15 years one-stop China custom CNC machining parts factory

47 |

Published by VMT at Oct 25 2025 | Reading Time:About 5 minutes

47 |

Published by VMT at Oct 25 2025 | Reading Time:About 5 minutes

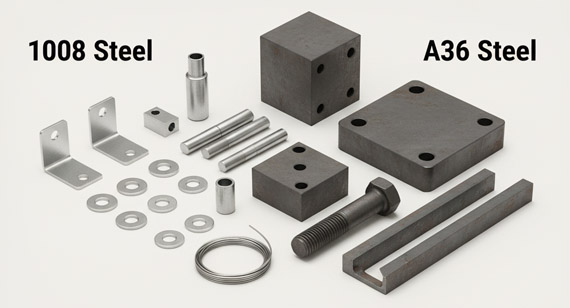

When choosing the right steel for your project, the differences between 1008 steel and A36 steel can be confusing. Both are popular low-carbon steels used in CNC machining and fabrication. But picking the wrong one can cause unnecessary machining challenges, higher costs, or lower part performance. You need to understand their real differences before deciding.

The difference between 1008 steel and A36 steel lies mainly in their chemical composition and strength. 1008 steel is a low-carbon steel with excellent formability and ductility, ideal for deep drawing and cold forming. A36 steel, on the other hand, has higher carbon content and strength, making it suitable for structural and general fabrication applications.

Now that you know the basic distinction between these two steels, let’s dive deeper. You’ll learn what 1008 steel and A36 steel actually are, their equivalent grades, and how their properties, advantages, and costs compare. By the end, you’ll be confident choosing the right material for your CNC machining or fabrication project.

1008 steel is a low-carbon mild steel known for its excellent ductility, formability, and surface finish. It contains about 0.08% carbon and small amounts of manganese, making it ideal for cold-forming, deep drawing, and bending applications. Because of its clean surface and consistent mechanical properties, 1008 steel is widely used in automotive panels, fasteners, and CNC machining parts requiring smooth finishes.

In CNC machining, 1008 steel offers excellent weldability and machinability, though it is softer than higher-carbon steels. This softness makes it easier to cut but limits its use in high-strength structural applications.

Related resource: Learn how we process 1008 stainless steel CNC machining parts with precision and efficiency at VMT CNC machining factory.

1008 steel is often considered equivalent to UNS G10080, AISI 1008, and EN DC01 in international standards. It is part of the AISI 10xx series, representing low-carbon steels with carbon content under 0.10%. In mechanical behavior, it’s comparable to 1010 steel, though 1008 contains slightly less carbon, offering better ductility but lower strength.

This steel grade also aligns closely with SAE J403 and ASTM A1008, both specifying high-quality cold-rolled carbon steel sheets. These equivalents make 1008 steel versatile across automotive, electrical, and CNC fabrication industries.

Related link: Explore our CNC machining services to see how VMT adapts machining strategies for equivalent grades like AISI 1008 and 1010 steel.

A36 steel is a low-carbon structural steel defined by the ASTM A36 standard. It’s widely used in construction, fabrication, and CNC machining because of its excellent weldability, strength, and affordability. The carbon content around 0.25% is higher than that of 1008 steel, giving A36 greater tensile and yield strength, though slightly lower ductility.

A36 steel is commonly used for beams, plates, frames, and structural components where strength is critical. It can be hot-rolled or cold-rolled, depending on surface finish requirements. Its consistent performance and cost-effectiveness make it one of the most popular steels for both manual fabrication and CNC machined parts.

A36 steel is equivalent to EN S275JR, DIN ST37-2, and JIS SS400 in international standards. These equivalents all represent low-carbon structural steels with similar mechanical strength and weldability. In the SAE system, it closely corresponds to AISI 1018 in terms of chemical composition and performance, though A36 allows a slightly broader range of carbon and manganese content.

