15 years one-stop China custom CNC machining parts factory

33 |

Published by VMT at Oct 23 2025 | Reading Time:About 3 minutes

33 |

Published by VMT at Oct 23 2025 | Reading Time:About 3 minutes

Is your stainless steel welding falling short, plagued by defects, and costing you valuable time and resources? The truth, unvarnished, is that achieving truly superior stainless steel welds demands an almost fanatical adherence to detail, a meticulous refinement of processes that many simply overlook. Discover the meticulously honed processes and expert insights that undeniably separate flawless stainless steel welds from those catastrophic failures, ensuring your critical components meet the highest standards of integrity and performance.

Achieving impeccably strong and corrosion-resistant stainless steel welds is an intricate ballet of metallurgy and craftsmanship. This guide dissects the paramount attention points, providing insights into best practices that prevent common stainless steel weld defects and elevate the overall stainless steel fabrication quality.

Achieving high-quality stainless steel welds necessitates meticulous attention to material preparation, including grade identification and thorough cleaning. Optimal welding parameters, precise process selection, and careful interpass temperature management are critical for controlling heat input and preventing defects like sensitization. Selecting the correct filler metal, matching base material, and ensuring proper storage are also paramount. Mastering heat control mitigates distortion and preserves the Heat-Affected Zone's integrity. Effective shielding gas and back purging are indispensable for preventing atmospheric contamination. Post-weld care, encompassing mechanical and chemical cleaning and passivation, restores corrosion resistance. Finally, rigorous quality assurance through visual, non-destructive, and metallurgical testing guarantees component reliability.

Oh, the initial steps – so often rushed, so frequently the genesis of truly vexing issues! Ignoring foundational preparation is, frankly, an unbelievably foolish assumption. We know this.

Material Identification & Grade Compatibility

Firstly, identifying the precise stainless steel grade is not merely important; its importance cannot be overstated. It is an absolutely irreplaceable truth. Different grades – austenitic, ferritic, martensitic, duplex – possess divergent metallurgical characteristics, demanding distinct welding approaches. For instance, welding 304L versus a super duplex 2507 requires utterly disparate heat input controls, shielding gas mixtures, and filler metal selections. Have you truly verified your material certifications? Because, honestly, mistaking a 316 for a 304 can lead to a downright catastrophic failure in highly corrosive environments.

Surface Cleaning & Contaminant Removal

Contaminants are the silent assassins of weld quality, insidious foes lurking on material surfaces. Mill scale, grease, oil, paint, or even residual marking crayon absolutely MUST be eradicated before any arc strikes. My preference? Thorough mechanical cleaning using stainless steel wire brushes—dedicated ones, mind you, never used on carbon steel!—followed by solvent degreasing. But let's be real, often a simple wipe isn't enough; sometimes, abrasive blasting with appropriate media becomes indispensable. Any organic residue will carbonize, introducing porosity and, worse, impairing corrosion resistance. A truly infuriating oversight, often.

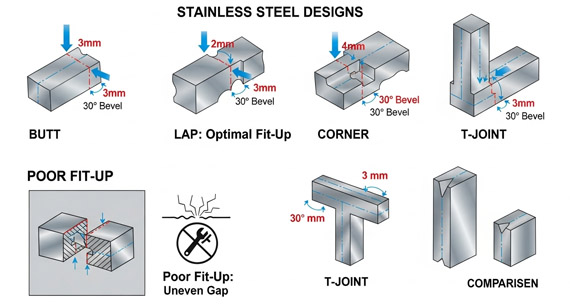

Joint Design & Fit-Up Precision

The geometry of the joint itself, coupled with the accuracy of its fit-up, exerts a profound influence on weld integrity. Poor fit-up means variable root gaps, which in turn leads to inconsistent penetration and an increased likelihood of defects like burn-through or incomplete fusion. Precision fixturing is absolutely essential here; it minimizes distortion and ensures consistent gaps throughout the entire joint. Achieving uniform root openings, proper bevel angles, and tight alignments is not optional. It is fundamental.

