15 years one-stop China custom CNC machining parts factory

1571 |

Published by VMT at Aug 01 2024

1571 |

Published by VMT at Aug 01 2024

Pins, also known as "pins" in mechanical contexts, are small mechanical components used for connecting, fastening, or positioning parts. In the field of CNC machined parts manufacturing, pins play a crucial role. They are widely used in various industrial scenarios, from precision instruments to large machinery, all of which rely on the secure connection provided by pins. This article will delve into the types of pins, their uses, manufacturing methods, material choices, advantages, and applications across different industries. It will also answer common questions about pins.

A pin is a mechanical component designed to connect, fasten, or position two or more parts. They typically have small sizes and precise tolerances to ensure the stability and reliability of the connection. In CNC machined parts manufacturing, pins are not only used for simple fastening tasks but also for assembling and positioning complex mechanical structures.

Cotter Pins

Cotter pins are cylindrical pins with split ends, mainly used to lock bolts, nuts, or other fasteners to prevent them from loosening. Their design allows them to lock through deformation after insertion, enhancing the stability of the connection.

Dowel Pins

Dowel pins are primarily used to ensure the precise positioning of parts during assembly. They typically have precise dimensions and shapes to ensure alignment and fit between parts. In CNC machining, dowel pins are often used in the manufacture of precision molds and fixtures.

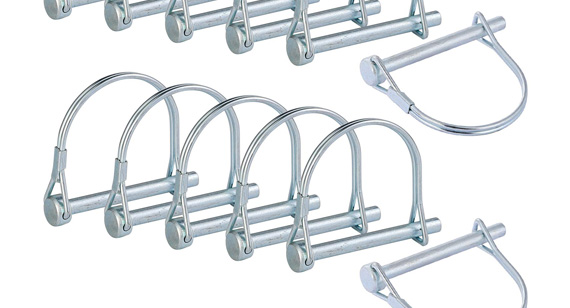

Lynch Pins

Lynch pins, also known as safety pins or quick-release pins, are designed for quick connection and disconnection. They usually have an enlarged head and an easy-to-operate tail, facilitating manual or tool operation. These pins are very useful in applications requiring frequent disassembly and reassembly.

Spring Pins

Spring pins have an internal spring that expands outward when inserted into a hole, fixing the pin in place. This design allows spring pins to maintain stable connections even in vibrating or impact environments.

Wire Lock Pins

Wire lock pins are slender pins made of wire, typically used for locking or fastening smaller parts. They can be locked by bending or twisting, offering high flexibility and adaptability.

Taper Pins

Taper pins have a tapered end and a cylindrical end. They are usually used for positioning or locking parts that require precise alignment. The tapered design helps in automatic alignment during insertion, improving connection accuracy.

L-Handle Pins

L-handle pins are pins with an L-shaped handle for easy manual operation. They are commonly used in situations requiring frequent insertion and removal, such as mold changes or equipment adjustments.

Clip Pins

Clip pins have a clamping function, typically used to secure pipes, cables, or other elongated parts. They fix parts in a predetermined position through clamping force, ensuring a stable connection.

Spring Plungers

Spring plungers are plunger-type pins with an internal spring. When external force is applied, the spring pushes the plunger out to lock or fix parts. This design is very useful in applications requiring automatic locking or unlocking.

Clevis Pins

Clevis pins are special pins usually used to connect U-clamps or other similar-shaped parts. They have specific shapes and sizes to ensure stable and reliable connections.

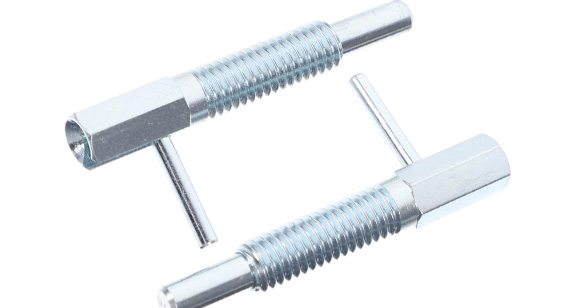

Retractable Spring Pins

Retractable spring pins are spring pins that can retract, typically used in situations requiring adjustable length or adaptability to different hole diameters. They meet different connection needs through a retractable mechanism, enhancing connection flexibility and adaptability.

Pin fasteners can be manufactured using various methods, including CNC machining, stamping, forging, and more. Each method has its unique advantages and suitable applications. Choosing the right manufacturing method based on specific needs and material characteristics is crucial.

