flexibility for shaping | Excellent; easily drawn, rolled, or stamped | Both materials can be formed, but coating limits deep drawing in aluminized steel. |

| Machinability (Annealed Condition) |

Good; easier to machine than stainless | Moderate; harder on cutting tools | Stainless steel requires slower speeds and high-quality tooling. |

| Environmental Adaptability |

Performs well in dry and high-heat conditions | Performs well in wet, chemical, or marine conditions | Choose based on exposure—heat for aluminized, moisture for stainless. |

Aluminized Steel vs. Stainless Steel: Mechanical Properties

The mechanical properties of aluminized steel and stainless steel determine their performance under stress, load, and heat. These factors—such as tensile strength, hardness, ductility, and elastic modulus—are critical when selecting materials for CNC machining parts, structural components, or automotive systems.

Aluminized steel provides strong mechanical stability with excellent heat resistance, making it suitable for parts that experience constant temperature changes. Stainless steel, on the other hand, offers higher tensile strength, ductility, and fatigue resistance, giving it superior performance for long-term applications under mechanical stress.

Aluminized Steel vs. Stainless Steel: Mechanical Properties Comparison Table

| Property |

Aluminized Steel |

Stainless Steel (304 Grade) |

Remarks / Performance Insight |

| Hardness (HRC) |

10–20 | 15–30 | Stainless steel can be heat-treated to higher hardness levels. |

| Hardness (HV) |

120–160 HV | 150–200 HV | Stainless steel maintains hardness better at high temperatures. |

| Hardness (HRB/HRC) |

HRB 65–80 | HRB 80–95 / HRC 15–30 | Stainless steel offers improved wear resistance. |

| Tensile Strength (MPa) |

340–480 | 520–750 | Stainless steel provides greater overall strength and durability. |

| Yield Strength (Rp0.2 / MPa) | 250–300 | 205–310 | Both materials show comparable yield strength depending on processing. |

| Ultimate Tensile Strength (MPa) | 420–500 | 600–750 | Stainless steel resists deformation under higher loads. |

| Ductility (%) |

25–30% | 40–50% | Stainless steel is more ductile and suitable for forming operations. |

| Elongation at Break (%) |

25–30 | 40–45 | Stainless steel stretches more before failure, ideal for deep drawing. |

| Reduction of Area (Z/%) |

45–50 | 55–60 | Indicates higher deformation tolerance for stainless steel. |

| Elastic Modulus (Young’s Modulus, GPa) |

200 | 193 | Both materials offer similar rigidity for precision parts. |

| Shear Strength (MPa) |

250–300 | 350–450 | Stainless steel handles higher shear loads. |

| Shear Modulus (GPa) |

~80 | ~77 | Comparable, ensuring similar deformation response under shear. |

| Fatigue Strength (MPa) |

200–250 | 240–310 | Stainless steel maintains longer fatigue life under cyclic stress. |

| Poisson’s Ratio |

0.28–0.30 | 0.30 | Nearly identical, important for stress-strain calculations. |

| Heating Temperature (°C) |

700–800 (safe limit) | 870–925 (annealing range) | Stainless steel tolerates higher heat during processing. |

| Elastic Modulus |

200 GPa | 193 GPa | Both materials have similar stiffness levels. |

Heat treatment affects the mechanical performance and durability of both aluminized steel and stainless steel. Proper treatment can improve hardness, tensile strength, and fatigue resistance, but the approach differs for each material.

Aluminized steel generally undergoes annealing or stress-relief processes to maintain the coating integrity while enhancing strength. Stainless steel, depending on the grade, may require annealing, solution treatment, or tempering to achieve the desired balance of strength, ductility, and corrosion resistance.

Aluminized Steel vs. Stainless Steel: Heat Treatment Comparison Table

| Material |

Common Heat Treatments |

Purpose / Benefits |

Notes |

| Aluminized Steel | Annealing | Relieves internal stresses, improves formability, preserves coating | Keep temperature below 660°C to protect aluminum coating |

| Stress-Relief | Reduces distortion after forming or welding | Used for exhaust parts and fabricated assemblies | |

| Stainless Steel (304 Grade) | Annealing | Restores ductility after cold working | Temperature: 1010–1120°C, then rapid cooling |

| Solution Treatment | Enhances corrosion resistance | Dissolves carbides to prevent intergranular corrosion | |

| Tempering (for martensitic grades) | Improves hardness and toughness | Not typically required for austenitic grades like 304 |

Both aluminized steel and stainless steel are widely used in industries that demand corrosion resistance, heat resistance, and mechanical strength. The choice depends largely on the operating environment, temperature exposure, and cost considerations.