Because of these similarities, A36 can often replace other mild steels in fabrication, construction, and CNC machining applications. However, it’s important to verify each standard’s tolerance and mechanical limits to ensure compatibility for your specific project.

Both 1008 steel and A36 steel are widely used in manufacturing, but they serve different purposes.

In short: choose 1008 steel when you need formability and smooth finishes, and choose A36 steel when you need strength and weldability for load-bearing parts.

Comparison Chart: 1008 Steel vs. A36 Steel

| Property |

1008 Steel |

A36 Steel |

| Type |

Low-carbon mild steel | Low-carbon structural steel |

| Carbon Content |

~0.08% | ~0.25% |

| Main Standard |

ASTM A1008, SAE J403 | ASTM A36 |

| Strength |

Lower | Higher |

| Ductility |

Excellent | Moderate |

| Formability |

Excellent ideal for cold forming, deep drawing | Good suitable for general forming |

| Machinability |

Easy to machine but soft | Good machinability with higher tool wear |

| Weldability |

Excellent | Excellent |

| Applications |

Automotive panels, fasteners, CNC machined parts | Structural beams, frames, plates, heavy fabrication |

| Corrosion Resistance |

Low requires coating | Low requires coating |

| Cost |

Slightly lower | Slightly higher |

| Typical Finish |

Smooth cold-rolled surface | Hot-rolled or cold-rolled surface |

Both 1008 steel and A36 steel follow well-established international and national standards. These standards ensure consistent chemical composition, mechanical properties, and performance across global markets. Understanding the equivalent grades helps you select the right material when working with suppliers or CNC machining factories in different regions.

Comparison Table: National Standards and Equivalent Grades

| Standard System |

1008 Steel Equivalent Grades |

A36 Steel Equivalent Grades |

| ASTM / SAE USA |

ASTM A1008, SAE 1008 | ASTM A36 |

| UNS Number |

G10080 | K02600 |

| EN Europe |

EN DC01, EN 1.0330 | EN S275JR, EN 1.0044 |

| DIN Germany |

DIN 1.0330 DC01 | DIN ST37-2 |

| JIS Japan |

JIS SPCC | JIS SS400 |

| GB China |

GB Q195 | GB Q235 |

| ISO |

ISO 3574-DC01 | ISO 630-Fe360B |

| Typical Use Region |

Sheet metal, automotive, CNC components | Structural fabrication, heavy machinery, CNC parts |

Although both 1008 steel and A36 steel belong to the low-carbon steel family, their intended uses and performance characteristics differ significantly. 1008 steel focuses on formability and surface finish, while A36 steel prioritizes strength and structural performance. Understanding these differences helps you select the right material for your machining or fabrication project.

Comparison Chart: Key Differences Between 1008 and A36 Steel

| Aspect |

1008 Steel |

A36 Steel |

| Carbon Content |

~0.08% | ~0.25% |

| Primary Use |

Cold-forming, deep drawing, CNC precision parts | Structural components, beams, plates |

| Strength Level |

Low | Medium to high |

| Ductility |

Excellent | Moderate |

| Formability |

Outstanding for cold work | Good for general fabrication |

| Surface Quality |

Very smooth cold-rolled finish | Rougher hot-rolled or cold-rolled |

| Weldability |

Excellent | Excellent |

| Machinability |

Easy to machine; less tool wear | Good machinability; more tool wear due to hardness |

| Corrosion Resistance |

Low — must be coated | Low — must be coated |

| Heat Treatment |

Limited benefits due to low carbon | Can be normalized or stress relieved |

| Typical Products |

Fasteners, brackets, panels, CNC machined parts | Structural frames, supports, heavy-duty plates |

Both 1008 steel and A36 steel are versatile, affordable, and widely available. However, each has its own advantages and limitations that determine where it performs best. Knowing these strengths and weaknesses helps you select the right steel for your CNC machining, forming, or structural fabrication needs.

