15 years one-stop China custom CNC machining parts factory

54 |

Published by VMT at Oct 22 2025 | Reading Time:About 3 minutes

54 |

Published by VMT at Oct 22 2025 | Reading Time:About 3 minutes

Choosing between surgical steel and titanium for your critical components isn't merely an engineering decision; it's a profound gamble with patient safety, device longevity, and ultimately, your brand's very existence. Are you genuinely convinced you've made the most sagacious selection, or does a gnawing doubt persist? An erroneous choice can, frankly, precipitate utterly catastrophic consequences—think product recalls, monumental legal liabilities, and an irreversible erosion of trust! But despair not, for here at VMT, we dissect these monumental materials with unparalleled acumen, ensuring your peace of mind and, most importantly, your project's resounding success.

Medical-grade titanium alloys (e.g., Ti-6Al-4V ELI) and surgical stainless steels (e.g., 316L, 17-4 PH) are paramount for biomedical applications due to their exceptional biocompatibility, corrosion resistance, and robust mechanical properties. Titanium, a truly remarkable element, often excels in strength-to-weight ratio and osseointegration, while surgical steel consistently offers a cost-effective, resilient solution for numerous non-implantable and short-term implantable devices. This is, you understand, not a trivial distinction.

This guide meticulously compared medical-grade surgical steel and titanium alloys, delving into their distinct properties, applications, and manufacturing considerations for critical components. We examined their biocompatibility, corrosion resistance, strength-to-weight ratios, and machinability, emphasizing that optimal material selection hinges entirely on specific project requirements and regulatory compliance. VMT's expertise in surgical steel and titanium CNC machining services was highlighted as a crucial resource for achieving high-precision, reliable results.

Let's just plunge right into the magnificent realm of surgical steel, shall we? Its enduring presence in the medical arena is, quite frankly, a testament to its formidable blend of mechanical attributes and respectable resistance to biological environments. The discernment of appropriate grades, however, remains an absolutely indispensable exercise. We're talking about substances designed to perform within the human body, after all—an unbelievably challenging environment!

Key Medical Steel Attributes Scrutinized

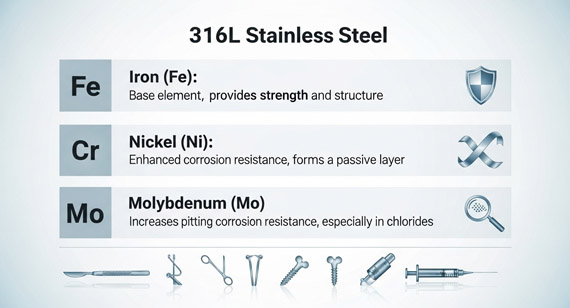

Surgical stainless steel, encompassing a family of iron-based alloys, boasts chromium for corrosion resistance, nickel for ductility, and molybdenum for enhanced strength and pitting resistance, among other elements. Its inherent robustness and malleability make it a compelling candidate for a myriad of instruments and implants; the sheer versatility is, I must confess, quite impressive. But you must ask yourself: how does it truly hold up under long-term physiological stress? It's a critical question.

Common Surgical Stainless Steel Grades

We typically encounter a select few grades when contemplating surgical steel CNC machining parts. The specific composition dictates everything, you see, from its resilience to corrosive bodily fluids to its capacity for intricate CNC machining services.

| Surgical Steel Grade | Key Characteristics | Typical Applications |

| 316L Stainless Steel | Low carbon, excellent corrosion resistance, non-magnetic. | Surgical instruments, temporary implants, external fixation devices. |

| 17-4 PH Stainless Steel | High strength, good corrosion resistance, precipitation-hardened. | Orthopedic implants (non-load-bearing), surgical tools, dental components. |

| 440C Stainless Steel | Very high hardness, wear resistance. | Surgical cutting instruments, knife blades. |

Typical Application Domains for Surgical Steel

Consider its pervasive use in everything from scalpels to bone plates. Surgical steel CNC machining parts are simply ubiquitous! This material, with its commendable balance of strength and cost-effectiveness, finds its home in internal fixation devices, some dental tools, and an expansive range of external support structures. Its familiarity to manufacturers and clinicians alike, one might argue, simplifies its adoption—a tangible benefit, no doubt.

Ah, titanium! The very name evokes images of aerospace marvels and, indeed, its application in medical devices is equally, if not more, extraordinary. When one considers the rigorous demands placed upon implants, the unique properties of medical grade titanium elevate it to a truly singular standing. It really is quite something, wouldn't you agree?

