15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

262 |

Published by VMT at Nov 08 2023

262 |

Published by VMT at Nov 08 2023

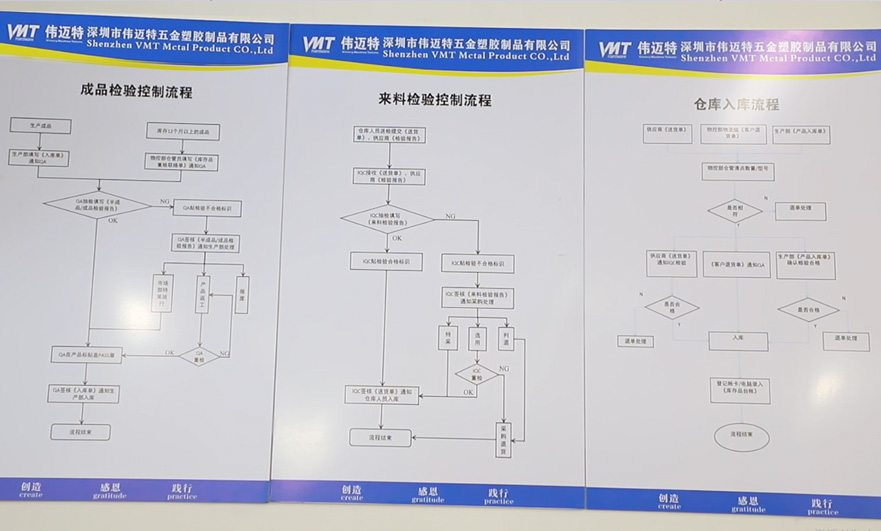

In the realm of CNC machining part factories, IPQC (In-Process Quality Control) plays a crucial role in ensuring the quality and reliability of the manufacturing process.

Role and Importance of IPQC in CNC Machining Part Factories:

Quality Assurance at Each Stage:

IPQC is pivotal as it monitors and ensures the quality of CNC machined parts at various stages of production. It involves inspections, checks, and verifications to maintain the specified quality standards during each step of the manufacturing process.

Early Detection of Defects:

By conducting regular inspections during production, IPQC helps identify and rectify any defects or deviations in the early stages. This early detection is vital in preventing the escalation of issues, reducing scrap, and ensuring that only high-quality parts move to subsequent production phases.

Process Optimization and Efficiency:

IPQC aids in analyzing the manufacturing process, identifying potential areas for improvement, and optimizing the workflow. This continuous improvement ensures that the production process is efficient, reliable, and meets the required quality standards.

Reducing Rework and Costs:

Early detection and correction of issues through IPQC significantly minimize the need for rework, reducing overall manufacturing costs. It ensures that resources are used efficiently and that the final products meet quality specifications.

Customer Satisfaction and Trust:

Consistent quality assured by IPQC instills confidence in customers, establishing trust in the reliability and quality of the CNC machined parts. Satisfied customers are more likely to maintain long-term relationships and partnerships.

Compliance with Standards:

IPQC ensures that the manufactured parts comply with industry standards, customer specifications, and regulatory requirements. This is crucial in delivering products that meet or exceed expectations and adhere to safety and quality norms.

IPQC is integral in maintaining high-quality standards, ensuring process efficiency, and meeting customer demands in CNC machining part factories. It serves as a crucial mechanism in delivering reliable, high-quality products to the market.

Looking for a reliable cooperative CNC machining factory

Are you looking for the right CNC machining manufacturer? Why not give VMT CNC machining factory a try and let us help you.

We provide customized CNC machining and surface treatment services for copper, stainless steel, aluminum, titanium and other metal materials. Focusing on CNC machining and production for 13 years, whether it is prototype CNC machining and manufacturing or small batch CNC machining parts production, our team of professional engineers can choose the appropriate CNC machining process and surface treatment for you, reduce your production costs, and meet high standards. Your CNC machining needs. Now, just upload your CAD files to our email: inquiry@vimetal.com.cn to get a project quote.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!