1008 Steel: Advantages and Disadvantages

1008 steel stands out for its formability, ductility, and surface finish, making it ideal for cold-forming applications and precision CNC machined parts. However, its low carbon content limits its strength and wear resistance, making it unsuitable for heavy-load or high-stress structures.

Comparison Chart: 1008 Steel Pros and Cons

| Advantages |

Disadvantages |

| Excellent ductility and formability | Low strength and hardness |

| Easy to weld and machine | Poor wear and impact resistance |

| Smooth surface finish for plating or coating | Low corrosion resistance — rusts easily |

| Uniform composition and predictable behavior | Not suitable for structural or high-load use |

| Cost-effective for mass production | Requires protective coating or surface treatment |

A36 Steel: Advantages and Disadvantages

A36 steel is known for its high strength, versatility, and excellent weldability, making it a go-to material for construction and heavy-duty fabrication. While it offers better load-bearing capacity than 1008 steel, it’s less suitable for deep drawing or precision cold-forming because of its higher carbon content.

Comparison Chart: A36 Steel Pros and Cons

| Advantages |

Disadvantages |

| High strength and toughness | Lower ductility compared to 1008 steel |

| Excellent weldability | Surface may require machining for precision work |

| Readily available and affordable | Rougher finish especially hot-rolled |

| Suitable for structural and load-bearing parts | Not ideal for deep drawing or tight-tolerance machining |

| Can be heat-treated for stress relief | Susceptible to rust if uncoated |

To choose between 1008 steel and A36 steel, it’s essential to compare their chemical and mechanical properties. These determine how each material performs in machining, welding, and forming applications. Chemical composition especially affects factors like strength, ductility, and corrosion resistance, which directly influence CNC machining quality and tool life.

1008 Steel and A36 Steel: Chemical Composition

The main difference between 1008 steel and A36 steel lies in their carbon and manganese content.

This difference defines their ideal applications: 1008 for deep drawing and precision forming, and A36 for structural and load-bearing uses.

Comparison Table: Chemical Composition of 1008 vs. A36 Steel % by weight

| Element |

1008 Steel Typical Range |

A36 Steel Typical Range |

Effect on Properties |

| Carbon C |

0.05 – 0.10 | 0.20 – 0.29 | Higher carbon increases hardness and strength but decreases ductility. |

| Manganese Mn |

0.30 – 0.50 | 0.60 – 1.20 | Improves tensile strength and hardenability. |

| Phosphorus P |

≤ 0.04 | ≤ 0.04 | Excess phosphorus can make steel brittle. |

| Sulfur S |

≤ 0.05 | ≤ 0.05 | Improves machinability but can reduce toughness. |

| Iron Fe |

Balance | Balance | Primary base metal. |

| Silicon Si |

≤ 0.10 | ≤ 0.40 | Enhances strength and elasticity slightly. |

| Copper Cu |

— | ≤ 0.20 | Improves corrosion resistance slightly. |

1008 Steel and A36 Steel: Physical Properties

While both 1008 steel and A36 steel are low-carbon steels, their physical properties differ slightly due to variations in carbon and alloy content. These differences affect how each material behaves during CNC machining, welding, and forming. Understanding these properties helps you select the right steel for your project’s strength, precision, and cost requirements.

Density

Both have nearly identical densities, ensuring similar weight per unit volume. The slight difference has minimal effect on fabrication or CNC machining performance.

Melting Point °C

The melting points are nearly the same. A36 may exhibit slightly higher resistance to heat due to higher carbon content.

Thermal Conductivity W/m·K

1008 steel has slightly better thermal conductivity, helping it dissipate machining heat more efficiently.

Resistivity Ω·m

Both steels conduct electricity well. The difference is negligible for most applications but may matter in electrical or magnetic component fabrication.

Thermal Expansion

Linear Thermal Expansion Coefficient 10⁻⁶/K:

Both expand at similar rates when heated. A36’s slightly higher coefficient may cause minor dimensional shifts during welding or machining.