Titanium Alloy's Distinctive Attributes Elucidated

What truly distinguishes titanium alloys, you might wonder? Well, it's their unparalleled strength-to-weight ratio, their astounding resistance to corrosion, and, perhaps most miraculously, their remarkable biocompatibility—an almost inert quality within the human body. This allows for direct osseointegration, a literal melding with bone, which is a downright revolutionary trait for long-term implants. I find it simply breathtaking.

Prevalent Titanium Alloy Classifications and Characteristics

Not all titanium is created equal, of course! Understanding the nuances between grades is absolutely paramount for anyone contemplating titanium CNC machining parts.

| Titanium Alloy Grade | Key Characteristics | Typical Applications |

| Commercially Pure (CP) Ti | Good ductility, excellent biocompatibility. | Dental implants, casings for pacemakers, surgical mesh. |

| Ti-6Al-4V ELI (Grade 23) | High strength, superior fracture toughness, excellent biocompatibility. | Orthopedic implants (load-bearing), spinal implants, dental prosthetics, aerospace components. |

| Ti-6Al-7Nb | Good strength, improved biocompatibility over Ti-6Al-4V (less vanadium toxicity concern). | Specific surgical implants, orthopedic devices. |

Why Titanium Excels in the Medical Domain

Titanium's dominance in permanent implants is not a mere preference; it's a scientific imperative! Its capacity to integrate directly with bone—without eliciting an adverse immunological response—is nothing short of a biological miracle. For critical load-bearing applications, such as hip and knee replacements or spinal fusion devices, the robustness of titanium vs stainless steel implants is often an unassailable argument. This is where the rubber, or rather, the titanium, truly meets the road.

Now, let's get down to the brass tacks, or perhaps, the titanium and steel tacks, of mechanical performance. This is where the empirical data truly begins to sculpt our understanding, moving beyond mere anecdotal admiration. The choices you make here are fundamental, utterly defining.

Tensile Strength Divergence Explored

When we dissect tensile strength, the maximal stress a material can withstand before fracturing, both materials exhibit commendable performance, but with distinct profiles. Titanium alloys, particularly Ti-6Al-4V ELI, frequently outstrip many surgical steel variants in this critical metric. It's not always a clean sweep, mind you, but often, the advantage belongs to titanium.

| Property (Approximate) | 316L Surgical Steel | Ti-6Al-4V ELI Titanium |

| Ultimate Tensile Strength (MPa) | 490-690 | 860-950 |

| Yield Strength (MPa) | 170-310 | 795-860 |

| Elastic Modulus (GPa) | 193 | 114 |

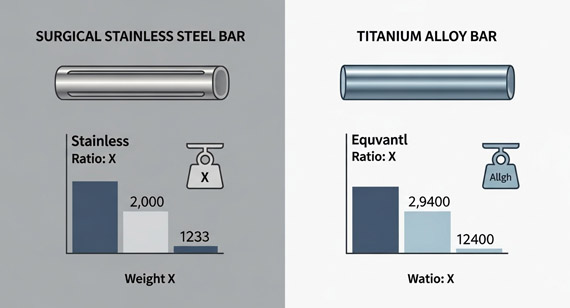

Strength-to-Weight Ratio's Concrete Manifestation

Here's where titanium truly, unequivocally shines! Its density is approximately 4.5 g/cm³, whereas stainless steel hovers around 8.0 g/cm³. This dramatically lower density, coupled with its high strength, grants medical grade titanium an astonishing strength-to-weight ratio. For a patient, this means lighter implants, less physiological burden, and, ultimately, improved comfort and mobility. Imagine the difference!

Fatigue Resistance Investigation for Both Materials

Fatigue resistance is an absolutely indispensable parameter for any material destined for long-term implantation, particularly in dynamic environments like joint replacements. Both surgical steel properties and titanium exhibit commendable fatigue life, but the internal microstructure, the precision of the CNC machining parts, and the surface finish all play immensely pivotal roles. Honestly, a perfectly machined titanium component might outperform a poorly finished surgical steel one, irrespective of inherent material capabilities. It's all in the execution.

This section, quite frankly, is the very cornerstone of medical device material selection. Without impeccable biocompatibility and unimpeachable corrosion resistance, all other mechanical advantages crumble to dust! The human body is a fiercely demanding host, you see.

Biological Interaction Factors to Consider

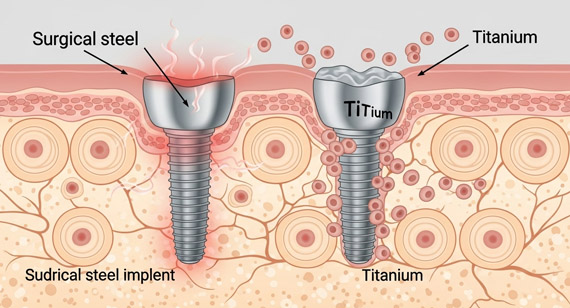

Biocompatibility isn't merely the absence of toxicity; it’s the body's entire physiological response to the material. Surgical steel, while generally well-tolerated, can release trace amounts of nickel and chromium ions, which, in some sensitive individuals, might elicit allergic reactions or inflammatory responses. Medical grade titanium, by contrast, is known for its remarkable inertness—it hardly registers as a foreign body at all! This allows for that truly enviable osseointegration. A single noun: Harmony.

