15 years one-stop China custom CNC machining parts factory

119 |

Published by VMT at Dec 06 2024 | Reading Time:About 5 minutes

119 |

Published by VMT at Dec 06 2024 | Reading Time:About 5 minutes

When it comes to turning an innovative idea into a tangible product, prototype development plays a crucial role in ensuring that the design works, fits the intended purpose, and can be manufactured effectively. Many businesses struggle with the complexities of prototyping, unsure about the best methods, costs, and timelines involved. If you’re facing these challenges, understanding the nuances of product prototype development can help you avoid costly mistakes, improve your final product, and accelerate the go-to-market process. Whether you’re working with CNC machining parts, 3D printing, or other techniques, this article will guide you through everything you need to know to develop a successful prototype.

Product prototype development involves transforming your initial design ideas into physical representations, allowing you to test and refine functionality before full-scale production. From 3D printing to CNC machining services, selecting the right prototyping method is essential for meeting your project’s requirements. The process typically includes researching concepts, detailed design, testing, and preparing for manufacturing. Understanding these steps ensures you can validate your product, avoid costly errors, and ultimately create a functional, market-ready design.

Now that you have a general understanding of prototype development, let’s dive deeper into the techniques and tools that make prototyping a streamlined process. From cutting-edge 3D printing technologies to CNC machining services, the right method can greatly influence the speed, accuracy, and cost-effectiveness of your product development cycle. Keep reading to explore the different prototyping methods, the role of CNC machining in the process, and how each stage of development contributes to a successful final product.

Rapid prototyping has revolutionized the way products are developed. In the past, creating prototypes was a slow, expensive process that required high levels of expertise and equipment. With modern advancements in technology, prototyping is faster and more accessible, enabling businesses to bring ideas to life in weeks rather than months. Rapid prototyping techniques allow for the quick iteration of product designs, which is critical when testing functionality, aesthetics, and manufacturing feasibility.

The primary benefit of rapid prototyping lies in its speed and flexibility. Engineers and designers can quickly create a physical model of a product to test various iterations before committing to expensive, large-scale production. Moreover, rapid prototyping enables a more cost-effective approach to design validation, allowing for more prototypes to be tested within the same budget. The faster you can identify flaws or improvements, the quicker you can move forward with your product development cycle.

CAD and CAM Software

One of the core tools in the rapid prototyping process is CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. These programs allow designers and engineers to create highly detailed digital models and translate them into precise manufacturing instructions. CAD software enables users to design 3D models, while CAM software takes these designs and generates tool paths for manufacturing equipment. The integration of these two systems ensures that prototypes are created with a high level of accuracy and that the transition from digital concept to physical product is seamless.

With the rise of CNC machining and 3D printing, these software tools have become essential in product prototype development. Custom CNC machining, for instance, relies on precise digital models to create parts with the necessary specifications. CNC machining factories use these models to produce prototype parts that accurately reflect the intended design, ensuring that the final product meets the required tolerances and functional performance.

Definition

Prototyping is the process of creating an early model or sample of a product to test and evaluate its design, functionality, and usability before committing to full-scale manufacturing. It serves as a proof of concept that allows designers and engineers to assess whether a product will meet user needs, perform as expected, and be manufacturable at scale. Prototypes can be physical or digital, and the choice of prototyping method depends on the complexity of the design, the materials involved, and the testing requirements.

Prototyping is an essential part of the product development cycle because it allows businesses to validate their ideas before investing significant time and money into mass production. It’s an iterative process that helps fine-tune designs, catch potential issues early on, and ensure the final product is both functional and manufacturable.

Prototype Categories

When discussing prototyping, it’s important to understand the different categories that prototypes can fall into. There are four primary types of prototypes that are commonly used in product development:

Working Prototype

A working prototype is a fully functional version of the product, designed to demonstrate its core features and performance. This type of prototype allows designers and engineers to test the functionality and usability of a product before production.

Functional Prototype

Similar to a working prototype, a functional prototype is designed to test specific functions or components of a product. For example, if you’re developing a new electronic device, you may create a functional prototype to test the circuitry, battery life, or user interface.