Corrosion Resistance

Both steels have low natural corrosion resistance and require protective coatings such as painting, galvanizing, or plating.

Tip: Always apply protective coatings to prevent rust during storage or service exposure.

Magnetic Properties

Both 1008 and A36 steels are ferromagnetic, meaning they can be magnetized. Their magnetic permeability is high, making them suitable for electromagnetic components and motor housings.

Formability

Tip: Choose 1008 steel for parts requiring multiple forming operations or complex shapes.

Machinability

Note: For high-volume CNC machining, 1008 steel offers smoother operation and longer tool life.

Weldability

Both steels have excellent weldability, with A36 being slightly more robust for heavy structural welding due to higher strength.

Tip: Use appropriate filler materials to prevent cracking and ensure consistent weld strength.

While both 1008 steel and A36 steel are mild carbon steels, their physical properties differ slightly due to variations in composition and manufacturing processes. These differences influence their machinability, weldability, and thermal performance, making one more suitable than the other for specific CNC machining or fabrication applications.

Comparison Table: Physical Properties of 1008 Steel and A36 Steel

| Property |

1008 Steel |

A36 Steel |

Remarks |

| Density |

7.87 g/cm³ | 7.85 g/cm³ | Both have nearly identical density, typical of mild carbon steels. |

| Melting Point °C |

1,425 – 1,530 °C | 1,425 – 1,535 °C | Very similar melting range, suitable for welding and hot forming. |

| Thermal Conductivity W/m·K |

~60 | ~51.9 | 1008 has slightly better heat transfer, beneficial for forming and machining. |

| Electrical Resistivity Ω·m |

1.6 × 10⁻⁷ | 1.58 × 10⁻⁷ | Both are good conductors; differences are negligible in practice. |

| Thermal Expansion Linear, 10⁻⁶/K |

11.7 | 12.0 | A36 expands slightly more when heated. |

| Corrosion Resistance |

Low requires coating | Low requires coating | Both require surface treatments for outdoor or humid environments. |

| Magnetic Properties |

Ferromagnetic | Ferromagnetic | Both materials are magnetic. |

| Formability |

Excellent | Good | 1008 is more ductile and preferred for deep drawing and forming. |

| Machinability |

Good | Fair to Good | 1008 machines more easily due to lower carbon content. |

| Weldability |

Excellent | Excellent | Both weld well using common techniques MIG, TIG, arc. |

1008 Steel and A36 Steel: Mechanical Properties

The mechanical properties of 1008 steel and A36 steel define their performance in forming, machining, and structural applications.

While 1008 steel is a low-carbon material with superior ductility and formability, A36 steel offers higher strength and rigidity, making it a preferred choice for load-bearing and welded structures.

Understanding these differences is essential for selecting the right material for CNC machining parts, automotive components, or construction projects.

Comparison Table: Mechanical Properties of 1008 Steel and A36 Steel

| Property |

1008 Steel |

A36 Steel |

Remarks |

| Hardness HRC |

~50 annealed: <20 | ~55 annealed: <25 | A36 is slightly harder in normalized condition. |

| Hardness HV |

90–120 HV | 120–150 HV | A36 generally exhibits higher hardness due to carbon-manganese content. |

| Hardness HRB |

55–70 HRB | 70–85 HRB | Indicates greater wear resistance for A36. |

| Tensile Strength MPa |

270–410 MPa | 400–550 MPa | A36 provides higher tensile strength for structural applications. |

| Yield Strength MPa |

180–240 MPa | 250–400 MPa | A36 resists deformation better under load. |

| Ultimate Tensile Strength MPa |

370 MPa avg | 485 MPa avg | A36 offers higher ultimate tensile strength. |

| Elongation Rp0.2 / MPa |

— | — | Yield ratio typically lower for 1008, improving ductility. |

| Ductility % |

35–40% | 20–25% | 1008 steel is more ductile and better suited for deep drawing. |