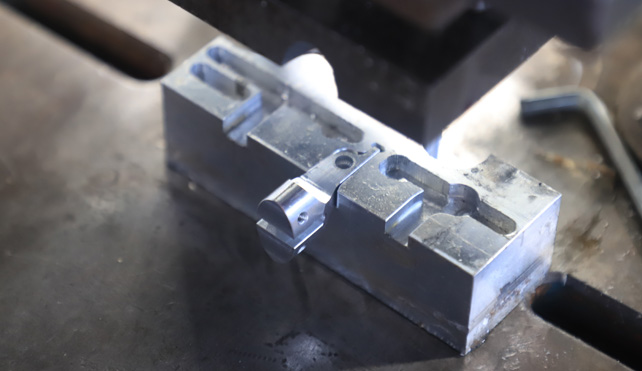

CNC machining is a high-precision, high-efficiency manufacturing method widely used in the production of pin fasteners. By programming and controlling machine tools, various shapes and sizes of pin fasteners can be precisely machined. The advantages of CNC machining include high machining accuracy, high production efficiency, and strong adaptability, meeting the requirements for complex shapes and precise tolerances.

Stamping

Stamping is a cold-working process that uses molds to deform metal sheets plastically. During the stamping process, metal sheets are plastically deformed under the action of molds to form the required shapes and sizes. Stamping has the advantages of high production efficiency and low cost, suitable for mass production of simple pin fasteners.

Forging

Forging is a process that plastically deforms metal materials through heating and mechanical force. The forging process can produce pin fasteners with complex shapes and high strength. Forgings have dense structures and good mechanical properties, suitable for applications requiring high load-bearing capacity.

The manufacturing process of metal pin fasteners typically includes the following steps:

Cutting: Cutting the raw material (such as wire or bar) to the appropriate length.

Wire Forming: Bending or pressing the wire into the desired shape through molds or mechanical devices.

CNC Turning: Using CNC lathes to precisely turn the formed pins to meet size and tolerance requirements.

Material Removal: Removing excess material through milling, grinding, or laser cutting to further refine the pin's shape and size.

Grinding: Grinding the pin's surface to improve its finish and reduce roughness, enhancing connection smoothness and durability.

Drilling: For pins requiring internal holes or specific hole shapes, performing drilling operations to meet design requirements.

Rolling: In some cases, rolling processes can enhance the pin's strength and toughness, especially for large or heavy pins.

Heat Treatment: Performing heat treatment processes such as annealing, quenching, and tempering to improve the pin's physical and mechanical properties, such as hardness, wear resistance, and fatigue resistance.

Finishing: Performing final finishing steps such as polishing and deburring to ensure the pin's accuracy and appearance quality.

Pins can be made from a wide range of materials, each with its unique physical and chemical properties, suitable for different applications. Common materials for making pins include brass, aluminum, steel, stainless steel, and titanium.

Brass

Brass, an alloy of copper and zinc, has good machinability and corrosion resistance. Brass pins are commonly used in decorative and electrical connection applications, with their golden appearance enhancing product aesthetics.

Aluminum

Aluminum is a lightweight metal with good thermal and electrical conductivity. Aluminum pins are suitable for applications requiring weight reduction or heat conduction, such as radiator components and electronic devices.

Steel

Steel is one of the most commonly used materials for making pins due to its high strength, wear resistance, and cost-effectiveness. Different types of steel (such as carbon steel and alloy steel) can be selected based on specific needs to meet different strength and corrosion resistance requirements.

Stainless Steel

Stainless steel is an alloy steel with excellent corrosion resistance, widely used in making pins, especially in humid and corrosive environments. Stainless steel pins are not only durable and resistant to rust and corrosion, but also extend their service life.

Titanium

Titanium is a lightweight, high-strength, and corrosion-resistant metal suitable for making high-end pins. Titanium pins have excellent physical properties, unique metallic luster, and biocompatibility, widely used in medical, aerospace, and other fields.

Pin fasteners offer various significant advantages in connecting and fastening applications, making them the preferred choice in many industrial applications.

Durability

Pin fasteners usually have high strength and wear resistance, maintaining stable connections in harsh working environments and extending the service life of equipment.

Universality

Pin fasteners are among the most common components in mechanical connections, widely used across various industries and fields. Their simple design and reliable functionality meet diverse connection needs.

Ease of Installation

Most pin fasteners are designed with easy-to-install and remove structures, such as L-handles and spring-locking mechanisms, simplifying the installation and replacement process.

Cost-Effectiveness

Compared to some complex connectors, pin fasteners have relatively low manufacturing costs and are easy to mass-produce, making them a cost-effective connection solution.

Safety and Adjustability

Some specially designed pin fasteners (such as spring pins and adjustable pins) offer automatic locking or adjustment functions, maintaining stable connections in vibrating or impact environments and allowing for adjustments to adapt to different installation conditions.

When selecting the appropriate pin type, several factors need to be considered to ensure the chosen pin meets specific application requirements.

Material

Choose suitable materials based on working environment, load requirements, and corrosion resistance. For example, in corrosive environments, stainless steel or titanium alloys should be selected for their corrosion resistance.

Size and Shape

Ensure the selected pin's size and shape match the connection hole or slot to achieve precise alignment and stable connections. Additionally, consider parameters such as pin length and diameter to meet specific connection needs.