Selecting the correct parameters is an alchemical blend of science and seasoned experience; a careful calibration, really. We always say, it is not just about turning knobs.

Process Selection: TIG, MIG, or Laser Welding

Choosing the right welding process for stainless steel is a critical strategic decision. Gas Tungsten Arc Welding (GTAW or TIG) is generally preferred for its unparalleled control over heat input and weld puddle, yielding exceptionally clean, high-quality welds, particularly for thinner gauges or critical applications. Gas Metal Arc Welding (GMAW or MIG) offers higher deposition rates, suitable for thicker sections or less stringent aesthetic requirements. Laser welding, a truly advanced technique, provides extremely focused heat, minimal distortion, and high speeds, making it ideal for precision fabrication or automated lines. It all depends on the application, doesn't it?

Amperage, Voltage & Travel Speed Control

These three parameters form the holy trinity of welding control. Amperage dictates penetration and bead size; voltage influences arc length and bead width (in MIG); and travel speed, well, that controls heat input and bead contour. For stainless steel, maintaining a relatively lower heat input is paramount to prevent sensitization and distortion. This often means a faster travel speed coupled with appropriate amperage. In my view, it's a dynamic balance, requiring continuous adjustment and monitoring. An unbelievable amount of practice goes into mastering it, mind you.

Interpass Temperature Management

Overheating is a cardinal sin in stainless steel welding. It seems to me, allowing the base material to reach excessive temperatures between weld passes can lead to sensitization—a chromium depletion at grain boundaries that devastates corrosion resistance. We diligently monitor interpass temperatures, often utilizing contact thermometers or infrared devices. Often, controlled cooling methods, perhaps forced air or specific dwell times, are employed to ensure the material remains below critical thresholds. This vigilance is not merely good practice; it is absolutely indispensable for preserving material integrity.

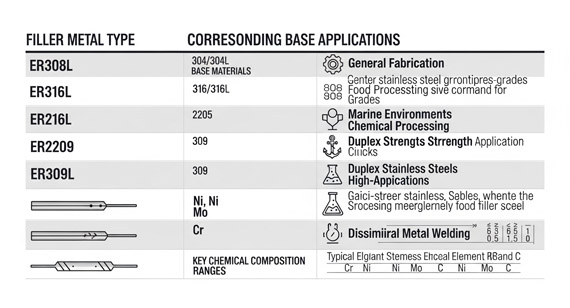

The filler metal, often an unsung hero, plays an absolutely crucial role in the final properties of your weld; it truly is.

Matching Base Material & Service Environment

The filler metal must be meticulously selected to complement the base material and, just as importantly, withstand the intended service environment. For most austenitic stainless steels (like 304, 316), over-alloyed fillers are often chosen, for instance, a 308L for 304, or a 316L for 316. This provides additional delta ferrite in the weld metal, which mitigates hot cracking tendencies. But honestly, for duplex stainless steels, a more complex filler matching is required to maintain the desired ferrite-austenite balance. Consideration of corrosive agents, temperature extremes, and mechanical loads is absolutely non-negotiable here.

Understanding Alloy Composition & Microstructure

Delving into the microstructure of the filler metal is not just for metallurgists, but for anyone serious about weld quality. The precise balance of chromium, nickel, molybdenum, and other elements influences the weld's strength, ductility, and corrosion resistance. An incorrect choice can lead to brittle welds, or, perhaps worse, welds that corrode preferentially. It truly is fascinating, this intricate chemistry.

Filler Metal Storage & Handling Practices

Filler metals, particularly stainless steel wires and rods, are not impervious to environmental degradation. Contamination from dust, moisture, or even fingerprints can introduce impurities into the weld. We insist on storing filler metals in dry, clean conditions, often in sealed containers or heated cabinets, protecting their pristine surface. Proper handling—always with clean gloves—prevents surface oxidation or oil transfer. Such a small thing, yet its impact can be so massive!

Heat, that double-edged sword, can be your greatest ally or your most formidable adversary in stainless steel welding. One must respect it.