| Reduction of Area Z/% |

~70% | ~55% | 1008 shows higher reduction, indicating better malleability. |

| Elongation at Break % |

38% | 23% | 1008 elongates more before fracture. |

| Elastic Young’s Modulus GPa |

200–210 GPa | 200 GPa | Both have nearly identical stiffness. |

| Shear Strength MPa |

~220 MPa | ~330 MPa | A36 has greater shear resistance. |

| Shear Modulus GPa |

~80 GPa | ~79 GPa | Comparable elasticity under shear stress. |

| Fatigue Strength MPa |

~150 MPa | ~200 MPa | A36 offers slightly higher fatigue endurance. |

| Elastic Modulus |

200 GPa | 200 GPa | Similar for both steels. |

| Poisson’s Ratio |

0.29 | 0.26–0.30 | Minor difference, negligible for most design cases. |

| Heating Temperature Forging / Hot Working |

870–1200 °C | 925–1260 °C | A36 requires slightly higher hot-working temperature. |

Summary:

1008 Steel and A36 Steel: Heat Treatment

Heat treatment is a crucial process that modifies the mechanical properties, microstructure, and machinability of steels.

Both 1008 steel and A36 steel respond differently to heat treatment because of their varying carbon content and alloy composition.

Understanding their respective heat treatment behaviors helps determine the most suitable process for forming, machining, or strengthening CNC parts and structural components.

Comparison Table: Heat Treatment of 1008 Steel and A36 Steel

| Heat Treatment Process |

1008 Steel |

A36 Steel |

Remarks |

| Annealing Temperature |

870–900 °C | 843–871 °C | Annealing improves ductility and relieves internal stresses. |

| Normalizing Temperature |

900–940 °C | 870–925 °C | A36 benefits more from normalizing due to higher strength gain. |

| Hardening Austenitizing Temperature |

Not applicable low carbon | 870–950 °C | 1008 steel cannot be hardened effectively by heat treatment. |

| Tempering Temperature |

— | 150–650 °C | A36 may be tempered after hardening to adjust toughness. |

| Stress Relieving |

540–650 °C | 540–675 °C | Reduces residual stresses after cold working or welding. |

| Carburizing |

900–950 °C | 900–950 °C | Both steels can be surface carburized to improve wear resistance. |

| Quenching Medium |

Not recommended | Water or oil depending on application | A36 may be quenched for hardness but risks distortion. |

| Solution Treatment |

Not applicable | Not applicable | Neither is alloyed for precipitation hardening. |

| Typical Cooling Method |

Furnace or air cool | Air cool after forging or normalizing | 1008 usually air-cooled for fine-grain structure. |

| Effect on Machinability |

Improves after annealing | Improves after normalizing | Both show smoother chip formation post-treatment. |

Summary:

The applications of 1008 steel and A36 steel differ based on their mechanical properties, formability, and strength.

Understanding these applications ensures you select the right steel for your project and avoid unnecessary machining or material costs.

Comparison Table: Applications and Uses of 1008 vs. A36 Steel

| Property / Factor |

1008 Steel |

A36 Steel |

Typical Applications |

| Strength Requirement |

Low to moderate | Medium to high | 1008: Panels, brackets, small parts |

| Formability |

Excellent | Moderate | 1008: Deep drawing, stamping |

| Surface Finish Requirement |

High | Moderate | 1008: Automotive panels, CNC machined components |

| Weldability |

Excellent | Excellent | Both suitable for welded assemblies |

| Machinability |

Easy | Good | 1008: CNC machining with minimal tool wear |

| Load-Bearing Applications |

Limited | Excellent | 1008: Light-duty brackets |

| Corrosion Protection Needed |

Yes coating recommended | Yes coating recommended | Both benefit from painting, galvanizing, or plating |

| Typical Industries |

Automotive, Electrical, CNC Machining parts Brackets, Panels, Fasteners, Enclosures, Deep-drawn parts |

Construction, Heavy Fabrication, Machinery, Structural Engineering Beams, Frames, Plates, Girders, Welded Assemblies |

1008 steel:Excellent ductility and formability; smooth cold-rolled surface; easy CNC machining; requires coating for corrosion protection. A36 steel: Higher strength and toughness; excellent weldability; suitable for load-bearing parts; hot-rolled or cold-rolled options; may require machining for precision parts. |

Cost is a critical factor when selecting between 1008 steel and A36 steel, especially for CNC machining, fabrication, and structural applications.