Corrosion Mechanism Principles Elucidated

Both materials form a passive oxide layer that protects them from degradation in the highly corrosive environment of bodily fluids. For surgical steel, particularly 316L, this chromium oxide layer offers substantial, but not absolute, protection. Titanium, however, forms an extremely stable and robust titanium dioxide layer, which self-repairs almost instantaneously if scratched. This superior corrosion resistance is a significant factor in titanium vs stainless steel implants, especially for extended periods. It's an internal armor, constantly vigilant.

Long-Term Implant Safety Crucial Considerations

When we speak of long-term implant safety, the stakes are undeniably astronomical. The implications of material failure, whether from fatigue or corrosion, are horrifying. It's why careful consideration of surgical steel properties against those of medical grade titanium for specific applications is absolutely non-negotiable. For a hip implant designed to last decades, a slight edge in corrosion resistance or biocompatibility transforms into a monumental advantage. One wrong move, and the consequences are dire.

The theoretical superiority of a material counts for precious little if it cannot be precisely, economically, and consistently machined into its intended form. This is where the rubber meets the road for us, as a CNC machining factory.

Precision Machining Challenges and Techniques

Both materials present unique challenges during CNC machining. Surgical steel, particularly tougher grades, requires robust tooling and careful chip management to avoid work hardening. Titanium, while softer, is notorious for its poor thermal conductivity, causing heat to build up in the cutting zone, which can rapidly wear tools and affect surface integrity. We must employ specific tooling geometries, cutting fluids, and feed/speed rates for each. It demands absolute mastery, really.

Production and Manufacturing Cost Influence Dissected

Now, about the elephant in the room: cost! Generally speaking, raw titanium stock is significantly more expensive than surgical stainless steel. Furthermore, the specialized tooling, slower machining speeds, and increased wear associated with titanium CNC machining parts often translate to higher manufacturing costs per unit. This isn't just a simple calculation; it involves weighing the initial outlay against the long-term performance benefits. For many applications, the initial cost might sway the decision towards surgical steel. It's a pragmatic consideration, after all.

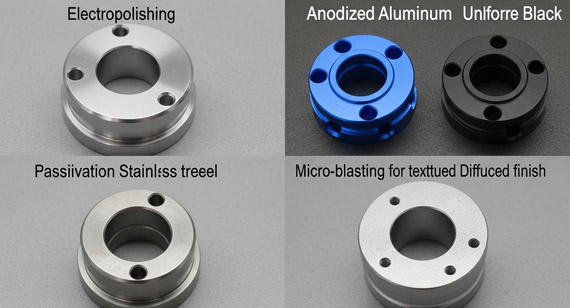

Surface Treatment and Post-Processing Strategies

The journey doesn't end with machining! Both materials frequently require specific surface treatments to enhance performance. For surgical steel, electropolishing can improve corrosion resistance and surface finish. Titanium often undergoes anodization, passivation, or even specialized coatings to further augment its biocompatibility and wear properties. These post-processing steps are integral to achieving the desired outcome for any high-end CNC machining parts. They are not optional extras; they are vital.

So, after all this dissection, how does one, or rather, how do you, make the definitive choice? It's not a facile "either/or" scenario; it's a meticulously nuanced evaluation!

Application-Driven Material Selection

The specific application is your guiding star. Is it a temporary internal fixation device, or a permanent, load-bearing spinal implant? Are you designing a surgical instrument that demands extreme hardness, or a pacemaker casing prioritizing inertness? For temporary, non-critical, or cost-sensitive components, surgical steel often presents an entirely viable and robust solution. However, for long-term implantation, especially where osseointegration and minimal biological response are paramount, medical grade titanium is the overwhelming, undeniable champion.

Industry Regulations and Standard Compliance

This point, I must stress, is utterly non-negotiable! Adherence to stringent industry standards like ASTM F138 for 316L surgical steel or ASTM F136 for Ti-6Al-4V ELI is an absolute prerequisite. Furthermore, ISO 10993 for biocompatibility testing is a colossal undertaking that must be navigated with expert precision. As a reputable CNC machining factory, we are intimately familiar with these complex regulatory landscapes, offering complete material traceability and process validation—a promise of absolute compliance.

