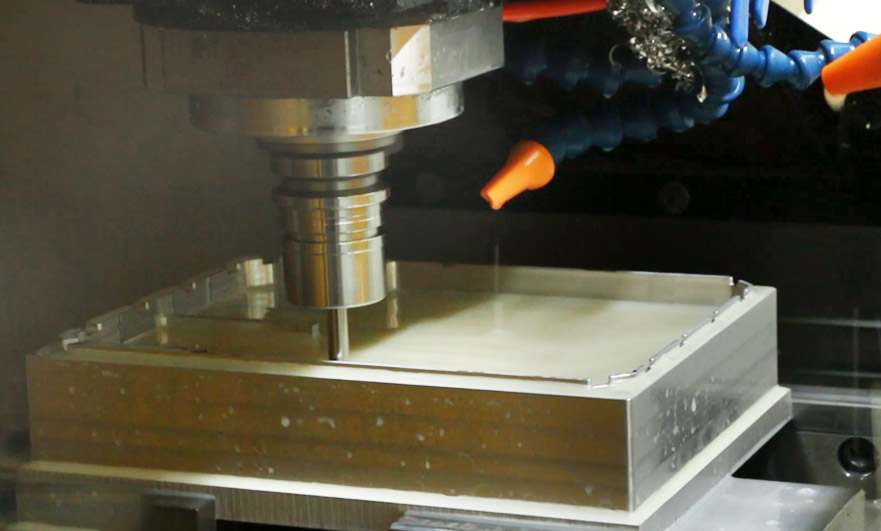

15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

129 |

Published by VMT at Sep 07 2022

129 |

Published by VMT at Sep 07 2022

Just reduce the burr and choose the right machining center.

When doing aluminum CNC machining, the cost must be an aspect that everyone is very concerned about. Burrs in CNC machining should be a problem that everyone has encountered. It not only reduces the CNC machining accuracy of parts, increases the cost of CNC machining, but also affects the performance of aluminum CNC machining parts. Usually, deburring operations are required, which is troublesome. Not to mention, if it is not done well, it will sometimes damage the aluminum CNC machined parts. So is there any better way to reduce or reduce the generation of burrs in the CNC machining process to save us cost and money? Today, I will share with you some experiences in glitch control and model selection.

What is a glitch?

The burr is the thorn or flash formed around the machined part of the aluminum CNC machined part, which is characterized by the protruding molding surface. It is the excess that does not conform to the shape and size required by the design.

Burrs are usually produced at the edge of the cutting end of the material to be processed due to the plastic deformation of the material, and are especially common in materials with good ductility such as aluminum alloys (or materials with good toughness such as stainless steel).

Its shape and size mainly depend on multiple factors such as the material of CNC machined parts and the support stiffness of their ends, tool geometry, tool cutting trajectory, tool wear, cutting parameters, and the use of coolant.

Why deburr? (brief list part)

The existence of burrs will make CNC machining, measurement or installation lose accuracy, and affect the dimensional accuracy and shape and position accuracy of aluminum CNC machining parts.

The hardening and falling off of burrs are the source of cracks, which will reduce the service life of CNC machined parts.

May cause injury to the production operator or the user of the machine.

The presence or detachment of the burr may cause an electrical short circuit, and if it falls into the sliding part, it will accelerate the wear and cause an accident.

Some experience in controlling glitches

Selection of CNC machining sequence

When arranging the CNC machining sequence, try to arrange the processes that generate burrs in the front, and arrange the processes that do not generate burrs (or small burrs and a small number) in the back, or rationally use some of the following processes to remove the previous process. glitches. For example, when CNC machining stepped grooves, deep grooves are machined first, and then shallow grooves are machined, which can remove the groove edge burrs generated during CNC machining of deep grooves and effectively improve the quality of aluminum CNC machining parts.

Selection of CNC machining methods

In the process design, the CNC machining method that generates less burrs or is conducive to burr removal should be selected as far as possible.

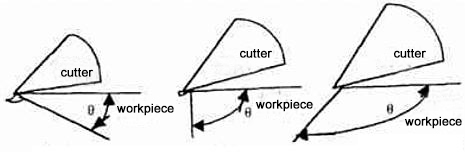

For example, during cutting, the cutting edge should be placed at a position with a larger value of the edge angle θ of the part (the edge intersection angle of two adjacent machined surfaces), and the support rigidity of its end is better, which can be effectively reduced or even completely Eliminate the generation of burrs.

Just two more examples:

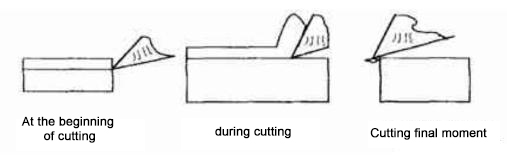

In CNC milling, the cut-in layer is thick and the cut-out layer is thin, the cutting is smooth, and the burr is small. To reduce CNC milling burrs, climb milling should be used as much as possible.