Visual Prototype

A visual prototype focuses on the appearance and aesthetic design of a product rather than its functionality. This type of prototype is commonly used in industries like consumer products or automotive design to assess how the product will look to potential customers.

User Experience Prototype

A user experience (UX) prototype is designed to test how the product interacts with the end user. It focuses on the usability and user interface, such as the ease of use, ergonomics, and overall customer satisfaction.

Prototype development plays a vital role in the product development process. It provides companies with the opportunity to test ideas, validate concepts, and ensure that a product will meet the needs of the market and the end user. The process of prototyping can save time and money in the long run by catching design flaws early, helping teams make better decisions, and avoiding costly manufacturing mistakes.

1. Design Evaluation and Testing

One of the most important reasons for creating a prototype is to evaluate the design. A prototype allows designers to visually and physically inspect the product, ensuring that it meets the intended specifications. Testing the design in real-world conditions provides valuable insights into how the product will perform, how it feels, and whether it is durable enough for its intended use.

For example, in custom CNC machining, creating a prototype part allows you to check for fit and function, ensuring that the tolerances are correct before proceeding with the final production run. This step helps prevent costly rework down the line.

2. Selling Products

Prototypes are also valuable marketing tools. Whether you’re presenting a new product to potential investors, customers, or stakeholders, having a physical prototype can help convey the value of your idea. Prototypes make it easier to demonstrate how a product works, and they can be used to create prototypes for demonstration purposes or as part of a pitch.

3. Concept Verification

A prototype helps verify the viability of your product concept. It’s one thing to have a great idea on paper, but seeing it come to life in a physical form can reveal challenges you may not have anticipated. A prototype allows you to identify potential issues with functionality, manufacturing, or user experience early in the process, which is essential for successful product development.

4. Reducing Production Costs

By creating prototypes before beginning mass production, companies can identify design issues that may require costly adjustments. It’s far cheaper to fix problems in the prototype phase than it is to make changes during large-scale manufacturing. Prototypes help reduce the risk of product failure by enabling designers to make the necessary adjustments before launching full production.

The purpose of prototyping is multifaceted, but the core goal is to bring an idea to life in a way that allows it to be tested, refined, and prepared for manufacturing. Prototypes are used to validate design concepts, assess product functionality, and ensure that the final product meets user expectations and market demand.

1. Validate Your Product Idea

The first purpose of prototyping is to validate the product idea itself. Prototypes allow businesses to test whether their concept is feasible, functional, and desirable to potential customers. This step helps to determine if the product is worth pursuing further and if additional iterations are needed.

2. Test Functionality

Prototypes allow engineers to test the functionality of the product before full-scale manufacturing. Whether it’s a new piece of technology, a mechanical part, or an everyday consumer product, testing functionality is crucial for ensuring that the product works as intended.

3. Iterate Until Perfection

Product development is rarely a linear process. With each prototype iteration, you can identify weaknesses and make improvements. This iterative process helps refine the design, ultimately resulting in a more polished, effective final product.

4. Prepare for Manufacturing

Finally, prototypes are critical for preparing for large-scale manufacturing. A well-made prototype ensures that production will proceed smoothly and that there are no surprises during the manufacturing phase. Prototypes can also be used to create detailed manufacturing plans, providing valuable insights into materials, tooling, and processes.

Conclusion

In product development, prototyping is an essential step for bringing an idea to life and ensuring that the final product will be successful. Whether you’re using CNC machining services, 3D printing, or traditional fabrication techniques, understanding the prototyping process will help you avoid mistakes, reduce costs, and ultimately deliver a product that meets customer needs and market demands. By following the stages of product prototype development and selecting the appropriate methods for your project, you can refine your design, test functionality, and ensure a smooth path to mass production.

Prototyping is a structured process that helps transform an abstract idea into a tangible reality. The prototyping process is generally broken down into several key stages, each with a specific purpose aimed at refining the product design, testing its functionality, and preparing it for mass production. These stages not only guide the development team but also help mitigate risks and streamline the production process. Understanding the phases involved in product prototyping can ensure that the prototype effectively meets the desired specifications and ultimately leads to a successful final product.

The prototyping process typically consists of three primary phases: the initial concept phase, the detailed design phase, and the final manufacturing phase. In each of these phases, the focus shifts from idea validation and testing to design refinement and eventual readiness for production. Let’s break down each phase in detail.