Aluminized steel is often used in automotive exhaust systems, furnaces, and industrial heating equipment, where heat resistance and affordability are critical. Stainless steel is preferred in marine, food processing, medical, and chemical applications, where long-term corrosion protection and hygienic surfaces are essential.

Aluminized Steel vs. Stainless Steel: Applications and Uses Table

| Material |

Typical Applications |

Key Advantages in Application |

| Aluminized Steel |

Automotive exhaust systems, heat shields, furnaces, ovens, industrial heaters | Excellent heat resistance, cost-effective, moderate corrosion resistance |

| Stainless Steel (304/316) |

Marine equipment, food processing machinery, medical devices, chemical tanks, architectural structures | Superior corrosion resistance, high durability, hygienic surface, strong mechanical properties |

| CNC Machining Parts |

Custom exhaust components, heating panels, industrial brackets | Aluminized steel: easier to machine with coating protection; Stainless steel: precise parts with high corrosion resistance |

| Long-Term Use |

Components exposed to moderate heat and dry conditions | Stainless steel outperforms aluminized steel in moisture, chemical, or salt-exposed environments |

Aluminized Steel vs. Stainless Steel: Cost and Price

When evaluating aluminized steel vs. stainless steel cost, it’s important to consider both initial material price and long-term value. Aluminized steel typically has a lower upfront cost, making it attractive for heat-resistant applications like exhaust systems or furnaces. Stainless steel, however, offers superior corrosion resistance, durability, and long-term reliability, which can reduce maintenance and replacement costs over time.

Additionally, CNC machining costs vary between the two materials. Aluminized steel is generally easier to machine, while stainless steel requires slower speeds, specialized tooling, and cutting fluids, increasing processing costs. Understanding these factors helps you select the most cost-effective material for your project.

Aluminized Steel vs. Stainless Steel: Cost and Price Comparison Table

| Cost Aspect |

Aluminized Steel |

Stainless Steel (304/316) |

Aluminized Steel vs. Stainless Steel Cost Note |

Remarks |

| Initial Material Cost |

Lower($1.5–$2.5 per kg) |

Higher($3.0–$5.0 per kg) |

— |

Stainless steel is 2–3× more expensive but offers longer lifespan. |

| Processing / CNC Machining Cost |

Moderate; easier to machine than stainless |

Higher; requires specialized tooling and cutting fluids |

— |

Stainless steel increases tool wear and machining time. |

| Market Price |

Lower; widely available |

Higher; varies by grade and market demand |

— | Stainless steel price fluctuates more due to nickel and chromium content. |

| Long-Term Cost-Effectiveness |

Moderate; coating may degrade over time in corrosive environments | High; excellent corrosion resistance and durability reduce replacements | Stainless steel’s higher upfront cost often offsets maintenance costs for long-term projects |

Stainless steel’s durability often offsets higher upfront cost. |

Selecting the right material between aluminized steel vs. stainless steel depends on your project’s environment, temperature exposure, and budget. Both materials have unique advantages, so understanding their strengths ensures you make the most cost-effective and durable choice for your CNC machining parts.

When Should I Use Aluminized Steel?

You should choose aluminized steel when your components will be exposed to high temperatures but minimal moisture or corrosive conditions. Common applications include:

Its aluminum–silicon coating provides excellent oxidation and heat resistance, while keeping material costs low.

When Should I Use Stainless Steel?

Stainless steel is ideal when corrosion resistance, mechanical strength, and long-term durability are priorities. Suitable scenarios include:

Grades like 304 or 316 stainless steel offer excellent resistance to rust, chemical attack, and wear, making them perfect for CNC machined parts that need to withstand harsh or wet environments.

Galvanizing is a method used to protect steel from corrosion by applying a protective zinc coating. While it is different from aluminized steel or stainless steel, galvanizing is an alternative approach for extending the service life of steel components, especially in outdoor or humid environments.

What Are the Common Galvanizing Processes?

There are several widely used galvanizing processes, each offering different levels of protection and application methods:

Hot-Dip Galvanizing

Electro-Galvanizing (Electroplating)

Mechanical Galvanizing (Powder Coating)

Sherardizing (Thermal Diffusion)

Tip: Choose the galvanizing method based on part size, geometry, and required corrosion resistance. Hot-dip is best for heavy-duty protection, while electro-galvanizing works for aesthetic or precision parts.