When milling the plane, if the part plane is machined with an end mill, the cutting force generated by cutting perpendicular to the machining plane is large, so the generated burrs are also larger, and the use of cylindrical plane milling cutters for down milling can effectively reduce the generation of burrs.

In addition, even if the generation of burrs cannot be completely suppressed during CNC machining, the knife edge should be placed in a position where it is easy to remove burrs, so as to reduce the cost of subsequent burr removal.

Selection of tools

Metal CNC machining is realized by the tool extruding the workpiece and the machining part is realized by elastic deformation - plastic deformation - cutting. The aluminum alloy itself has better toughness and extension, and it is not easy to break chips, so the blade of the tool must be sharp.

Sharp high-speed steel tools, carbide tools (aluminum tools), and PCD tools are all available. The purpose is to shorten the elastic deformation and plastic deformation time of the workpiece itself, and avoid burrs caused by tearing the machining parts of the parts.

However, at the same time, tool wear has a great influence on the formation of burrs. If it is continuous production in batches, it is also necessary to consider the wear resistance of the tool to keep the tool in a sharp state for a longer time. At this time, it is recommended to use a PCD tool (see: You Did you notice that PCD tools are used more and more in aluminum CNC machining).

Special compound tools (compound milling cutters, compound drills, etc.) can also be used in the CNC machining process. The burr generated by the previous tool can be removed by the latter tool, which can improve the machining quality while controlling the burr generation.

Adjust the cutting parameters

For example: increase the rake angle of the tool, reduce the cutting thickness, adjust the cutting speed, etc., which can be adjusted according to the actual situation.

Optimization of tool path

Tool withdrawal is the main factor for the formation of burrs in the cutting direction. Under normal circumstances, the burr generated by the milling cutter when it is rotated out of the workpiece is larger, and the burr generated when it is rotated into the workpiece is smaller. Therefore, the milling cutter should be avoided as far as possible during the CNC machining process.

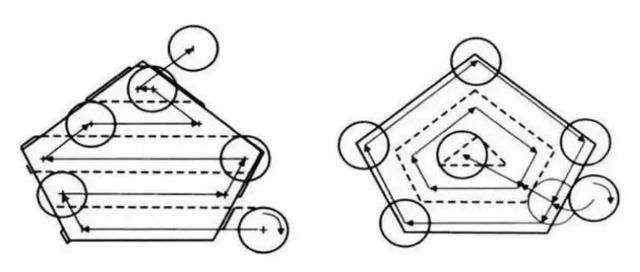

Another classic example:

The picture on the left shows the traditional zigzag tool path, and the shaded part in the picture indicates the part that may produce large burrs in the cutting direction. The image on the right uses an improved toolpath that avoids cutting out burrs. Although the tool path on the right is slightly longer than the one on the left, and it takes a little more time for milling, since no additional deburring process is required, in general, in terms of burr control, the tool path shown on the right is better. The route shown on the left (all edges where the burr is must be completed when deburring).

Selection of cutting fluid

Use cutting fluids with good anti-adhesion properties to reduce tool wear, extend their service life, lubricate the milling process, and reduce burr size (see: Selection of cutting fluids for aluminum).

Other methods

Multi-piece overlapping machining is adopted, so that the machining edge of one part is close to the machining input edge of another part. This not only shortens the cutting stroke and improves the production efficiency, but also enhances the rigidity of the parts during CNC machining, reduces the cutting deformation, and can effectively prevent and reduce the generation of burrs.

For attachment machining, various attachments are used for auxiliary support and filling at the cutting edge of the parts. For example, when machining small holes in thin-walled pipe fittings, insert a mandrel into the aluminum CNC machined part, drill it and then take it out, which can avoid the deformation of the CNC machined part and reduce the generation of burrs in the hole.

Selection of Aluminum CNC Machining Center

If it is specialized in aluminum CNC machining and the machining requirements are not very high-precision, it is recommended that you use a special aluminum CNC machining center. This kind of equipment can be regarded as an upgrade in the advertising industry or woodworking industry. In the three-axis model, the XY axis adopts rack drive, and the CNC machining speed is faster. On the basis of ensuring the CNC machining accuracy range, unnecessary parts are made. In order to simplify and optimize, it is more suitable for CNC machining of soft metals such as copper, aluminum and titanium in the industrial field and non-metal CNC machining such as PC, PA, bakelite, FR4, and wood. The purchase price and maintenance cost will be lower than general CNC machining centers. It is very suitable for large-scale CNC machining production.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!