Phase 1: Define the Product and Its Feasibility

The first step in product prototype development is defining the product and evaluating its feasibility. This is the conceptual phase where you lay the groundwork for the entire prototyping process. The goal at this stage is to ensure that the product idea is viable from both a technical and business perspective.

Research and Ideation

In this initial phase, the team conducts research to assess the market, understand customer needs, and identify potential competitors. This helps to determine whether the product idea is innovative and meets an existing gap in the market. The research phase often involves brainstorming sessions to generate creative ideas and solutions, alongside reviewing trends and emerging technologies that could be leveraged in product development.

Concept Development and Evaluation

After ideation, the next step is to create an initial product concept. This might be in the form of rough sketches, 3D renderings, or digital models using CAD software. The concept is then evaluated for its feasibility, which includes analyzing technical challenges, budget constraints, and the potential for scalability. For example, in CNC prototype machining, designers will evaluate whether the proposed parts can be manufactured with existing equipment, whether the design fits the intended purpose, and if the material choices are appropriate.

Initial Specifications and Drawings

Once the concept has been evaluated, the next step is to produce more refined specifications. These are detailed documents that outline the product’s dimensions, features, and materials. For complex products, this may also involve initial functional testing on a basic prototype to gauge whether the design will work as intended.

Phase 2: Detailed Design

The detailed design phase is where the product starts to take shape. Here, engineers and designers fine-tune the prototype, incorporating feedback from earlier evaluations and test results. This is the phase where you move from concept to a working model.

Product Design

During this phase, the team focuses on refining the design to meet all functional and aesthetic requirements. This may involve reworking some elements to address weaknesses identified in earlier phases. For example, if a CNC machining part doesn’t fit as intended in an earlier prototype, the design will be adjusted to ensure precision in future versions. Tools like CAD software play an essential role in this stage to develop detailed and accurate product models.

Alpha and Beta Testing

Once the design is finalized, it’s time to test the prototype in real-world conditions. Alpha testing usually involves in-house testing, where a small group of users or engineers evaluates the prototype for functionality and usability. This phase helps identify any performance or design issues that weren’t initially apparent. Afterward, beta testing may involve a broader group, sometimes outside the development team, to gain additional feedback and catch any overlooked problems.

Pilot Phase

Following alpha and beta testing, a pilot phase may be initiated. This involves creating a small batch of prototypes that resemble the final product as closely as possible. The goal of the pilot phase is to simulate the conditions of mass production, allowing the development team to refine the manufacturing process and evaluate production costs. It also helps identify any additional issues in materials, assembly processes, or quality control.

Phase 3: Final Design and Manufacturing

Once the prototype has been tested and refined, the final design is ready for mass production. The purpose of this phase is to ensure that the prototype’s design can be efficiently manufactured on a larger scale while maintaining the same quality and functionality.

Final Design Refinements

During this phase, all the lessons learned from previous testing and prototypes are incorporated into the final design. This may involve tweaking the design to simplify the production process, reduce costs, or improve the overall quality. The final design will be optimized for manufacturability, meaning it’s tailored to be produced in the most cost-effective and efficient way possible. For example, this could involve adjusting tolerances for CNC machining parts to streamline production or selecting more readily available materials.