Balancing material cost, processing, and project requirements ensures optimal performance and budget efficiency.

Comparison Table: Cost and Price of 1008 Steel vs. A36 Steel

| Cost Factor |

1008 Steel |

A36 Steel |

Notes / Comments / Advantages |

| Initial Cost |

~$0.60–$0.80 per kg | ~$0.70–$0.90 per kg | 1008 steel is slightly cheaper; good for high-volume CNC machining and small parts. |

| Long-Term Cost Benefits |

Lower tool wear, easy machining | Higher strength reduces replacement for structural parts | 1008 saves machining time; A36 reduces part failure and maintenance costs. |

| Processing Costs |

Lower easy forming, minimal preheat | Moderate welding may need preheat for thick sections | 1008’s ductility reduces forming costs; A36 requires careful handling during welding. |

| Market Price |

Stable, widely available | Stable, widely available | Both steels are commonly stocked; price fluctuations are minimal in industrial markets. |

| Advantages |

Smooth finish, easy CNC machining, ductile | High strength, excellent for structural fabrication, load-bearing | 1008 ideal for precision and forming; A36 ideal for heavy-duty applications. |

Choosing the right steel is crucial for project success, machining efficiency, and cost management.

Both 1008 steel and A36 steel have advantages depending on your application, mechanical requirements, and fabrication methods. Understanding their key characteristics helps you make an informed decision for CNC machining, structural parts, or forming processes.

When to Choose 1008 Steel?

Comment: 1008 steel is perfect for automotive panels, brackets, fasteners, enclosures, and precision CNC machined parts.

When to Choose A36 Steel?

Comment: A36 steel is ideal for construction, structural frameworks, industrial machinery, and welded assemblies.

Summary:

While A36 steel is widely used for structural applications due to its moderate strength, good weldability, and affordability, there are steels with higher tensile strength and improved mechanical properties for projects that demand more durability or load-bearing capacity. Knowing the alternatives ensures your parts can handle stress, wear, and heavy loads.

Steels Stronger than A36 Steel

| Steel Type |

Tensile Strength MPa |

Key Advantages |

Applications |

| A572 Grade 50 |

450–620 | Higher strength, good weldability | Structural beams, bridges, construction |

| A992 Steel |

450–550 | Excellent for welded I-beams and columns | Structural framing, industrial construction |

| 4140 Alloy Steel |

655–895 | High tensile and fatigue strength, wear resistance | Machinery parts, shafts, gears |

| 1045 Carbon Steel |

570–700 | Medium carbon steel with high strength | Axles, gears, heavy-duty components |

| A516 Grade 70 |

485–620 | High-strength pressure vessel steel | Boilers, tanks, pressure vessels |

Summary:

If your project involves heavy loads, structural stress, or critical machinery parts, consider steels like A572, A992, 4140, or 1045 over A36 for enhanced strength and durability.

Choosing the right steel ensures your project meets performance, durability, and cost requirements.

Both 1008 steel and A36 steel are versatile, but their suitability depends on mechanical demands, machining processes, and final application. Understanding their strengths and limitations helps you avoid overengineering or material failure.

Suitability of 1008 Steel

Comment: 1008 steel is cost-effective for high-volume production and small components, but it is not recommended for structural or heavy-duty parts.

Suitability of A36 Steel

Comment: A36 steel is more robust but less ductile than 1008, so consider machining requirements and surface finish when precision is critical.