Expert Consultation to Aid Decision Optimization

Wait, I need to clarify that point: while the information here is comprehensive, no guide, however definitive, can substitute for a direct, personalized consultation. Your project's unique demands, its precise geometric complexities, and its regulatory environment all coalesce into a bespoke challenge. Engaging with our engineering experts at VMT for tailored advice and a transparent quote for your CNC machining services is, frankly, the smartest move you can make. Do not simply guess; seek professional illumination!

At VMT, we don't just machine parts; we engineer solutions! Our profound technical expertise, honed over years of relentless dedication to high-precision CNC machining, positions us as your unparalleled partner for both surgical steel CNC machining parts and titanium CNC machining parts. We comprehend the infinitesimal tolerances, the exacting surface finishes, and the absolute necessity for regulatory compliance required for your most critical components. Our factory isn't merely a production facility; it's a crucible of precision, where the most challenging designs are brought to flawless fruition.

So, what have we unearthed today, what indelible truths have we carved from the bedrock of material science? The choice between surgical steel and titanium for your pivotal components is, and always will be, a decision steeped in the specific exigencies of your design. It demands rigorous evaluation of biocompatibility, mechanical performance, manufacturing feasibility, and, yes, the inevitable cost implications. But one truth remains gloriously constant: partnering with a CNC machining factory that possesses both profound technical acumen and an unwavering commitment to quality—like VMT—is your paramount guarantor of success. Do not settle for anything less! Your project deserves nothing short of absolute perfection.

Q1: What are the primary differences between surgical steel and medical grade titanium regarding biocompatibility?

A1: Medical grade titanium exhibits superior biocompatibility due to its inertness and ability to promote osseointegration, meaning it can directly bond with bone tissue without adverse reactions. Surgical steel, while generally well-tolerated, can, on rare occasions, release ions that may cause allergic reactions or inflammatory responses in sensitive individuals.

Q2: For load-bearing implants, which material is generally preferred, titanium vs stainless steel implants?

A2: For load-bearing implants requiring long-term stability and integration, medical grade titanium alloys like Ti-6Al-4V ELI are overwhelmingly preferred. Their exceptional strength-to-weight ratio, fatigue resistance, and unparalleled biocompatibility make them ideal for applications such as hip, knee, and spinal implants, significantly outperforming surgical steel properties in these critical scenarios.

Q3: Is surgical steel always cheaper to machine than titanium?

A3: Generally, yes, surgical steel CNC machining parts tend to be more cost-effective to produce than titanium CNC machining parts. The raw material cost of titanium is higher, and its unique thermal and mechanical properties often necessitate specialized tooling, slower machining speeds, and specific cooling strategies, all contributing to increased manufacturing expenses.

Q4: How important is surface finish for both surgical steel and titanium CNC machining parts in medical applications?

A4: Surface finish is absolutely paramount for both materials in medical applications. A superior surface finish minimizes friction, reduces potential sites for bacterial adhesion, and can significantly enhance biocompatibility and corrosion resistance. Precision post-processing, such as electropolishing or anodization, is often crucial for achieving the required surface quality.

Q5: What regulatory standards apply to these materials for medical devices?

A5: Key regulatory standards include ASTM F138 for 316L surgical steel, ASTM F136 for Ti-6Al-4V ELI titanium, and ISO 10993 for biological evaluation of medical devices. Adherence to these standards, alongside robust quality management systems like ISO 13485, is non-negotiable for medical device manufacturing and VMT provides full traceability for all CNC machining services.

Q6: Can VMT handle both surgical steel and titanium CNC machining parts?

A6: Absolutely, VMT specializes in providing high-precision CNC machining services for both surgical steel and medical grade titanium alloys. Our factory is equipped with advanced machinery and experienced engineers adept at navigating the unique challenges posed by each material, ensuring the production of top-tier CNC machining parts.

Q7: What are typical applications for surgical steel cnc machining parts versus titanium cnc machining parts?

A7: Surgical steel CNC machining parts are commonly found in surgical instruments, temporary implants (e.g., bone screws, plates for short-term fixation), and external support devices. Titanium CNC machining parts, especially medical grade titanium, are reserved for critical, long-term implants like dental implants, spinal fusion devices, joint replacements, and pacemakers due to their superior biocompatibility and strength.

Q8: How can I ensure I select the correct material for my specific project?

A8: The most prudent approach is to consult with material science and machining experts. Your decision should be based on a comprehensive analysis of the component's function, anticipated stresses, required longevity, biological environment, and cost constraints. Contacting a specialized CNC machining factory like VMT for expert advice and a detailed assessment is highly recommended to mitigate risks and optimize material selection.