Manufacturing

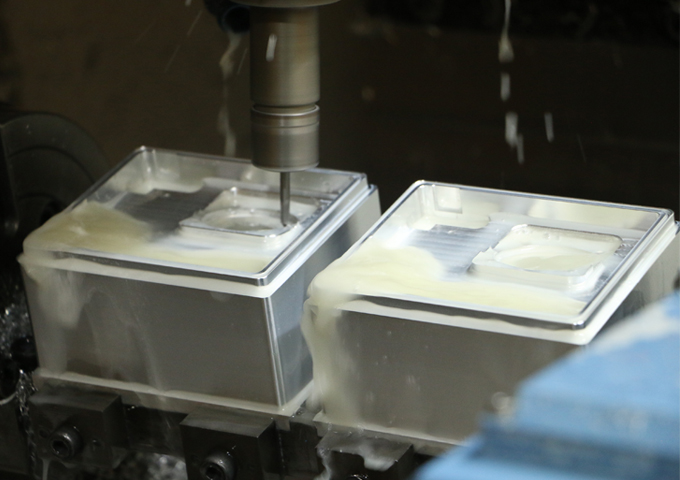

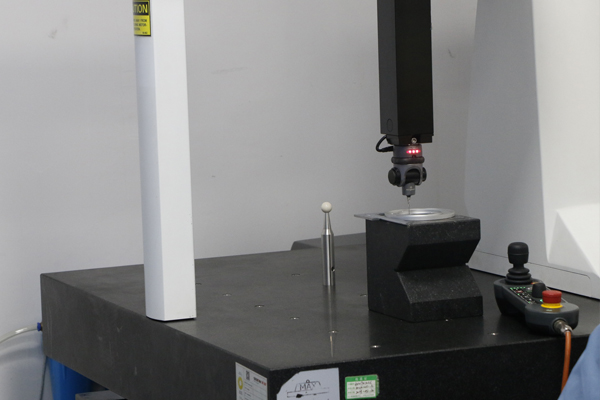

Once the design is finalized, the next step is to move into full-scale manufacturing. In the context of CNC prototype machining, this involves setting up the necessary machinery and tooling to produce parts according to the exact specifications of the final design. CNC machining services often come into play at this stage, as they provide precision machining of the final prototype parts. Quality control is an essential part of this process to ensure that each piece meets the required standards. It’s crucial to maintain consistency and precision in this phase to avoid any defects that could affect the performance or appearance of the product.

Prototypes play an essential role in a wide range of industries, from automotive to consumer products, where rapid testing and iteration are necessary for product success. In each industry, prototypes are used to verify designs, assess functionality, and ultimately bring innovations to market. Let’s explore how prototyping works across various sectors and how it impacts product development in these industries.

In the automotive industry, prototypes are critical for testing vehicle designs, safety features, and functionality before mass production begins. Engineers use prototypes to assess aerodynamics, safety features, and ergonomics, which are all crucial for ensuring the car meets regulatory standards and consumer expectations. CNC machining and additive manufacturing technologies are often used in the automotive sector to create prototype parts for engine components, interiors, and other specialized parts. With these advanced techniques, automotive manufacturers can test and refine their designs before committing to large-scale production.

Prototyping is also a cornerstone of the electronics industry, where products such as smartphones, wearable devices, and home appliances require highly detailed, intricate designs. Prototypes in electronics allow engineers to test circuitry, battery life, and wireless capabilities. Technologies such as 3D printing and CNC machining are often employed to create early-stage prototypes of printed circuit boards (PCBs) or enclosures. These prototypes allow engineers to refine the design, test functionality, and verify performance before committing to mass production.

In the medical device industry, prototypes are essential for ensuring product safety, efficacy, and usability. Medical device prototypes undergo rigorous testing to meet regulatory standards, such as those set by the FDA. Prototyping in this industry often involves creating models of implants, surgical tools, and diagnostic devices. CNC machining services are heavily utilized to produce precise components that must adhere to strict tolerance requirements. The prototyping phase helps ensure that medical devices are safe and effective before they are cleared for clinical use.

Aerospace Industry

The aerospace industry relies on prototypes to test and evaluate complex systems such as aircraft, satellites, and other space-bound technology. Prototyping allows engineers to test materials, aerodynamics, and the performance of various systems under different conditions. In aerospace, prototypes are often built using CNC machining and advanced materials to simulate real-world stress and environmental factors. Prototype testing ensures that the final product will be both functional and safe under extreme conditions.

Consumer Products

For consumer products such as electronics, toys, and household goods, prototyping is key to ensuring that the product meets consumer needs, performs reliably, and can be produced at scale. Prototypes are used to assess user experience (UX), design aesthetics, and functionality. Technologies such as 3D printing are increasingly popular for developing consumer product prototypes, as they allow for rapid iteration and design testing.

While prototyping is an essential step in the product development process, there are common mistakes that can hinder its effectiveness. These mistakes can result in delays, increased costs, and ultimately, a product that fails to meet the desired specifications. Let’s explore some of the most frequent prototyping mistakes and how to avoid them.