Summary:

At VMT, we specialize in providing precision CNC machining services for both 1008 steel and A36 steel. Whether your project requires high-ductility components or load-bearing structural parts, our team delivers high-quality, cost-effective solutions that meet strict tolerances and surface finish requirements.

Our 1008 and A36 Steel CNC Machining Capabilities

| Services |

1008 Steel |

A36 Steel |

Notes / Advantages |

| CNC Milling |

Ideal for precision brackets, panels, and enclosures | Suitable for thicker structural components and plates | 1008 offers smooth surface finishes; A36 provides strength for heavy-duty parts |

| CNC Turning / Lathe |

Shafts, fasteners, and small cylindrical components | Industrial shafts, rods, and load-bearing parts | High dimensional accuracy for both steels |

| Laser / Waterjet Cutting |

Thin sheets and delicate components | Structural plates and heavy sections | Clean edges with minimal thermal distortion |

| Drilling / Tapping |

Quick, precise holes for light-duty components | Accurate holes for thick plates and assemblies | 1008 reduces tool wear; A36 may require coolant and sharper tools |

| Surface Finishing / Polishing |

Smooth finishes for enclosures and automotive parts | Polished edges for structural and industrial parts | Ensures parts meet aesthetic and functional requirements |

Why Choose VMT?

Note: Partnering with a professional CNC machining factory like VMT ensures consistent quality, reduces material waste, and improves overall project efficiency.

Choosing between 1008 steel and A36 steel depends on your project’s mechanical requirements, formability, and load-bearing needs.

By understanding their chemical, physical, and mechanical properties, as well as cost and processing considerations, you can make an informed choice that balances performance, manufacturability, and budget.

Partnering with a reliable CNC machining service like VMT ensures your 1008 or A36 steel parts are manufactured efficiently, accurately, and to the highest quality standards, helping your project succeed.

1. Is A36 steel the same as 1018 steel?

No. A36 steel is a structural carbon steel with higher strength, primarily used in construction, while 1018 steel is a low-carbon steel commonly used for precision machining and mechanical parts.

2. Which is stronger, 1018 or A36?

A36 steel is stronger in terms of tensile and yield strength, making it more suitable for structural and load-bearing applications. 1018 is more ductile and easier to machine.

3. Does A36 steel rust easily?

Yes. A36 steel is prone to corrosion if left uncoated. Painting, galvanizing, or plating is recommended for outdoor or humid environments.

4. Can A36 steel be galvanized?

Yes. Hot-dip galvanizing or zinc coating can protect A36 steel from rust and increase durability.

5. Is 1008 a mild steel?

Yes. 1008 steel is a low-carbon mild steel with excellent formability, weldability, and machinability.

6. What is the SAE 1008 steel grade?

SAE 1008 steel is a low-carbon, cold-rolled mild steel used for parts requiring smooth surface finish and good ductility.

7. Does 1008 steel rust?

Yes. Like other mild steels, 1008 steel can rust if exposed to moisture. Surface treatment like painting, plating, or coating is recommended.

8. Is A36 steel the same as Grade 50 steel?

No. Grade 50 A572-50 steel is stronger than A36, with higher yield strength, making it better for heavy-duty structural applications.

9. What is the difference between 1008 steel and 1018 steel?

1008 steel has lower carbon content and better formability, while 1018 has slightly higher carbon, offering higher strength and wear resistance, making it better for machined components under moderate load.

10. Is A36 suitable for welding?

Yes. A36 steel has excellent weldability and can be joined using MIG, TIG, or arc welding methods. Preheating may be required for thick sections.

11. Is A36 hot-rolled or cold-rolled?

A36 steel is primarily hot-rolled, which makes it ideal for structural shapes, beams, and plates.

12. Is A36 cast iron?

No. A36 steel is a mild carbon steel, not cast iron. It is ductile and weldable, unlike brittle cast iron.