Capacity

Choose the appropriate pin capacity based on the load and stress it will bear. Insufficient capacity may cause pin failure or connection loosening, while excessive capacity may increase unnecessary costs and weight.

Corrosion and High-Temperature Resistance

For work in special environments (such as high temperatures and corrosive conditions), choose pin materials with corresponding corrosion and high-temperature resistance.

Cost

Consider the cost of the pin while ensuring performance and quality. Optimize material selection and manufacturing processes to reduce costs and improve economic efficiency.

Pin fasteners are widely used in multiple industries due to their simplicity, reliability, and cost-effectiveness. Here are some major application areas:

Automotive Industry

In the automotive industry, pin fasteners are widely used to connect and fasten components such as engines, suspension systems, brake systems, and interior trims. High-strength, wear-resistant pins help improve the vehicle's overall performance and safety.

Aerospace Industry

In the aerospace industry, pin fasteners play a critical role in aircraft structure assembly, engine components, and landing gear systems. Pins need to meet stringent quality and precision requirements to ensure the reliability and safety of aircraft.

Medical Equipment

In the medical equipment field, pin fasteners are commonly used in the connection and fixation of surgical instruments, implants, and medical devices. High-precision, biocompatible pin materials (such as titanium) ensure the reliability and safety of medical devices.

Electronics and Electrical Industry

In the electronics and electrical industry, pin fasteners are widely used in the connection and fastening of circuit boards, connectors, and electronic components. Pins with good conductivity and corrosion resistance improve the stability and reliability of electronic devices.

Construction Industry

In the construction industry, pin fasteners are commonly used in the connection and assembly of structural elements, pipelines, and mechanical equipment. High-strength, corrosion-resistant pins help ensure the safety and durability of building structures.

Consumer Products

In the consumer products field, pin fasteners are used in the connection and fixation of household appliances, furniture, and sports equipment. Simple, easy-to-install pin fasteners improve product assembly efficiency and user experience.

Conclusion

Pin fasteners are essential components widely used in various industrial applications due to their simplicity, reliability, and cost-effectiveness. By understanding the different types of pins, their uses, manufacturing methods, material choices, advantages, and applications, you can select the appropriate pin fastener to meet your specific needs. Whether you are in the automotive, aerospace, medical, electronics, construction, or consumer products industry, pin fasteners play a crucial role in ensuring stable and reliable connections, enhancing the overall performance and safety of your products.

As an expert in the field of CNC machined parts manufacturing, VMT offers high-quality custom machining services to meet your specific needs for pins and other precision components. With advanced CNC machining equipment and extensive manufacturing experience, we can perform precise machining according to your requirements and drawings. Whether it's complex geometries, high-precision tolerance requirements, or special material selections, VMT provides customized solutions.

Our service scope includes CNC prototyping, batch production, and custom CNC machined parts. Our team will work closely with you throughout the process, from design consultation, material selection, process formulation to final product delivery, offering professional technical support and high-quality service. Choosing VMT as your partner ensures high-quality products, on-time delivery, and a satisfactory customer experience.

Pins (dowels) play a crucial role as essential components for connection and fastening in various industries. Understanding the different types of pins, their uses, manufacturing methods, material choices, and advantages helps you make informed decisions in selection and application. When choosing pin types, consider factors like material, size and shape, capacity, corrosion and high-temperature resistance, and cost. Moreover, partnering with a professional CNC machining factory like VMT ensures you receive high-quality custom machined pins and parts tailored to your specific needs.

What are the three types of pins?

There is no fixed answer to this question because the types of pins are very diverse. However, based on common classifications, pins can be categorized into three main types: straight pins, bent pins, and specially shaped pins. Straight pins include simple cylindrical dowels, bent pins such as L-handle pins or U-clips, and specially shaped pins like taper pins, spring pins, which have unique shapes and functions.

What are the most common types of pins?

The most common pins include cotter pins, dowel pins, spring pins, and taper pins. These pins are popular due to their simple design, wide applications, and reliable connection performance.

What are the advantages of using pin fasteners compared to other types of fasteners?

Advantages of using pin fasteners include durability, ease of installation, cost-effectiveness, and providing automatic locking or adjustment functions in some applications. Compared to traditional fasteners like bolts and nuts, pins usually have simpler structures and faster installation times, ensuring stable and reliable connections.

What common challenges are faced when using pin fasteners?

Common challenges when using pin fasteners include selecting the right material and size, ensuring precise alignment and fit, and maintaining stable connections in special environments (e.g., high temperature, corrosive environments). Additionally, for applications requiring frequent disassembly and reassembly, choosing the right pin type and design is crucial.

Can pins be customized for specific industrial applications?

Yes, customizing pins for specific industrial applications is entirely feasible. Professional CNC machining factories like VMT can provide custom machining based on customers' specific requirements and drawings, including design, material selection, process formulation, and final product delivery. Customized pins ensure meeting special requirements and improve the performance and reliability of the products.