1. Ignoring Professional Advice

One of the most common mistakes is failing to consult with experts during the prototyping process. Whether it’s engineers, designers, or CNC machining specialists, professional advice is crucial for ensuring that the prototype is manufacturable, functional, and cost-effective. Relying solely on internal teams without outside expertise can lead to overlooked flaws or inefficiencies in the design.

2. Inaccurate Cost Forecasts

Prototyping can be expensive, and inaccurate cost forecasting can lead to unexpected financial strain. It’s essential to account for all materials, labor, and production costs when planning the prototype. Be sure to get quotes from manufacturers, including CNC machining services, and factor in any potential revisions to avoid running over budget.

3. Lack of Adequate User Feedback

Failing to incorporate user feedback early in the process can lead to a product that doesn’t meet consumer needs or expectations. Prototypes should be tested by real users to gain insights into how the product performs in real-world conditions. This helps identify usability issues and improve the overall design before moving to production.

4. Speeding Up the Process

While it’s tempting to speed up the prototyping process to meet tight deadlines, rushing through the stages can lead to incomplete testing, overlooked flaws, and ultimately, a subpar product. It’s important to allow enough time for thorough testing and iteration to ensure that the final prototype meets all functional and aesthetic requirements.

Product prototype development is an essential part of the product development cycle. By following a structured prototyping process, you can validate your ideas, test functionality, and refine designs before full-scale manufacturing. Whether you’re utilizing CNC machining services, 3D printing, or other rapid prototyping technologies, the insights gained during the prototyping phase are invaluable for ensuring that the final product meets both technical requirements and consumer expectations. With careful planning, adequate testing, and the right prototyping methods, you can bring your product to market more quickly and cost-effectively while reducing the risk of failure.

For companies looking to develop high-quality prototypes quickly and efficiently, partnering with a reliable prototyping service provider is essential. VMT (Virtual Machine Technologies) Rapid Prototyping Services offer a comprehensive solution for businesses in need of precision-engineered prototypes for a wide variety of industries. By leveraging advanced technologies such as CNC machining, 3D printing, and other rapid prototyping methods, VMT helps streamline the product development process, allowing for faster iterations, more accurate designs, and cost-effective manufacturing.

Whether you're working on a prototype for automotive, aerospace, consumer products, or medical devices, VMT's services are tailored to meet the specific needs of each project. They work closely with clients to ensure that every detail of the prototype is optimized for functionality, performance, and manufacturability. In this section, we’ll explore the advantages of using VMT Rapid Prototyping Services, the technologies they employ, and how their expertise can help you bring your product ideas to life.

Advanced Technologies for Precision Prototypes

VMT Rapid Prototyping Services utilize a wide range of cutting-edge technologies to produce prototypes that meet the highest standards of quality and precision. These technologies include:

CNC machining is one of the most accurate and reliable methods for producing functional prototypes. By using computer-controlled machines, VMT can produce parts with precise tolerances, high surface quality, and intricate details. CNC prototype machining is especially useful for parts that require high strength, durability, or complexity.

3D Printing

3D printing, also known as additive manufacturing, is a versatile prototyping technique that allows for rapid and cost-effective production of complex geometries. It’s an excellent option for creating detailed models and testing designs before committing to expensive tooling. VMT offers 3D printing services in various materials, such as thermoplastics, metals, and resin-based materials, allowing for prototypes that closely resemble the final product in terms of both form and function.

Injection Molding and Casting

For projects that require multiple iterations or large quantities of prototypes, VMT also offers injection molding and casting services. These processes are ideal for testing materials, surface finishes, and the fit and function of your prototype parts before scaling up for mass production. Injection molding is particularly effective for producing high volumes of plastic prototypes, while casting is used for metal parts that need to be tested under stress or specific conditions.

Hybrid Prototyping

VMT also provides hybrid prototyping, which combines the benefits of different technologies to produce highly functional, versatile prototypes. This approach allows the development of prototypes that integrate features from both CNC machining and 3D printing, making it possible to test designs at various stages of production.

Advantages of Using VMT Rapid Prototyping Services

Faster Time to Market

One of the main benefits of using VMT’s rapid prototyping services is the significantly reduced lead time for developing prototypes. With advanced manufacturing technologies and experienced engineers on hand, VMT can produce prototypes much faster than traditional methods, helping you get your product to market sooner.