Preventing Sensitization & Carbide Precipitation

This is, for us, one of the most critical aspects. Sensitization, as I mentioned, is the bane of stainless steel integrity; it occurs when chromium carbides precipitate at grain boundaries due to prolonged heating in a specific temperature range (around 450-850°C). This robs the surrounding matrix of chromium, rendering it susceptible to intergranular corrosion. To combat this, we meticulously control heat input, utilize low-carbon "L" grades, or employ stabilized grades containing titanium or niobium. The goal? To zip through that dangerous temperature window as quickly as possible. Truly, a race against metallurgical time!

Minimizing Distortion & Residual Stress

Stainless steel's higher coefficient of thermal expansion compared to carbon steel makes it notoriously prone to distortion and the accumulation of residual stresses. These stresses, if unchecked, can lead to cracking or dimensional instability—an unbelievably frustrating outcome after all that effort. Techniques like balanced welding sequences, skip welding, strategic tack welds, and robust fixturing are deployed. Pre-setting or pre-bending parts can also compensate for anticipated distortion. It’s an art form, honestly.

Techniques for Managing Heat-Affected Zone (HAZ)

The HAZ, that region adjacent to the weld metal, experiences microstructural changes due to the welding heat. Its properties can significantly differ from the unaffected base metal. Controlling the heat input directly manages the width and metallurgical changes within the HAZ. A narrow HAZ generally means less impact on the parent material's properties. Rapid cooling, where permissible, also helps. Wait, I need to clarify that point—while rapid cooling helps prevent sensitization, for some martensitic grades, a controlled, slower cool might be necessary to avoid cracking. It really is about understanding the specific alloy's nuances, isn't it?

Atmospheric contamination? That’s an absolute disaster waiting to happen, a truth that cannot be denied. Oxygen and nitrogen are the arch-nemeses of stainless steel welds.

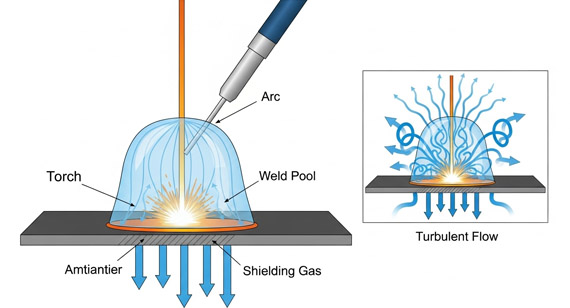

Choosing Inert Gas Type & Purity

For stainless steel, inert shielding gases are paramount. Argon (Ar) is overwhelmingly preferred for TIG welding due to its stable arc characteristics and excellent cleaning action. For MIG welding, a mixture of argon with a small percentage of carbon dioxide (CO2, typically 1-2%) or oxygen (O2, 0.5-2%) can improve arc stability and wetting, but higher percentages of active gases must be approached with extreme caution, as they can lead to carbide precipitation or reduced corrosion resistance. Purity is non-negotiable; even trace contaminants can ruin a weld.

Optimizing Shielding Gas Flow Rates

Too little gas and you get atmospheric contamination—porosity, sugaring, a visibly oxidized weld bead. Too much gas, and you invite turbulence, drawing ambient air into the shield, which is, frankly, just as bad. Finding that Goldilocks flow rate is critical; it ensures complete, laminar coverage over the weld puddle and the adjacent hot metal. We often conduct flow tests, making subtle adjustments based on joint geometry and environmental factors like drafts. It's a delicate dance!

Effective Back Purging for Root Pass Integrity

This is where many falter, leading to the infamous "sugaring" on the root side of the weld. When the backside of a stainless steel weld is exposed to air during welding, it oxidizes severely, forming a crumbly, sugared appearance that compromises corrosion resistance and mechanical properties. Effective back purging with an inert gas—typically argon—is absolutely crucial for any full penetration weld. The purge gas must completely displace oxygen from the backside, creating a protective atmosphere. We even use oxygen sensors to confirm oxygen levels are below 50 ppm (parts per million) before striking an arc. A truly mind-blowing miracle of engineering when done right!