Hot-dip galvanizing is one of the most common and effective methods for protecting steel from corrosion. In this process, steel components are cleaned, fluxed, and immersed in molten zinc at around 450°C (842°F). The zinc reacts with the steel to form a strong metallurgical bond, creating a durable and corrosion-resistant coating.

This method provides long-lasting protection, even in harsh outdoor environments, and is widely used for structural steel, automotive parts, and industrial equipment. The coating thickness and uniformity can be controlled by immersion time and withdrawal speed.

Choosing between aluminized steel vs. stainless steel depends on your project’s environmental conditions, temperature exposure, and budget.

Aluminized steel is ideal for high-temperature, dry environments like automotive exhaust systems, industrial heaters, and furnaces. It offers excellent heat resistance at a lower cost but has moderate corrosion resistance.

Stainless steel excels in moist, corrosive, or chemical-rich environments, such as marine equipment, food processing, and medical devices. It provides long-term durability and requires minimal maintenance, though the initial cost is higher.

At VMT, we specialize in custom CNC machining of both aluminized steel and stainless steel parts. Our expertise ensures that your components meet tight tolerances, precise dimensions, and high-quality surface finishes, whether for automotive, industrial, or architectural applications.

We offer a full range of services including:

By combining advanced machinery, skilled technicians, and industry knowledge, VMT ensures that your parts perform reliably in high-heat, corrosive, or mechanically demanding environments.

Choosing between aluminized steel vs. stainless steel ultimately comes down to your project’s requirements for corrosion resistance, heat tolerance, mechanical strength, and cost.

Aluminized steel is a cost-effective option for high-temperature, dry environments, offering moderate corrosion resistance and excellent heat reflectivity. It’s ideal for exhaust systems, furnaces, and industrial heating equipment.

Stainless steel excels in moist, corrosive, or chemically aggressive environments, providing superior durability, corrosion resistance, and long-term reliability. It is the preferred choice for marine applications, food processing, medical devices, and structural components.

For CNC machining, both materials can be precisely fabricated, but stainless steel requires specialized tooling and slower machining speeds, while aluminized steel is easier to process if heat management is controlled.

By understanding the chemical composition, physical and mechanical properties, heat treatment options, and cost implications, you can make an informed decision that balances performance, longevity, and budget.

1. What material is better than stainless steel?

Materials like titanium, Inconel, or duplex stainless steels can outperform standard stainless steel in corrosion resistance, strength, or high-temperature performance. The choice depends on your application and budget.

2. How long does it take for aluminized steel to rust?

Aluminized steel resists rust significantly longer than bare carbon steel. Under normal conditions, the aluminum–silicon coating can protect the steel for 5–10 years, depending on environmental exposure.

3. How can I prevent aluminized steel from rusting?

4. Which is better, 304 stainless steel or 409 stainless steel?

5. How durable is aluminized steel?

Aluminized steel is durable in high-heat, low-moisture conditions, making it suitable for exhaust systems, furnaces, and heating elements. Its lifespan is shorter in moist or corrosive environments compared to stainless steel.

6. What grade of aluminized steel is used?

Common grades include Type 1 and Type 2 aluminized steel, which differ in coating thickness and heat resistance. Type 1 is typical for high-temperature applications, while Type 2 is used for general corrosion resistance.

7. Does aluminum or stainless steel last longer?

Stainless steel generally outlasts aluminum in moist, chemical, or high-wear conditions due to its corrosion resistance and mechanical strength. Aluminum may perform better in lightweight, non-corrosive applications.

8. How thick is the aluminized steel coating?

The aluminum–silicon coating typically ranges from 20–30 microns on each side, depending on the grade and application. Thicker coatings provide better oxidation and heat resistance.

9. Why use aluminized steel?

Aluminized steel is chosen for its heat resistance, moderate corrosion protection, cost-effectiveness, and ease of CNC machining. It’s widely used in automotive, industrial heating, and furnace components.

10. Which is more durable, stainless steel or aluminum?

11. Which is more expensive, aluminum or stainless steel?

12. Is titanium better than stainless steel?

Titanium offers higher strength-to-weight ratio, excellent corrosion resistance, and high-temperature stability, making it superior in aerospace, marine, and chemical applications, but it is significantly more expensive and harder to machine than stainless steel.