Cost-Effective Solutions

Prototyping can be a costly process, especially if multiple iterations are required. VMT’s ability to provide rapid prototyping with technologies like CNC machining, 3D printing, and injection molding can help reduce production costs. By providing prototypes that can be quickly tested and refined, VMT minimizes the need for expensive rework and adjustments.

High-Quality Standards

VMT ensures that all prototypes meet stringent quality standards. Their use of precision CNC machining and other advanced techniques ensures that every part produced is accurate, durable, and fully functional. Additionally, their rigorous testing procedures ensure that prototypes are thoroughly evaluated before moving to the next phase of production.

Expert Guidance and Support

Throughout the prototyping process, VMT provides expert guidance to ensure that your design is optimized for performance, manufacturability, and cost-efficiency. Their team works closely with clients to address any challenges that arise, ensuring that each prototype meets or exceeds expectations.

Flexible Prototyping Options

VMT offers a wide range of prototyping options to suit the specific needs of your project. Whether you're developing small, intricate parts or large, complex assemblies, VMT has the technology and expertise to produce high-quality prototypes that match your exact requirements.

What is a prototype in the product development process?

A prototype is a preliminary model or sample of a product, created to test and validate its design, functionality, and usability before committing to full-scale production. Prototypes are used to identify potential issues, gather user feedback, and refine the product design before mass manufacturing begins.

How long does the prototyping process take?

The prototyping process can vary in length depending on the complexity of the product and the prototyping method used. Rapid prototyping technologies such as 3D printing and CNC machining can produce prototypes in a matter of days or weeks, while more complex designs may require additional time for testing and refinement. Generally, the faster you can iterate through testing and adjustments, the quicker you can bring your product to market.

How much does it cost to prototype a part?

The cost of prototyping depends on several factors, including the complexity of the design, the materials used, and the prototyping method chosen. For example, CNC machining services might be more expensive for highly detailed, precision parts, while 3D printing could offer a more cost-effective solution for rapid iterations of simpler designs. On average, prototyping can cost anywhere from a few hundred to several thousand dollars, depending on the requirements of the project.

What is prototyping?

Prototyping is the process of creating a preliminary model or sample of a product to test its design, functionality, and feasibility. The goal is to validate concepts, identify potential issues, and refine the product before proceeding with full-scale production. Prototypes are essential for improving the product development process and ensuring that the final product meets user needs and expectations.

What is the difference between a cosmetic prototype and a real prototype?

A cosmetic prototype primarily focuses on the appearance of the product and is typically used for visual representation. It may not have all the functional components or durability features of the final product. In contrast, a real prototype (also known as a functional prototype) is a fully functional version of the product, designed to test its performance, usability, and technical aspects.

What is rapid prototyping?

Rapid prototyping refers to a set of techniques used to quickly create physical models of a product from digital designs. This process allows for fast iterations, quick testing, and faster feedback, making it an essential tool in product development. Technologies like 3D printing, CNC machining, and injection molding are commonly used in rapid prototyping.

What are the 5 stages of prototyping?

The five stages of prototyping are:

What is the prototyping process?

The prototyping process involves creating a physical or digital representation of a product to test and validate its design. The process includes several phases, such as conceptualization, design refinement, prototype construction, testing, and iteration. The aim is to create a functional model that can be tested, refined, and prepared for mass production.

What are the six types of prototype design?

The six common types of prototype design are:

Prototyping is a vital step in the product development process, enabling designers and engineers to validate concepts, refine designs, and prepare for mass production. Whether you are developing a new automotive part, a medical device, or a consumer product, understanding the nuances of prototyping and selecting the right methods can dramatically improve your product’s success. Rapid prototyping services like those offered by VMT help businesses create high-quality, functional prototypes faster and more cost-effectively, accelerating the development cycle and reducing risks. By leveraging advanced technologies such as CNC machining, 3D printing, and injection molding, companies can ensure that their prototypes meet all necessary specifications and are ready for the next phase of production. With careful planning, expert advice, and the right tools, you can bring your product to life and ensure its success in the marketplace.