The weld is done. But is it? Not quite, not for stainless steel!

Mechanical & Chemical Cleaning Protocols

After welding, the surface of stainless steel often exhibits heat tint or discolored oxide layers, which are aesthetically displeasing and, more critically, have reduced corrosion resistance. Mechanical cleaning (brushing, grinding) removes these, but must be followed by chemical methods. Chemical cleaning protocols, like pickling with nitric-hydrofluoric acid solutions, remove heat tint and embedded iron particles, restoring the surface. However, pickling solutions are highly aggressive and demand extreme caution, specialized equipment, and proper waste disposal. This step cannot be understated; it truly cannot.

Passivation for Restoring Corrosion Resistance

Passivation is the final, absolutely vital step in post-weld care. It is not cleaning; it is a chemical treatment, typically with nitric acid, that removes free iron from the surface and promotes the rapid formation of a stable, passive chromium-rich oxide layer. This layer is what gives stainless steel its legendary corrosion resistance. Without proper passivation, even a perfect weld is susceptible to rust and degradation. It’s a process we view as non-negotiable, honestly.

Inspection for Discoloration & Oxide Formation

Visual inspection for heat tint and oxide formation after welding is a fundamental, almost instinctive step. Any blue, brown, or black discoloration indicates oxidation and a loss of corrosion resistance, demanding further cleaning and passivation. We look for a bright, silvery, uniform appearance—that’s the mark of quality. If it’s not there, it’s not done. Simple.

Quality assurance, for us, is not an afterthought; it is an omnipresent vigilance, a truly continuous commitment.

Visual Inspection for Surface Defects

Our initial layer of quality control always involves a meticulous visual inspection. We scrutinize welds for common surface defects: porosity, undercut, excessive spatter, incomplete fusion, and cracks. A keen eye can catch many issues before they escalate, saving untold frustration and cost. Every weld. Every time. It truly matters.

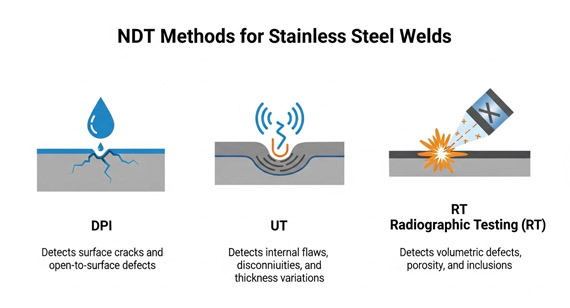

Non-Destructive Testing (NDT) Methods

For critical applications, visual inspection simply isn't enough. Non-Destructive Testing (NDT) methods like Dye Penetrant Testing (DPT) for surface cracks, Magnetic Particle Testing (MPT) for ferromagnetic stainless steels (less common), Ultrasonic Testing (UT) for internal defects, and Radiographic Testing (RT or X-ray) for volumetric defects provide deeper insights into weld integrity. These methods are indispensable for ensuring compliance with stringent industry standards like ASME or AWS.

Metallurgical Analysis & Performance Testing

Beyond NDT, sometimes we must dissect the very essence of the weld. Destructive testing, including tensile strength tests, bend tests, and micro-hardness testing, provides quantifiable mechanical property data. Metallurgical analysis, employing techniques like microscopy, examines the weld's microstructure, ensuring proper grain structure, absence of harmful phases, and confirming that sensitization has been successfully prevented. It is the ultimate truth-teller, isn't it?

At VMT, our factory does not just understand these points; we internalize them, elevate them to a creed. Our deep technical expertise, honed over years, allows us to deliver superior, defect-free stainless steel welds that maintain both material integrity and peak performance. As a trusted source manufacturer, we meticulously manage every aspect, from advanced material identification to stringent post-weld treatment, ensuring unparalleled quality. Our transparent pricing reflects the true value of high-quality parts, mitigating hidden costs down the line. We pride ourselves on offering comprehensive CNC machining services for stainless steel parts, integrating advanced welding capabilities with precision machining to provide complete, ready-to-use components that meet the most exacting specifications.

The pursuit of excellence in stainless steel welding is, unequivocally, a continuous journey, not a destination. It demands an unrelenting focus on detail, an unwavering commitment to process, and an almost obsessive attention to every single variable. For the uninitiated, it's a minefield; for the expert, a symphony of precision. We, as a factory, believe that by scrutinizing these essential attention points, you not only avoid catastrophic failures but also elevate the very performance and reliability of your critical components. The difference, you see, is not merely marginal. It is colossal.

1. What are the most common defects in stainless steel welding?

The most frequent defects observed in stainless steel welding include porosity (gas bubbles entrapped in the weld), cracking (hot cracking in the weld metal or cold cracking in the HAZ), sensitization (loss of corrosion resistance due to chromium carbide precipitation), distortion, and incomplete fusion or penetration. Discoloration, often referred to as "sugaring" on the backside of root passes, is also a pervasive issue that compromises corrosion resistance.

2. Why is heat input control so critical for stainless steel?

Heat input control is crucial for stainless steel to prevent sensitization, minimize distortion, and preserve the material's mechanical and corrosion-resistant properties. Excessive heat input can lead to chromium carbide precipitation (sensitization), which depletes chromium at grain boundaries and makes the steel susceptible to intergranular corrosion. It also contributes to greater distortion due to stainless steel's high coefficient of thermal expansion.

3. What is sensitization, and how can it be prevented?

Sensitization is a metallurgical phenomenon in stainless steel where chromium carbides precipitate at grain boundaries when the material is heated in a specific temperature range (approximately 450-850°C) for too long. This depletes chromium in adjacent areas, making the steel vulnerable to intergranular corrosion. Prevention involves using low-carbon "L" grades (e.g., 304L, 316L), stabilized grades (e.g., 321, 347), and meticulously controlling heat input to pass through the critical temperature range quickly.

4. Which shielding gases are typically used for stainless steel welding?

For TIG welding stainless steel, pure argon is overwhelmingly preferred due to its inert nature, stable arc characteristics, and good cleaning action. For MIG welding, mixtures of argon with small percentages of CO2 (1-2%) or oxygen (0.5-2%) are common. These active gas additions improve arc stability and weld puddle wetting. However, higher percentages of active gases must be used cautiously to avoid adverse metallurgical effects.

5. What is the purpose of back purging in stainless steel welding?

Back purging is essential for full penetration welds in stainless steel to protect the backside of the weld from atmospheric contamination, specifically oxygen. When hot stainless steel is exposed to oxygen, it oxidizes rapidly, forming an unsightly, crumbly, and corrosion-prone oxide layer known as "sugaring." Back purging with an inert gas, typically argon, displaces oxygen, ensuring a clean, corrosion-resistant weld root.

6. How does passivation enhance the performance of stainless steel welds?

Passivation is a critical chemical treatment that removes free iron from the stainless steel surface and promotes the spontaneous formation of a passive, chromium-rich oxide layer. This inert, protective layer is responsible for stainless steel's inherent corrosion resistance. Passivation restores this layer after welding, which can disrupt it, thereby preventing premature corrosion, rust, and maintaining the material's intended performance in its service environment.

7. What non-destructive testing (NDT) methods are common for stainless steel welds?

Common NDT methods for stainless steel welds include Visual Inspection (VT) for surface flaws, Dye Penetrant Testing (DPT) for surface-breaking discontinuities like cracks and porosity, Ultrasonic Testing (UT) for internal flaws such as lack of fusion or inclusions, and Radiographic Testing (RT or X-ray) for detecting volumetric defects within the weld.

8. Can VMT provide both CNC machining and welding services for stainless steel parts?

Absolutely. VMT specializes in providing comprehensive CNC machining services for stainless steel parts, and this expertise extends to integrating high-quality welding capabilities. We are a source manufacturer with deep technical expertise, allowing us to manage the entire fabrication process from precision machining to expert stainless steel welding, post-weld treatment, and rigorous quality assurance, delivering complete, ready-to-integrate components.